Blog

-

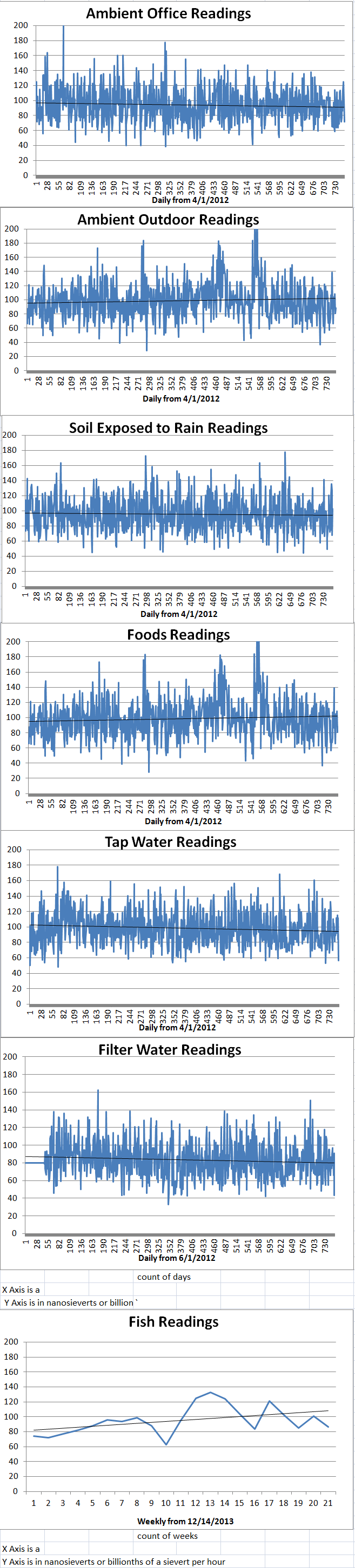

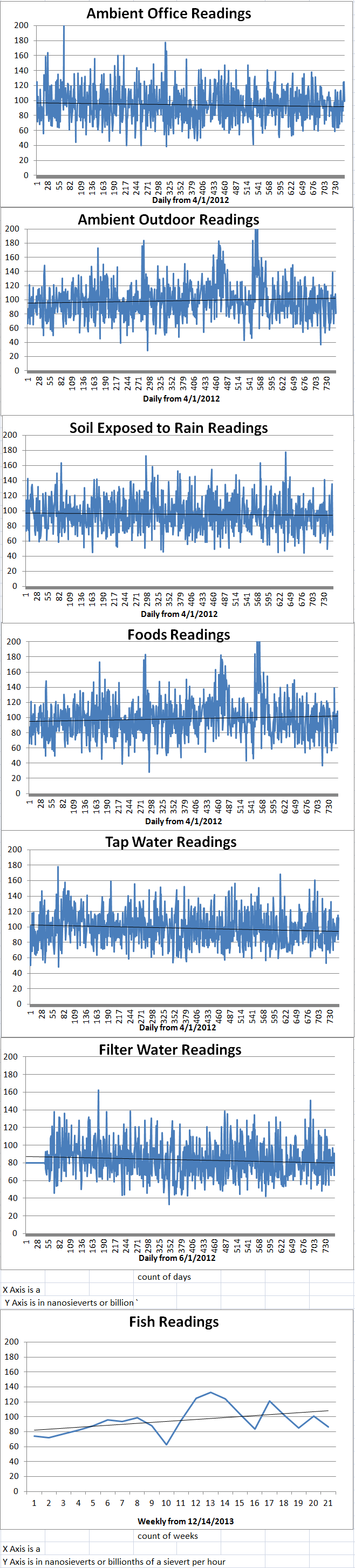

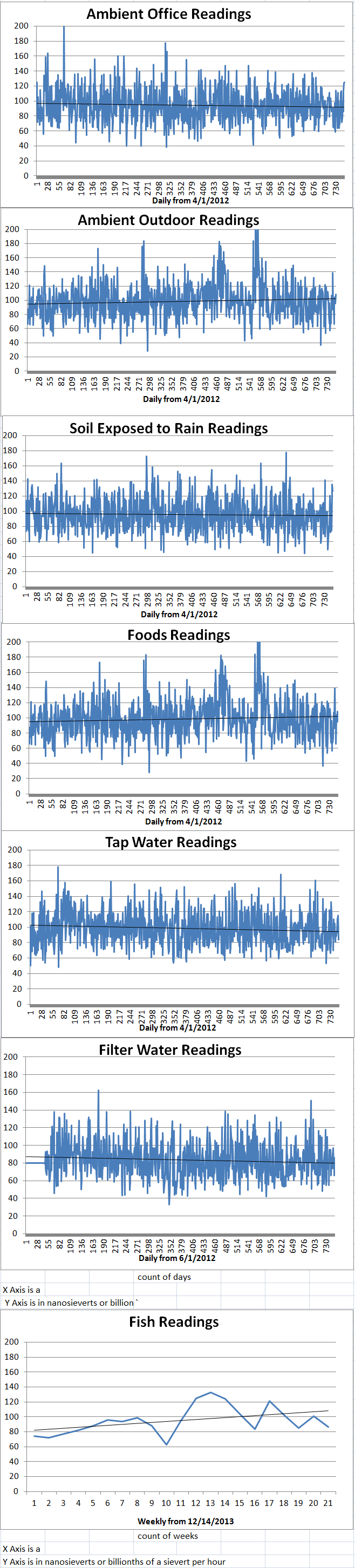

Geiger Readings for May 8, 2014

Ambient office = 72 nanosieverts per hourAmbient outside = 87 nanosieverts per hourSoil exposed to rain water = 103 nanosieverts per hourOrange bell pepper from Top Foods = 89 nanosieverts per hourTap water = 57 nanosieverts per hourFiltered water = 43 nanosieverts per hour -

Radioactive Waste 76 – Explosion during recent demolition of Hanford Plutonium Plant

Hanford is the gift that keeps on giving. I could blog about nothing but the cleanup work at the Hanford Nuclear Reservation and never run out of material. Recently there have been a series of Hanford Cleanup public meeting in Seattle, Portland and Richland. Well prepared officials from Hanford came to the meetings with slide shows and glossy handouts explaining how well everything is going. One thing that they failed to mention is the explosion at the Hanford Plutonium Finishing Plant (PFP) during demolition work a couple of weeks ago. The PFP may be the most radioactively contaminated building in the United States.

Workers at the Plutonium Finishing Plant reported that they first saw a spark and then flames shot out of a pipe that workers cutting into. Hanford management said that the incident was just a small pop but the workers who witnessed it said that it was a loud blast that was more like a shotgun being fired. The pipe was contained in a special structure to prevent worker exposure. However, if the pipe broke there was a possibility that workers could have inhaled particles of plutonium which could have had deadly consequences.

