Urenco is an international supplier of enrichment services and fuel cycle products for the civil nuclear industry, serving utility customers worldwide. It has just announced that it is withdrawing its support for the U-Battery advanced modular reactor (AMR) Project. It said that it had “exhausted its attempts to secure the commitment of new commercial investors”.

The U-Battery is a four megawatt high-temperature gas-cooled micro-reactor which will be able to produce local electricity and heat for a range of energy needs. The project was initiated by Urenco in 2008. The concept design was developed by the University of Manchester and Dalton Institute in the U.K. The Technology University of Delft in the Netherlands was also involved. The consortium says that the technology uses high-integrity TRISO fuel. They aim to replace diesel power with clean, safe, and cost-effective energy for a variety of applications. These include remote communities and other off-grid location such as mining operations.

The U-Battery consortium said that “Urenco has announced its intention to withdraw from the project due to necessary reprioritization under its strategy.”

U-Battery’s supporting organizations include BWXT Technologies Inc, Cavendish Nuclear, Costain, Kinectrics, Jacobs, the UK’s National Nuclear Laboratory, Nuclear AMRC, Rolls-Royce and the University of Manchester.

Urenco said, “The U-Battery team has completed its current program of work under the AMR RD&D program, and after dialogue and consultation with the Department for Energy Security and Net Zero, and with other stakeholders, Urenco’s intention is to preserve the public investment in U-Battery by transferring its intellectual property to the National Nuclear Laboratory, subject to necessary due diligence and governance approvals.”

Last January, U-Battery was granted its first legal patent for the design of its high-temperature gas-cooled reactor fuel element and core from the U.K. Intellectual Property Office. This means that the fuel element and reactor core design are protected in law for five years and up to a maximum of twenty years. U-Battery said that it was pursuing similar patents in the U.S. and Canada.

U-Batter said, “Our work to date has set and defined the technology’s core characteristics, operational parameters, and future decommissioning plans and all to achieve the highest levels of safety … we are proud to have created a full-size model of the reactor pressure vessel, the intermediate heat exchanger vessel and the connecting duct. This demonstrated how the AMR can be built using modular techniques, making it easy to construct and to transport.”

Chris Chater is the U-Battery Chief Technology Officer. He highlighted the “progress the U-Battery team have made to date; from a conceptual design developed by the Universities of Manchester (UK) and Delft (the Netherlands) to successfully winning UK government backing as part of AMR competitions from 2018 onwards. While Urenco has refocused its priorities, we continue to believe in the U-Battery design which could provide an innovative decarbonization solution for hard-to-abate sectors”.

A spokesperson was asked if Urenco’s exit meant the end of the project. They said, “It is too soon to answer about the future of the project. The focus for now is on transferring the intellectual property and securing new opportunities for the employees”.

Blog

-

Nuclear Reactors 1194 – Urenco Announces That It Is Pulling Out Of The U-Battery Project

-

Nuclear News Roundup Mar 20, 2023

Workers to start some maintenance, construction at Parks Township nuclear waste dump triblive.com

INL transfers spent nuclear fuel to dry storage as part of Idaho Settlement Agreement localnews8.com

