Part 1 of 2 Parts

RePlanet is an environmental group that advocates recycling spent nuclear fuel as a fuel for advanced fast reactors. They have just published a report titled “What a waste: How fast-fission power can provide clean energy from nuclear waste”. The report mentions that European nuclear power reactors “have a long history of safe use, and have provided prodigious quantities of clean electricity for decades”. However, they actually burn up less than one percent of the energy potential in the natural uranium used to make their fuel. In addition, irradiated fuel assemblies are classified as “nuclear waste”.

RePlanet states that it “is a network of grassroots charitable organizations driven by science-based solutions to climate change, biodiversity collapse and the need to eliminate poverty” which is funded exclusively from charitable sources. It adds that “We have not received any funding from industry or party-political sources.”

RePlanet goes on to says, “While this nuclear ‘waste’ is not a serious environmental or health threat – it occupies trivial volumes compared to waste produced by other industries, and does not harm anyone if properly shielded and safeguarded – it does provide a political challenge, and is among the most oft-cited reasons for continued opposition to carbon-free nuclear power.”

RePlanet says that utilizing this spent nuclear fuel in a new generation of fast-neutron reactors would “eliminate it as a ‘waste’ concern via a carbon-free waste-to-energy process”. It notes that most of the remaining fissions products in spent nuclear fuel would return to a level of radioactivity comparable to the original uranium ore in just two hundred to three hundred years. “This means that current deep geological disposal strategies can be simplified and scaled back.”

RePlanet issued a call to European green parties to end their “dangerous and unscientific” opposition to nuclear power because of the dangers of climate change. Mark Lynas is the RePlanet co-founder. He rejects the view that spent nuclear fuel is a waste product that needs to be buried in deep geological repositories. This just leaves a toxic legacy for future generations. He noted that “Anti-nuclear campaigners never tire of repeating this mantra in their campaign to shut down nuclear plants irrespective of our climate emergency. However, we show in this RePlanet report that nuclear waste simply needs to be recycled efficiently in order to generate centuries of clean power for Europe and the UK. This material is not waste, it is fuel for the future.”

The new RePlanet report proposes “a repurposing of nuclear materials with a view to fast-tracking an urgent program of fast reactor build-outs. These must be deployed in such a way as to reduce grid congestion and increase security of supply to enable the deployment of wind, solar and nuclear for the majority of electrical power generation and heat supply in a net zero Europe.”

It notes, “We find, using a calculation based mainly on current inventories of uranium, that there is sufficient energy in nuclear ‘waste’ to run Europe at current electrical power consumption for up to a thousand years. If unconventional uranium and thorium resources are considered in the global picture, nuclear fuel is essentially limitless.”

Please read Part 2 next.

Blog

-

Radioactive Waste 900 – RePlanet Calls For The Use Of Spent Nuclear Fuel To Power Fast Breeder Reactors – Part 1 of 2 Parts

-

Nuclear News Roundup Apr 06, 2023

Shoigu claims Russia placed aircraft, missile systems in Belarus capable of delivering nuclear strikes news.yahoo.com

How a school shutdown resurrected concerns over nuclear contamination in North Saint Louis uk.news.yahoo.com

Latvian foreign minister urges NATO not to “overreact” to Russia’s plans for tactical nukes in Belarus cbsnews.com

Bruce and Cameco partner for long-term nuclear fuel supply world-nuclear-news.org

