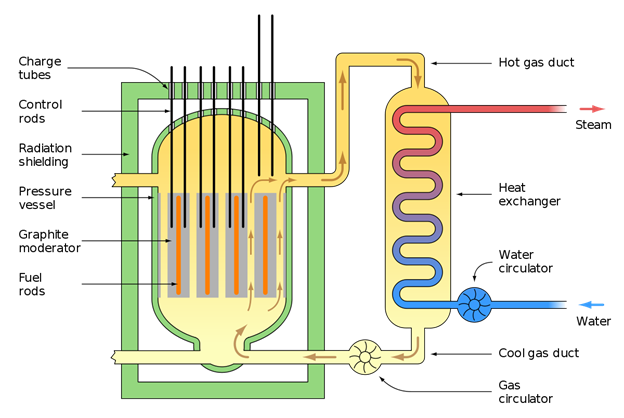

Most commercial nuclear power reactors around the globe use water for cooling the core. Advanced gas cooled reactors (AGCR) are a new generation of gas-cooled reactors developed and operated in the U.K. They use graphite as a moderator and carbon dioxide as a coolant. They have been a major part of the U.K. fleet of commercial nuclear power reactors since the 1980s.

The AGCR was developed from the U.K. Magnox reactor which was originally designed to produce plutonium. The Magnox could run on natural uranium with no refinement, but this required that the coolant have low neutron cross section such as carbon dioxide gas and a very efficient moderator such as graphite. Magnox reactors operate at a low temperature compared to many other reactor designs. This makes the Magnox less efficient than other reactor designs in extracting power from the uranium in the core.

The AGCR has the carbon dioxide coolant and graphite of the Magnox but operates at a higher temperature which makes it much more efficient. It produces the same type of steam that a coal fired power plant produces which means that turbines and generation equipment made for coal fired power plants can be used in AGCR plants.

AGCRs are inherently safer than water-cooled nuclear reactors. In order to assure this enhanced safety in an AGCR, carbon dioxide leaks must be detected and repaired if they cannot be prevented altogether. Carbon dioxide is less reactive that water and cannot explode. It is also more flexible with respect to operating temperatures and pressures. This means that it is a more stable coolant that will react more slowly to catastrophic faults that water-cooled reactors. On the other hand, carbon dioxide cooled reactors have lower power densities than water-cooled reactors. This means that they have to be larger because they are less efficient.

During operation of AGCRs, it is very important to be able to quickly detect carbon dioxide leaks. If the carbon dioxide leaks, there will be no coolant to cool the core and it may overheat. Big leaks of carbon dioxide can be dangerous to personnel and the local environment. Big leaks can also be expensive to deal with and can disrupt the operation of the plant.

Infrared sensors are excellent for monitoring carbon dioxide levels and in the detection of leaks. They are very easy to use and can quickly make online measurements of carbon dioxide concentrations. Infrared sensors are available in small packages that are sturdy, reliable, require little maintenance and are long-lived when compared to other gas sensors.

Edinburgh Sensors are a major supplier of infrared gas sensing devices including continuous carbon dioxide detectors. One of the problems with some carbon dioxide sensors is that they are adversely affected by temperature or pressure variation. The Edinburgh sensors incorporate temperature and pressure correction capabilities that ensure accurate readings in a wide variety of operating environments. They are idea for use in nuclear reactors such as AGCRs.

With the proper monitoring equipment, AGCRs are safe and reliable.

Nuclear Reactors 641 – U.K. Advanced Gas Cooled Reactor

Written by

in