The Japanese have a phrase that references jobs that are dirty, dangerous or drudgery. Robots have been handling drudgery for decades. Dirty is still being done by humans. Robots are being developed to handle dangerous. Robots have been developed there to penetrate the ruins of the Fukushima nuclear power plant that was destroyed by flooding and meltdowns resulting from the big earthquake in the ocean off Japan in March of 2011. Many of the robots were not able to finish their tasks because they were destroyed by the intense radiation. Fukushima continues to be an inspiration for robotic evolution.

Mitsubishi Heavy Industries (MHI) in Japan developed some of the robots used at Fukushima. They have used the experience gained to develop robots that can be used to inspect and monitor industrial facilities. An “explosion-proof” prototype MHI robot called EX ROVR has recently been tested at a Japanese oil refinery. The EX ROVR was designed to be able to withstand damage from explosions that might occur during inspections, including explosions that might have been caused by the robot itself.

MHI and JXTG Nippon Oil & Energy Corporation jointly conducted a test of the EX ROVER at the JXTG Mizushima Refinery in Kurashiki in Okayama Prefecture. As part of the test, the robot autonomously moved through several floors of the plant building. It had to deal with stairs as it collected data from various sensors and docking itself at a charging station to replenish batteries.

The robot is still being developed but the recent test proved that it meets the minimum requirements for basic functionality to carry out routine patrol inspections at the JXTG Energy plant. It was also able to handle emergency situations in the test. The results of the test will be analyzed in detail to resolve outstanding issues and to make improvements in the design.

More tests will be conducted, and demonstrations of abilities will be carried out in a wide range of different plant environments in order to “further expand inspection and surveillance functionality and enhance safety”, with the aim of developing a commercial inspection system. MHI said that it is developing the explosion-proof plant inspection robot “based on its success with robotics technologies in such areas as support for nuclear plant accident containment”.

MHI developed the MEISTeR (Maintenance Equipment Integrated System of Telecontrol Robot) based on the design of the RaBOT (Radiation-proof Robot) which was constructed to deal with a critical accident at the Tokai-mura nuclear fuel processing facility. The design of the MEISTeR includes two arms which can be fitted with different tools. It is able to execute such tasks as carrying objects, drilling holes and opening and closing valves.

MHI also developed the Super-Giraffe (Global Innovative Robot Arm for Future Evolution) to perform tasks at the Fukushima nuclear power plant. The Super Giraffe has four modules including a platform, a load-lifting module, a robot arm and an attachment tool.

While I am impressed by MHI’s accomplishments in robotics I would be interested in knowing just how bad an explosion the EX ROVR will be able to survive. The images I have seen make it look pretty vulnerable.

Author: Burt Webb

-

Nuclear Reactors 684 – Mitsubishi Heavy Industries Developing An Explosion Proof Robot For Plant Inspections

