The U.S. agency in charge of producing key components for the U.S. nuclear arsenal has cleared the way for new equipment to be installed at a New Mexico Laboratory. The new equipment is part of a multibillion-dollar mission. However, nuclear watchdog groups say that the project is already behind schedule and budgets have ballooned.

The approval for moving equipment into place at the Los Alamos National Laboratory was first outlined in an internal memo issued by the U.S. Deputy Secretary of Energy in January. the U.S. Department of Energy’s (DoE) National Nuclear Security Administration (NNSA) made a public announcement last Thursday.

The project will include the design, fabrication and installation of gloveboxes and other special equipment needed to make plutonium cores, also known as pits, for nuclear weapons. The work will be divided between Los Alamos in northern New Mexico and the Savannah River Site in South Carolina. These two locations are facing a congressional mandate to make at least eighty cores each year by 2030.

The deadline for meeting that capacity has been pushed back. The recent memo is the latest evidence that the minimum equipment necessary will be in place at Los Alamos by August 2030. This is four years later than originally expected.

The nuclear agency contends that the installation of the equipment is not necessary for Los Alamos to produce thirty pits per year. The lab will be building war reserve pits using existing equipment as the project proceeds.

Agency spokeswoman Shayela Hassan said in a recent email to the Associated Press that the NNSA expects an increasing number of pits to be produced each subsequent year until the new equipment is installed. She said that she had moderate confidence that the increased capability will be able to produce thirty pits per year.

The long-closed Rocky Flats Plant outside of Denver was capable of producing more than one thousand reserve pits annually before work halted in 1989 due to environmental and regulatory concerns. In 1996, the DoE provided for limited production capacity at Los Alamos. Los Alamos produced its first war reserve pit in 2007. The lab ceased operations in 2012 after producing what was needed at that time.

Greg Mello is the director of the watchdog Los Alamos Study Group. He said that the NNSA has made contradictory statements about the delays and what they mean for the overall plutonium pit project. He mentioned NNSA statements in 2017 and 2018 in which the agency predicted problems if it were producing pits while also replacing gloveboxes and other equipment at the same time.

Mello said that “There is more they aren’t saying. We believe NNSA and LANL will struggle mightily, with further setbacks, failures and accidents in a misguided attempt to produce any meaningful number of pits in that cramped, aging facility.”

The memo provides formal cost and schedule estimates for getting equipment installed in Los Alamos. However, it is not clear when construction will begin. The cost has been estimated to be about one billion eighty-five million dollars.

More details about spending and schedules for the project are expected when the NNSA submits its budget to congress next month.

In January, the Government Accountability Office (GAO) issued a report that NNSA plans to reestablish plutonium pit production do not follow best practices and run the risk of delays and cost overruns.

The GAO described the modernization effort as the agency’s largest investment in weapons production infrastructure to date. The GAO noted that plutonium is very dangerous material and making the cores for the nuclear weapons is difficult and time consuming.

Blog

-

Nuclear Weapons 811 – Los Alamos National Laboratory Is Installing New Equipment To Produce Plutonium Cores

-

Nuclear News Roundup Feb 14, 2023

Zaporizhzhia nuclear power plant staff refuse to train Russian workers news.yahoo.com

Cortez Masto, Titus lead Nevada delegation in efforts to prevent nuclear waste storage at Yucca Mountain cortezmasto.senate.gov

