Deep Isolation, the Nuclear Advanced Manufacturing Research Centre, the University of Sheffield and NAC International are collaborating in a project to engineer canisters that meet U.K. regulatory requirements for long-term storage of spent nuclear fuel and high-level radioactive waste in boreholes up to two miles underground.

The funding comes from the Department for Energy Security and Net Zero’s Energy Entrepreneurs Fund. It is intended to support the U.K.’s 2050 net-zero target by “tackling a fundamental challenge to the success of small modular reactors (SMRs) … the need for safe, secure, scalable and cost-effective spent nuclear fuel disposal solutions”.

Deep Isolation is based in Berkeley, California. It has been working on a system of using directional boreholes disposal of nuclear waste. The company is building on innovations in the drilling industry I recent decades. This means that “it is now inexpensive and routine to go down three quarters of a kilometer in depth and to have horizontal sections two, three or four kilometers in length”.

Deep Isolation’s solution for management of spent nuclear fuel and high-level radioactive waste involves emplacing it in corrosion-resistant canisters placed in deep horizontal drillholes. Deep Isolations approach utilizes existing directional drilling technology. The nuclear waste can be retrieved during a determined time frame or permanently secured. In 2019, Deep Isolation publicly demonstrated its system when it successfully placed and then retrieved a prototype nuclear waste canister hundreds of feet underground via a borehole.

The U.K. project will include the manufacturing and testing of two prototype canisters tailored to the U.K. requirements. A manufacturing supply chain needs to be established to support the new system.

Chris Parker is the Global Head of Business Development and Managing Director of Deep Isolation EMEA. He said, “This canister provides an option for disposal in a deep borehole that brings greater flexibility and potential cost-savings for disposal of spent nuclear fuel and high-level waste.”

Parker went on to say that in the U.K., the deep borehole system would not replace the need for a traditional mined geological disposal facility but “it has the potential to reduce costs and save time for the UK’s GDF program because it can accept selected high heat-generating waste streams at much greater depth”.

He added that it would also “provide us with an ideal supply chain with which to service the growing international demand for deep borehole disposal.” He said that each canister would dispose of used fuel that has enabled the generation of one hundred and thirty million kilowatts of low carbon electricity, of “a saving of nearly 27,000 ton of CO2 per canister”.

The Energy Entrepreneurs Fund grant award document stated that “high-quality disposal canisters represent a potential global market value of over GBP100 billion (USD121 billion) over the next 20-30 years. The current global inventory of waste suitable for disposal in the UK canister represents 1.1 million canisters; growth to 2035 (including reactors currently under construction or planned) represents a further requirement of 1.35 million canisters”.

Alan Woods is the strategic director of the UK SMR company Rolls-Royce SMR. He is also on the project board. He said that the option of small, modular disposal of radioactive waste in deep boreholes “will be an important enabler of the international SMR markets and a great export opportunity for UK manufacturers”.

Deep Isolation has more than a dozen contracts across three continents with projects including advanced reactor and SMR waste disposal, stand-alone borehole disposal of small existing nuclear waste inventories and to work with mined repository programs to increase safety and reduce costs by moving certain nuclear waste steams into boreholes.

Blog

-

Radioactive Waste 891 – Deep Isolation Developing Canisters For Deep Borehole Nuclear Waste Storage

-

Geiger Readings for Feb 13, 2023

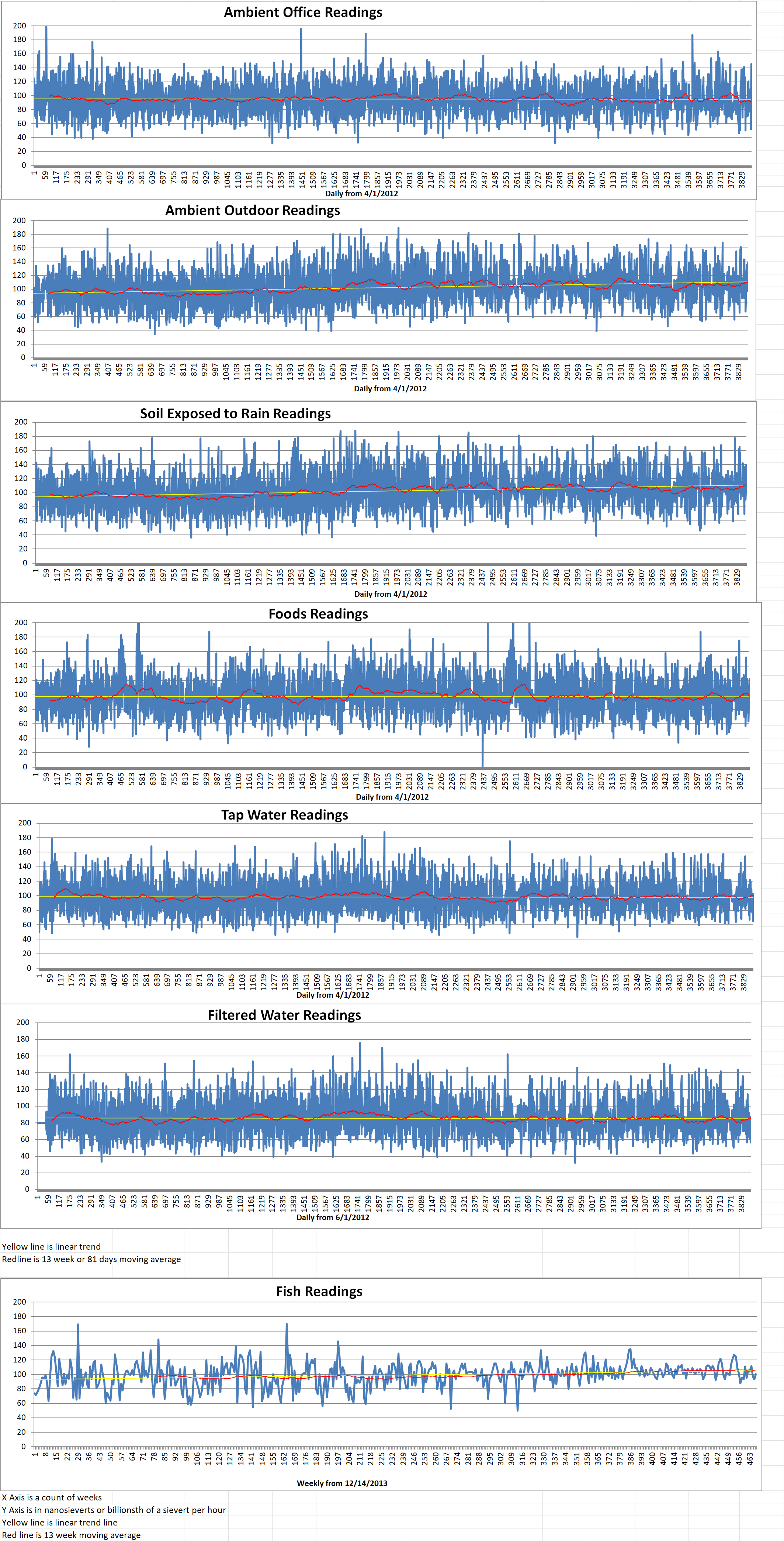

Ambient office = 145 nanosieverts per hour

Ambient outside = 137 nanosieverts per hour

Soil exposed to rain water = 135 nanosieverts per hour

Shallot from Central Market = 122 nanosieverts per hour

Tap water = 65 nanosieverts per hour

Filter water = 56 nanosieverts per hour

-

Nuclear News Roundup Feb 12, 2023

Hiroshima, Nagasaki urge G-7 engagement to understand nuclear war English.kyodonews.net

