Part 2 of 2 Parts (Please read Part 1 first)

The fleeting nature of defects during nuclear experiments explains why scientists have usually captured only a smattering of data points along important lines of measure.

Chen has spent the last two years developing computer vision to track material changes from recorded experiments at IVEM. In one of his projects, he examined one hundred frames per second from videos that were one to two minutes in duration. In another project, Chen extracted one frame per second in videos one to two hours long.

The computer vision utilized in Chen’s research is similar to facial recognition software that can recognize and track people in surveillance footage. It can single out material defects and structural voids. Instead of establishing a library of faces, Chen created a vast, reliable collection of information about temperature resistance, irradiation resilience, microstructural defects and materials lifetimes. This information can be plotted to inform better models and plan better experiments.

Che stresses that a frequently cited benefit of computer-enable work is saving time. However, that is not the only benefit of using artificial intelligence and computer vision at IVEM. With a greater ability to understand and direct experiments that are underway, IVEW users can make on-the-spot adjustments to use their time at IVEW more efficiently and capture important information.

Chen said, “Videos look very nice, and we can learn a lot from them, but too often they get shown one time at a conference and then are not used again. With computer vision, we can actually learn a lot more about observed phenomena and we can convert video of phenomena into more useful data.”

In the new report, Chen and his co-authors from the University of Connecticut (UConn) presented DefectTrack, a MOT that is able to extract complicated defect data in real time as the materials are irradiated. In the study, DefectTrack tracked up to four thousand three hundred and seventy-eight different defect clusters in just one minute. The tests ranged from nineteen to sixty-four milliseconds. The findings were significantly superior to the same work done by human beings. Besides improved speed, computer vision also has increased accuracy.

Rajat Sainju is a UConn co-author and a Ph.D. candidate. He said, “Our statistical evaluations showed that the DefectTrack is more accurate and faster than human experts in analyzing the defect lifetime distribution.”

Yuanyuan Zhu is the UConn assistant professor of materials science and engineer who led the university’s team of co-authors. He said, “We urgently need to speed up our understanding of nuclear materials degradation. Dedicated computer vision models have the potential to revolutionize analysis and help us better understand the nature of nuclear radiation effects.”

Chen is optimistic that computer vision software such as DefectTrack will improve nuclear reactor designs. He said, “Computer vision can provide information that, from a practical standpoint, was unavailable before. It’s exciting that we now have access to so much more raw data of unprecedented statistical significance and consistency.”

Blog

-

Nuclear Reactors 1132 – Scientists At The Argonne National Laboratory Is Using Artificial Intelligence To Find New Materials For Advanced Reactor Designs – Part 2 of 2 Parts