CH2M HILL Plateau Remediation Company(CHPRC) is the prime contractor for the environmental cleanup of the Central Plateau at the Hanford Site. A union representative suggested that CHPRC was downplaying the seriousness of the incident to avoid fines and litigation that could delay work..They feel that CHPRC is more interested in schedules and budgets that worker safety. The union representative also said that when workers express concerns about risks and safety, it “falls on deaf ears.” There have been charges that CHPRC has decided that they do not want experienced workers at the PFP because experienced workers raise too many uncomfortable questions.

CHPRC issued a stop order for pipe cutting following the incident. Some workers have said that they don’t think enough is being done to insure their future safety when work on the pipes resumes. CHPRC pointed out that the workers responded appropriately and no one was exposed to the plutonium in the pipe. They also said that there was no evidence of a release of radioactive materials from the pipe. For the time being the use of the mechanical pipe cutting equipment will be halted until it can be determined exactly what caused the explosion.

The U.S. Department of Energy has issued a statement that they are monitoring the response of CHPRC to the incident and will continue to do so until the cause has been determined and steps are taken to prevent a recurrence.

Recently there was an explosive release of vapors from waste storage tanks at Hanford. Twenty four workers were briefly hospitalized and treated for exposure to toxic fumes. Hanford management said that no one sustained serious injuries and all have returned to work. Some of the workers who were hospitalized have disagreed with the Hanford announcement saying that everyone has not returned to work and at least one man sustained injuries that will cause long term health problems.