-

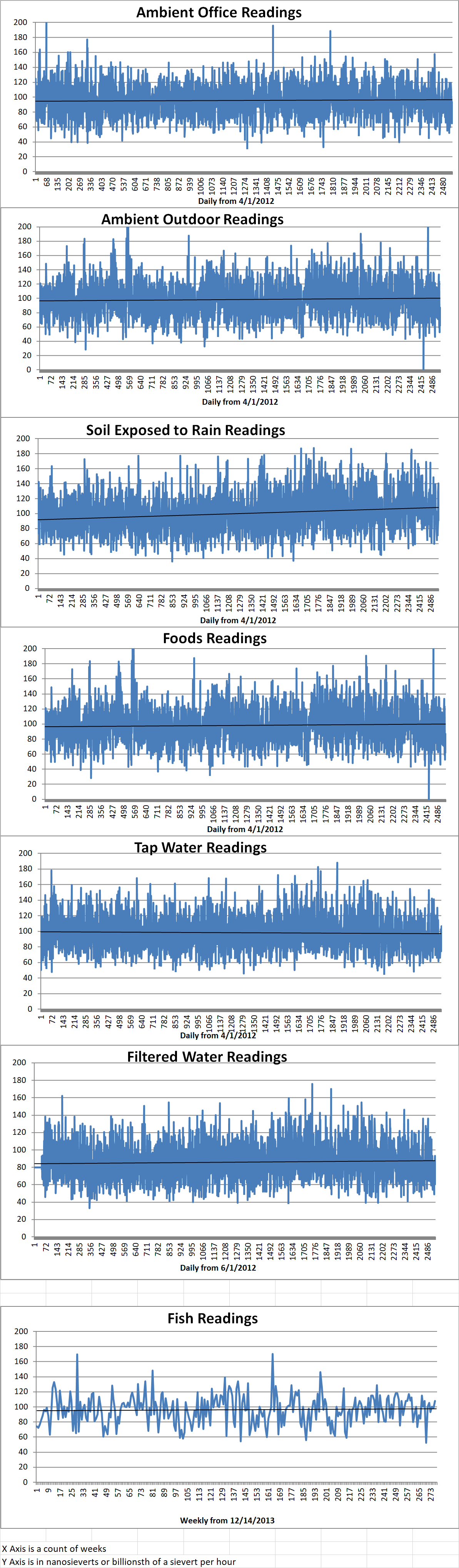

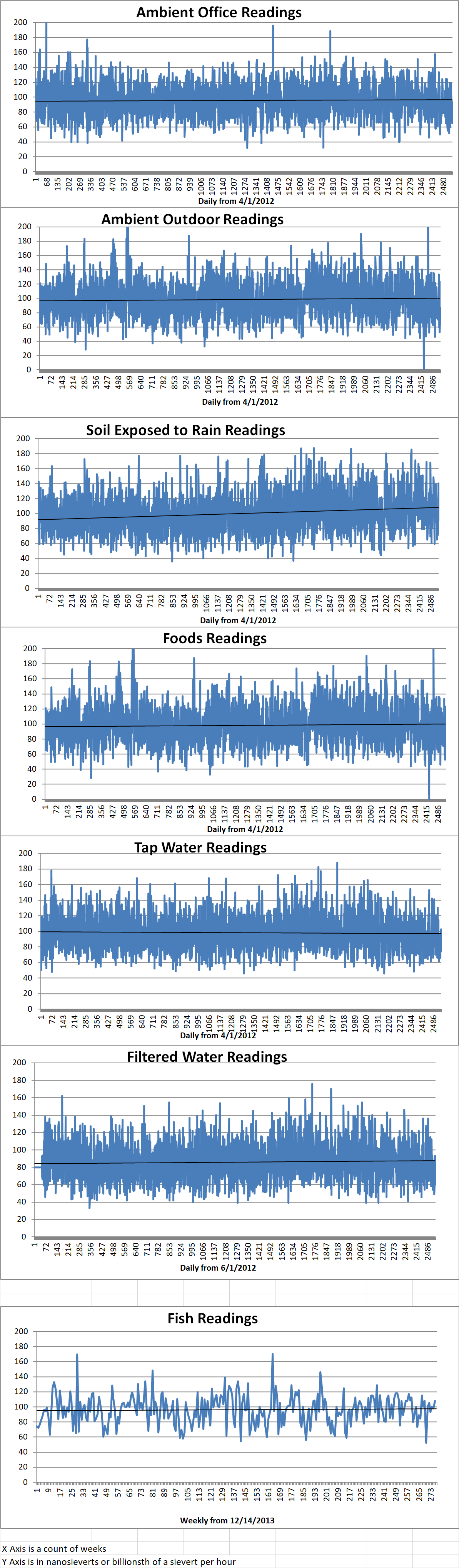

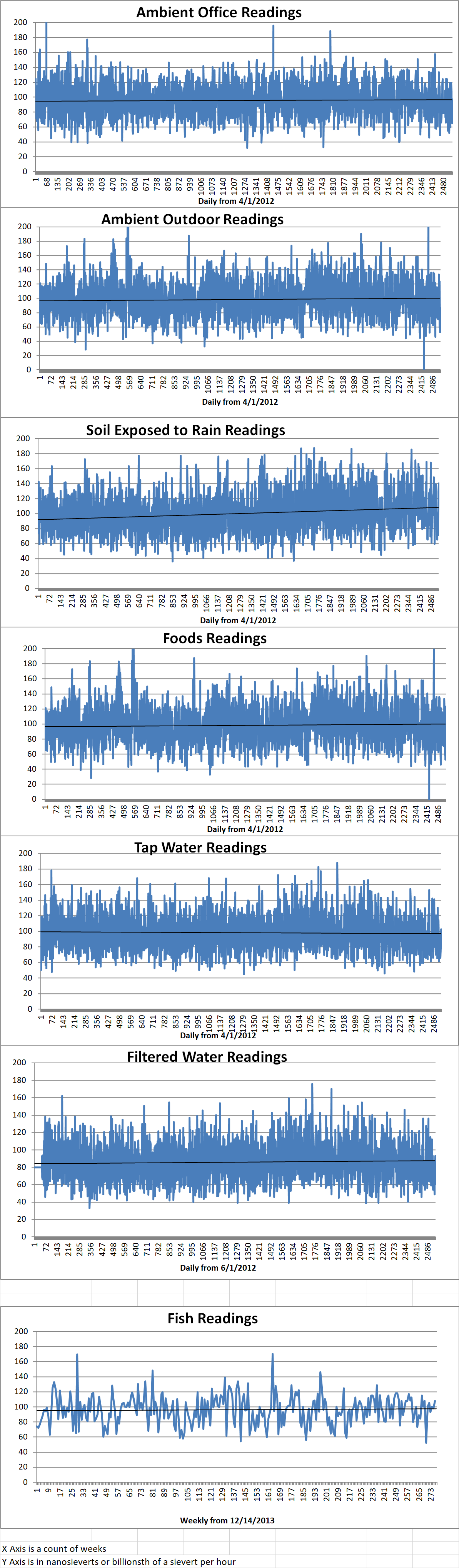

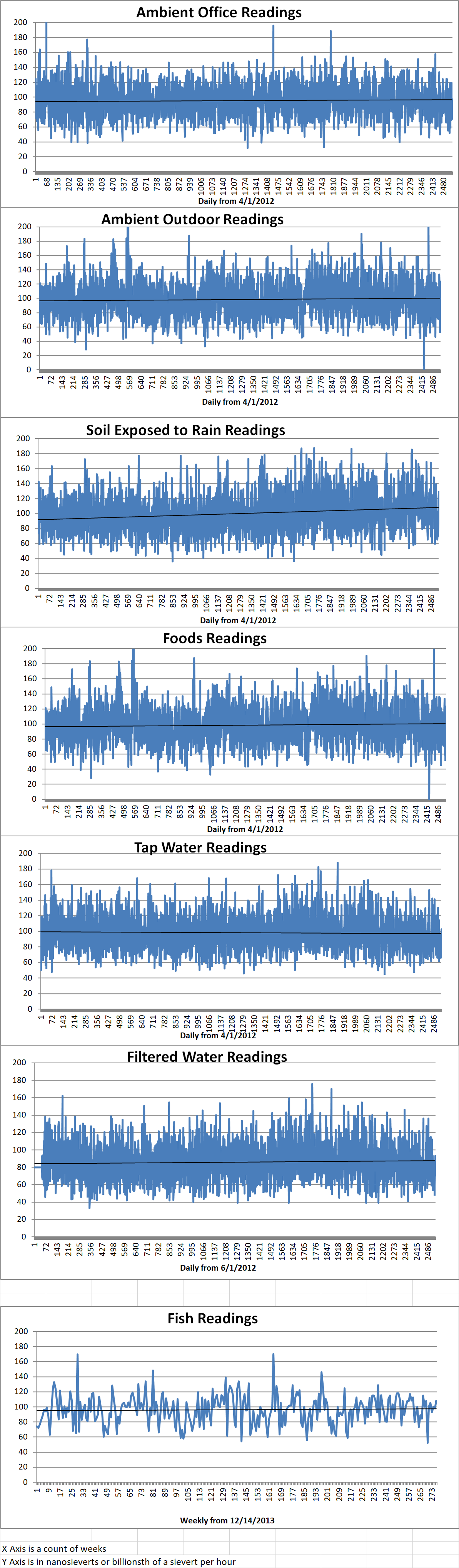

Geiger Readings for Jun 10, 2019

Ambient office = 93 nanosieverts per hour

Ambient outside = 108 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Cucumber from Central Market = 63 nanosieverts per hour

