Twice as much Fukushima radiation near California coast than originally reported. enenews.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

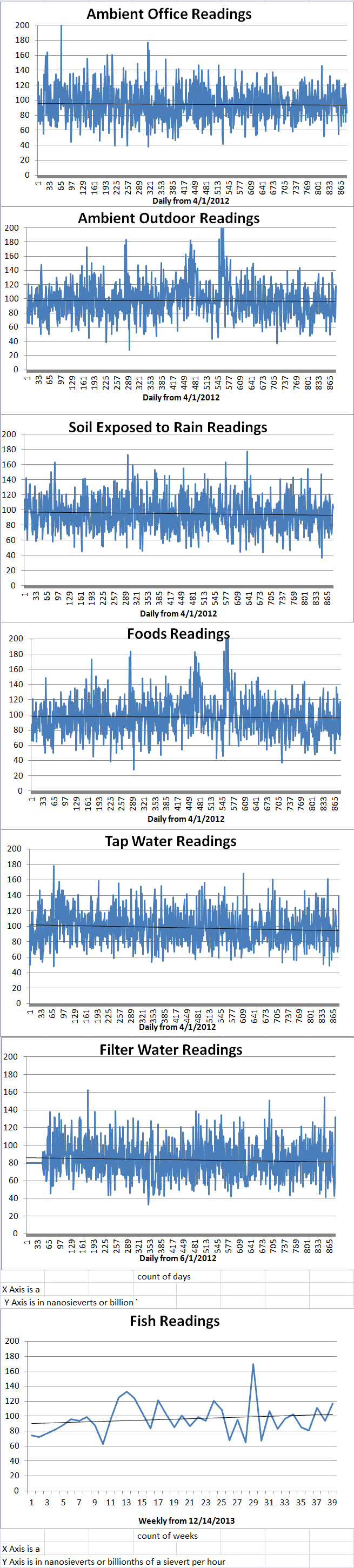

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

As part of nuclear disarmament, Russia and the U.S. agreed to convert the plutonium in many of their nuclear warheads into fuel for nuclear reactors. The plutonium is mixed with uranium to dilute it producing what is called Mixed Oxide fuel (MOX). For fifteen years, plutonium warheads from Russia were converted to nuclear fuel to burn in U.S. nuclear power reactors. This arrangement is just ending which will cause the price of MOX to rise.

In 2005, the Nuclear Regulatory Commission granted a ten year construction license to Shaw Areva MOX Services (SAMS) for the construction of the first MOX plant in the U.S. That license will run out in 2015 and the MOX plant is far from complete. After a two year delay, actual construction of the MOX plant began in 2007. The MOX plant design was based on the design of the French Melox MOX facility. The U.S. MOX plant was supposed to begin operation in 2016 with an estimated construction cost of about five billion dollars. In 2012, the U.S. Government Accountability Office estimated that the MOX plant would not be ready to operate before 2019 and that it would cost almost eight billion dollars. There have been budget cuts over the years and SAMS only requested three hundred and twenty million dollars for 2014 due to project delays.

SAMS requested an extension of its construction license in May of 2014. They said that there had been significant progress in construction of the MOX plant and that they estimated that the facility was sixty percent complete although some key structures still had to be built including the emergency generator building and the reagents processing building.

SAMS has offered several reasons for the extension request. Since this is the first such plant to be constructed in the U.S., they were not able to draw on prior experiences in such plant construction. They pointed out that the actual annual funding has been less than the project funding requirements for several years. There is a shortage of vendors who produce the necessary components. There is also a shortage of qualified construction workers available for the project. In addition, there was that two-year delay between the grant of the original construction license and the actual beginning of construction.

In October of 2014, the NRC basically said that extension “would not have a significant effect on the quality of the human environment because it does not involve any additional impacts or represent a significant change to those impacts described and analyzed in the previous environmental report and final environmental impact statement.” A week ago, the NRC granted SAMS the requested ten year license extension.

Since the funding for the MOX project comes from Congress, there could be delays in construction introduced by reduction of funding in Congressional budget negotiations. As with many other nuclear construction projects, the MOX project is way behind in schedule and way over its estimated cost.

I have blogged several times about the accidents and radiation releases at the Waste Isolation Pilot Plant (WIPP) near Carlsbad, New Mexico. The WIPP is the single repository for wastes from nuclear weapons development and manufacture in the U.S. In mid-February of 2014, the contents of a drum from the Los Alamos National Laboratory overheated and caused the drum to burst, raising the temperature in the WIPP chamber to a level that could have caused other drums to rupture. Radioactive materials from the burst drum made their way into the ventilation system which was not functioning properly. Plutonium and americium were detected in Carlsbad, over twenty of miles away. The WIPP had to be shut down which has resulted in hundred of problematic drums of waste being left at LANL, WIPP and in temporary storage in Texas. It will take years to repair the damage from the accident and hundreds of millions of dollars.

