I have blogged in the past about problems that NASA has with obtaining sufficient plutonium for nuclear batteries to supply power to space probes launched into deep space. Those problems have not been solved and NASA is facing a shortage of plutonium.

Space probes sent beyond Earth orbit require long-lived steady sources of power for instruments. Solar panels can be used when probes are in the inner solar system but for mission to the outer planets, another source of power is needed.

For decades, our outer space missions have been powered by the human-made isotope: plutonium-238. (Also known as Pu-238) This isotope is extremely radioactive and has a half-life of eighty-eight years. It can emit over five hundred watts of power for every kilogram that is present in a space probe.

Pu-238 can be stored safely in the form of plutonium oxide (PuO2). This compound is highly resistant to many different kinds of potential problems. It forms a crystalling lattice which means that chunks do not break or chip off. It has a very high melting point and will remain a solid at temperatures over forty-nine hundred degrees Fahrenheit. It is very insoluable in water which means that if a satellite falls to earth in a body of water, it will not dissolve.

Pu-238 has two uses on space probes. Radioisotope Heater Units are used to prevent instruments from freezing in space. Radioisotope Thermoelectric generators are small power sources that emit heat continuously which is used to generate electricity.

Many in the space industry feel that Pu-238 should be the standard for space missions to the outer solar system. They have been successfully used by probes such as the Pioneer 10 and 11 and Voyager 1 and 2. Power sources utilizing Pu-238 are light weight, consistent, reliable, long lasting and self warming. They are immune to such problems as dust, shadowing and surface damage.

The U.S. used to produce more than forty five pounds of Pu-238 per year as part of the production of nuclear weapons during the Cold War. The U.S. stopped producing Pu-238 in the 1980s as the Cold War drew to a close with the collapse of the Soviet Union. There were plans to produce about a hundred pounds of Pu-238 at the Savannah River Site starting in 1987 but those plans were abandoned.

Many analysts believe that the dangers association with the nuclear arms race have prevented the production Pu-238 for other uses in the U.S. The U.S. stockpile of Pu-238 is at the lowest level it have ever been. There is enough left to power the 2020 Mars Rover and one other deep space mission such as the Europa Clipper which is scheduled for the mid-2020s.

For the past twenty-five years, almost all of the thirty six pounds of Pu-238 used by NASA has been purchased from Russia. There have been a few attempts to restart Pu-238 production in the U.S. during that time but most of them were not implemented. The Oak Ridge National Laboratory started producing Pu0238 in 2013. Less than a pound of Pu-238 is being produced each year. They hope to be producing a little over three pounds a year by 2023. The Ontario Power Generation in Canada has also started producing Pu-238 which will provide a backup for NASA.

NASA has ambitions for many future space probes but without Pu-238 as a power source, NASA will not be able to accomplish them. With respect to safety, efficiency, weight, power output and design optimization, no other power source can equal Pu-238.

Author: Burt Webb

-

Nuclear Reactors 639 – NASA Does Not Have Enough Plutonium For Deep Space Missions