BWRX-300 selected for Estonia’s first nuclear power plant world-nuclear-news.org

Cameco signs major uranium supply deal with Ukraine neimagazine.com

Japan’s nuclear-power industry hikes hiring www3.nhk.or.jp

-

Geiger Readings for Feb 12, 2023

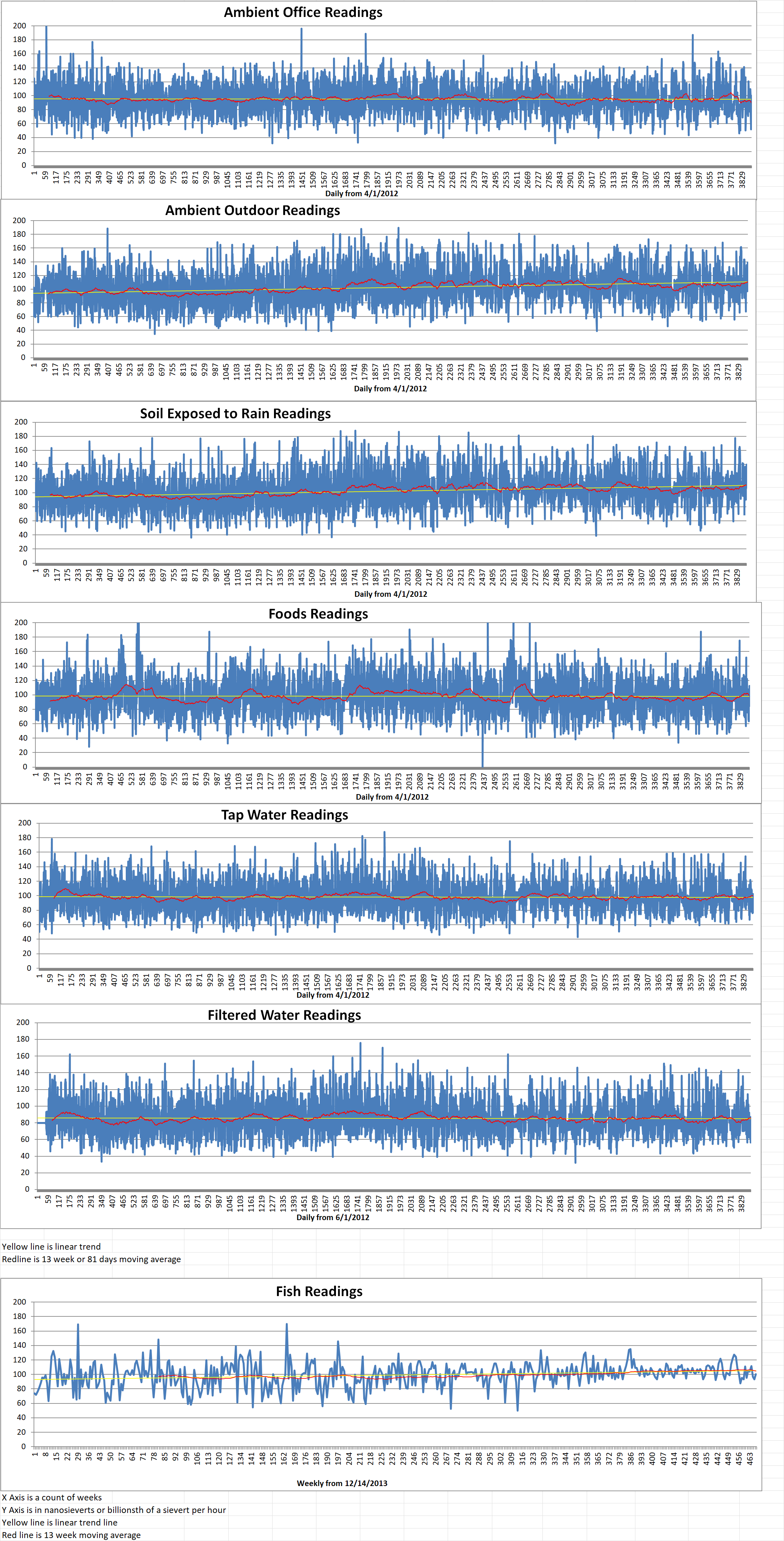

Ambient office = 100 nanosieverts per hour

Ambient outside = 139 nanosieverts per hour

Soil exposed to rain water = 140 nanosieverts per hour

Red bell pepper from Central Market = 112 nanosieverts per hour

Tap water = 77 nanosieverts per hour

Filter water = 57 nanosieverts per hour

-

Nuclear News Roundup Feb 11, 2023

Cameco to supply Ukraine’s uranium needs to 2035 world-nuclear-news.org

Iran announces start-up of uranium mine world-nuclear-news.org

Baltic Shipyard signs contract for two more nuclear-powered icebreakers : New Nuclear – World Nuclear News (world-nuclear-news.org) world-nuclear-news.org

