Laser Photonics Corporation (LPC) is a leading global developer of industrial laser systems for cleaning and other material processing applications. LPC announced today that it received an order from the Cooper Nuclear Station (CNS) which is Nebraska’s largest single-unit generator providing clean and reliable electricity.

LPC went on to say that “It is serving a growing number of clients in the nuclear energy sector, and is thrilled that Cooper Nuclear entrusted it to provide its team with innovative laser-powered equipment.

John Armstrong is the Executive Vice President of Laser Photonics. He said, “Laser cleaning technology is rapidly gaining ground as a highly effective alternative to hazardous surface preparation methods.”

In laser cleaning, a high-energy laser beam is used to ablate (break molecular bonds and vaporize) unwanted material, be it contaminants or coatings on a surface. The LPC technology can effectively remove corrosion, coatings, paint, and other substances without damaging the underlying substrate. This laser process is non-contact, controlled, and precise, allowing for the selective removal of unwanted layers. Laser cleaning is being widely adopted as professionals in various industries discover the benefits of this technology. Laser Photonics designs laser cleaning tools in-house. It offers its clients turnkey and custom-tailored solutions that replace outdated and harmful industrial cleaning processes.

LPC’s CleanTech laser cleaning technology transforms surface preparation across numerous industries. It helps preserve vintage vehicles, maintain critical infrastructural elements, restore historical artifacts, recommission military equipment, and stop corrosive deterioration on boats.

The CleanTech CR-3010 that was purchased by CNS, is a commercial-grade handheld continuous wave fiber laser machine for surface preparation. It effectively removes contaminants and coatings off a variety of surfaces during maintenance and production processes. It has demonstrated its capability to blast off radioactive particles along with unwanted material. Combined with a fume extractor, the system turns into an irreplaceable power tool for the regular maintenance of equipment and infrastructure.

CNS is operated by the Nebraska Public Power District (NPPD). It plans to use the CleanTech CR-3010 for paint and rust removal in the pre-weld preparation of valves, pipes and steel plates.

Laser ablation is an eco-friendly surface preparation method for businesses who want to reduce their ecological impact. It does not involve the use of hazardous consumables and generates minimal secondary waste. LPC technology continues to be adopted in the nuclear industry and others industries as companies worldwide advance toward their sustainability goals.

Laser Photonics is a vertically integrated manufacturer and research and development center for industrial laser technologies and systems. Laser Photonics seeks to disrupt the forty-six billion dollars, centuries-old sand and abrasives blasting markets by focusing on surface cleaning, rust removal, corrosion control, de-painting and other laser-based industrial applications. Laser Photonics’ new generation of leading-edge laser blasting technologies and equipment also deals with the numerous health, safety, environmental and regulatory issues associated with the old methods. As a result, Laser Photonics has quickly gained a reputation as an industry leader in industrial laser systems. It is a brand that stands for quality, technology and product innovation. World-renowned and Fortune 500 manufacturers in the aerospace, automotive, defense, energy, maritime, nuclear and space industries are using Laser Photonics’ “unique-to-industry” systems. For more information, visit Laser Photonics.

Blog

-

Nuclear Reactors 1458 – Laser Photonics Provides Laser Cleaning Tools For The Nuclear Industry

-

Nuclear News Roundup Jan 06, 2025

Iran steps up air defense drills near key nuclear site amid Israeli, US threats timesofisrael.com

Iran nuclear program nearing ‘point of no return’, France’s Macron says Aljazeera.com

Three SMRs selected for evaluation in ship propulsion study world-nuclear-news.org