Bid to keep California nuclear reactors running faces time squeeze cbsnews.com

South Korean Partners to Develop Nuclear-powered Ships marinelink.com

-

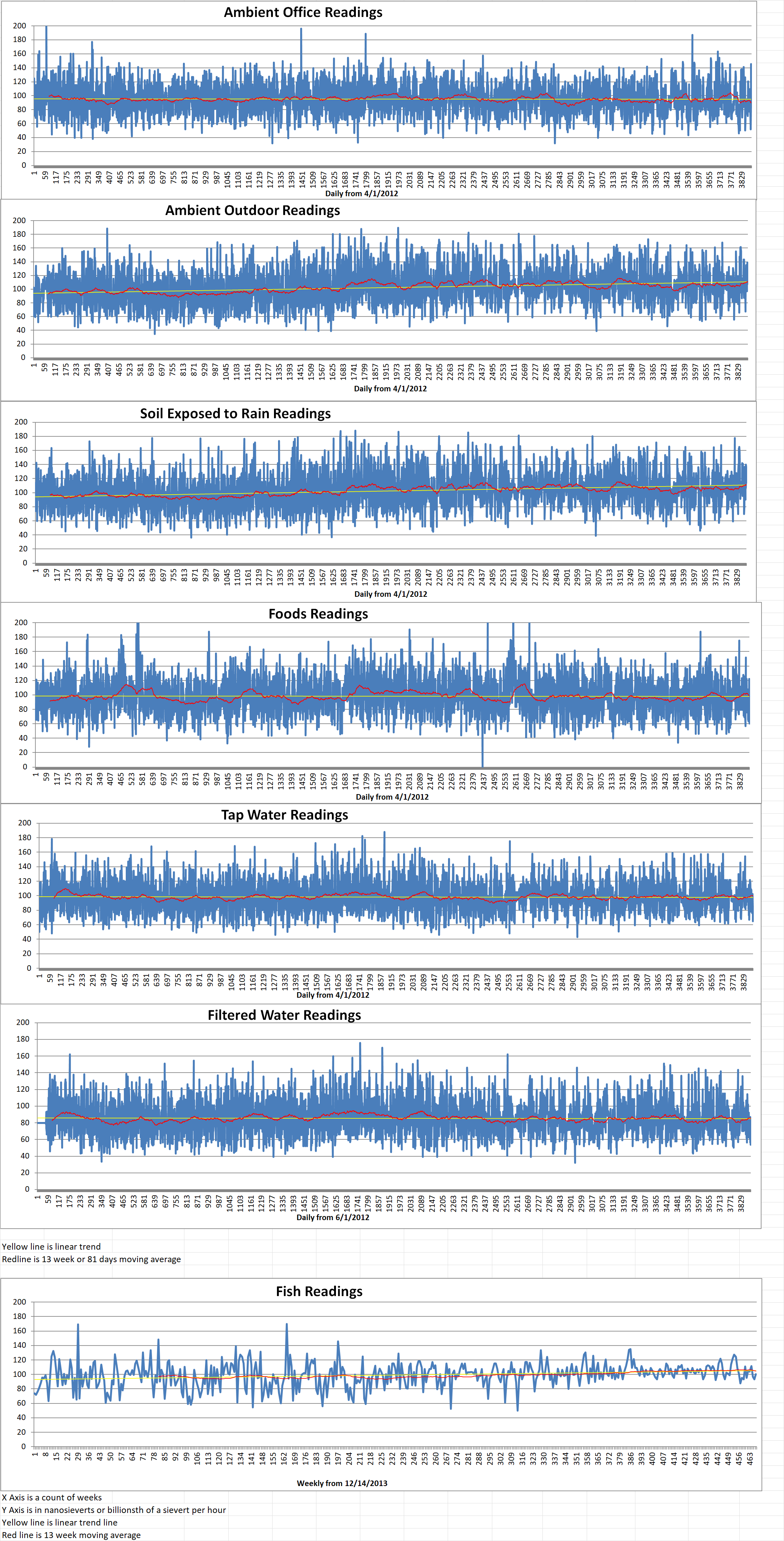

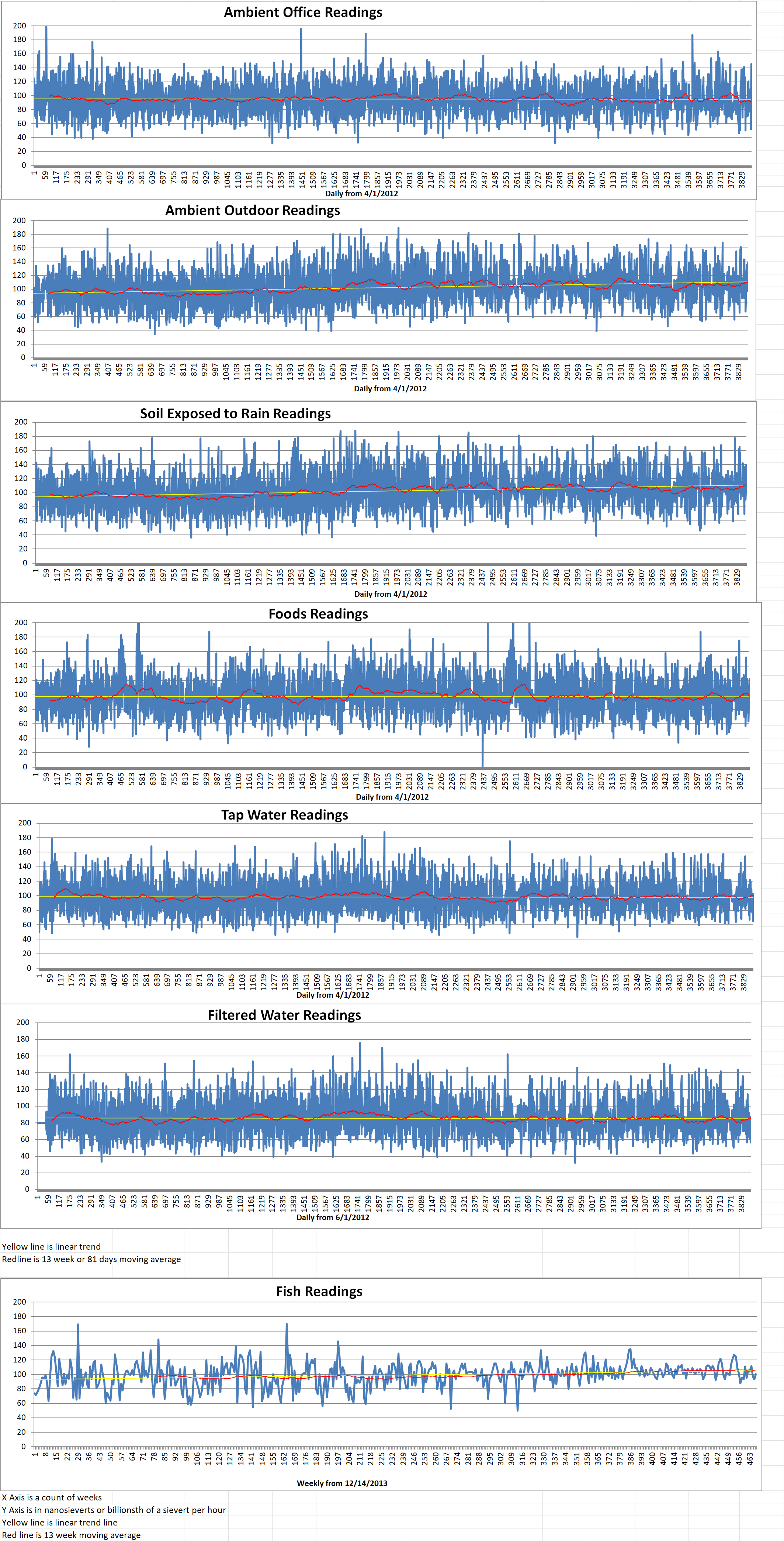

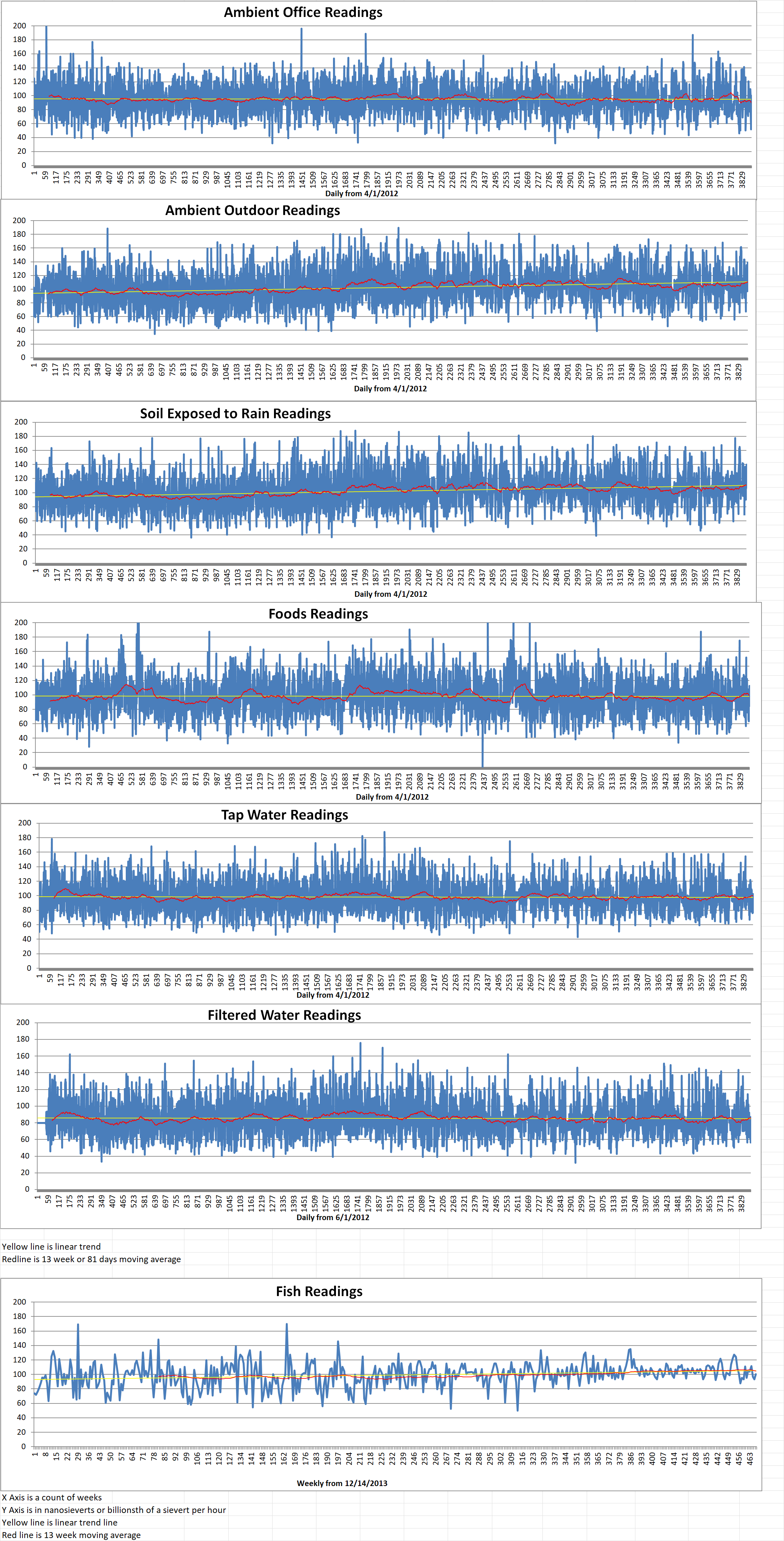

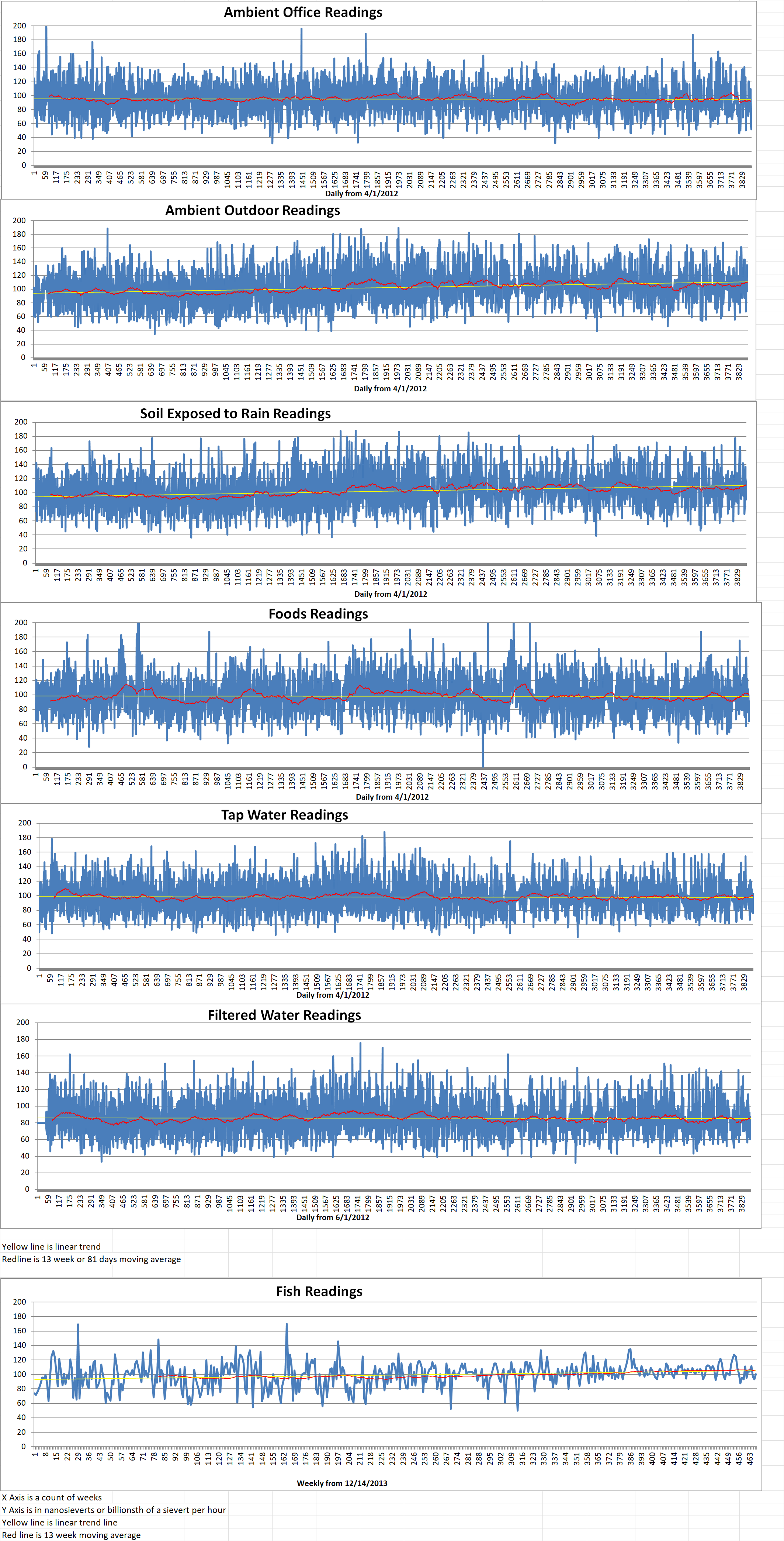

Geiger Readings for Feb 14, 2023

Ambient office = 88 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 114 nanosieverts per hour

Tomato from Central Market = 60 nanosieverts per hour

Tap water = 68 nanosieverts per hour

Filter water = 54 nanosieverts per hour

-

Radioactive Waste 891 – Deep Isolation Developing Canisters For Deep Borehole Nuclear Waste Storage

Deep Isolation, the Nuclear Advanced Manufacturing Research Centre, the University of Sheffield and NAC International are collaborating in a project to engineer canisters that meet U.K. regulatory requirements for long-term storage of spent nuclear fuel and high-level radioactive waste in boreholes up to two miles underground.

The funding comes from the Department for Energy Security and Net Zero’s Energy Entrepreneurs Fund. It is intended to support the U.K.’s 2050 net-zero target by “tackling a fundamental challenge to the success of small modular reactors (SMRs) … the need for safe, secure, scalable and cost-effective spent nuclear fuel disposal solutions”.

Deep Isolation is based in Berkeley, California. It has been working on a system of using directional boreholes disposal of nuclear waste. The company is building on innovations in the drilling industry I recent decades. This means that “it is now inexpensive and routine to go down three quarters of a kilometer in depth and to have horizontal sections two, three or four kilometers in length”.