Over and over Hanford management has been accused of putting budgets and schedules ahead of worker safety and downplaying the seriousness of any accidents. These are just two of the most recent incidents. While I agree that the contamination at Hanford must be cleaned up as quickly as possible, it should not be at the cost of workers’ health and lives.

-

Radiation News Roundup May 7, 2014

Unit 1 at Maryland’s Calvert Cliffs nuclear plant returned to service over the weekend following an automatic reactor trip Thursday. nuclearstreet.com

The company building the world’s first AP1000 reactors in China has filed for a $2.6 billion IPO to raise capital for further nuclear plant construction. nuclearstreet.com

The G7 group of industrialized nations has focused on energy security, prioritizing low-carbon sources including nuclear power for deployment in an effort to establish resilient low-carbon power systems. world-nuclear-news.org

-

Geiger Readings for May 7, 2014

Ambient office = 99 nanosieverts per hourAmbient outside = 81 nanosieverts per hourSoil exposed to rain water = 67 nanosieverts per hourOrange bell pepper from Top Foods = 81 nanosieverts per hourTap water = 112 nanosieverts per hourFiltered water = 91 nanosieverts per hour -

Geiger Readings for May 7, 2014

Ambient office = 99 nanosieverts per hourAmbient outside = 81 nanosieverts per hourSoil exposed to rain water = 67 nanosieverts per hourOrange bell pepper from Top Foods = 81 nanosieverts per hourTap water = 112 nanosieverts per hourFiltered water = 91 nanosieverts per hour -

Radioactive Waste 75 – Update on the Recent Accident at the Waste Isolation Pilot Plant 2

More information keeps coming out about the February 14th accident at the Waste Isolation Pilot Plant which resulted in the release of particles of plutonium and americium into the environment around Carlsbad, New Mexico. There are reports that the radioactive isotopes have been found much further away from the plant. Twenty one people in the facility were exposed to radiation during the accident. The site has been closed since the accident with only a skeleton staff and investigators being allowed into the facility. The room where the radiation was released has been so hot that investigators were having problems entering the area where the radiation release occurred. It is still not clear at this time exactly what happened.

The plant accepts mildly radioactive waste, tools, clothes and other materials generated by the production of U.S. nuclear weapons. It is located in an old salt mine where drums of waste are piled in large open “panels” which are each divided into seven rooms. When a room is full, it is sealed off. Bags of magnesium oxide powder weighing up to two tons each are placed on top of the drums of waste to serve as backfill. In addition, if water found its way into the room after it was closed off, the magnesium oxide would combine with the water to form a compact solid, immobilizing the radioactive materials and prevent the water from dissolving them and washing them out of the room. The magnesium oxide powder also absorbs carbon dioxide.

Two theories of what caused the accident were put forward. One suggested that gases built up in a drum of waste and then exploded, damaging other drums. The other theory suggests that the roof of the room collapsed on the drums and damaged them. Using cameras on telescopic extensions, on April 30 the investigators were able see deep into the room where the accident occurred and were able to verify that there was no evidence of damage to either the ceiling or the walls of the room. What was found was that there was damage to some of the bags of magnesium oxide. Large piles of powder were found on top of other bags but there was no sign of the bags that should have contained the loose powder.

With respect to the other theory about gas build up there have been reports that testing for gas build up had been declining since the facility was put into operation. Inspectors are checking the processing of some of the last drums of waste that were placed in that room to see if they were vented within sixty days of arrival as required by regulations.

Ninety staff members of WIPP have completed training courses on facility operations and have just been allowed to return to the facility. “Upon returning to the site, workers will perform plant and equipment maintenance and restoration, radiological checks, sampling activities, and support work procedure revisions.” Hopefully, the cause of the accident will be identified and dealt with before the facility is reopened to take waste.