Russia Commissions Fifth Yasen Nuclear Attack Sub news.usni.org

-

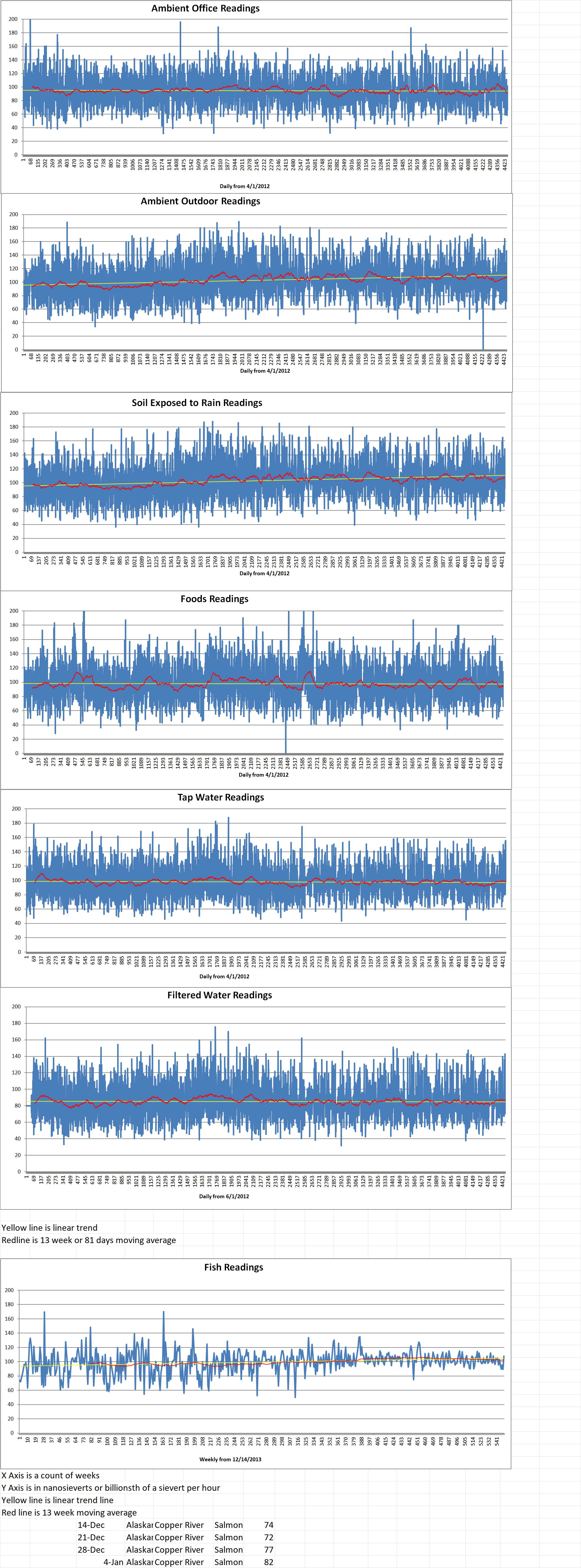

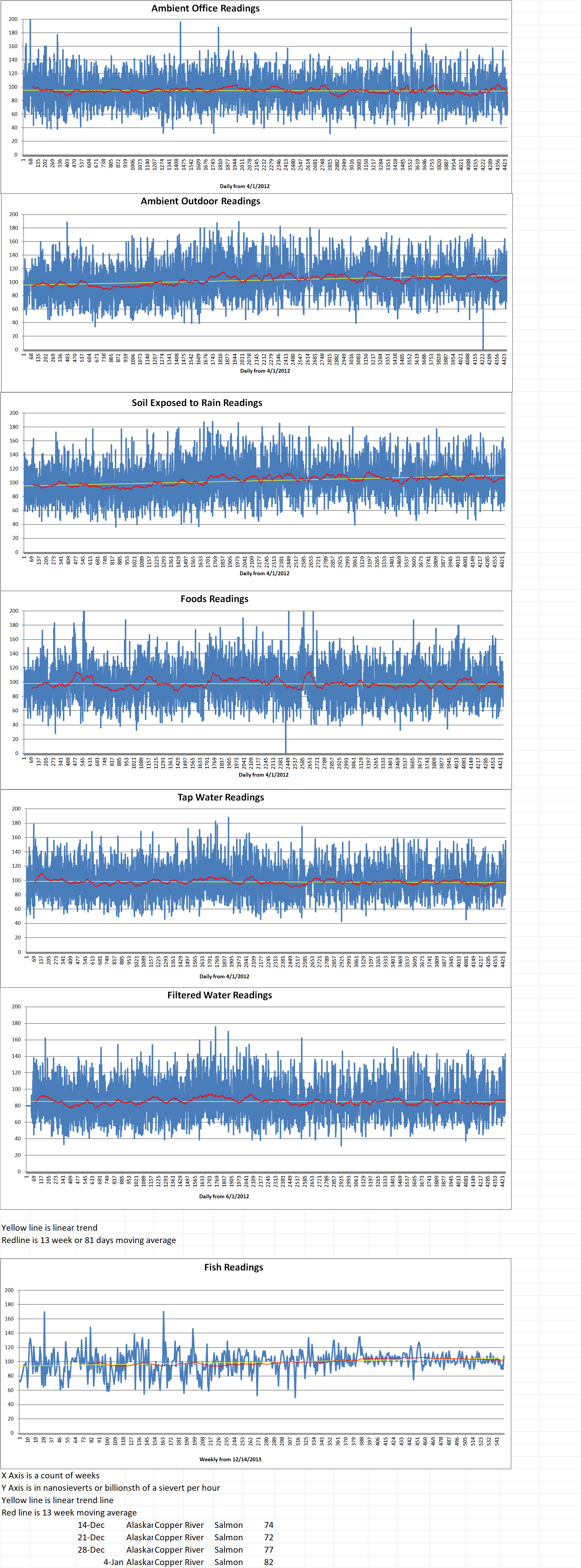

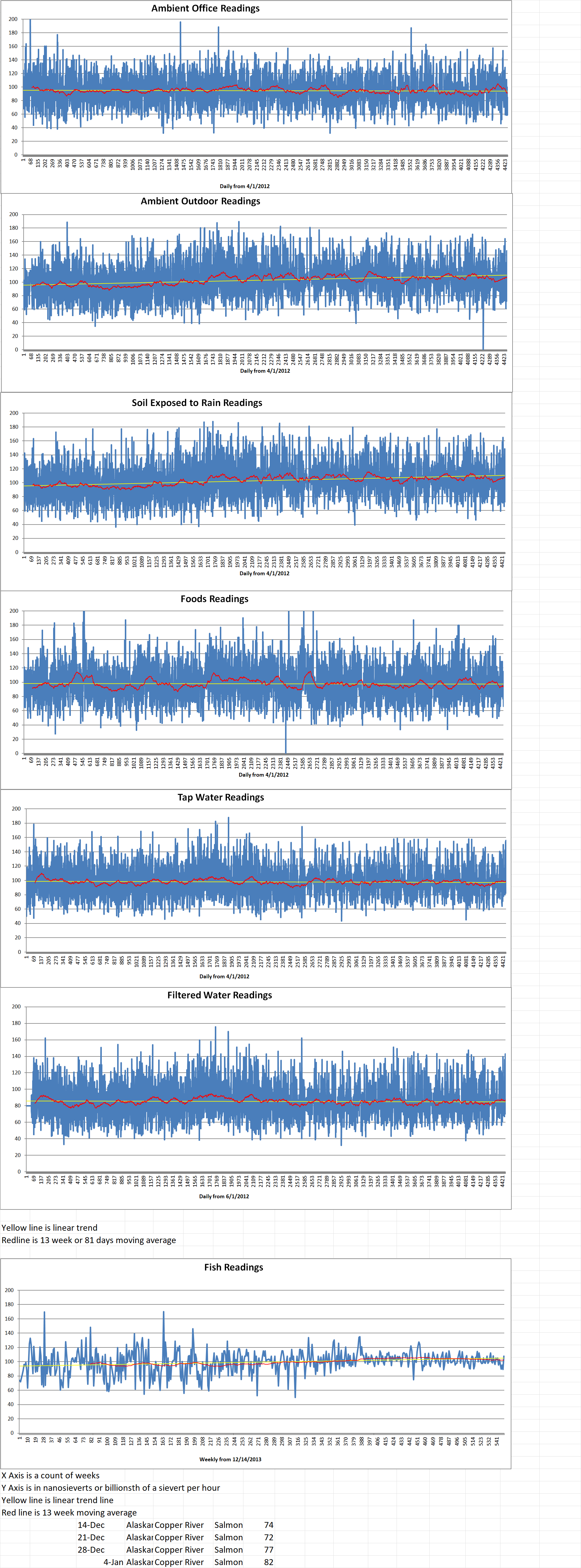

Geiger Readings for Jan 06, 2025

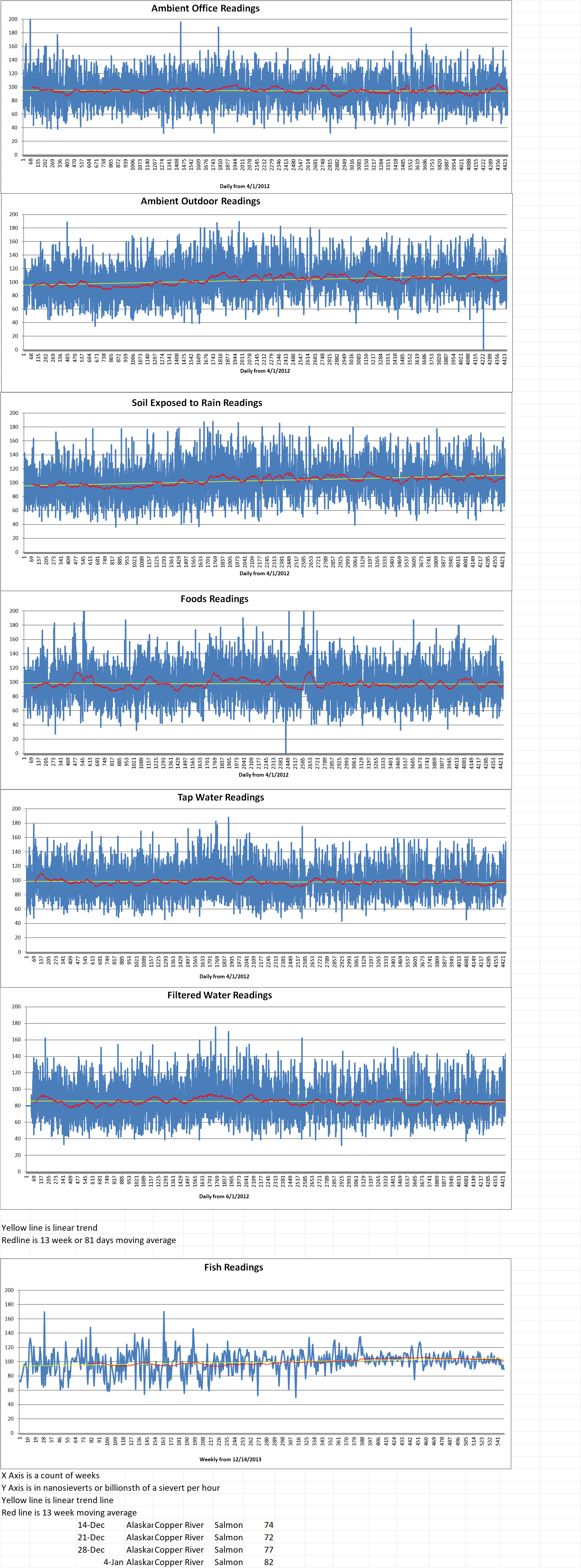

Ambient office = 77 nanosieverts per hour

Ambient outside = 99 nanosieverts per hour

Soil exposed to rain water = 92 nanosieverts per hour

Green onion from Central Market = 80 nanosieverts per hour

Tap water = 106 nanosieverts per hour

Filter water = 100 nanosieverts per hour

-

Nuclear News Roundup Jan 05, 2025

Nuclear weapons have no place in Iran’s doctrine: diplomat en.mehrnews.com

Landmark module installation at Lianjiang 2 world-nuclear-news.org

Kazakh-China fuel plant reaches nameplate capacity world-nuclear-news.org

Westinghouse Awarded NASA-DOE Contract to Continue Development of Space Microreactor Concept westinghousenuclear.com

-

Geiger Readings for Jan 05, 2025

Ambient office = 85 nanosieverts per hour

Ambient outside = 99 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Campari tomato from Central Market = 66 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filter water = 93 nanosieverts per hour

-

Nuclear News Roundup Jan 04, 2025

Ohio passes new law redefining nuclear power as ‘green’ energy publicnewsservice.org

Nuclear becomes eligible for hydrogen tax credits under updated US rules world-nuclear-news.org

Groundworks begin for new Chinese plant world-nuclear-news.org

BREST-OD-300 fuel fabrication facility begins pilot operation world-nuclear-news.org