-

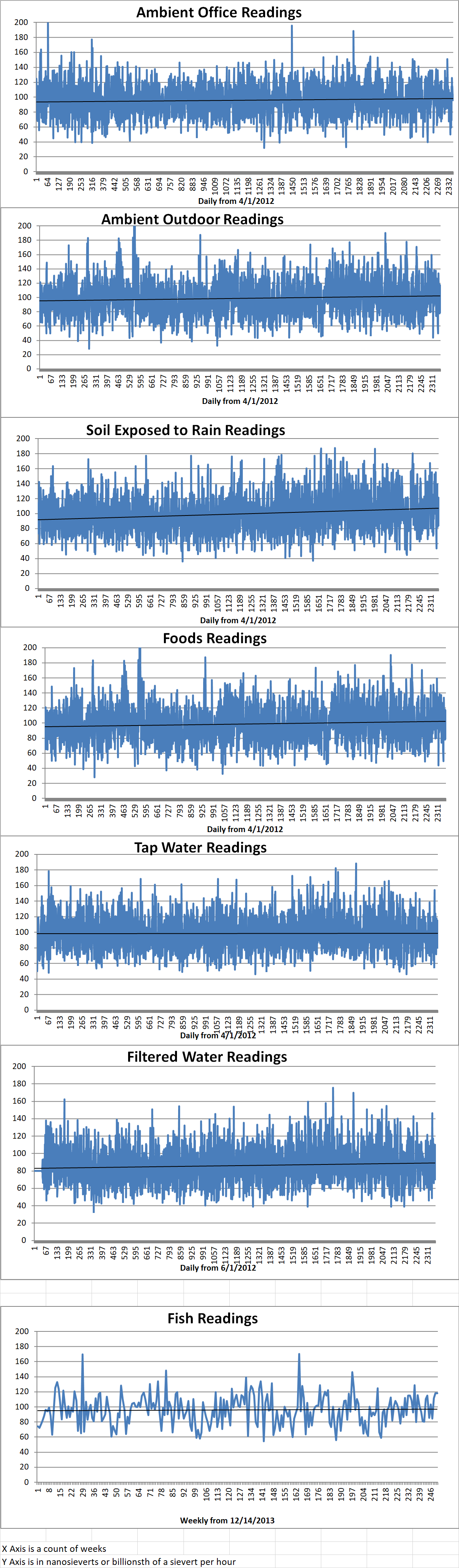

Geiger Readings for Dec 13, 2018

Ambient office = 97 nanosieverts per hour

Ambient outside = 88 nanosieverts per hour

Soil exposed to rain water = 85 nanosieverts per hour

Snap pea from Central Market = 79 nanosieverts per hour

Tap water = 80 nanosieverts per hour

Filter water = 70 nanosieverts per hour

-

1753 – Nuclear Weapons 365 – Chinese Are Building Their Own Z Machine For Nuclear Weapons Research

The Z Pulsed Power Facility (Z Machine) is the largest high frequency electromagnetic wave generator in the world. It was designed and constructed to test the behavior of materials in extreme temperature and pressure. It evolved from previous machines to its current configuration in 1996. It is used primarily as an inertial confinement fusion research facility. It gathers data to help with computer modeling of nuclear weapons and to help model processes in nuclear fusion pulsed power plants. It is operated by the Sandia National Laboratories.

The U.S. Z Machine fires two and three quarters million joules of energy at a target consisting of a small spool wound with hundreds of tungsten wires that are thinner than a human hair. When the pulse passes through the tungsten wires, they explode, evaporate and create a plasma with a powerful magnetic field that forces the particles in the plasma together. The particles collide and produce intense radiation that consist mostly of X-rays. This creates conditions that imitate a real nuclear explosion.

China is currently working on their own version of the Z Machine. This Z Machine will produce much more electricity in a sharp pulse that the U.S. Z Machine. The Chinese Z Machine is being built for the Chinese military by the Chinese Academy of Engineering Physics at the Chinese nuclear weapons development base in the city of Mianyang. It is expected to be operational by 2022.

The Chinese Z Machine will produce about sixty million joules of energy in a fraction of a second. This is over twenty times the two and three quarters million joules generated by the U.S. Z Machine. A Chinese nuclear physicist said, “The intensity is unprecedented. With so much energy, we can heat a target to more than 100 million degrees Celsius. It will dwarf the machine in Sandia.” Liu Bo is an associate professor with the Institute of Nuclear Science and Technology, Sichuan University in Chengdu, China. He said that the Chinese Z Machine might be powerful enough to start nuclear fusion in the compressed plasma cloud.

The Chinese say that they are not involved in a nuclear arms race with the U.S. and Russia. However, a Chinese newspaper recently said that the Chinese Z Machine was going to be used to surpass the U.S. in nuclear weapons development. One Chinese commentator said that the Chinese have an advantage in such research because of continuing strong support from the Chinese government.