The LANL was chasing a deadline of June of 2014 to have sent all of the radioactive waste from nuclear weapons development to the WIPP. If the private consortium could make the deadline, that would help it to get an extension of its two billion dollar annual contract from the U.S. Department of energy. In the summer of 2013, one batch of waste at LANL was found to be far too acidic to be transported to the WIPP. The official policy of LANL called for stopping work with that acidic waste until a specific set of reviews were conducted with respect to how to treat the waste. Such a process is time consuming and expensive and it might have interfered with meeting the June 2014 deadline. Instead of following its own guidelines, the lab and its subcontractors took shortcuts. LANL added a neutralizer to the waste to change its pH and added an organic wheat based kitty litter to absorb excess liquid. One of the subcontractors said that he was not an expert on the chemistry of the wastes at LANL and he requested that LANL experts review the treatment of the waste. This was not done. It turns out that the additives basically turned the contents of the drums of waste into potential bombs.

Drums of the treated acidic waste were shipped to WIPP for permanent disposal. Every drum that is shipped to the WIPP is supposed to be accompanied by documents that give a detailed and complete account of the contents of the drum. The documents that came with the acidic waste drums did not contain the required information. There was no mention of the high acidity, the neutralizer or the organic kitty litter. Most chemists would have recognized the explosive nature of the contents of the drums if they knew that organic kitty litter was being mixed with the nitrate salts in the waste.

For two years before the accident this year, the LANL would not allow inspectors who conducted annual permitting audits for New Mexico’s Environmental Department into the area where waste was treated for shipment. The WIPP did not find out about the explosive chemistry in the burst drum until after the accident. Even after the drum burst last February, the LANL continued to withhold critical information from the people at the WIPP. It appears that there may have been a typo in the LANL guidelines that led to the switch to organic kitty litter.

If the documentation for the waste shipments had been accurate and complete, they would not have been allowed on the road at all. The pending report from the National Nuclear Security Administration’s Accident Investigation Board is expected to be critical of the behavior of the staff at LANL and their subcontractors who were apparently more interested in meeting the deadline than they were in the safety of the wastes they were shipping. Once again this illustrates a point that I keep repeating. Corporations cannot be relied upon to follow nuclear safety regulations.

Yesterday, I blogged about a loan program at the U.S. Department of Energy’s National Nuclear Security Administration aimed at the development of domestic sources of Molybdenum-99 (Mo-99), a radioactive isotope that is critical for most medical imaging systems. Mo-99 has a half-life of about three days. Then it decays into technetium-99 which is the isotope that is actually used in medical imaging. Because of its short half-life, Mo-99 cannot be stockpiled and so it must be constantly produced.

Currently, five reactors in Belgium, the Netherlands, Canada, South Africa and Russia produce most of the commercial Mo-99 in the world. The primary method of production is based on bombarding highly enriched uranium with neutrons. Because of the dangers of proliferation of nuclear weapons, other methods of production not involving highly enriched uranium are being developed. In my last blog, I mentioned that Canada produces as much as forty percent of the world’s supply of Mo-99 in its NRU reactor which is slated for shut down in 2016. It turns out that this will not be the end of Mo-99 production in Canada.

The Canadian Medical Isotope Project (MIP) just used the Canadian Light Source linear accelerator in Saskatoon, Saskatchewan to produce a batch of Mo-99 that did not require a nuclear reactor. The CLS contains a target of enriched molybdenum-100 (Mo-100). The target is bombarded with high-energy X-rays which knock single neutrons out of the Mo-100 atoms which results in the creation of Mo-99.

The Canadian government has allocated over fifty billion dollars since 2010 to the development of non-reactor sources of useful radioisotopes through the Isotope Technology Acceleration Program (ITAP). The Saskatchewan Government and ITAP are funding the MIP in partnership with the Prairie Isotope Production Enterprise (PIPE). The MIP is testing the production of isotopes until they obtain approval from Health Canada, the Canadian national health regulatory agency. It is anticipated that upon completion of testing and approval, this project will be able to supply Mo-99 to healthcare facilities across Western Canada by 2016.

CLS has stated that just three accelerators systems could produce enough Mo-99 to supply all of Canada’s domestic needs for the radioisotope. CLS hopes to that the commercialization of Mo-99 productions from accelerators will provide sufficient funding to extend production and seek foreign markets.

The Canadian announcement about new processes for M0-99 production came just a few days after the U.S. Department of Energy’s National Nuclear Security Administration announced an eight million dollar loan program aimed at new methods of production of Mo-99 that do not utilize highly-enriched uranium. The timing of the Canadian announcement is very interesting. Is it possible that Canada which has announced the shut down of the reactor currently producing forty percent of the global supply of Mo-99 is concerned about losing that market share due to efforts of other countries such as the U.S. to produce their own Mo-99 internally? Perhaps the recent Canadian announcement was intended to reassure current Canadian customers for Mo-99 that Canada will continue to be a major source for Mo-99 after the scheduled closing of the NRU reactor.

Canada’s NRU reactor:

The prime ministers of India and Australia have underlined their commitment to implementing agreements that will enable Australian uranium to be exported to India. world-nuclear-news.org

The US House of Representatives on has passed legislation to authorize Department of Energy (DoE) research on whether low-dose ionizing radiation poses a risk. world-nuclear-news.org