Heating plasma to the ultra-high temperatures needed for fusion reactions new techniques. Researchers have considered multiple methods, one of which involves injecting electromagnetic heating waves into the plasma. This is basically the same process that heats food in microwave ovens. However, when they produce one type of heating wave, they can sometimes simultaneously create another type of wave that does not heat the plasma. This is a waste of energy.

To solve this problem, scientists at the U.S. Department of Energy’s (DoE) Princeton Plasma Physics Laboratory (PPPL) have performed computer simulations. They have developed a new technique that prevents the production of the unhelpful waves, known as slow modes. This boosts the heat put into the plasma and increases the efficiency of the fusion reactions.

Eun-Hwa Kim is a PPPL principal research physicist and lead author of the paper reporting the results in Physics of Plasmas. He said, “This is the first time scientists have used 2D computer simulations to explore how to reduce slow modes. The results could lead to more efficient plasma heating and possibly an easier path to fusion energy.”

The team included researchers from General Atomics who use the DIII-D tokamak fusion facility. They determined that positioning a metal grate known as a Faraday screen at a slight five-degree slant with respect to the antenna producing the heating waves (which are also known as helicon waves) stops the production of the slow modes. Researchers want to avoid creating slow modes because they cannot penetrate the magnetic field lines confining the plasma to heat the core. This is where most fusion reactions occur. In addition, the slow modes are easily damped or cancelled out by the plasma itself. Any energy used to create slow modes is energy that is not used to heat the plasma and foster fusion reactions.

The researchers simulated the production of helicon waves and slow modes using the Petra-M computer code. This is a powerful and versatile program used to model electromagnetic waves in fusion devices and space plasmas. The simulations replicated conditions in the DIII-D tokamak which is a doughnut-shaped plasma device operated by General Atomics for the DoE.

The team carried out a series of virtual experiments to test which of the following methods had the greatest effect on the production of slow modes: the antenna’s alignment, the Faraday screen’s alignment or the density of electrons in front of the antenna. The simulations confirmed that when the Faraday screen was aligned at an angle of five degrees or less from the orientation of the antenna, the screen, in effect, short-circuits the slow modes, making them dissipate before they propagate into the plasma. The suppression of the slow modes depends mainly on how much the Faraday screen leans to the side.

Masayuki Ono is a PPPL Principal Research Physicist and one of the paper’s authors. He said, “We found that when the screen’s orientation exceeds five degrees by only a little bit, the slow modes grow by a great deal. We were surprised by how sensitive the development of slow modes was to the screen alignment.” Scientists will be able to use this information to refine the design of new fusion facilities to make their heating more powerful and efficient.

In the future, the scientists plan to improve their understanding of how to prevent slow modes by running computer simulations that consider more of the plasma’s properties and factor in more information about the antenna.

Blog

-

Nuclear Fusion 105 – General Atomics Researchers Use Computer Simulations To Reduce Energy Loss In Tokamaks

-

Nuclear News Roundup Jan 03, 2025

Kazakh-Chinese nuclear fuel plant Ulba-TVS reaches full capacity news.az

Keel laid for service ship for nuclear-powered icebreakers world-nuclear-news.org

Israeli attack on Iran’s nuclear program in 2025 could transform Middle East – analysis jpost.com

Nuclear storage site, consent decree project on agenda for first Fort Smith Board of Directors meeting of 2025 nwaonline.com