-

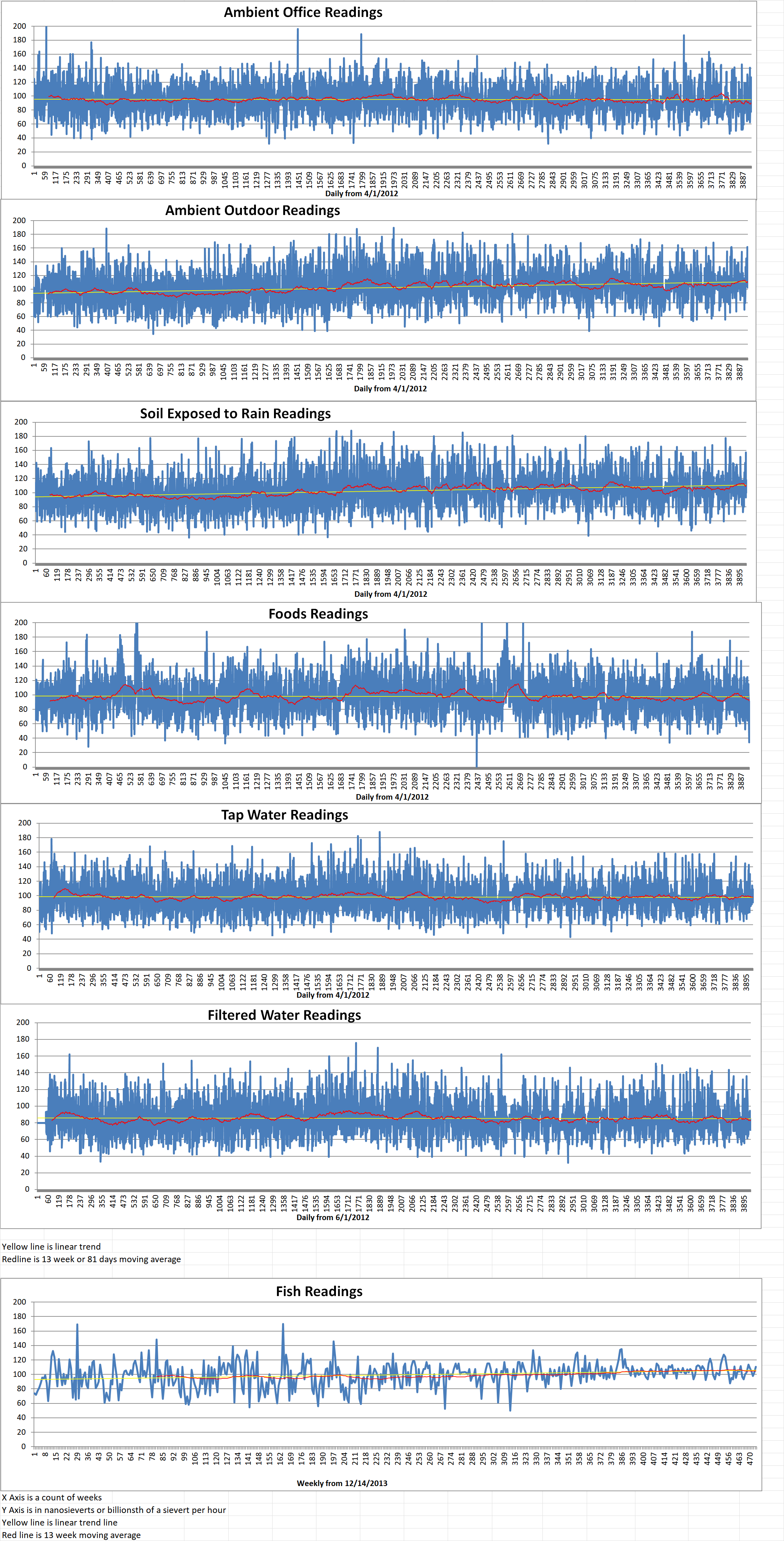

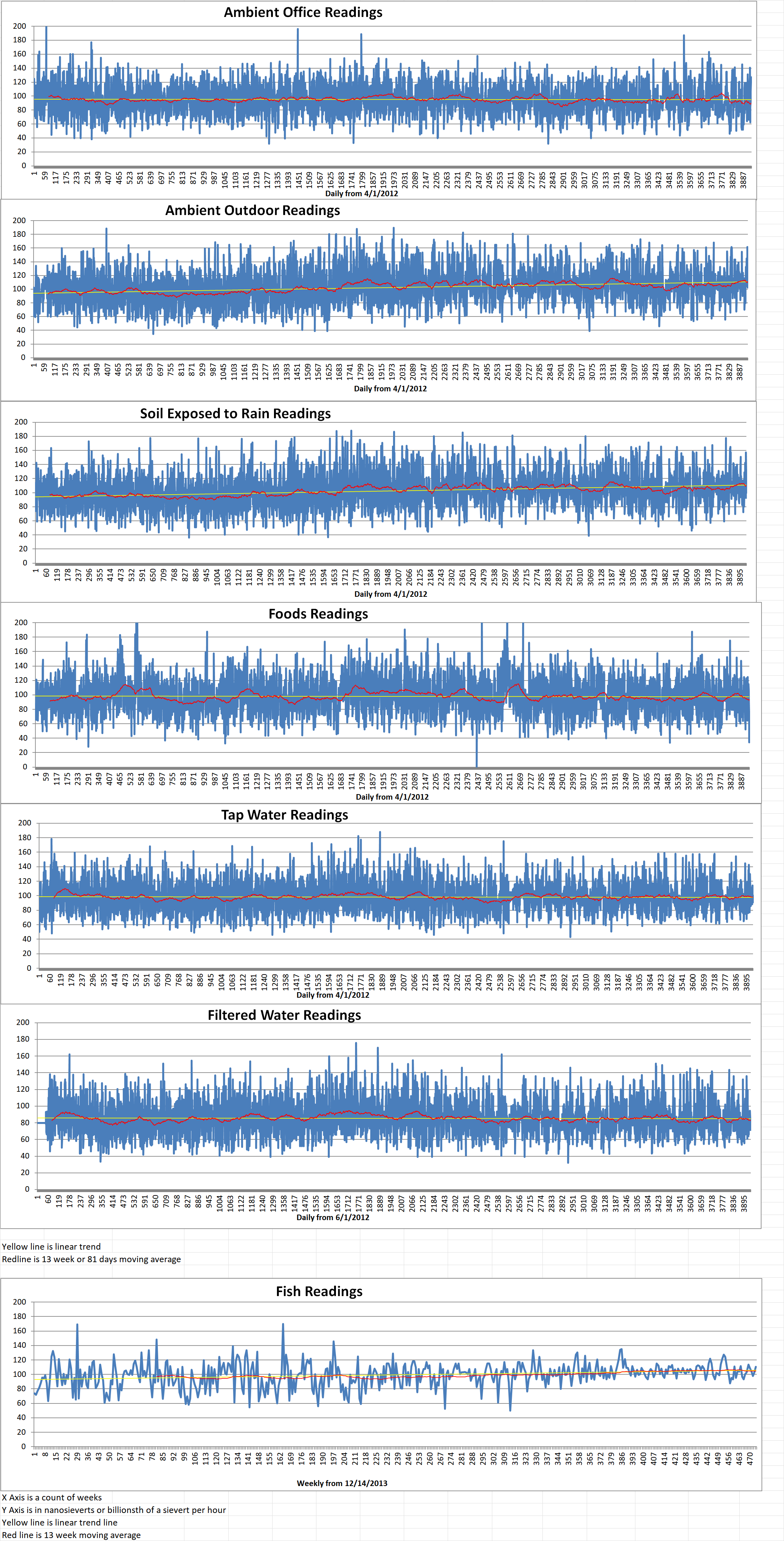

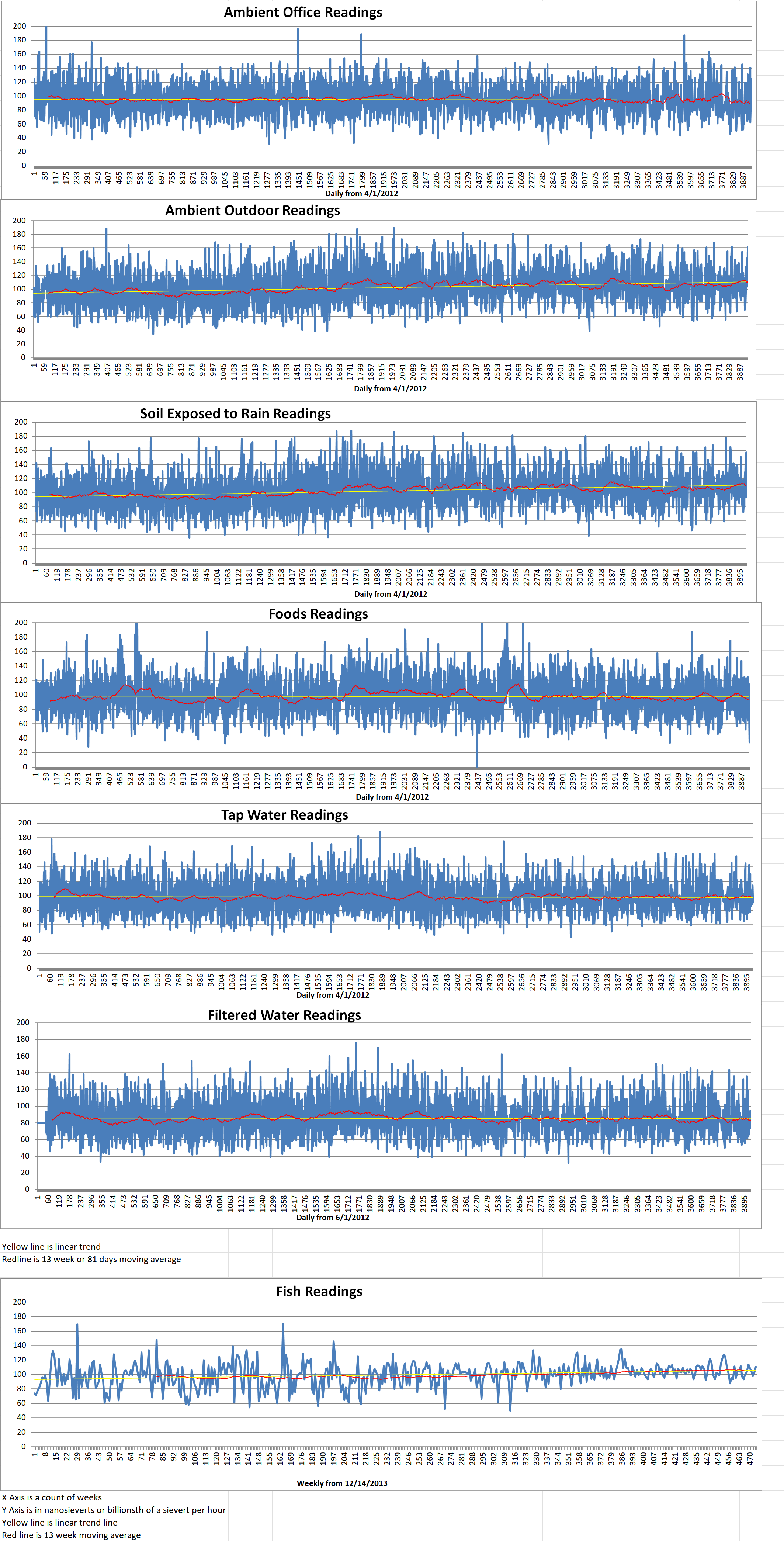

Geiger Readings for Apr 06, 2023

Ambient office = 78 nanosieverts per hour

Ambient outside = 119 nanosieverts per hour

Soil exposed to rain water = 117 nanosieverts per hour

Blueberry from Central Market = 691 nanosieverts per hour

Tap water = 109 nanosieverts per hour

Filter water = 84 nanosieverts per hour

-

Nuclear Reactors 1201 – Rapidly Rising World Demand For Cobalt-60 Is Prompting Producers To Increase Production – Part 2 of 2 Parts

Part 2 of 2 Parts (Please read Part 1 first)

Russian Co-60 production in the reactors of the Leningrad nuclear power plant which are closing in 2018 and 2027 is being replace with Co-60 production at new reactors at Kursk and Smolensk. In Canada, the Pickering reactors operated by Ontario Power Generation (OPG) that have produced Co-60 since the 1970s have been scheduled to shut down in 2024. However, life extension to 2025 and refurbishment are now being considered for these reactors. The Darlington reactors also operated by OPG are being refurbished and will be converted to Co-60 production.

Currently, most of the world’s Co-60 is produced in Canada Deuterium Uranium (CANDU) pressurized heavy water reactors and a limited number Reaktor Bolshoy Moshchnosti Kanalnyy (RBMK) light water graphite-moderated reactors. The best opportunity to significantly increase the availability of Co-60 is to develop production in new reactor types.

