Voting for BJP means dropping nuclear bomb on Pakistan: UP minister Keshav Prasad Maurya. Indiatoday.in

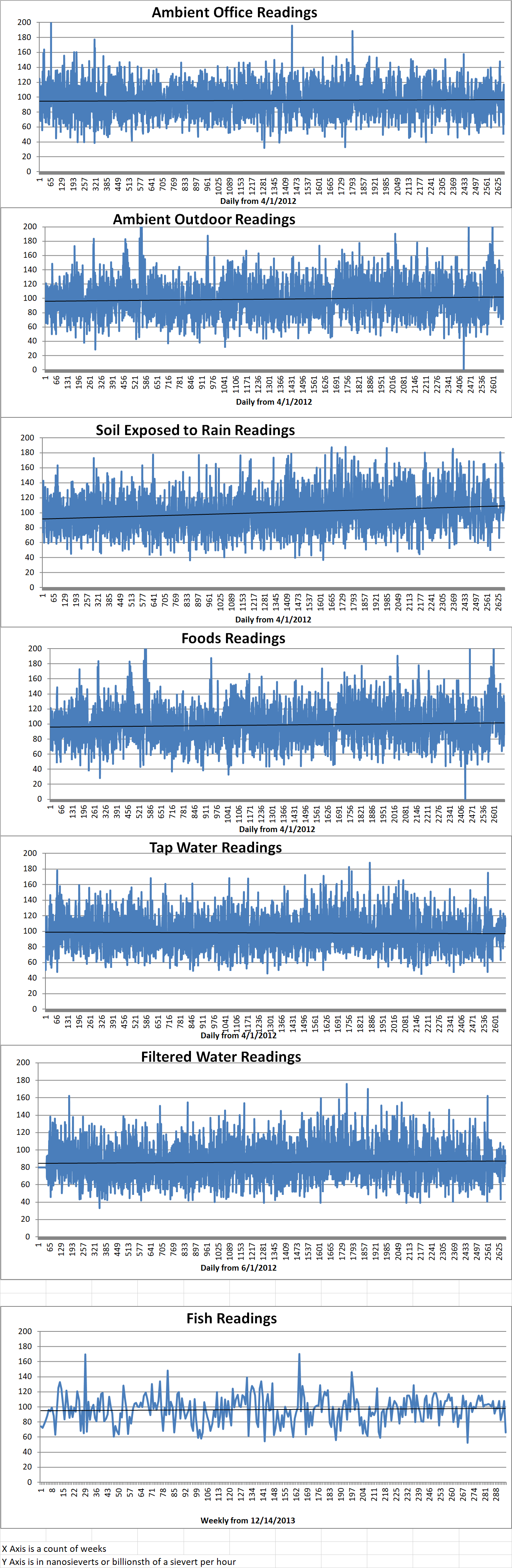

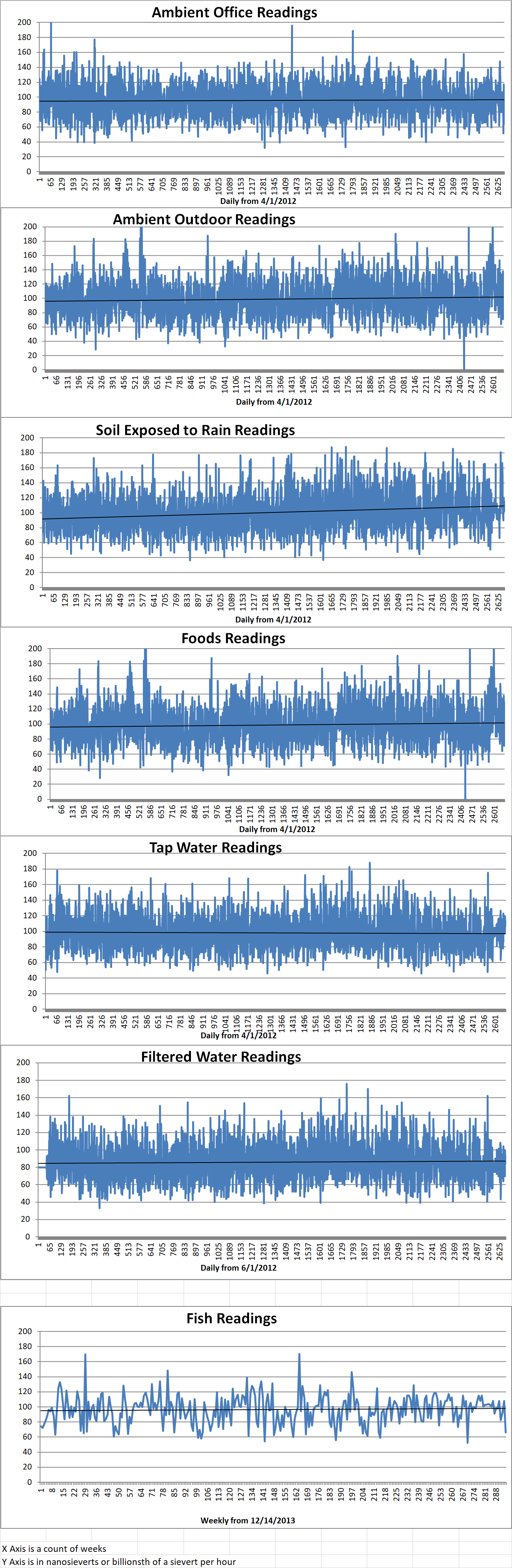

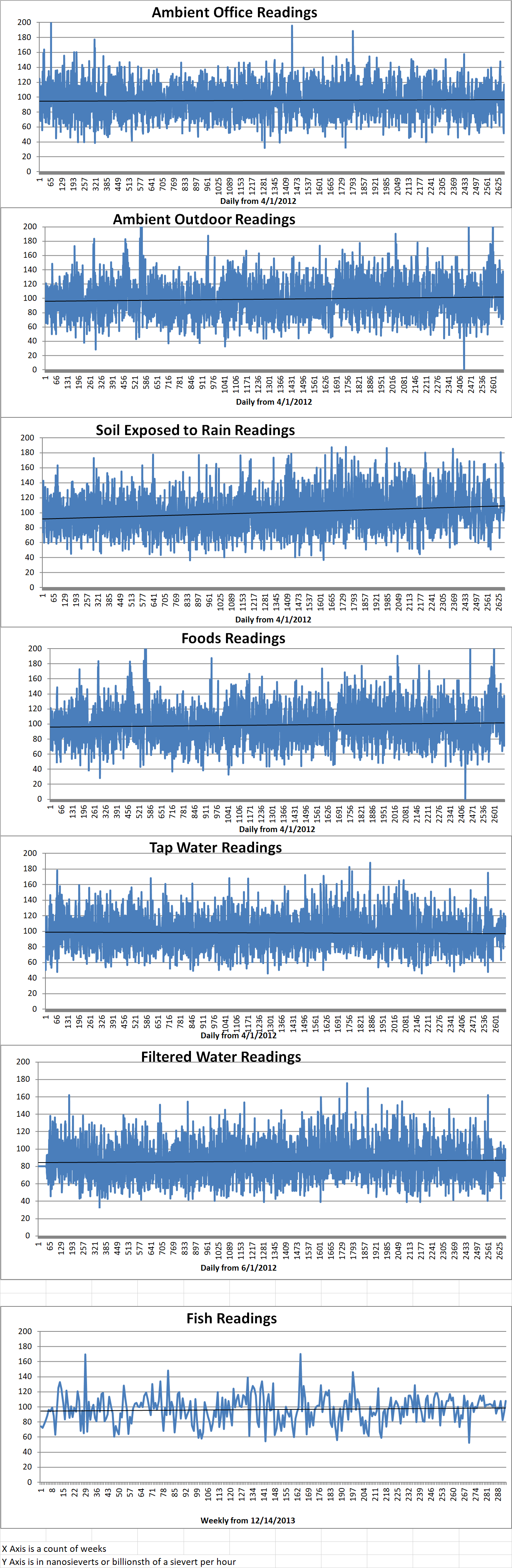

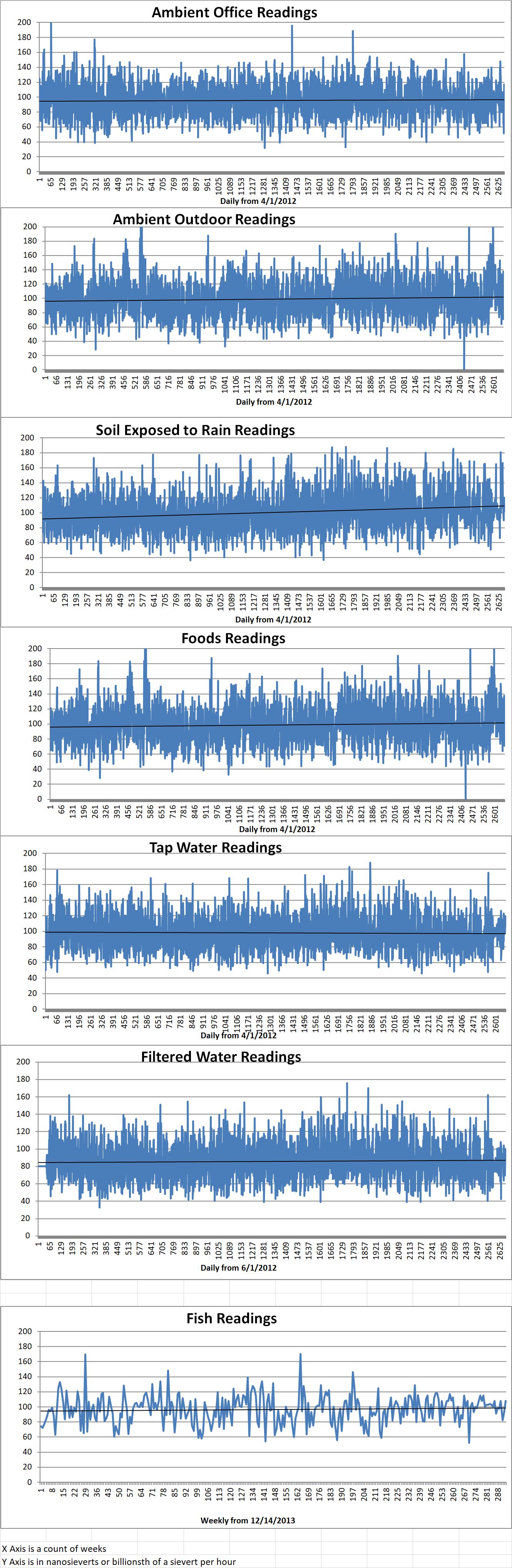

Ambient office = 84 nanosieverts per hour

Ambient outside = 106 nanosieverts per hour

Soil exposed to rain water = 106 nanosieverts per hour

Bartlett pear from Central Market = 86 nanosieverts per hour

Tap water = 116 nanosieverts per hour

Filtered water = 93 nanosieverts per hour

Ambient office = 64 nanosieverts per hour

Ambient outside = 104 nanosieverts per hour

Soil exposed to rain water = 107 nanosieverts per hour

Red bell pepper from Central Market = 93 nanosieverts per hour

Tap water = 113 nanosieverts per hour

Filtered water = 84 nanosieverts per hour

Dover sole – Caught in USA = 66 nanosieverts per hour

Part 1 of 3 Parts

I often blog about the problems associated with the permanent disposal of over eighty thousand tons of spent nuclear fuel produced by U.S. nuclear power plants. It is estimated that the earliest a permanent geological repository for spent nuclear fuel could be constructed and put into operation in the U.S. would be 2050. With the spent nuclear fuel assemblies rapidly filling up the cooling pools at U.S. nuclear power