There are very serious technical challenges in the development of Z Machines that face both the U.S. and Chinese research efforts. One major technical problem that faces Z Machines is the possibility that fusion in a Z Machine could produce a huge quantity of fast neutron which would weaken or damage critical components.

The Chinese may use their Z Machine to develop what is called a “pure” fusion bomb. Such a bomb could be made any size. It would cost a fraction of the cost of building current nuclear warheads. Theoretically, a pure fusion bomb would burn “cleanly” and not produce any radioactive fallout. -

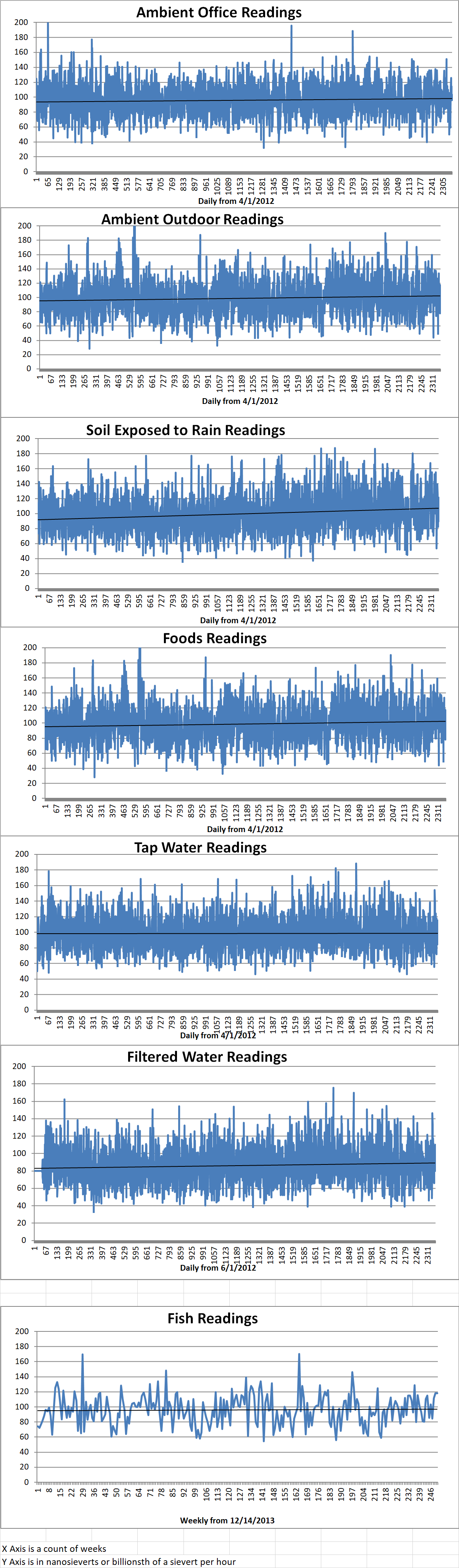

Geiger Readings for Dec 12, 2018

Ambient office = 97 nanosieverts per hour

Ambient outside = 120 nanosieverts per hour

Soil exposed to rain water = 121 nanosieverts per hour

Avocado from Central Market = 117 nanosieverts per hour

Tap water = 85 nanosieverts per hour

Filter water = 80 nanosieverts per hour

-

Nuclear Reactors 638 – Moscow Institute Of Physics and Technology Is Developing A New Coating For Zirconium Alloy Fuel Assemblies

There are four hundred and forty eight operating commercial nuclear power reactors in the world today. Fifty more reactors are under construction. Most of these reactors are water-cooled and water-moderated. The fuel elements in these reactors are mostly zirconium alloys. These alloys are stable and effective up to a temperature of six hundred and sixty-two degrees Fahrenheit. If the heat-removal systems in the reactors are shut down, the temperatures of the fuel containers can reach as high as one thousand six hundred and fifty two degrees Fahrenheit. At these high temperatures, a chemical reaction between zirconium and water vapor can generate explosive hydrogen gas.