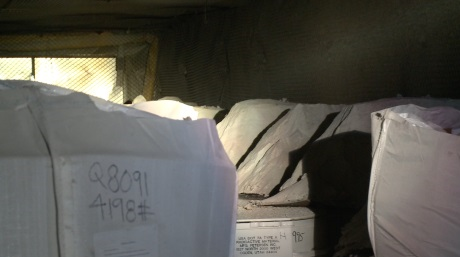

Bags of magnesium oxide in the Waste Isolation Pilot Plant:

-

Radiation News Roundup May 6, 2014

Shocking 62,700 Bq/kg of cesium has been measured in mushrooms near Fukushima. enenews.com

Nuclear fuel fragments from Fukushima have been found in Europe. enenews.com

A Toshiba-GDF Suez consortium hoping to build a new nuclear power station adjacent to Sellafield has extended its option to purchase the land until after the European Commission ruling on UK market reforms. world-nuclear-news.org

Nuclear power remains important for France and Japan, the leaders of both countries have affirmed. world-nuclear-news.org

-

Geiger Readings for May 6, 2014

Ambient office = 125 nanosieverts per hourAmbient outside = 117 nanosieverts per hourSoil exposed to rain water = 126 nanosieverts per hourOrange bell pepper from Top Foods = 109 nanosieverts per hourTap water = 84 nanosieverts per hourFiltered water = 66 nanosieverts per hour -

Nuclear Reactors 123 – Many U.S. Nuclear Power Stations are not in Compliance with NRC Fire Safety Rules

In 1975 at the Brown’s Ferry nuclear power plant in Alabama, they were having problems with electrical wiring below the control room. There were air leaks in the cable spreading room and engineers were working to repair the leaks with spongy foam rubber. One of the men was using a candle to detect the air leaks. When he held the candle too close to a piece of the foam rubber, it burst into flame. The fire spread and destroyed a lot of the wiring including the controls for the emergency cooling system. There was almost a meltdown in the core of the reactor.

In 1980, the Nuclear Regulatory Commission drafted and adopted new rules for comprehensive fire protection to prevent any more fires like the one at Brown’s Ferry. Over the next twenty years, the NRC discovered that about half of the one hundred and four nuclear power plants in the U.S. did not comply with the new fire safety standards. Some of the plants that were not in compliance would required very expensive changes that would have afforded little more protection. The U.S. nuclear industry resisted the demand for compliance.

In response to the industry resistance to the new standards, the NRC came up with new rules in 2004 that gave the owners of nuclear power plants an option. The plant operators could bring their installations into compliance with the 1980 NRC fire safety rules or they could opt to meet the National Fire Protection Association’s (NFPA) standards for nuclear power plants that were based on performance. In contrast to the 1980 rules that state what plants are required to do and how those tasks should be accomplished, the alternative NFPA standards points out what the end result of changes should be but they do not explain exactly what the nuclear plants have to do to meet the NFPA standards. It is left to the individual nuclear power plants to assess the risk of fire throughout the plant and then to make procedural and/or physical changes to mitigate the risks. The two sets of standards are obviously different in their details but the end result of both standards is to insure that the nuclear power plant would be safer from the risk of fires.

In 2005, about four dozen nuclear power plants notified the NRC that they were planning on moving to the NFPA standards. Implicit in these notifications is the admission that those nuclear power plants were not in compliance with the 1980 NRC standards despite the fact that twenty five years had passed since the new NRC standards were adopted. Analyses of nuclear plant risks show that about half of the risk of triggering a nuclear core melt down can results from fires even taking the new fire safety standards into account.

FirstEnergy has petitioned the NRC for more time to complete the exhaustive reviews and analyses that the NRPA standards require before any work can be done at their Davis-Besse Nuclear Power Station in Ohio. FirstEnergy says that they can finish the review process by 2015. Then they want to wait until the NRC issues a ruling on the NRPA plan before starting any work. If the NRC accepts their proposal, that means that there will be no work on mitigating fire risks before 2017 at the earliest. They want to continue to violate NRC rules for another three years at least. This is the sort of lax regulation that makes me nervous. A quarter of the nuclear power plants in the U.S. are at greater risk for fires and meltdowns than they would be if the NRC did not allowed them to drag their feet for decades before complying with improved fire safety standards. If a fire at one of these plants results in a serious nuclear accident, just remember that it could have been prevented.

Davis-Besse Nuclear Power Station: