House panel OKs nuclear energy bill news.abs-cbn.com

French Parliament Votes Nuclear Plan With Large Majority usnews.com

Russia says risk of nuclear conflict at highest level in decades reuters.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

House panel OKs nuclear energy bill news.abs-cbn.com

French Parliament Votes Nuclear Plan With Large Majority usnews.com

Russia says risk of nuclear conflict at highest level in decades reuters.com

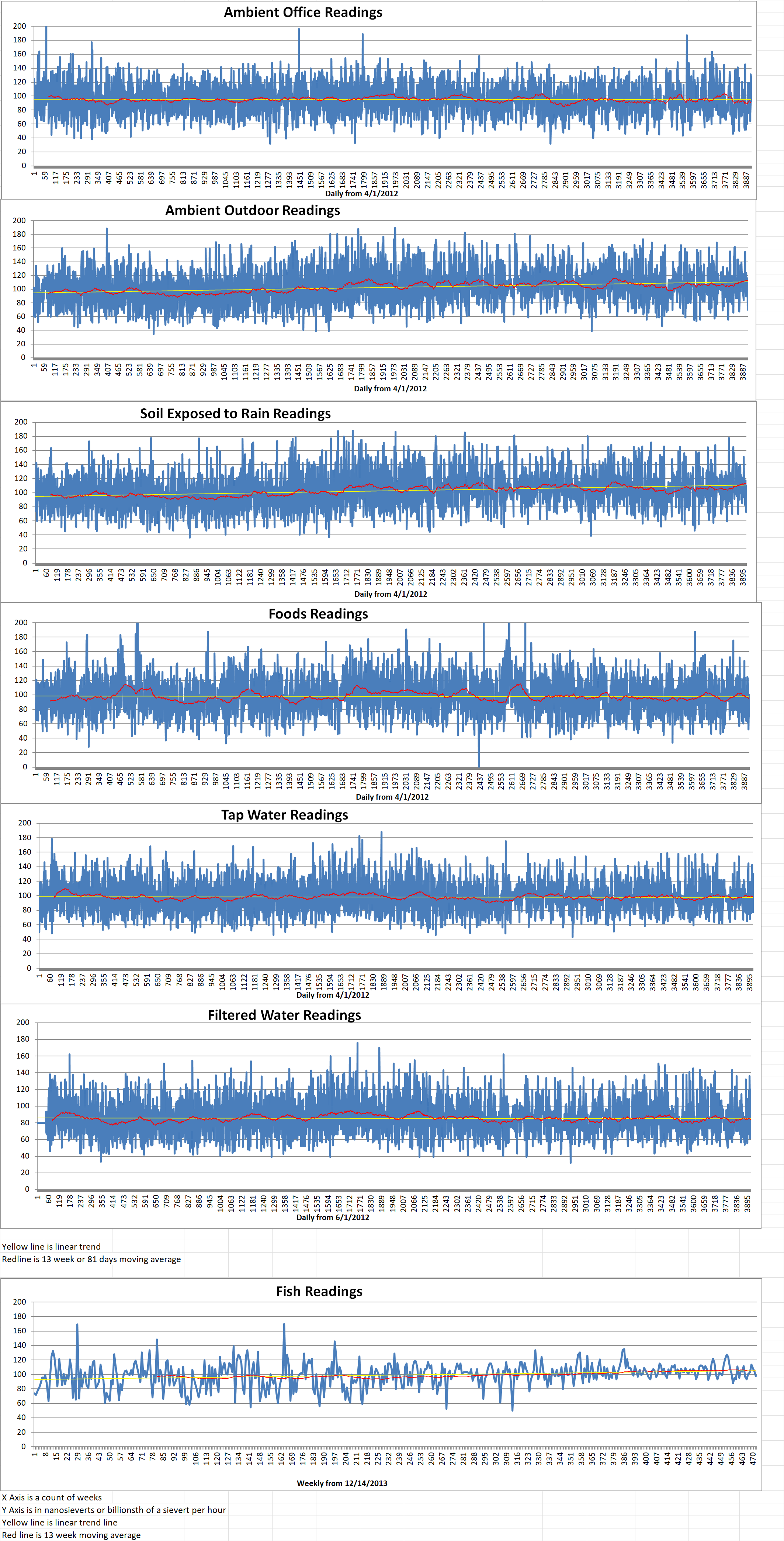

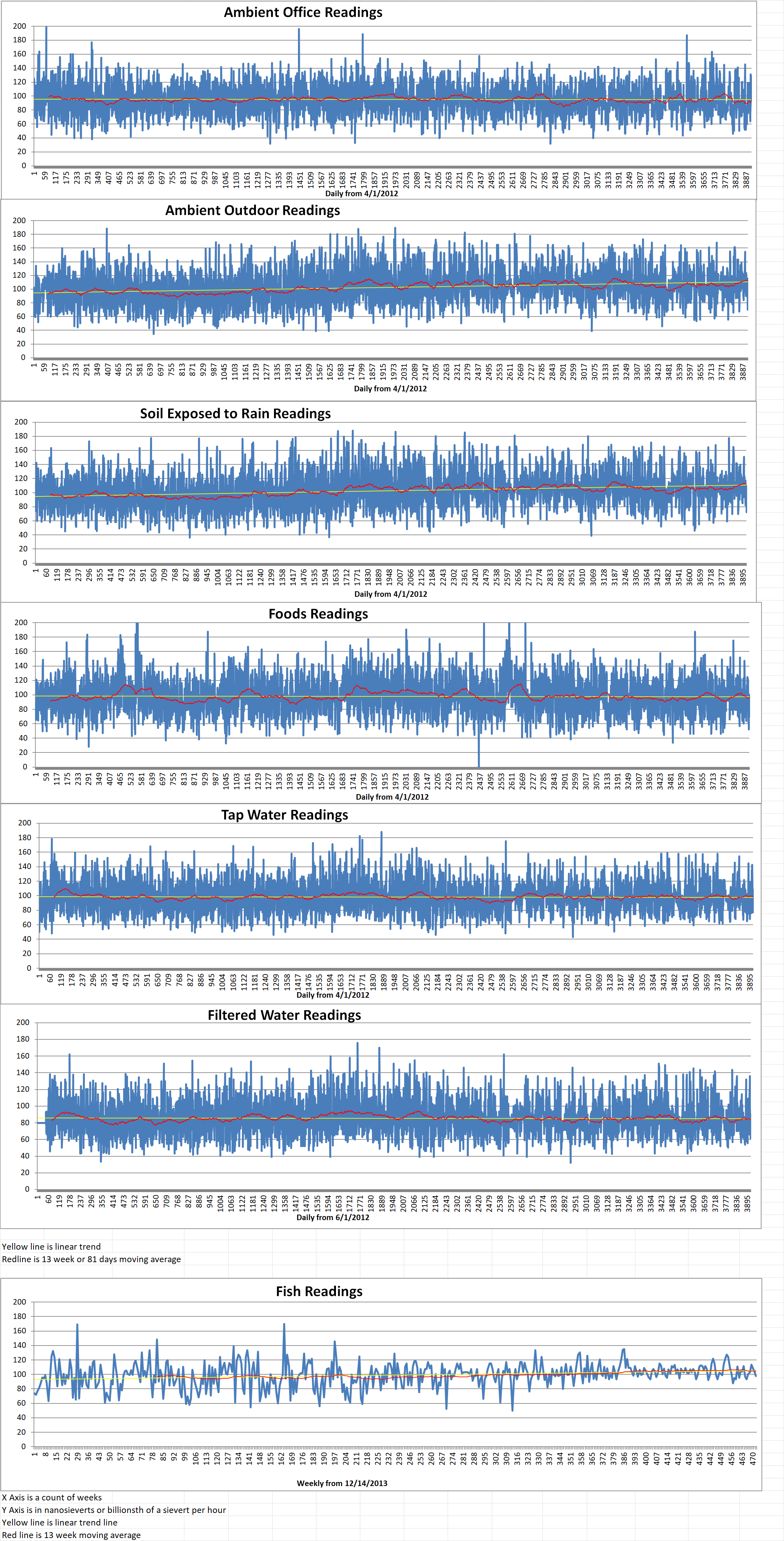

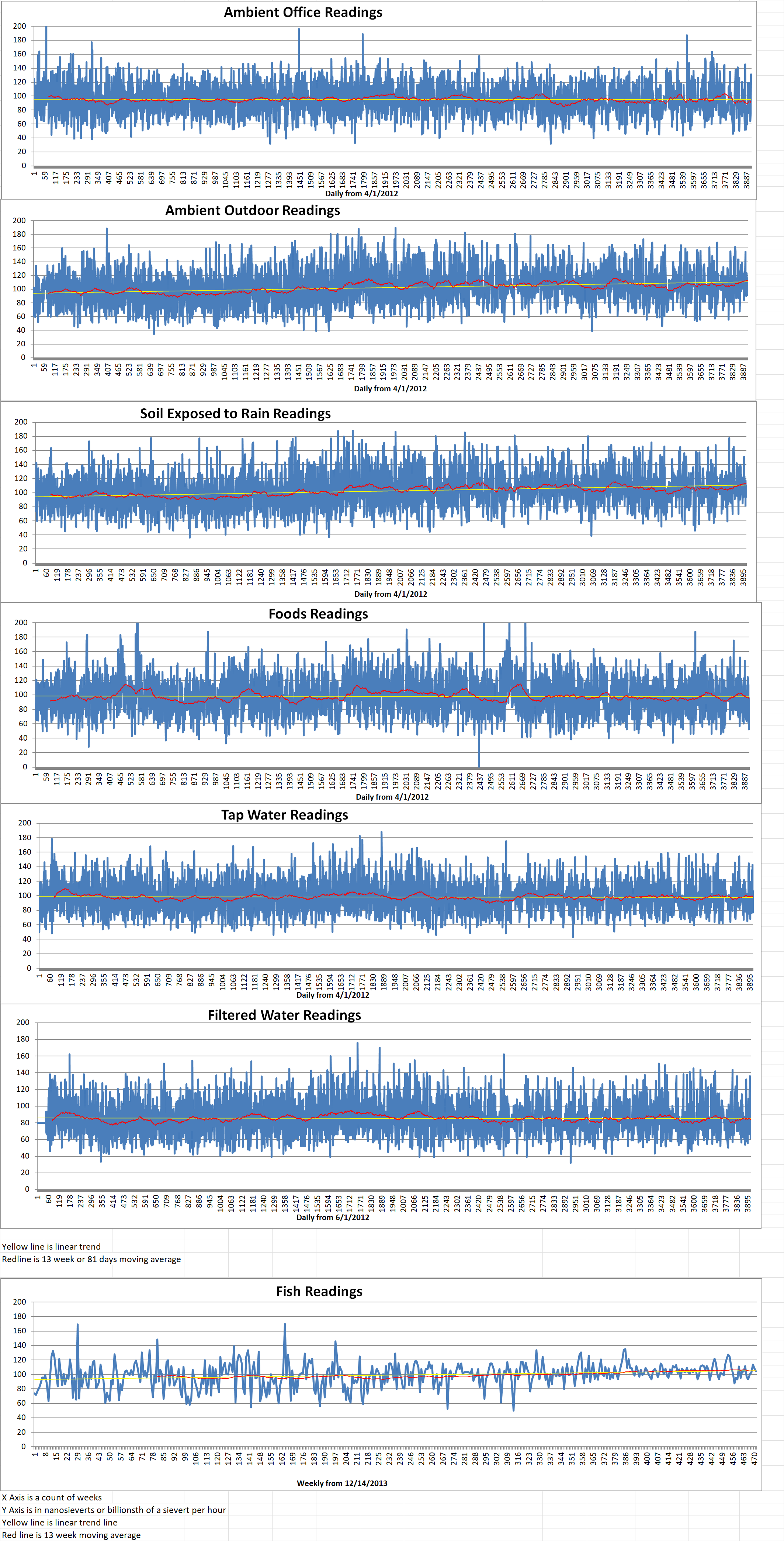

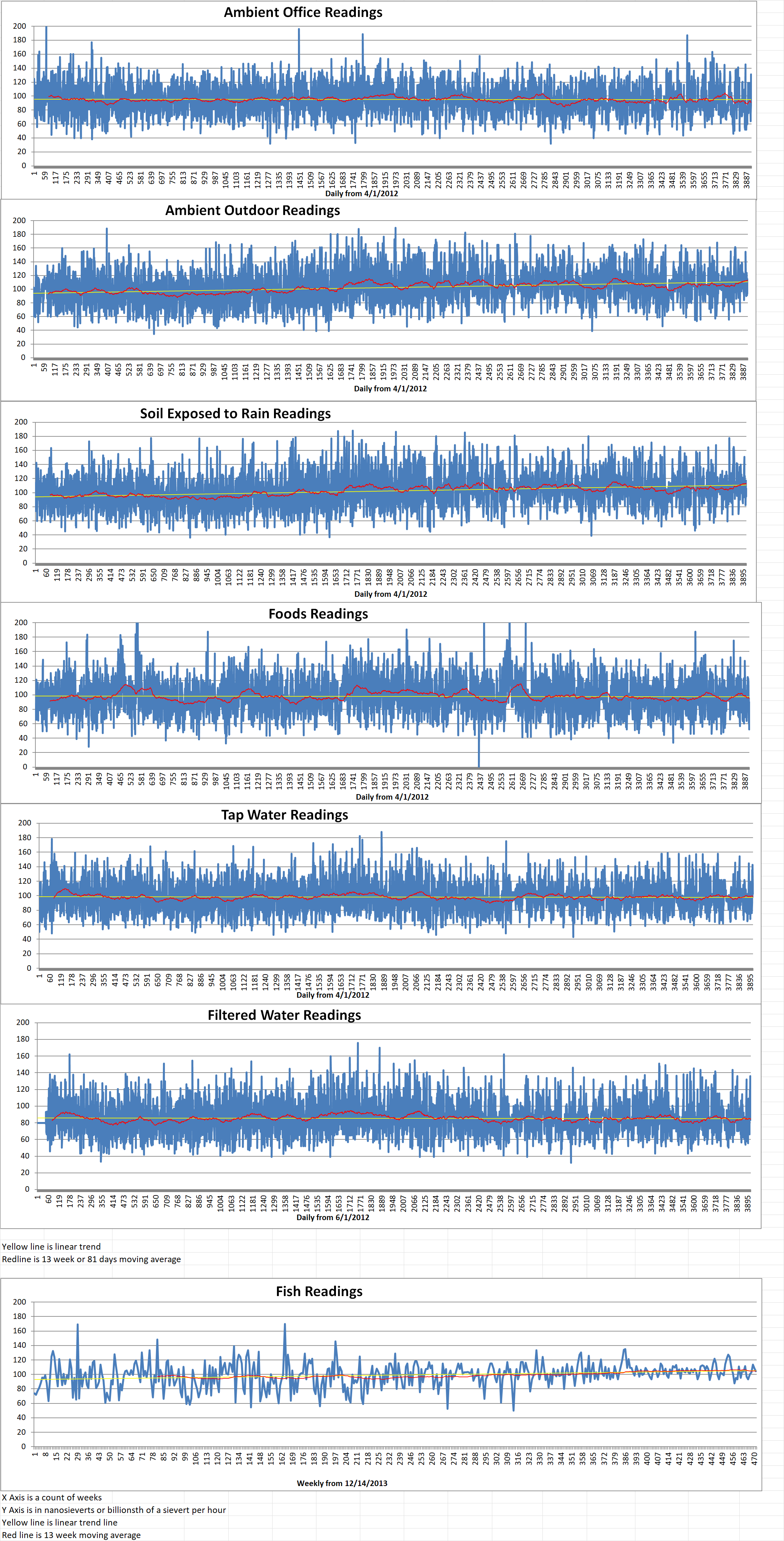

Ambient office = 93 nanosieverts per hour

Ambient outside = 84 nanosieverts per hour

Soil exposed to rain water = 82 nanosieverts per hour

Oyster mushroom from Central Market = 87 nanosieverts per hour

Tap water = 130 nanosieverts per hour

Filter water = 119 nanosieverts per hour

Nuclear missile fired from North Korea could hit US in 33 minutes, says Chinese study indiatoday.in

Nuclear is an afterthought in the EU’s Net-Zero Industry neimagazine.com

ENEC signs MoU with Nuclearelectrica to collaborate on nuclear energy program development wam.ae

UCF Joins $25M National Consortium on Nuclear Forensics ucf.edu

Ambient office = 119 nanosieverts per hour

Ambient outside = 70 nanosieverts per hour

Soil exposed to rain water = 73 nanosieverts per hour

Green onion from Central Market = 100 nanosieverts per hour

Tap water = 108 nanosieverts per hour

Filter water = 90 nanosieverts per hour

Dover Sole from Central = 98 nanosieverts per hour

The United Kingdom Atomic Energy Authority (UKAEA) and the US Department of Energy’s (DoE’s) Oak Ridge National Laboratory (ORNL) have just entered into a strategic research partnership. The purpose of the partnership is to better understand the performance and behavior of materials required for use in commercial fusion power plants.

UKAEA said, “One of the major challenges in harnessing fusion energy is developing materials to cope in extreme environments,” UKAEA said. “This is because high energy neutrons and extreme temperatures can weaken or change the desirable mechanical, thermal, optical or electronic properties of materials, which can reduce the lifetime of fusion machines.”

The five-year partnership has three million six hundred thousand dollars in funding. Materials will be irradiated using neutrons at the ORNL High Flux Isotope Reactor, a DOE Office of Science user facility, located in the U.S. This research will attempt to understand how certain materials respond to irradiation over long periods. The ultimate purpose of this research is to increase the longevity of the materials tested.

The material selected for testing under the partnership will primarily focus on the ‘breeder blanket’. This is a component used to provide the tritium fusion fuel to make fusion power plants self-sufficient.

Post irradiation testing will include tensile and hardness property measurements. This will help illuminate both the effect and the extent of radiation-induced hardening and concurrent loss of ductility in these materials.

Advanced microstructural analysis will also be carried out to understand the effects of neutron radiation on chemical segregation and precipitate stability. UKAEA said that these assessments are critical to provide assurance that these alloys will be sufficiently durable and reliable to support a fusion power plant throughout the expected lifetimes of each component.

The partnership will also see staff from the U.S. and the U.K. visits their counterpart facilities to share industry skills. The project is part of the UK Fusion Materials Roadmap, which was launched by UKAEA in 2021. The aim is to deliver new neutron-resilient materials as well as irradiation and post-irradiation testing to provide design engineers with data to build future fusion power plants.

Amanda Quadling is the UKAEA’s Director of Materials Research. She said, “The partnership will allow UKAEA access to ORNL’s archive of existing irradiated materials, which include binary iron-chromium alloys, advanced steels, silicon carbide composites and copper alloys Alongside this, UKAEA will also be placing entirely new materials into the ORNL High Flux Isotope Reactor, including new high-temperature steels developed by both UKAEA and wider UK industry, permeation barrier coatings and welded materials.”

Mickey Wade is ORNL’s Fusion Energy Division director. He said, “This research collaboration will be a critical piece of the economics of a fusion device in the future, establishing which materials can last for long periods in the fusion environment. This is a great opportunity for ORNL and UKAEA to partner on a key area for fusion.”

Last February, UKAEA announced that it had awarded contracts worth a total of three million, eight hundred thousand dollars to eighteen organization. The contracts are to focus on overcoming specific technical and physical challenges to make fusion energy a commercial reality. Feasibility studies will be funded from sixty million dollars to two hundred forty-four million dollars from the UKAEA’s Fusion Industry Program and awarded through the UK government platform Small Business Research Initiative. The selected projects aim to tackle specific challenges linked to the commercialization of fusion energy. These include novel fusion materials and manufacturing techniques as week as innovative heating and cooling systems.

Ukraine aims to produce nuclear fuel by 2026, exports to follow world-nuclear-news.org

Russian, Chinese nuclear cooperation spurs House to sound alarm courthousenews.com

New Mexico Opts for Veto Power on Spent Nuclear Fuel Debate usnews.com

Fresh progress for Poland’s Orlen Synthos SMR project world-nuclear-news.org

Ambient office = 127 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 110 nanosieverts per hour

English cucumber from Central Market = 94 nanosieverts per hour

Tap water = 77 nanosieverts per hour

Filter water = 61 nanosieverts per hour

Xcel Energy Inc. is a U.S. regulated electric utility and natural gas delivery company based in Minneapolis, Minnesota, serving more than three million seven hundred thousand electric customers and two million natural gas customers across parts of eight states (Colorado, Minnesota, Wisconsin, Michigan, North Dakota, South Dakota, Texas and New Mexico).

Xcel owns and operates the Monticello nuclear power plant in Monticello, Minnesota. The site, which began operating in 1971, has a single nuclear reactor (boiling water reactor) of the General Electric BWR-3 design generating 613 megawatts,

Xcel Energy has reported that about four hundred thousand gallons of water which contains radioactive tritium leaked from a water pipe running between two building at its Monticello facility. Xcel said it is monitoring groundwater from two dozen wells in the area.

Tritium is a radioactive form of hydrogen with two neutrons in the nucleus. It is a byproduct of producing electricity at nuclear power plants, according to the Minnesota Pollution Control Agency (MPCA).

Kirk Koudelka is a MPCA assistant commissioner for land and strategic initiatives. He said, “Our top priority is protecting residents and the environment, and the MPCA is working closely with other state agencies to oversee Xcel Energy’s monitoring data and cleanup activities. We are working to ensure this cleanup is concluded as thoroughly as possible with minimal or no risk to drinking water supplies.”

When the leak was detected, the facility diverted water to an in-plant water treatment system to contain it and prevent additional water from leaving the plant. The MPCAS added that the leak has stopped. The contaminated water has not reached the Mississippi or contaminated drinking water sources.

The MPCA said in a press release on Thursday that “There is no evidence at this time to indicate a risk to any drinking water wells in the vicinity of the plant.”

Xcel Energy said that it completed a thorough inspection of all piping at the plant. It determined that no other areas of the facility are of concern. It will also be examining the pipe that leaked in the laboratory to determine why it happened.

The contaminated water is contained in the grounds of the plant. It has not been detected beyond the facility or any local drinking water. Xcel is continuing to monitor groundwater from over two dozen wells on-site.

An estimated twenty five percent of the leaked tritium water has been recovered. More of the water will be recovered over the course of next year. Xcel is considering options to store the recovered contaminated water. They are considering building above-ground storage tanks or a retention pool. Any new construction will be reviewed by the state agencies.

Chris Clark is the President of Xcel Energy–Minnesota, North Dakota and South Dakota. He said in a statement, “We have taken comprehensive measures to address this situation on-site at the plant. While this leak does not pose a risk to the public or the environment, we take this very seriously and are working to safely address the situation.”

The MPCA is monitoring Xcel’s process of cleaning up the leak in coordination with the Minnesota Department of Health, and the Minnesota Department of Natural Resources.

Watchdog pledges ‘demanding’ oversight of nuclear sub deal apnews.com

Nuclear waste: Public to have a say on plans to bury radioactive material news.sky.com

TVEL to supply lithium-7 for Brazil’s nuclear units world-nuclear-news.org

Nuclear a wise choice, says President of Uganda world-nuclear-news.org

Ambient office = 131 nanosieverts per hour

Ambient outside = 98 nanosieverts per hour

Soil exposed to rain water = 95 nanosieverts per hour

Corn from Central Market = 70 nanosieverts per hour

Tap water = 103 nanosieverts per hour

Filter water = 88 nanosieverts per hour