-

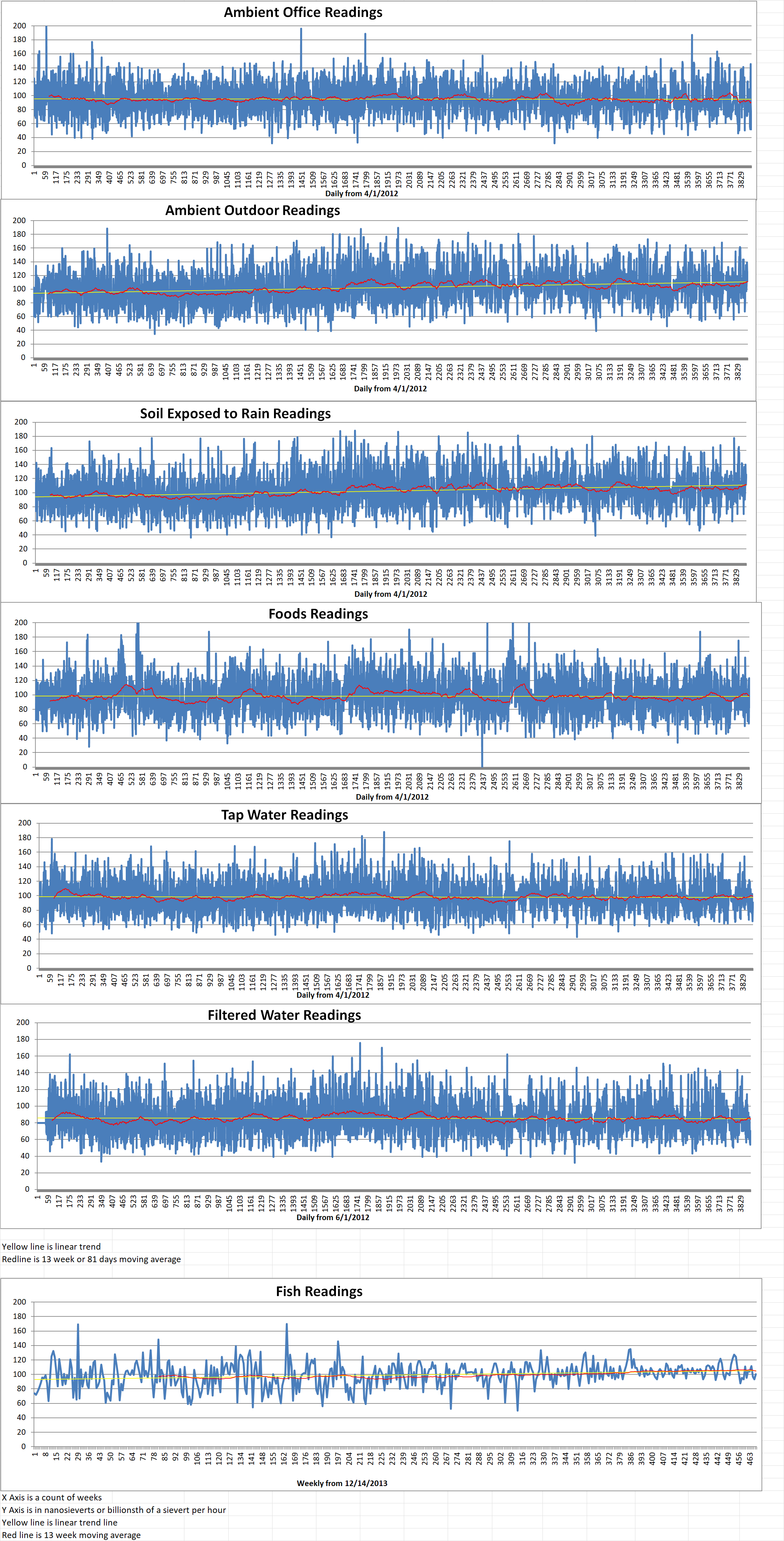

Geiger Readings for Feb 17, 2023

Ambient office = 52 nanosieverts per hour

Ambient outside = 121 nanosieverts per hour

Soil exposed to rain water = 121 nanosieverts per hour

Hierloom tomato from Central Market = 83 nanosieverts per hour

Tap water = 84 nanosieverts per hour

Filter water = 67 nanosieverts per hour

-

Nuclear Reactors 1131 – Scientists At The Argonne National Laboratory Is Using Artificial Intelligence To Find New Materials For Advanced Reactor Designs – Part 1 of 2 Parts

Part 1 of 2 Parts

The future of nuclear energy depends on the discovery of new materials. A researcher at the Argonne National Laboratory is using computer vision to identify the best candidate from a crowded field.

It is often said that a single picture can tell a thousand words. The frame-by-frame story that can be extracted from a single video will far exceed that estimation. Five minutes of video can contain two hundred frames per second which yields sixty thousand images. It would definitely be tedious to digest and catalog such a huge number of images. This means that most scientists don’t usually analyze their experiments’ videos in such detail.

Wei-Ying Chen is a principal materials scientist in the nuclear materials group at the Department of Energy’s (DOE) Argonne National Laboratory. He is experimenting with advances in artificial intelligence to change that. He uses a deep learning-based multi-object tracking (MOT) algorithm to extract data from his videos. His work was detailed in a study recently published in Scientific Reports. His goal is to help the U.S. improve advanced nuclear reactor designs. Modernized nuclear power would produce safe reliable electricity without releasing harmful greenhouse gases.

Currently, nuclear power plants produce more electricity on less land than any other clean energy source. Many commercial nuclear reactors use older materials and technology. Commercial nuclear power plants supply about twenty percent of total U.S. electricity. Scientists and engineers believe newer materials and advanced designs could substantially increase the percentage of clean electricity produced by nuclear power plants.