-

Geiger Readings for Jan 04, 2025

Ambient office = 67 nanosieverts per hour

Ambient outside = 146 nanosieverts per hour

Soil exposed to rain water = 141 nanosieverts per hour

Blueberry from Central Market = 108 nanosieverts per hour

Tap water = 156 nanosieverts per hour

Filter water = 141 nanosieverts per hour

Dover Sole from Central = 108 nanosieverts per hour

-

Nuclear Fusion 105 – General Atomics Researchers Use Computer Simulations To Reduce Energy Loss In Tokamaks

Heating plasma to the ultra-high temperatures needed for fusion reactions new techniques. Researchers have considered multiple methods, one of which involves injecting electromagnetic heating waves into the plasma. This is basically the same process that heats food in microwave ovens. However, when they produce one type of heating wave, they can sometimes simultaneously create another type of wave that does not heat the plasma. This is a waste of energy.

To solve this problem, scientists at the U.S. Department of Energy’s (DoE) Princeton Plasma Physics Laboratory (PPPL) have performed computer simulations. They have developed a new technique that prevents the production of the unhelpful waves, known as slow modes. This boosts the heat put into the plasma and increases the efficiency of the fusion reactions.

Eun-Hwa Kim is a PPPL principal research physicist and lead author of the paper reporting the results in Physics of Plasmas. He said, “This is the first time scientists have used 2D computer simulations to explore how to reduce slow modes. The results could lead to more efficient plasma heating and possibly an easier path to fusion energy.”

The team included researchers from General Atomics who use the DIII-D tokamak fusion facility. They determined that positioning a metal grate known as a Faraday screen at a slight five-degree slant with respect to the antenna producing the heating waves (which are also known as helicon waves) stops the production of the slow modes. Researchers want to avoid creating slow modes because they cannot penetrate the magnetic field lines confining the plasma to heat the core. This is where most fusion reactions occur. In addition, the slow modes are easily damped or cancelled out by the plasma itself. Any energy used to create slow modes is energy that is not used to heat the plasma and foster fusion reactions.

The researchers simulated the production of helicon waves and slow modes using the Petra-M computer code. This is a powerful and versatile program used to model electromagnetic waves in fusion devices and space plasmas. The simulations replicated conditions in the DIII-D tokamak which is a doughnut-shaped plasma device operated by General Atomics for the DoE.

The team carried out a series of virtual experiments to test which of the following methods had the greatest effect on the production of slow modes: the antenna’s alignment, the Faraday screen’s alignment or the density of electrons in front of the antenna. The simulations confirmed that when the Faraday screen was aligned at an angle of five degrees or less from the orientation of the antenna, the screen, in effect, short-circuits the slow modes, making them dissipate before they propagate into the plasma. The suppression of the slow modes depends mainly on how much the Faraday screen leans to the side.

Masayuki Ono is a PPPL Principal Research Physicist and one of the paper’s authors. He said, “We found that when the screen’s orientation exceeds five degrees by only a little bit, the slow modes grow by a great deal. We were surprised by how sensitive the development of slow modes was to the screen alignment.” Scientists will be able to use this information to refine the design of new fusion facilities to make their heating more powerful and efficient.

In the future, the scientists plan to improve their understanding of how to prevent slow modes by running computer simulations that consider more of the plasma’s properties and factor in more information about the antenna. -

Nuclear News Roundup Jan 03, 2025

Kazakh-Chinese nuclear fuel plant Ulba-TVS reaches full capacity news.az

Keel laid for service ship for nuclear-powered icebreakers world-nuclear-news.org

Israeli attack on Iran’s nuclear program in 2025 could transform Middle East – analysis jpost.com

Nuclear storage site, consent decree project on agenda for first Fort Smith Board of Directors meeting of 2025 nwaonline.com

-

Geiger Readings for Jan 03, 2025

Ambient office = 66 nanosieverts per hour

Ambient outside = 139 nanosieverts per hour

Soil exposed to rain water = 149 nanosieverts per hour

Beefsteak tomato from Central Market = 115 nanosieverts per hour

Tap water = 154 nanosieverts per hour

Filter water = 143 nanosieverts per hour