-

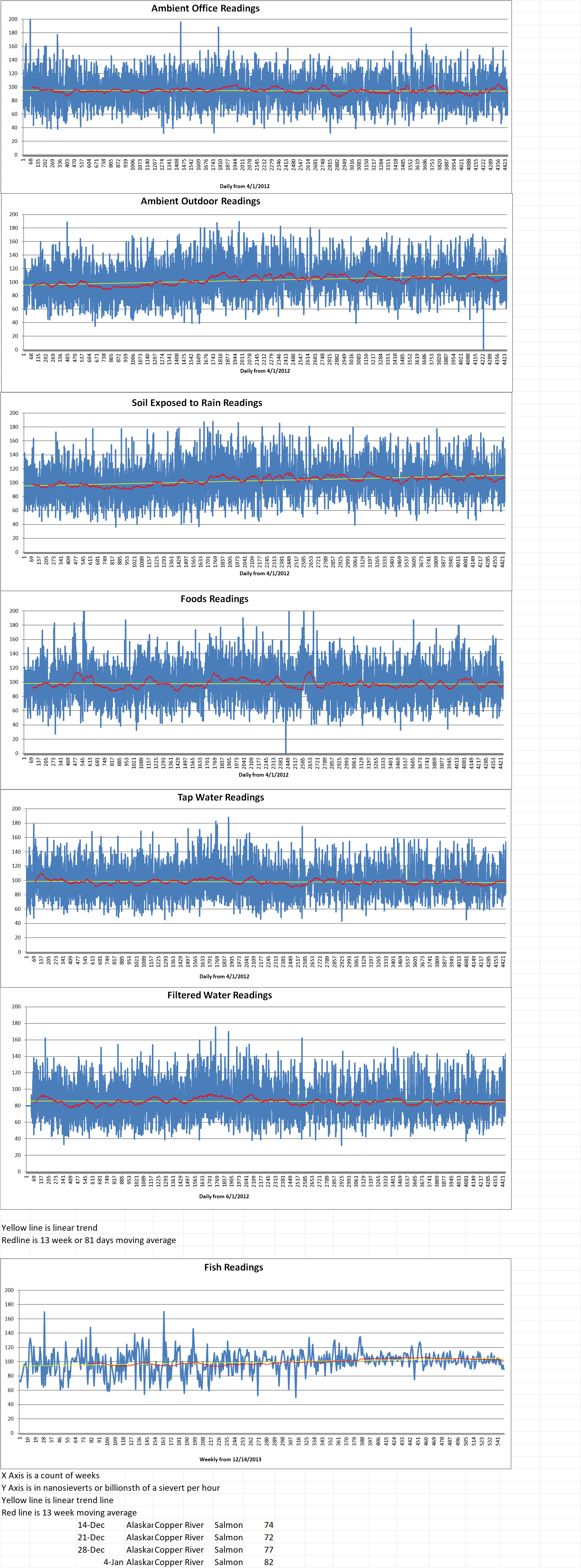

Geiger Readings for Jan 03, 2025

Ambient office = 66 nanosieverts per hour

Ambient outside = 139 nanosieverts per hour

Soil exposed to rain water = 149 nanosieverts per hour

Beefsteak tomato from Central Market = 115 nanosieverts per hour

Tap water = 154 nanosieverts per hour

Filter water = 143 nanosieverts per hour

-

Nuclear Fusion 104 – A Collaborations Of U.S. Laboratories Is Working On Making An Alloy Of Vanadium For Fusion Reactor Cores – Part 3 of 3 Parts

Part 3 of 3 Parts (Please read Parts 1 and 2 first)

Sid Pathak is an assistant professor at Iowa State. He is leading the team that will test the material samples for the second layer. When the material powder made by the Ames Lab group is ready, it will be formed into plates at PNNL by spraying the powder onto a surface.

Pathak said, “Once you make that plate, we need to test its properties, particularly its response under the extreme radiation conditions present in a fusion reactor, and make sure that we get something better than what is currently available. That’s our claim, that our materials will be superior to what is used today.”

Pathak explained that it can take ten to twenty years for radiation damage to appear on materials in a nuclear reactor. It would be impossible to recreate that timeline during a three-year research project. Instead, his team utilizes irradiation to see how materials respond in extreme environments. His team will use a particle accelerator to attack a material with ions available at University of Michigan’s Michigan Ion Beam Laboratory. The results will simulate how the material is affected by radiation.