stations, solutions to the waste problem will need to be developed as soon as possible. Without a geological repository or a massive construction of dry casks to store spent nuclear fuel onsite at nuclear power plants, in a few years, the cooling pools will be so full at many U.S. nuclear power plants that there will no longer be room to carry out refueling and plants will have to be shut down.

The Natural Resources Defense Council (NRDC) is one of the biggest environmentalist groups in the United States. It was recently invited to send representatives to testify by several Congressional committees on the subject of disposal of spent nuclear fuel at hearings dedicated to consideration of bills aimed at dealing with the approximately eighty thousand tons of spent nuclear fuel stored at nuclear power plants across the nation.

One fact became very clear during the Congressional hearings. It appears that the important stake holders in the process have lost trust in each other. Geoffrey Fettus is a senior attorney at the NRDC. He said, “Our government is at its strongest when each players’ role is respected. State consent and public acceptance of potential repository sites will never be willingly granted, unless and until power on how, when, and where the waste will be disposed of is shared, rather than decided by federal fiat.”

Trust can only flourish when there is a balance of power between the stakeholders in a discussion, especially when a dangerous and difficult issue like disposal of nuclear waste in underground repositories is being discussed. States will only agree to host permanent nuclear waste repositories when state officials can trust that other actors, such as federal officials, can be trusted. Currently, there is no equal balance of power between stakeholders on the nuclear waste disposal problem. States are afraid that if they allow any nuclear waste to be stored there, they will be open to demands that the entire stock of spent nuclear fuel waste will wind up in their state.

Currently, strong environmental laws have a successful history in the U.S. However, it is assumed that the federal government has the exclusive right to determine the fate of spent nuclear fuel. Such nuclear waste is exempt from all environmental laws. This means that the storage and disposal of spent nuclear fuel is also exempt from state and EPA regulatory oversight. The NRDC strongly believes that this needs to change. If the states are given regulatory oversight with respect to spent nuclear fuel, then there will be an increase of trust in the process and states will be able to make informed consent based on realistic scientific and political terms.