Modular nuclear firm launches £900m equity raise constructionnews.co.uk

Zaporizhzhia nuclear plant’s situation ‘perilous,’ says UN agency head cbc.ca

-

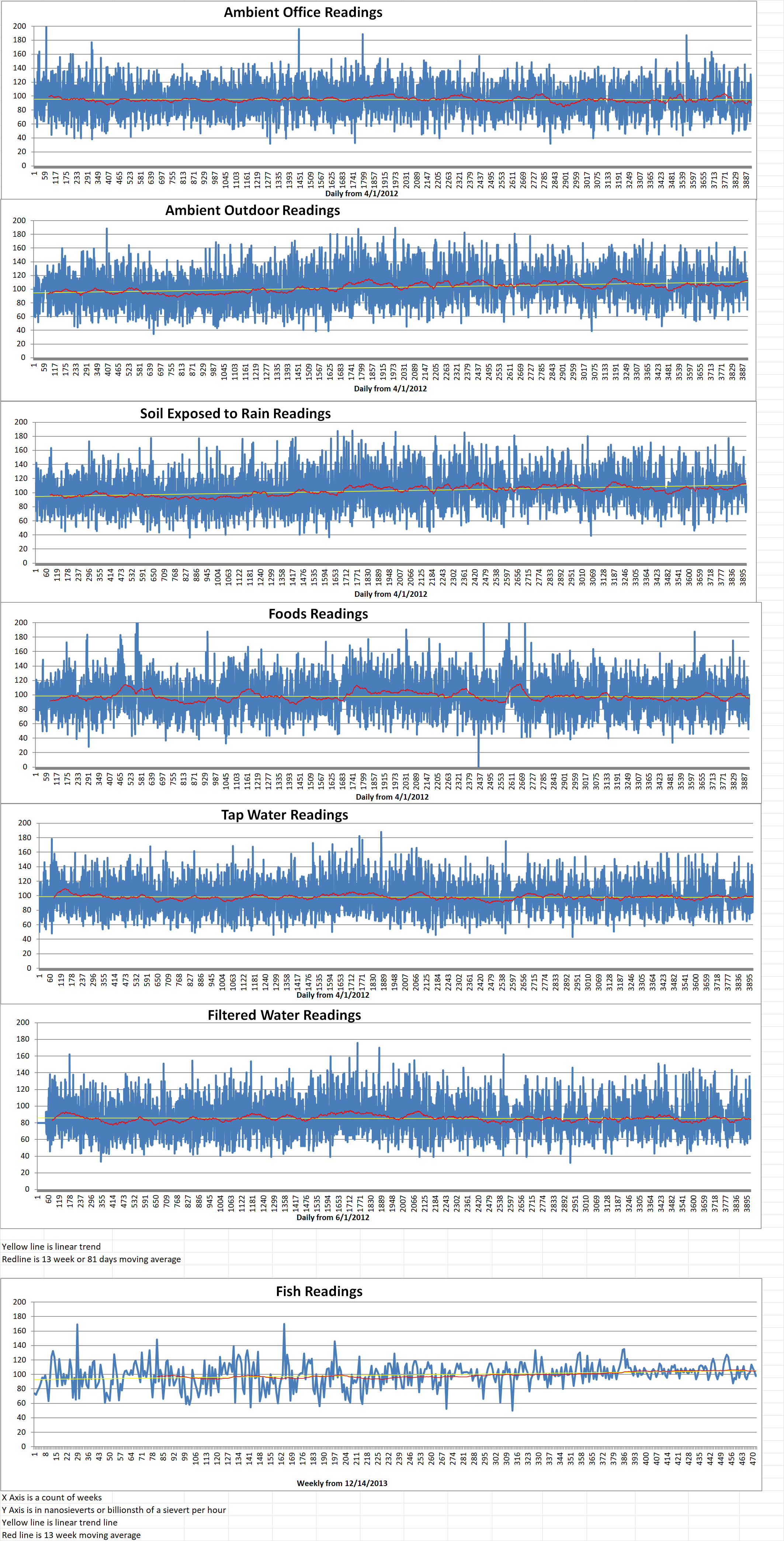

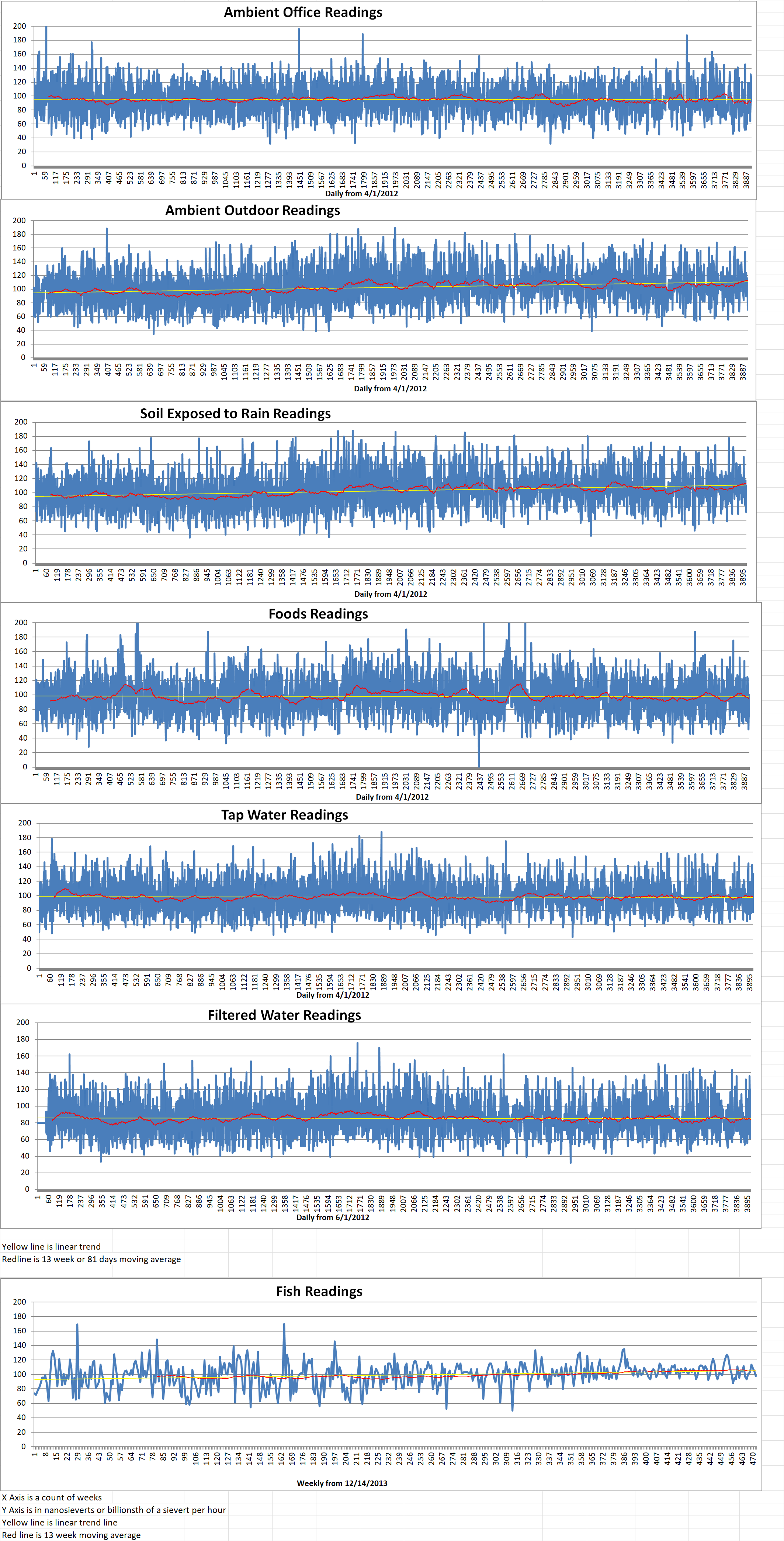

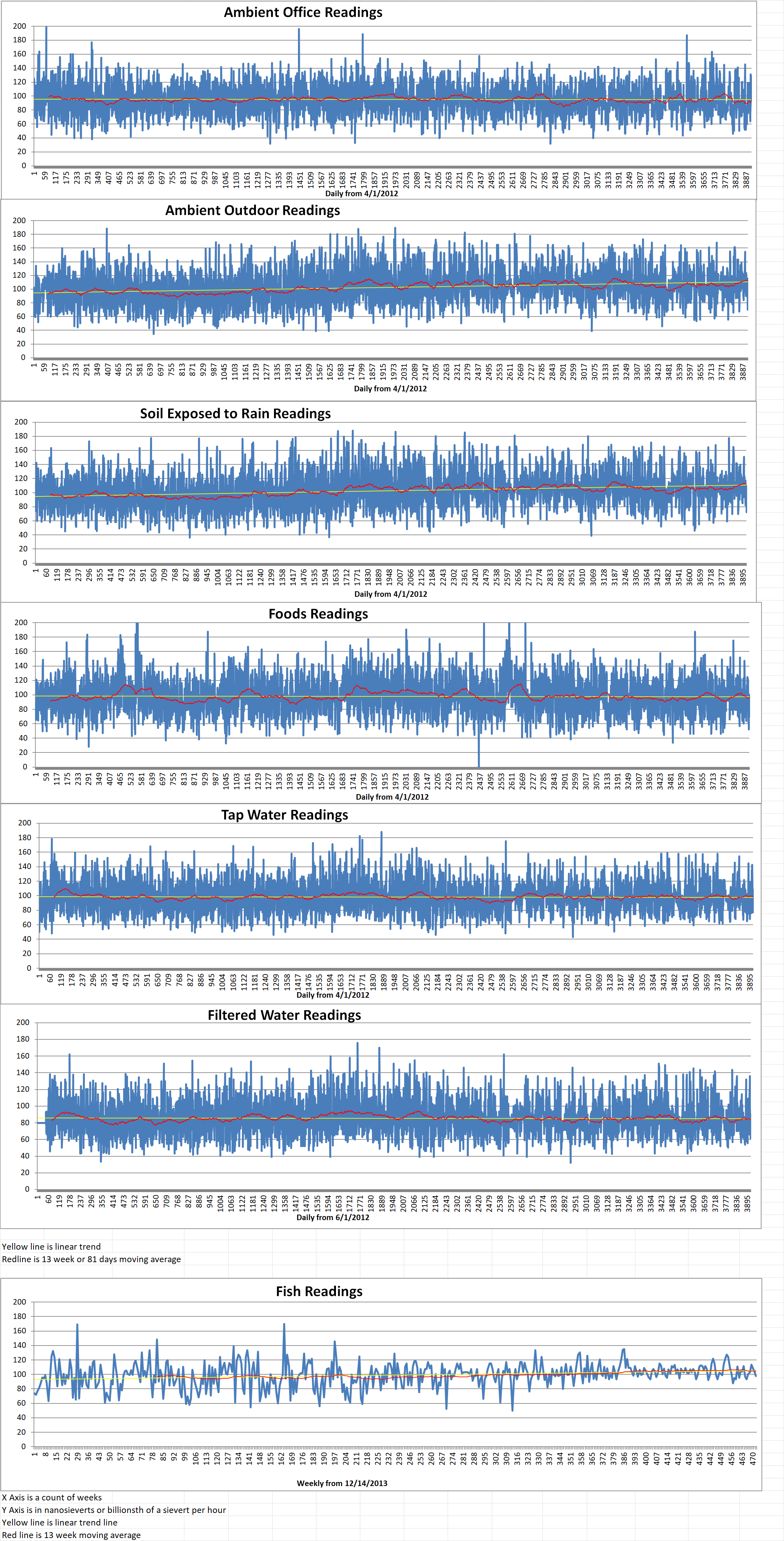

Geiger Readings for Mar 20, 2023

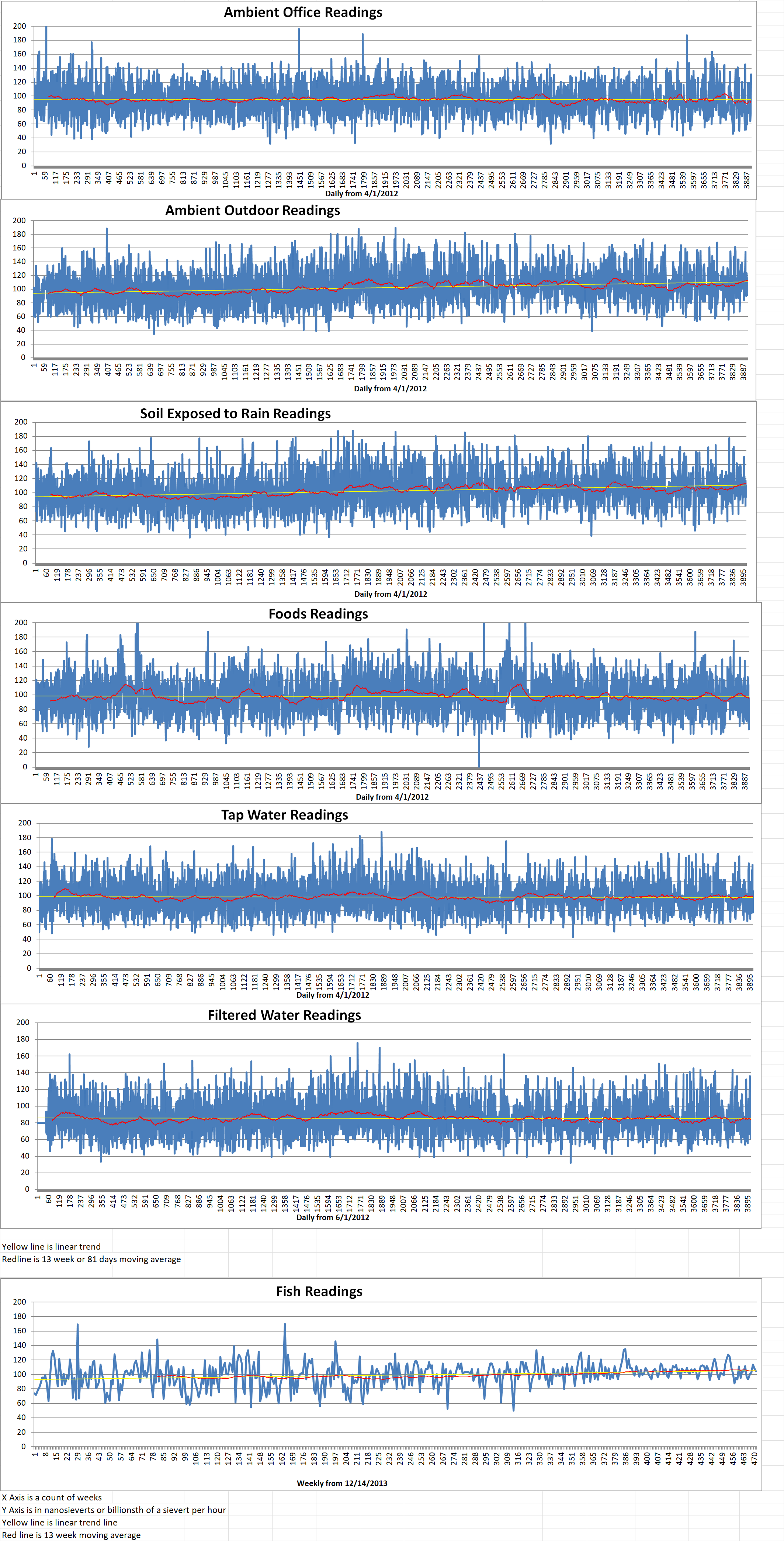

Ambient office = 87 nanosieverts per hour