Pathak said, “Ion irradiation is a technique where you radiate [the material] with ions instead of neutrons. That can be done in a matter of hours. Also, the material does not become radioactive after ion irradiation, so you can handle it much more easily.”

There is one disadvantage to the use of ion irradiation. The damage caused by the ions only penetrates the material one or two micrometers deep. This means that it can only be seen with a microscope. Testing materials at these very small depths requires specialized tools that work at micro-length scales such as those which are available at Pathak’s lab at Iowa State University.

Tiarks said, “The pathway to commercial nuclear fusion power has some of the greatest technical challenges of our day but also has the potential for one of the greatest payoffs—harnessing the power of the sun to produce abundant, clean energy. It’s incredibly exciting to be able to have a tiny role in solving that greater problem.”

Argibay commented that “I’m very excited at the prospect that we are kind of in uncharted water. So there is an opportunity for Ames to demonstrate why we’re here, why we should continue to fund and increase funding for national labs like ours, and why we are going to tackle some things that most companies and other national labs just can’t or aren’t. We hope to be part of this next generation of solving fusion energy for the grid.”

Extreme levels of temperature and pressure are required for the creation of nuclear fusion on the surface of the Earth. This means that new materials must be developed and tested to withstand these extreme conditions before commercial nuclear fusion will be possible. The prospects are bright for the development of commercial nuclear fusion but there are many technical challenges that must be solved before fusion energy will be available at grid scale. -