The generation of hydrogen gas from the interaction of zirconium in fuel tubes with water vapor at very high temperatures in nuclear power reactors has led to destructive explosions at nuclear power plants in the past.

Boris Kalin is the head of the Moscow Engineering Physics Institute’s (MEPI) Faculty of Physical Problems in Material Science. He leads a team of researchers at the National Research Nuclear University (NRNU) at the MEPI. He recently said “To prevent zirconium-vapor interaction, the researchers propose coating the surface of heat elements with materials (including chromium) that will prevent contact between zirconium and water vapors. We have achieved the science and technological goal of selecting the required compound and coating sections of fuel-element tubes up to 500 mm long with a protective chromium-content substance. This slows the zirconium-oxidization process in water vapors at up to twenty two hundred degrees Fahrenheit.”

The NRNU team says that their ion-beam method requires that the surface of the tubes containing the fuel pellets be polished with argon ions. This insures a very smooth surface. Then alloys acting as electrodes are sprayed onto the surface of the tubes inside the vacuum chamber. This continues until a layer of alloy up to ten micrometers thick is deposited on the surface of the tubes.

After treating the fuel tubes with their process, the NRNU technicians examined the composition, structure and thickness of the alloy coatings with electron and ion microscopes. The wear resistance of the coatings were tested by rubbing them against zirconium components. They also tested the water-oxidation at six hundred and sixty-two degrees Fahrenheit for seventy two hours and then repeated the test at twenty two hundred degrees Fahrenheit.

Kalin said, “We repeated the experiment several times, adjusted the composition of magnetron electrodes and treatment modes, and analyzed each result. This allowed us to choose the optimal composition of coatings and prevent the oxidization of the external surface of zirconium tubes at plus 1,200 degrees Celsius for 400 seconds.”

The results of the work at NRNU are going to be presented at the Sixteenth International school conference: New Materials: Tolerant Nuclear Fuels which was held at the NRNU. The event was initiated by the research school and the Laboratory for the Ion-Beam Treatment of Materials at the Faculty of Physical Problems of Materials Science.

Improving the safety of the fuel assemblies under extreme conditions is a high priority research subject in the nuclear industry. -