Chen said, “We want to build advanced reactors that can run at higher temperatures, so we need to discover materials that are resistant to higher temperature and higher irradiation dose. With computer vision tools, we are on track to get all the data we need from all of the video frames.”

Chen assists users and conducts experiments at Argonne’s Intermediate Voltage Electron Microscope (IVEM) facility. IVEM is a national user facility and partner facility of DOE’s Nuclear Science User Facilities (NSUF). The IVEM is one of about a dozen instruments in the world that let researchers look at material changes caused by ion irradiation as the changes happen (in situ). This will permit scientists like Chen can study the effects of different energies on materials proposed for use in future nuclear power reactors. The IVEM is part transmission electron microscope and part ion beam accelerator.

Understanding why, where and when materials breakdown and show defects under extreme conditions over the course of their lifetimes is critical in order to assess a material’s suitability for use in a nuclear power reactor. Extremely tiny defects are the first indications that a material will corrode, become brittle or fail. During experiments, defects happen within a picosecond. A picosecond is one-trillionth of a second. At extreme temperatures, these defects appear and disappear in tens of milliseconds. Chen is an expert in IVEM experiments. He said that even he struggles to plot and interpret such fast moving data.

Please read Part 2 next. -

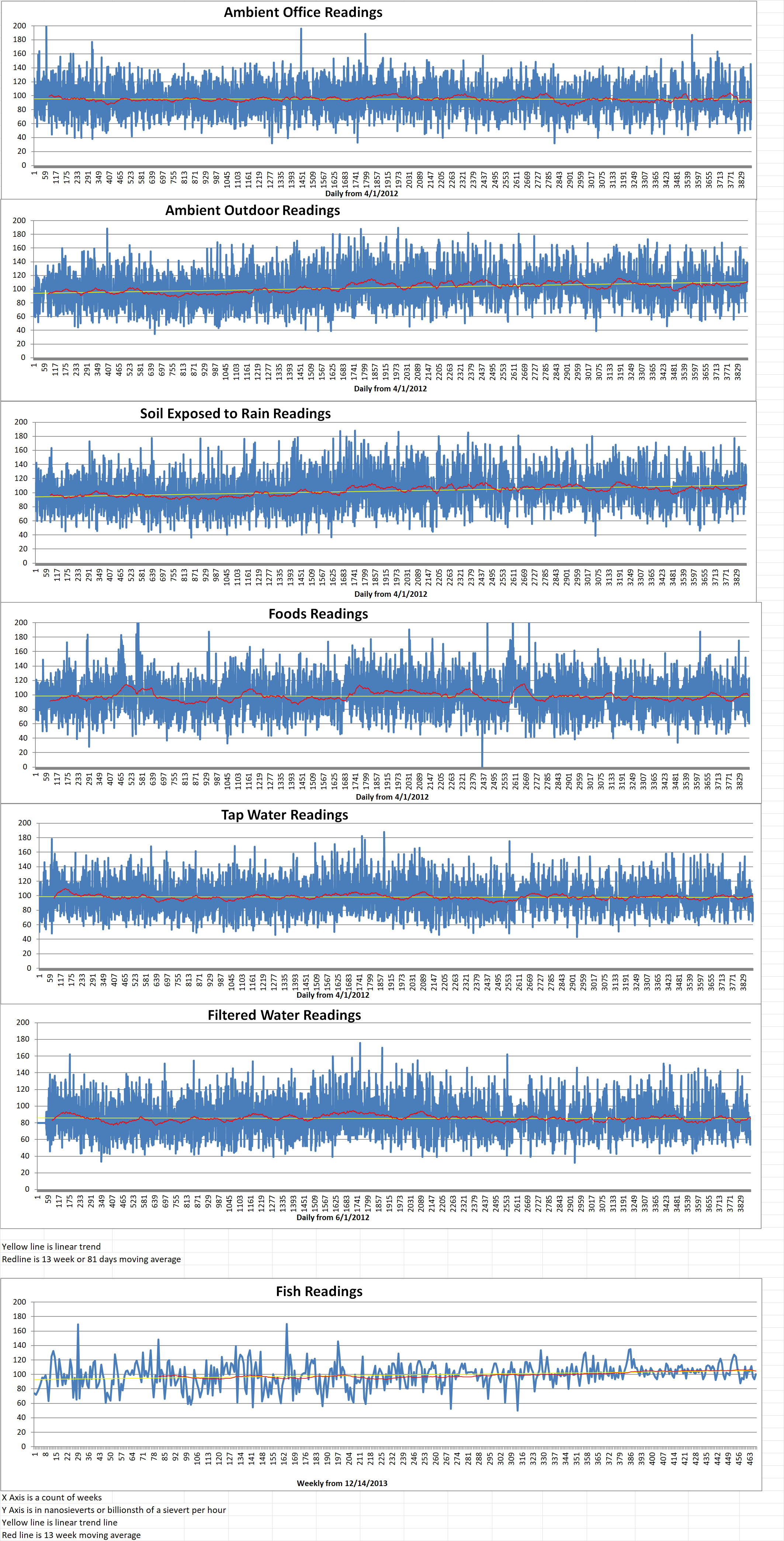

Geiger Readings for Feb 16, 2023

Ambient office = 66 nanosieverts per hour

Ambient outside = 125 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

English cucumber from Central Market = 96 nanosieverts per hour

Tap water = 80 nanosieverts per hour

Filter water = 70 nanosieverts per hour

-

Nuclear News Roundup Feb 16, 2023

Russia deploys nuclear-armed ships for first time in 30 years politico.eu

How to bring innovation to America’s nuclear strategy defensenews.com

NRA approves use of Japanese reactors beyond 60 years world-nuclear-news.org

Work starts on Belgian isotope residue recycling facility world-nuclear-news.org

-

Nuclear Reactors 1130 – Centrus Energy Corporation Is Working On The Production Of HALEU Nuclear Fuel

U.S. Centrus Energy Corporation has just completed construction of a demonstration cascade of advanced uranium enrichment centrifuges and major supporting systems in Piketon, Ohio. This is a step towards a U.S. first-of-a-kind production of High-Assay, Low-Enriched Uranium (HALEU) scheduled for the end of 2023. This rests on the assumption that it completes the remaining support systems and obtains final approval from the Nuclear Regulatory Commission (NRC). This will be the first new U.S. enrichment plant to begin production in seventy years.