There are about four hundred and forty commercial nuclear reactors in operation around the globe. More than three hundred of them are pressurized water reactors (PWRs). This has made the PWRs the reactor platform of choice for future Co-60 production. Nordion is the world’s largest manufacturer of Co-60 radiation sources used for sterilization. In February of 2020, Nordion announced that it was partnering with Westinghouse to develop large scale production of Co-60 in PWRs. At the IMRP20 meeting in November of 2022, Westinghouse updated the radiation processing industry on its progress and timeline for this important initiative. Production of Co-60 in PWRs would be highly scalable with the capacity to double existing production volumes form PWRs in the U.S. alone.

Other Co-60 initiatives include the announcement in December of 2021 that Framatome and Exelon Generation will cooperate to understand and develop solutions to produce Co-60 in PWRs operated by Exelon Generation. In June of 2020, Nuclearelectrica Romania announced that its 2020-2025 strategic investment plan includes the study of Co-60 production at tis Cernavoda nuclear power plant. Design and implementation are targeted to be completed by 2027.

The healthcare industry has relied on Co-60 since the 1960s when demand for sterilization began to increase. The technology is now applied globally by an international network of irradiation facilities backed up by a robust regulatory infrastructure. There are alternatives to Co-60 technology for sterilization. However, these alternatives do no have the capacity to meet existing demands or the infrastructure to allow for rapid growth to meet future demand.

The production of Co-60 in nuclear reactors remains critical to healthcare. Steps are underway to increase Co-60 production. Co-60 supply volumes have started to increase but not at the rate of increasing demand. The International Irradiation Association represents the radiation processing industry. It supports all the initiatives that will allow meeting the demand for sterilization of health care products. It also encourages reactor operators to engage with the nuclear industry on Co-60 production. In addition to the provision of clean energy, the production of isotopes in support of health care remains a highly positive contribution of the nuclear industry to societal wellbeing. -

Geiger Readings for Apr 05, 2023

Ambient office = 127 nanosieverts per hour

Ambient outside = 102 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Avocado from Central Market = 70 nanosieverts per hour

Tap water = 92 nanosieverts per hour

Filter water = 72 nanosieverts per hour

-

Nuclear News Roundup Apr 05, 2023

Small Areas Reopen Near Fukushima Nuclear Plant, Few Return usnews.com

Former PM Barak says Israel has nuclear weapons clevelandjewishnews.com

Review Meeting of Convention on Nuclear Safety Identifies Shared Priorities for Future Action iaea.org

US considering partial nuclear deal with Iran, Washington tells Israel middleeastmonitor.com

-

Nuclear Reactors 1200 – Rapidly Rising World Demand For Cobalt-60 Is Prompting Producers To Increase Production – Part 1 of 2 Parts

Part 1 of 2 Parts

Radioactive isotopes are used extensively in the healthcare industry. The gamma radiation from radioactive isotope Cobalt-60 (Co-60) is critical to healthcare. Demand is growing rapidly and it is important to increase production to expand the supply.

Co-60 is manufactured in some nuclear reactors. It is used to sterilize about forty percent of single-use medical devices around the globe. These devices include such items as syringes, catheters, IV sets, surgical gloves and gauze that are utilized in a wide range of healthcare applications. A patient in surgery, wound care or giving a blood sample is very likely to be treated with products that have been sterilized with Co-60. This process is referred to as irradiation or radiation processing.

Other important uses for Co-60 include non-invasive treatment of cancers and brain tumors, polymer processing, food treatment and environmental applications.

The demand for Co-60 to be used for sterilization is increasing at rates never seen before. This is partially due to an increasing and aging population, greater access to health care and the development of new devices that will require sterilization. The typically reported growth rate is currently six to eight percent per year. The demand for sterilization is estimated to double over the next ten years. Some sectors such as the biopharmaceutical industry that is switching to single use systems are experiencing growth at much higher double digit rates. However, they only represent a small proportion of current sterilization demand.

In recent years, the pressure on vaccine supply has concentrated Co-60 for sterilization and, in some case, a backlog has appeared. In a recent conference titled International Meeting on Radiation Processing (IMRP20) held in November 2022, the increasing gap between sterilization capacity and demand was singled out as a highly significant concern of the healthcare industry.