Democrats wrestle with studying ‘advanced’ nuclear energy in wake of Minnesota carbon-free bill energynews.com

-

Geiger Readings for Feb 11, 2023

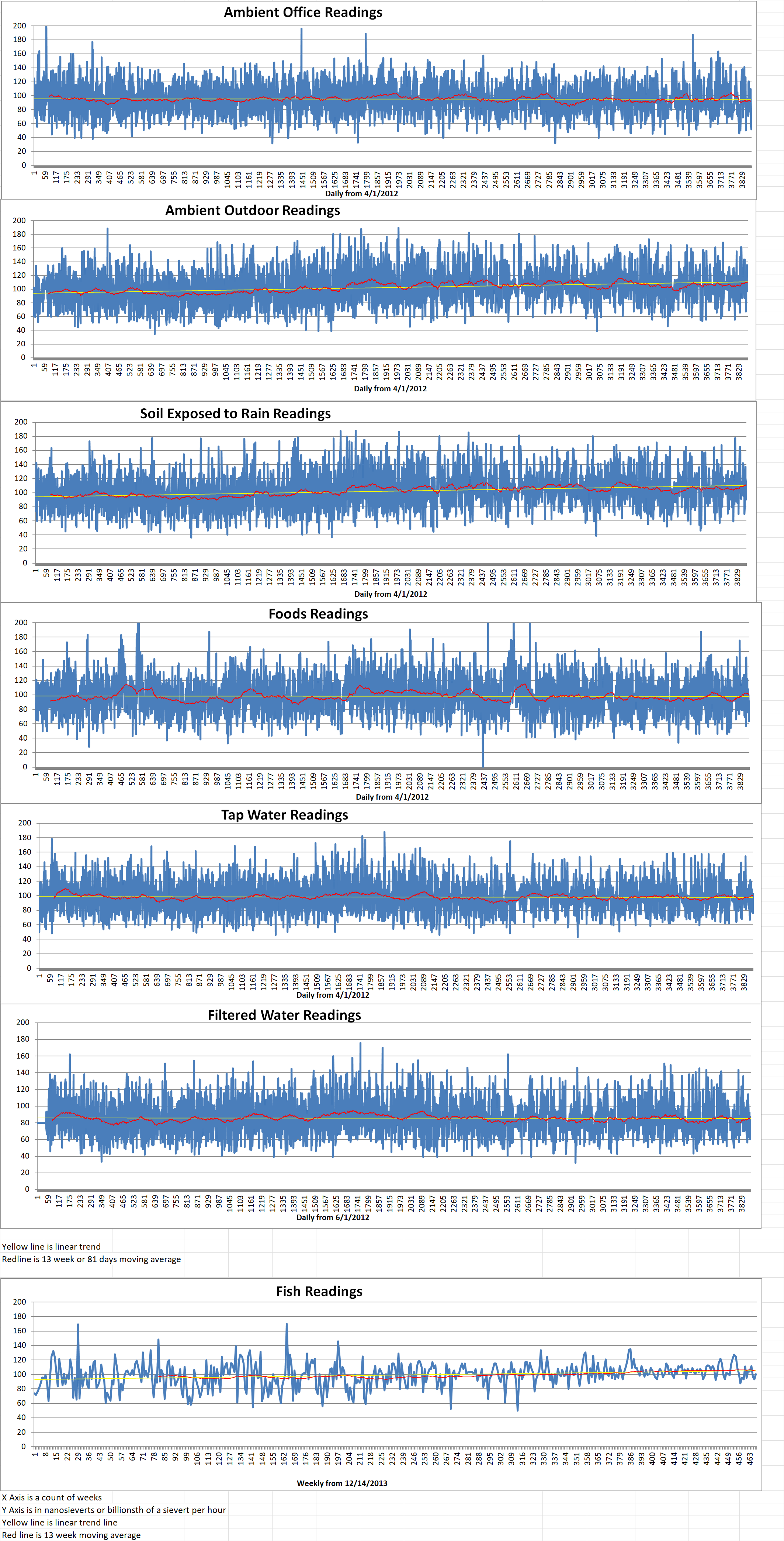

Ambient office = 52 nanosieverts per hour

Ambient outside = 108 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Crimini mushroom from Central Market = 91 nanosieverts per hour

Tap water = 103 nanosieverts per hour

Filter water = 87 nanosieverts per hour

Dover Sole from Central = 100 nanosieverts per hour

-

Nuclear Reactor 1129 – The Akkuyu Nuclear Power Plant Construction Project Was Not Harmed By The Recent 7.6 Earthquake in Turkey

There have been no reports of damage to the Akkuyu nuclear power plant after two big earthquakes struck Turkey. The project teams says that after safety checks, construction is continuing.