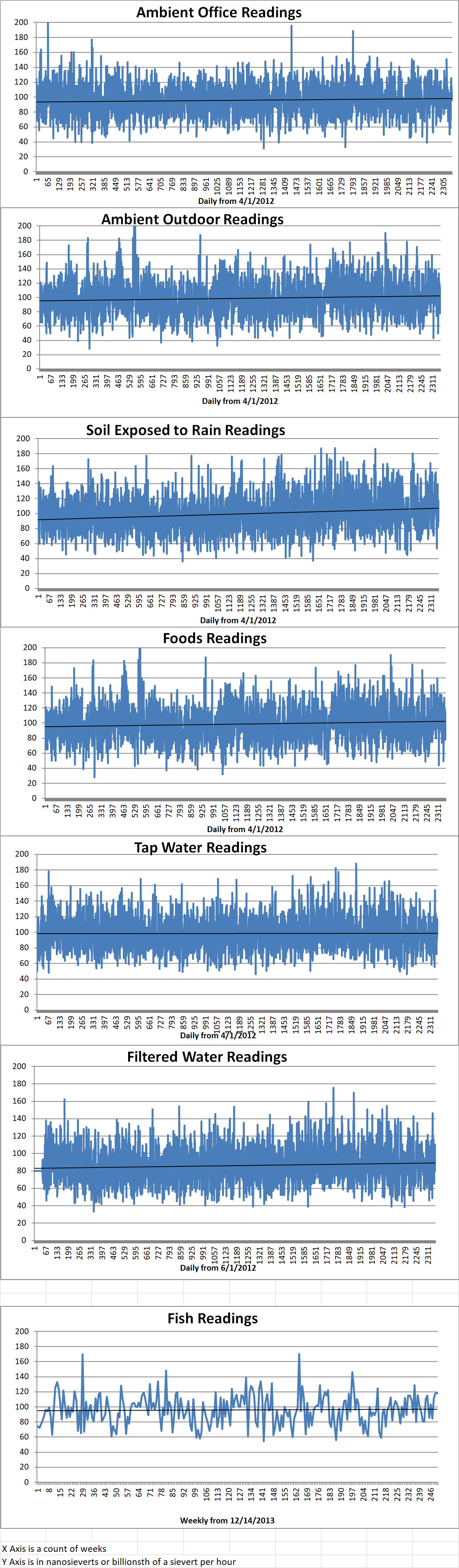

Geiger Readings for Dec 11, 2018

Ambient office = 96 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 117 nanosieverts per hour

Beefsteak tomato from Central Market = 112 nanosieverts per hour

Tap water = 115 nanosieverts per hour

Filter water = 110 nanosieverts per hour

-

Radioactive Waste 370 – The Advanced Mixed Waste Treatment Project At The Idaho National Laboratory Is Being Shut Down

The Hanford Nuclear Reservation was established in 1943 in south central Washington State. The plutonium that was used in World War II to bomb Nagasaki, Japan was produced at the Reservation. During the Cold War, most of the plutonium for the sixty thousand nuclear warheads in the U.S. arsenal was produced at Hanford by the nine reactors and the five plutonium processing facilities constructed on the site.

Nuclear weapons production at Hanford was halted in 1987. Fifty-three million gallons of high-level radioactive waste were left behind by these activities and remain at Hanford in underground tanks, some of which have been leaking.

The high-level radioactive liquid waste at Hanford contains transuranic materials which are man-made unstable radioactive elements such as plutonium that are beyond the natural occurring elements in the periodic table. They will be dangerously radioactive for thousands of years.

The Idaho National Laboratory in south east Idaho was established by the U.S. federal government in 1949 to be a center for nuclear research. Over the years, fifty experimental reactors have been constructed at the INL. Such research continues today with plans to construct one of the first commercial small modular reactors at the INL.

There are more transuranic wastes at the INL than any other federal facility. This waste includes work clothing, rags, machine parts and tools that have been contaminated with plutonium and other radioactive elements. There have been court battles between the State of Idaho and the U.S. Department of Energy over the radioactive waste at the INL site. In 1995 an agreement was reached which required the DoE to clean up the INL site. The Advanced Mixed Waste Treatment Project (AMWTP) was constructed to deal with transuranic wastes.

The Waste Isolation Pilot Plant near Carlsbad New Mexico was opened in 1999 to receive solid transuranic waste from facilities around the U.S. which had been used for research and development of nuclear warheads. A few years ago, an accident closed the WIPP for several years, but it is now back in operation.

The AMWTP at the INL was set up to compact and solidify transuranic wastes which could then be shipped to the WIPP for disposal. The AMWTP is just finishing up the processing of eighty-five thousand cubic yards of transuranic wastes for shipment to the WIPP. The DoE has just announced that the AMWTP will be closed next year.

There have been proposals for keeping the AMWTP open to process liquid transuranic wastes from other national laboratories and other facilities used in the development of nuclear warheads with most of the waste coming from Hanford. A thirty-eight page economic analysis from the DoE was just released that said that “it does not appear to be cost effective due to packaging and transportation challenges in shipping waste” to Idaho.

Currently, there are efforts to reclassify some of the high-level radioactive waste at Hanford to low-level radioactive waste. This would allow some of the waste currently stored in disintegrating underground tanks to remain in the tanks. The tanks would be topped off with grout and permanently buried. This might result in leakage of some wastes into the Columbia River. Unfortunately, the better solution of treatment at the INL and shipment to WIPP seems to be dead.