Deep Isolation’s solution for management of spent nuclear fuel and high-level radioactive waste involves emplacing it in corrosion-resistant canisters placed in deep horizontal drillholes. Deep Isolations approach utilizes existing directional drilling technology. The nuclear waste can be retrieved during a determined time frame or permanently secured. In 2019, Deep Isolation publicly demonstrated its system when it successfully placed and then retrieved a prototype nuclear waste canister hundreds of feet underground via a borehole.

The U.K. project will include the manufacturing and testing of two prototype canisters tailored to the U.K. requirements. A manufacturing supply chain needs to be established to support the new system.

Chris Parker is the Global Head of Business Development and Managing Director of Deep Isolation EMEA. He said, “This canister provides an option for disposal in a deep borehole that brings greater flexibility and potential cost-savings for disposal of spent nuclear fuel and high-level waste.”

Parker went on to say that in the U.K., the deep borehole system would not replace the need for a traditional mined geological disposal facility but “it has the potential to reduce costs and save time for the UK’s GDF program because it can accept selected high heat-generating waste streams at much greater depth”.

He added that it would also “provide us with an ideal supply chain with which to service the growing international demand for deep borehole disposal.” He said that each canister would dispose of used fuel that has enabled the generation of one hundred and thirty million kilowatts of low carbon electricity, of “a saving of nearly 27,000 ton of CO2 per canister”.

The Energy Entrepreneurs Fund grant award document stated that “high-quality disposal canisters represent a potential global market value of over GBP100 billion (USD121 billion) over the next 20-30 years. The current global inventory of waste suitable for disposal in the UK canister represents 1.1 million canisters; growth to 2035 (including reactors currently under construction or planned) represents a further requirement of 1.35 million canisters”.

Alan Woods is the strategic director of the UK SMR company Rolls-Royce SMR. He is also on the project board. He said that the option of small, modular disposal of radioactive waste in deep boreholes “will be an important enabler of the international SMR markets and a great export opportunity for UK manufacturers”.

Deep Isolation has more than a dozen contracts across three continents with projects including advanced reactor and SMR waste disposal, stand-alone borehole disposal of small existing nuclear waste inventories and to work with mined repository programs to increase safety and reduce costs by moving certain nuclear waste steams into boreholes. -

Geiger Readings for Feb 13, 2023

Ambient office = 145 nanosieverts per hour

Ambient outside = 137 nanosieverts per hour

Soil exposed to rain water = 135 nanosieverts per hour

Shallot from Central Market = 122 nanosieverts per hour

Tap water = 65 nanosieverts per hour

Filter water = 56 nanosieverts per hour

-

Nuclear News Roundup Feb 12, 2023

Hiroshima, Nagasaki urge G-7 engagement to understand nuclear war English.kyodonews.net

BWRX-300 selected for Estonia’s first nuclear power plant world-nuclear-news.org

Cameco signs major uranium supply deal with Ukraine neimagazine.com

Japan’s nuclear-power industry hikes hiring www3.nhk.or.jp

-

Geiger Readings for Feb 12, 2023

Ambient office = 100 nanosieverts per hour

Ambient outside = 139 nanosieverts per hour

Soil exposed to rain water = 140 nanosieverts per hour

Red bell pepper from Central Market = 112 nanosieverts per hour

Tap water = 77 nanosieverts per hour

Filter water = 57 nanosieverts per hour

-

Nuclear News Roundup Feb 11, 2023

Cameco to supply Ukraine’s uranium needs to 2035 world-nuclear-news.org

Iran announces start-up of uranium mine world-nuclear-news.org

Baltic Shipyard signs contract for two more nuclear-powered icebreakers : New Nuclear – World Nuclear News (world-nuclear-news.org) world-nuclear-news.org

Democrats wrestle with studying ‘advanced’ nuclear energy in wake of Minnesota carbon-free bill energynews.com

-

Geiger Readings for Feb 11, 2023

Ambient office = 52 nanosieverts per hour

Ambient outside = 108 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Crimini mushroom from Central Market = 91 nanosieverts per hour

Tap water = 103 nanosieverts per hour

Filter water = 87 nanosieverts per hour

Dover Sole from Central = 100 nanosieverts per hour