Anastasia Zoteeva is the CEO of JSC Akkuyu Nuclear. She said last Monday, “Aftershocks of about 3.0 magnitude were felt here at the Akkuyu NPP site, but our specialists did not detect any damage to building structures, cranes, equipment, Nevertheless, we are carrying out extensive diagnostic measures to make sure that construction and installation operations can continue safely.”

Later on Monday, Russia’s Tass news agency reported an update issued by a spokesperson for Akkuyu Nuclear. The update said, “specialists conducted a prompt, operational inspection of all buildings, structures, tower cranes, scaffolding and other structures under construction for deviations and damage. No damage was found as a result of the inspection. Construction and installation work continues.”

The International Atomic Energy Agency tweeted on Monday afternoon about the situation. The tweet read, “As of now, no impact from earthquakes on nuclear safety & security in Türkiye, its Nuclear Regulatory Authority told IAEA.” The tweet continued, adding that there were “no issues so far related to radiological safety & security of radioactive sources, & the country’s under construction nuclear power plant is unaffected”.

The seven-point eight magnitude earthquake struck near the city of Gaziantep around 4:30 local time. It was the biggest earthquake to hit the country in eighty years. As of Monday at 16:00 GMT there were about two thousand three hundred deaths confirmed in Turkey and Syria. Many more were injured or are still missing. The Akkuyu nuclear power plant is being built in the southern Mersin province about two hundred sixty-seven to the west of the epicenter of the quake.

The Akkuyu plant is the first nuclear power plant constructed in Turkey. The Russian state-owned Rosatom is building four VVER-1200 reactors. The contract is a build-own-operate (BOO) type. Construction of the first unit began in 2018. It is scheduled to go operational in 2023. The four thousand eight-hundred megawatt plant is intended to meet about ten percent of Turkey’s electricity needs.

Nuclear reactors are designed to be able to survive natural hazards such as earthquakes. The Akkuyu plant has been designed with additional earthquake protection measures. These measures include the reactor building foundation slab being designed to be “highly earthquake-resistant”. Tass reported that the Akkuyu “project is designed to withstand a maximum earthquake of up to 9 on the Richter Scale”.

The World Nuclear Association’s information paper on Nuclear Power Plants and Earthquakes said, “Reactors of both western and Soviet design have been subjected to major seismic activity in North America and Europe without damage. California’s power reactors, San Onofre 2 and 3 and Diablo Canyon 1 and 2, continued to operate normally during the 6.6 magnitude earthquake in January 1994. San Onofre, the closer station, was about 112 km from the epicenter. In December 1988, a magnitude 6.9 earthquake, resulting in the deaths of at least 25,000 people, occurred in northwestern Armenia. It was felt at the two-unit Armenian nuclear power station located approximately 75 km south of the epicenter, but both Soviet-designed PWRs operated normally, and no damage was reported. This was the first Russian nuclear power plant specifically adapted for seismic areas, and it started operating in 1976.”

The report also said, “In April 2013 a magnitude 7.7 earthquake in Iran caused no damage [to the Bushehr plant] according to Iran’s report to IAEA, though some cracking of concrete was later reported. The plant is designed to withstand magnitude 8 quakes.” -

Nuclear News Roundup Feb 10, 2023

Ukraine greenlights first steps on new nuclear reactor builds bellona.org

Partnership for UK fusion materials development world-nuclear-news.org

Four nations call on Iran to comply with its obligations world-nuclear-news.org

Community Leaders Urge Government To Back Plans For Ohma Nuclear Plant nucnet.org