The NRDC presented this idea to all of the Congressional Committees involved in the consideration of bills regarding the disposal of spent nuclear fuel. Unfortunately, Congressional consideration has been locked into a set of talking points that are not necessarily valid and have hampered progress on the issue. Here are three major talking points that really need to be debunked.

Please read Part 2

Ambient office = 90 nanosieverts per hour

Ambient outside = 113 nanosieverts per hour

Soil exposed to rain water = 115 nanosieverts per hour

Avocado from Central Market = 129 nanosieverts per hour

Tap water = 106 nanosieverts per hour

Filtered water = 93 nanosieverts per hour

3D printing in rapidly being adopted for a number of applications from printing small object to printing boats, houses and spacecraft. 3D printing consists of building up thin layers of material in order to create a complex three dimensional object. Many different materials have been used for 3D printing including resins, polymers, metals, and dirt.

Researchers at the U.S. Department of Energy Argonne National Laboratory have just published an article in Science Reports about the use of 3D printing to help with the recycling of spent nuclear fuel and the disposal of radioactive wastes.

There are several different ways to recycle spent nuclear fuel from nuclear power reactors. Argonne scientists created one method in the 1970s. These recycling methods allow ninety five percent of the spent nuclear fuel to be recycled. Only five percent of the processed spent nuclear fuel needs to be stored for a long period of time. Now, the Argonne scientists have been able to print 3D parts that help prepare for recycling even more than ninety five percent of spent nuclear fuel. Recycling two percent more spent nuclear fuel may not seem like much of an advance but even managing that would significantly reduce the amount of waste and the time it remains dangerous.

Andrew Breshears is a nuclear chemist and the co-author of the Argonne research report. “Rather than store five percent for hundreds of thousands of years, the remaining three percent needs to be stored at a maximum of about one thousand years. In other words, this additional step may reduce the length of storage almost one thousandfold.” The remaining radioactive waste could be burned in a fourth-generation fast reactor to generate power.

In order to carry out this task, the Argonne researchers had to start by separating highly radioactive actinide isotopes such as americium and curium from the rare earth metals or lanthanides, few of which are radioactive. In 2013, nuclear chemist Artem V. Gelis was working at the Argonne National Laboratory. His team developed a blueprint for recycling an extra two percent of spent nuclear fuel. It was referred to as the Actinide Lanthanide Separation Process (ALSEP).

The Argonne researchers had to find a way to move from the processes they developed in the lab into a process that could be scaled up for industrial use. This was accomplished through the use of 3D printing. The ALSEP process was modified to make use of devices that could separate chemicals. These devices are called centrifugal contactors.

Peter Kozak is an Argonne engineer. He 3D printed several contractors and connected them together. This allowed turning the slow laboratory separation process into one in which actinides and lanthanides could be continuously separated at an industrial scale. Breshears said, “This bridges the gap between separating the elements at the laboratory scale and at the industrial scale.”

The Argonne researchers started the work with simulated nuclear fuel. The uranium, plutonium and neptunium were extracted from the simulated fuel by a modified Plutonium Uranium Reduction Extraction (PUREX) process. The researchers introduced the liquid mixture which contained americium and curium to one side of a row of twenty contractors. At the other end of the row of contractors, a combination of industrial chemical designed to separate actinides was added.

Using a thirty-six stage separation process, the researchers were able to remove ninety nine and nine tenths percent of the actinides from the lanthanides. This was very difficult because the two types of elements have very similar chemical properties. Breshears said, “Their oxidation states are the same, making them very difficult to separate.”

During their work, the researchers discovered two more benefits from using 3D printed parts. The tubes that connect the twenty contractors are run inside the device. This means that it would be difficult to divert plutonium or other radioactive materials from the process as it separates the isotopes. The design of the devices would make nuclear proliferation more difficult and less likely. The second benefit of using 3D printed parts is that they will be much more easily replaced than conventionally manufactured parts. They could even be printed at the same location where the separation of isotopes is being carried out.

Breshears said, “Maybe we will find a new way to cut down on the size of the process. The greater we can separate the actinides, the more we can reduce the impact they have on the public and environment.”

Ambient office = 117 nanosieverts per hour

Ambient outside = 108 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Heirloom tomato from Central Market = 103 nanosieverts per hour

Tap water = 106 nanosieverts per hour

Filtered water = 89 nanosieverts per hour