Co-60 is currently produced in a small number of nuclear reactors located in Argentina, Canada, China, India and Russia. This Co-60 is manufactured into radiation sources by a few specialist manufacturers that serve the radiation processing industry. Most of the Co-60 produced in China and India and some produced in Argentine is used to supply only their local markets. This means that most of the rest of the world’s Co-60 is supplied by Canada and Russia. Most of this Co-60 is contracted to one Canadian source manufacturer.

During the time of increasing sterilization demand, there have been a few disruptions that have caused problems for Co-60 production. These include a brief period of reduced supply from one Russia reactor as well as the temporary shutdown for refurbishment of some existing Co-60 production reactors in Canada and Argentina. Reactor refurbishment is critical to extend the life of Co-60 production reactors. These initiatives will enable existing reactors to continue Co-60 production for another twenty-five to thirty years.

Some Co-60 production reactors have been permanently closed in recent years. However, a variety of initiatives have resulted in the production of Co-60 being replaced or exceeded by the production of new or refurbished reactors.

Please read Part 2 next -

Geiger Readings for Apr 04, 2023

Ambient office = 122 nanosieverts per hour

Ambient outside = 120 nanosieverts per hour

Soil exposed to rain water = 119 nanosieverts per hour

Asparagus from Central Market = 34 nanosieverts per hour

Tap water = 91 nanosieverts per hour

Filter water = 83 nanosieverts per hour

-

Nuclear News Roundup Apr 04, 2023

High level of activity spotted at North Korea’s key nuclear complex English.kyodonews.com

Türkiye’s 1st nuclear plant reflects Ankara’s willingness to deepen energy ties with Moscow English.news.cn

UK looks to nuclear to bolster energy independence world-nuclear-news.org

UK assessment of Rolls-Royce SMR design progresses : Regulation & Safety – World Nuclear News (world-nuclear-news.org) world-nuclear-news.org

-

Radioactive Waste 899 – Sweden Is Expanding Its Repository for Radioactive Waste

Svensk Kärnbränslehantering AB (SKB) is Sweden’s radioactive waste management company. SKB has just submitted an application to the Radiation Safety Authority, (SSM) to extend the existing Final Repository for Short-lived Radioactive Waste (SFR) at Fosmark. Fosmark is located on the east coast of Sweden. The company has plans to expand the repository to almost three times its current size so that it can receive demolition waste from decommissioned Swedish commercial nuclear power plants.

The SKB application includes the preliminary safety analysis report (PSAR). This is a report on safety during the construction phase, system descriptions and a decommissioning plan. SKB cannot begin work to excavate rock for the extension of the SFR until SSM has approved.

Jenny Brandefelt is the project leader. She said, “The analyses are now updated with refined methods, data and calculations, while the conclusion from previous analyses remains firm: the plant is safe both during operation and after closure. It certainly feels satisfying that the updated analyses continue to show a safe facility in both the short and long-term”.

The SFR repository is situated almost two hundred feet below the bottom of the Baltic Sea. It began operations in 1988. The facility contains four five hundred- and sixty-five-foot rock vaults. It also contains a chamber cut into the bedrock with a one hundred- and sixty-five-foot concrete silo to hold the most radioactive waste. Two parallel access tunnels that are three thousand two hundred and eighty feet long provide access from the facility to the surface. The facility currently has a total final disposal capacity of about eighty-two thousand cubic yards.

Most of the short-lived waste deposited in the SFR was produced from Swedish nuclear power plants. However, radioactive waste from hospitals, veterinary medicine, research and industry are also stored in the repository.

SKB applied in December of 2014 for permission to triple the size of the repository to about twenty-three thousand five hundred cubic yards. The application was submitted to the government by the Land and Environment Court and the SSM in November of 2019. In April of 2021, the extension was approved by the municipality of Östhammar, where the repository is located. The matter was referred back to SSM and the Court following a government decision in December of 2021 to approve the extension.

SKB received an environmental permit from the Land and Environment Court for the extension in December of 2022. That permit regulates noise and transport among other things.

The plan for the extended repository will include six new rock vaults. The new vaults will be up to nine hundred feet long. The extension will be constructed at a depth of up to four hundred and sixty feet. It will be level with the current lowest part of the SFR repository.

The SFR expansion is expected to require six years to complete. In the first phase, earthworks, water treatment plants, and other infrastructure will be put in place. In the second phase, tunnelling work in the rock underground will be carried out.