HALEU is an advanced nuclear fuel that is required for most of the next-generation nuclear reactor designs currently under development. HALEU is uranium that has been enriched between five percent and twenty percent uranium 235 (U-235). This is higher that the three percent to five percent U-235 low-enriched uranium fuels used in the existing fleet of light water reactors.

Nine of the ten advanced reactor designs selected for funding under the Department of Energy’s (DoE’s) Advanced Reactor Demonstration Program (ARDP) will require HALEU. This includes two demonstration reactors including the Terrapower’s Natrium sodium-cooled fast reactor and the X-energy’s Xe-100 high temperature gas-cooled reactor. However, currently the only company capable of producing HALEU fuel is Russia’s Techsnabexport (Tenex). Daniel B. Poneman is the Centrus Energy President and CEO. He said, “This is a major milestone for Centrus, for the advanced nuclear sector, and for the vital effort to restore America’s domestic uranium enrichment capability. We are strongly committed to pioneering production of HALEU to support the deployment of US advanced reactor designs around the world. Our goal is to scale up this facility to meet the full range of commercial, government, and national security requirements for uranium enrichment, including low-enriched uranium for existing reactors and HALEU for advanced reactors.”

In November of 2022, the DoE announced a new, competitively-awarded contract with Centrus’ wholly-owned subsidiary, American Centrifuge Operating (ACO), signed a ‘definitized’ contract with the DoE to pioneer production of HALEU. As part of a previous, cost-sharing contract awarded in 2019. Centrus had been deploying its AC100M advanced uranium enriched centrifuges in Piketon. It has secured a license amendment from the NRC, making it the only NRC-licensed HALEU production site.

Before operations can begin, Centus needs to finish construction of the remaining support systems, including a fissile materials storage area. This allows the HALEU produced for the DoE to be stored onsite. Centrus must also complete final operational readiness reviews with the NRC to obtain approval to begin HALEU production. The operational readiness reviews are required under Centrus’ NRC license. This license was successfully amended in 2021 to allow for HALEU production.