Tap water =106 nanosieverts per hour

Filtered water = 85 nanosieverts per hour

-

Geiger Readings for Jun 09, 2019

Ambient office = 93 nanosieverts per hour

Ambient outside = 94 nanosieverts per hour

Soil exposed to rain water = 91 nanosieverts per hour

Avocado from Central Market = 78 nanosieverts per hour

Tap water = 74 nanosieverts per hour

Filtered water = 63 nanosieverts per hour

-

Geiger Readings for Jun 08, 2019

Ambient office = 65 nanosieverts per hour

Ambient outside = 141 nanosieverts per hour

Soil exposed to rain water = 140 nanosieverts per hour

Carrot from Central Market = 84 nanosieverts per hour

Tap water = 81 nanosieverts per hour

Filtered water = 60 nanosieverts per hour

Dover sole – Caught in USA = 108 nanosieverts per hour

-

Nuclear Reactors 683 – ThorCon Developing A Thorium Based Molten Salt Reactor For Third World Customers

The idea of putting a nuclear reactor on a ship to provide power for remote locations off the grid has been floating around for some time. (pun intended) I have written about the Russian construction of a floating nuclear power plant. They have finished one and it is on its way to the Artic to support oil exploration efforts. China recently announced that it was working on a floating nuclear power plant. These floating power plants are based on conventional nuclear power reactor designs, Now, there is interest in developing such floating power plants with new reactor designs that are smaller, cheaper and safer than conventional reactors.

In 1977, Gary Bergson founded Acadian Asset Management LLC which is a global quantitative investment firm with ninety-five billion dollars under management. He stepped down as chairman in 2011. He is now the lead investor in ThorCon International Pte. ThorCon is a Singapore-based company that is dedicated to supplying relatively inexpensive electricity to countries in the developing world. Bergstrom said, “Our major commercial focus is not on the U.S. or other developed economies. We’re focused on emerging markets where there are huge power needs.”

ThorCon is also the name of a small thorium molten salt nuclear fission power reactor designed by Bergman. He wants to mass produce ThorCon reactors at a shipyard in South Korea and then deliver them to customer via ship. ThorCon is in negotiation with Daewoo Shipbuilding & Marine Engineering Co. in South Korea to build the ThorCon reactors. ThorCon wants to manufacture their reactors on a shipyard assembly line to keep the costs down.

ThorCon estimates that a demonstration model of the ThorCon reactor may cost as little as one billion dollars. This is substantially less than the twenty billion dollars that can be the price tag for construction of a conventional nuclear fission power reactor. ThorCon hopes that its new reactor may be able to ultimately produce electricity for about three cents per kilowatt hour. This is much cheaper than the average price of electricity in the U.S. which is around twelve cents per kilowatt hour.

ThorCon has an immediate goal of raising ten million dollars to start construction of a non-fission test system within twelve months. They estimate that ThorCon could deliver a fully functional five hundred megawatt plant in four years if everything works out. ThorCon has a preliminary agreement with Indonesia to deliver the first unit.

ThorCon Chief Executive Officer David Devanney says that his company is facing a common problem for innovative startups. Investors are cautious and would like someone else to fund the prototype of the ThorCon reactor because the ThorCon reactor is a new unproven design. Some potential customers have said that they would prefer to be ThorCon’s second customer. Devanney said that the technology development was much easier for ThorCon than fining funding.

There are a number of current projects involving new designs for small modular reactors which could also be used to provide electricity for remote locations far from the grid. If they can be made cheaply enough, they will be stiff competition for the ThorCon. -

Geiger Readings for Jun 07, 2019

Ambient office = 71 nanosieverts per hour

Ambient outside = 129 nanosieverts per hour

Soil exposed to rain water = 129 nanosieverts per hour

Broccoli from Central Market = 87 nanosieverts per hour

Tap water = 102 nanosieverts per hour

Filtered water = 93 nanosieverts per hour