-

Geiger Readings for Feb 10, 2023

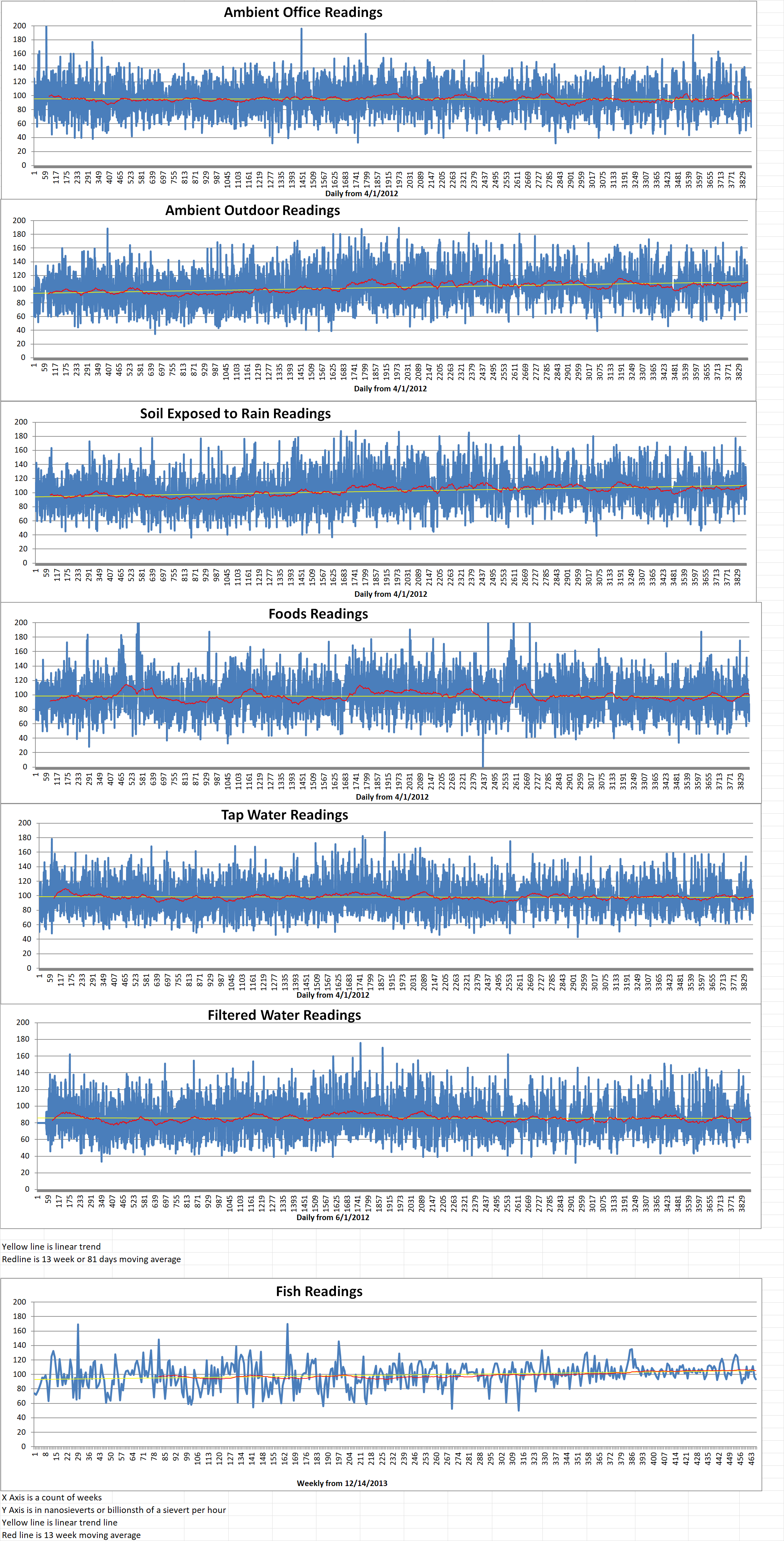

Ambient office = 56 nanosieverts per hour

Ambient outside = 106 nanosieverts per hour

Soil exposed to rain water = 115 nanosieverts per hour

Grape from Central Market = 84 nanosieverts per hour

Tap water = 91 nanosieverts per hour

Filter water = 83 nanosieverts per hour