Centrus states that it is also investigating the possibility of scaling up the Piketon facility with additional centrifuge cascades to expand HALEU production. This is dependent on securing sufficient funding or offtake contracts. A full-scale HALEU cascade comprises one hundred and twenty individual centrifuge machines. They will have a combined capacity of about thirteen thousand pounds of HALEU production. This could be brought online within about forty-two months of securing the funding with the capability to add an addition cascade every six months. Such expansion would support thousands of direct and indirect jobs across a one hundred percent domestic manufacturing supply chain. Centrus notes that it would be capable of meeting U.S. national security requirements. -

Nuclear News Roundup Feb 15, 2023

Holtec, Sheffield Forgemasters team up on SMR forgings world-nuclear-news.org

Canadian and Polish regulators announce SMR collaboration world-nuclear-news.org

China’s Xi Calls for Early Resolution of Iran Nuclear Issue voanews.com

Minuteman III test launch showcases readiness of US nuclear force’s safe, effective deterrent af.mil

-

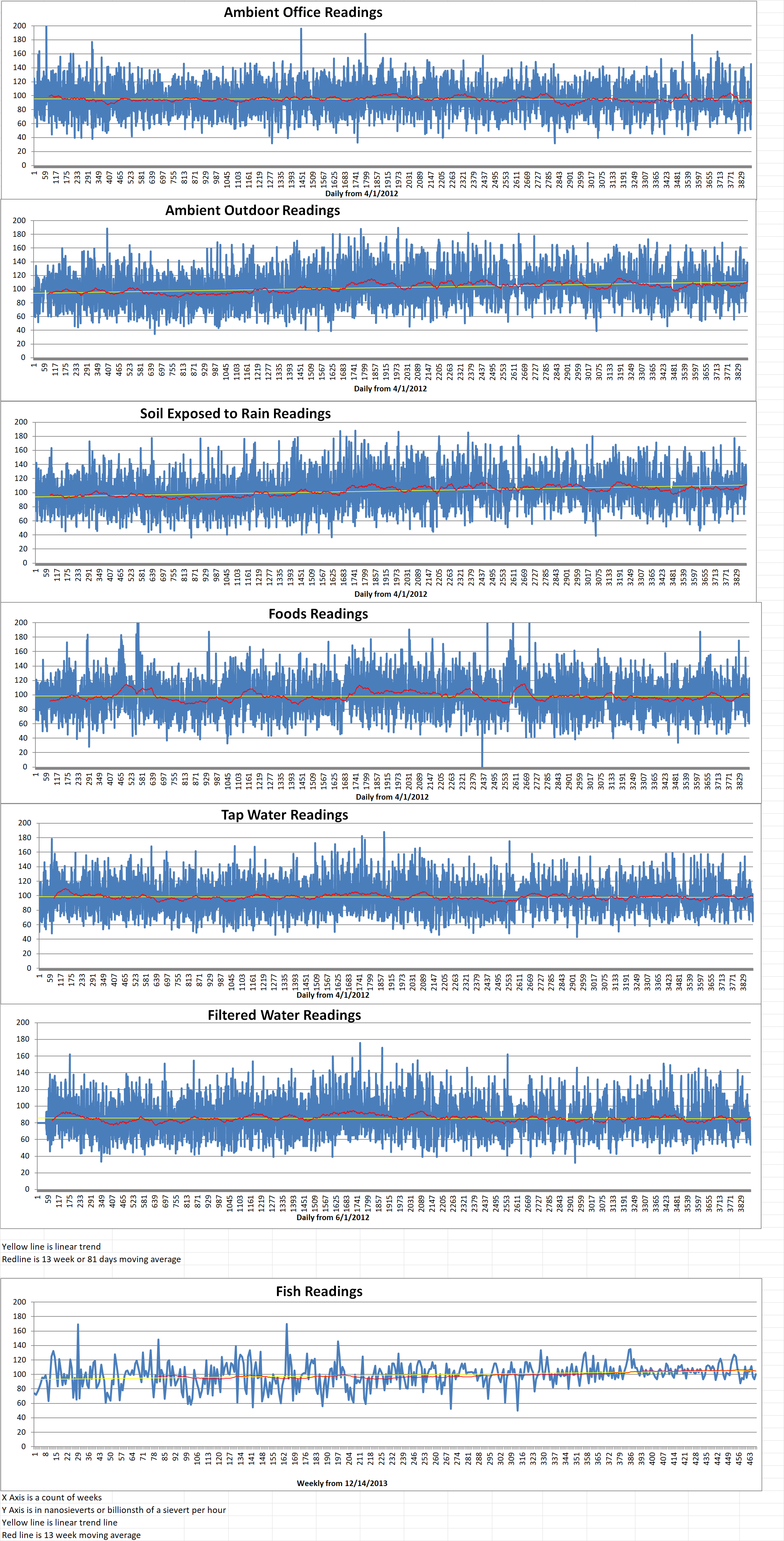

Geiger Readings for Feb 15, 2023

Ambient office = 73 nanosieverts per hour

Ambient outside = 112 nanosieverts per hour

Soil exposed to rain water = 111 nanosieverts per hour

Blueberry from Central Market = 123 nanosieverts per hour

Tap water = 91 nanosieverts per hour

Filter water = 63 nanosieverts per hour

-

Nuclear Weapons 811 – Los Alamos National Laboratory Is Installing New Equipment To Produce Plutonium Cores

The U.S. agency in charge of producing key components for the U.S. nuclear arsenal has cleared the way for new equipment to be installed at a New Mexico Laboratory. The new equipment is part of a multibillion-dollar mission. However, nuclear watchdog groups say that the project is already behind schedule and budgets have ballooned.

The approval for moving equipment into place at the Los Alamos National Laboratory was first outlined in an internal memo issued by the U.S. Deputy Secretary of Energy in January. the U.S. Department of Energy’s (DoE) National Nuclear Security Administration (NNSA) made a public announcement last Thursday.

The project will include the design, fabrication and installation of gloveboxes and other special equipment needed to make plutonium cores, also known as pits, for nuclear weapons. The work will be divided between Los Alamos in northern New Mexico and the Savannah River Site in South Carolina. These two locations are facing a congressional mandate to make at least eighty cores each year by 2030.