Ambient outside = 99 nanosieverts per hour

Soil exposed to rain water = 97 nanosieverts per hour

Red bell pepper from Central Market = 98 nanosieverts per hour

Tap water = 111 nanosieverts per hour

Filter water = 102 nanosieverts per hour

-

Nuclear News Roundup Mar 19, 2023

Nuclear hydrogen rejected by nations as ‘renewable’ energylivenews.comHouse panel OKs nuclear energy bill news.abs-cbn.com

French Parliament Votes Nuclear Plan With Large Majority usnews.com

Russia says risk of nuclear conflict at highest level in decades reuters.com

-

Geiger Readings for Mar 19, 2023

Ambient office = 93 nanosieverts per hour

Ambient outside = 84 nanosieverts per hour

Soil exposed to rain water = 82 nanosieverts per hour

Oyster mushroom from Central Market = 87 nanosieverts per hour

Tap water = 130 nanosieverts per hour

Filter water = 119 nanosieverts per hour

-

Nuclear News Roundup Mar 18, 2023

Nuclear missile fired from North Korea could hit US in 33 minutes, says Chinese study indiatoday.in

Nuclear is an afterthought in the EU’s Net-Zero Industry neimagazine.com

ENEC signs MoU with Nuclearelectrica to collaborate on nuclear energy program development wam.ae