The deadline for meeting that capacity has been pushed back. The recent memo is the latest evidence that the minimum equipment necessary will be in place at Los Alamos by August 2030. This is four years later than originally expected.

The nuclear agency contends that the installation of the equipment is not necessary for Los Alamos to produce thirty pits per year. The lab will be building war reserve pits using existing equipment as the project proceeds.

Agency spokeswoman Shayela Hassan said in a recent email to the Associated Press that the NNSA expects an increasing number of pits to be produced each subsequent year until the new equipment is installed. She said that she had moderate confidence that the increased capability will be able to produce thirty pits per year.

The long-closed Rocky Flats Plant outside of Denver was capable of producing more than one thousand reserve pits annually before work halted in 1989 due to environmental and regulatory concerns. In 1996, the DoE provided for limited production capacity at Los Alamos. Los Alamos produced its first war reserve pit in 2007. The lab ceased operations in 2012 after producing what was needed at that time.

Greg Mello is the director of the watchdog Los Alamos Study Group. He said that the NNSA has made contradictory statements about the delays and what they mean for the overall plutonium pit project. He mentioned NNSA statements in 2017 and 2018 in which the agency predicted problems if it were producing pits while also replacing gloveboxes and other equipment at the same time.

Mello said that “There is more they aren’t saying. We believe NNSA and LANL will struggle mightily, with further setbacks, failures and accidents in a misguided attempt to produce any meaningful number of pits in that cramped, aging facility.”

The memo provides formal cost and schedule estimates for getting equipment installed in Los Alamos. However, it is not clear when construction will begin. The cost has been estimated to be about one billion eighty-five million dollars.

More details about spending and schedules for the project are expected when the NNSA submits its budget to congress next month.

In January, the Government Accountability Office (GAO) issued a report that NNSA plans to reestablish plutonium pit production do not follow best practices and run the risk of delays and cost overruns.

The GAO described the modernization effort as the agency’s largest investment in weapons production infrastructure to date. The GAO noted that plutonium is very dangerous material and making the cores for the nuclear weapons is difficult and time consuming.