UCF Joins $25M National Consortium on Nuclear Forensics ucf.edu

-

Geiger Readings for Mar 18, 2023

Ambient office = 119 nanosieverts per hour

Ambient outside = 70 nanosieverts per hour

Soil exposed to rain water = 73 nanosieverts per hour

Green onion from Central Market = 100 nanosieverts per hour

Tap water = 108 nanosieverts per hour

Filter water = 90 nanosieverts per hour

Dover Sole from Central = 98 nanosieverts per hour

-

Nuclear Fusion 114 – U.K. and U.S. Colaborating On Testing Materials For Fusion Reactors

The United Kingdom Atomic Energy Authority (UKAEA) and the US Department of Energy’s (DoE’s) Oak Ridge National Laboratory (ORNL) have just entered into a strategic research partnership. The purpose of the partnership is to better understand the performance and behavior of materials required for use in commercial fusion power plants.

UKAEA said, “One of the major challenges in harnessing fusion energy is developing materials to cope in extreme environments,” UKAEA said. “This is because high energy neutrons and extreme temperatures can weaken or change the desirable mechanical, thermal, optical or electronic properties of materials, which can reduce the lifetime of fusion machines.”

The five-year partnership has three million six hundred thousand dollars in funding. Materials will be irradiated using neutrons at the ORNL High Flux Isotope Reactor, a DOE Office of Science user facility, located in the U.S. This research will attempt to understand how certain materials respond to irradiation over long periods. The ultimate purpose of this research is to increase the longevity of the materials tested.

The material selected for testing under the partnership will primarily focus on the ‘breeder blanket’. This is a component used to provide the tritium fusion fuel to make fusion power plants self-sufficient.

Post irradiation testing will include tensile and hardness property measurements. This will help illuminate both the effect and the extent of radiation-induced hardening and concurrent loss of ductility in these materials.

Advanced microstructural analysis will also be carried out to understand the effects of neutron radiation on chemical segregation and precipitate stability. UKAEA said that these assessments are critical to provide assurance that these alloys will be sufficiently durable and reliable to support a fusion power plant throughout the expected lifetimes of each component.

The partnership will also see staff from the U.S. and the U.K. visits their counterpart facilities to share industry skills. The project is part of the UK Fusion Materials Roadmap, which was launched by UKAEA in 2021. The aim is to deliver new neutron-resilient materials as well as irradiation and post-irradiation testing to provide design engineers with data to build future fusion power plants.

Amanda Quadling is the UKAEA’s Director of Materials Research. She said, “The partnership will allow UKAEA access to ORNL’s archive of existing irradiated materials, which include binary iron-chromium alloys, advanced steels, silicon carbide composites and copper alloys Alongside this, UKAEA will also be placing entirely new materials into the ORNL High Flux Isotope Reactor, including new high-temperature steels developed by both UKAEA and wider UK industry, permeation barrier coatings and welded materials.”

Mickey Wade is ORNL’s Fusion Energy Division director. He said, “This research collaboration will be a critical piece of the economics of a fusion device in the future, establishing which materials can last for long periods in the fusion environment. This is a great opportunity for ORNL and UKAEA to partner on a key area for fusion.”

Last February, UKAEA announced that it had awarded contracts worth a total of three million, eight hundred thousand dollars to eighteen organization. The contracts are to focus on overcoming specific technical and physical challenges to make fusion energy a commercial reality. Feasibility studies will be funded from sixty million dollars to two hundred forty-four million dollars from the UKAEA’s Fusion Industry Program and awarded through the UK government platform Small Business Research Initiative. The selected projects aim to tackle specific challenges linked to the commercialization of fusion energy. These include novel fusion materials and manufacturing techniques as week as innovative heating and cooling systems. -

Nuclear News Roundup Mar 17, 2023

Ukraine aims to produce nuclear fuel by 2026, exports to follow world-nuclear-news.org

Russian, Chinese nuclear cooperation spurs House to sound alarm courthousenews.com

New Mexico Opts for Veto Power on Spent Nuclear Fuel Debate usnews.com

Fresh progress for Poland’s Orlen Synthos SMR project world-nuclear-news.org

-

Geiger Readings for Mar 17, 2023

Ambient office = 127 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 110 nanosieverts per hour

English cucumber from Central Market = 94 nanosieverts per hour

Tap water = 77 nanosieverts per hour

Filter water = 61 nanosieverts per hour