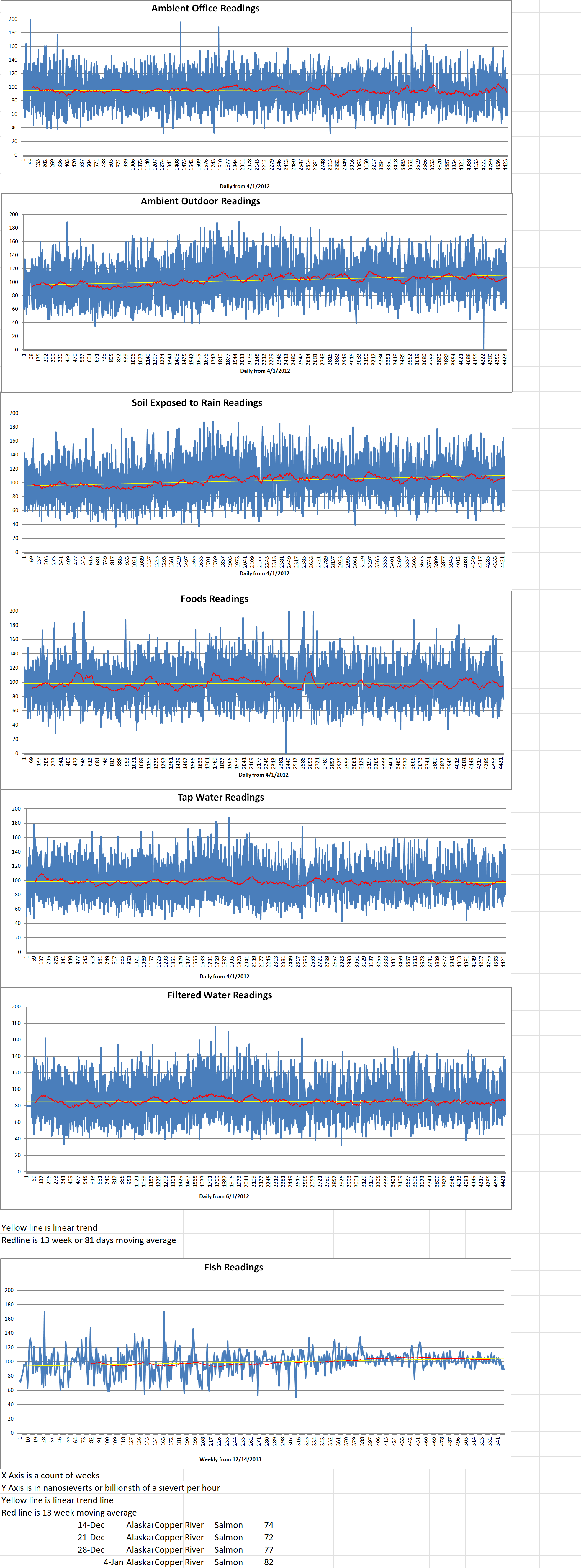

Geiger Readings for Jan 02, 2025

Ambient office = 69 nanosieverts per hour

Ambient outside = 72 nanosieverts per hour

Soil exposed to rain water = 73 nanosieverts per hour

Avocado from Central Market = 87 nanosieverts per hour

Tap water = 82 nanosieverts per hour

Filter water = 70 nanosieverts per hour

-

Nuclear Fusion 103 – A Collaboration Of U.S. Laboratories Is Working On Making An Alloy Of Vanadium For Fusion Reactor Cores – Part 2 of 3 Parts

Part 2 of 3 Parts (Please read Part 1 first)

Jordan Tiarks is another scientist at Ames Lab who is working on the project led by PNNL. He is focused on a different aspect of this reactor research. His team is relying on Ames Lab’s thirty-five years of experience leading the field in gas atomization, powder metallurgy, and technology transfer to industry to develop materials for the first wall structural material in a fusion reactor.

Tiarks said, “The first wall structural material is the part that holds it all together. It requires more complexity and more structural strength. Things like cooling channels need to be integrated in the structural wall so that we can extract all of that heat, and don’t just melt the first wall material.”

Tiarks’s team hopes to utilize over a decade of research focused on developing a unique way of creating oxide dispersion strengthened (ODS) steel for next generation nuclear fission reactors. ODS steel contains very small ceramic particles (nanoparticles) that are distributed throughout the steel. These particles improve the metal’s mechanical properties and assist in the ability to withstand high irradiation.

Tiarks said, “What this project does is it takes all of our lessons learned on steels, and we’re going to apply them to a brand-new medium, a vanadium-based alloy that is well suited for nuclear fusion.”

The major challenge that Tiarks’s team now faces is how vanadium behaves differently from steel. Vanadium has a much higher melting point, and it is more reactive than steel. It cannot be contained with ceramic. Instead, his team must use a similar but different process for creating vanadium-based powders.

Tiarks explained, “We use high pressure gas to break up the molten material into tiny droplets which rapidly cool to create the powders we’re working with. And [in this case] we can’t use any sort of ceramic to be able to deliver the melt. So what we have to do is called ‘free fall gas atomization’. It is essentially a big opening in a gas die where a liquid stream pours through, and we use supersonic gas jets to attack that liquid stream.”

There are some significant challenges with the method Tiarks described. The first problem is that it is less efficient than other methods that rely on ceramics. The second problem is that due to the high melting point of vanadium, it is harder to add more heat during the pouring process. This would provide more time to break up the liquid into droplets. The third problem is that vanadium tends to be reactive.

Tiarks added that “Powders are reactive. If you aerosolize them, they will explode. However, a fair number of metals will form a thin oxide shell on the outside layer that can help ‘passivate’ them from further reactions. It’s kind of like an M&M. It’s the candy coating on the outside that protects the rest of the powder particle from further oxidizing.”

Tiarks continued that, “A lot of the research we’ve done in the Ames lab is actually figuring out how we passivate these powders so you can handle them safely, so they won’t further react, but without degrading too much of the performance of those powders by adding too much oxygen. If you oxidize them fully, all of a sudden, now we have a ceramic particle, and it’s not a metal anymore, and so we have to be very careful to control the passivation process.”

Tiarks went on to explain that discovering a powder processing method for vanadium-based materials should make them easier to form into the complicated geometric shapes that are necessary for the second layer to function properly. In addition, vanadium will not interfere with the powerful magnetic fields in the reactor core.

Please read Part 3 next -

Nuclear News Roundup Jan 01, 2025

Pickering-4 Nuclear Plant In Canada Permanently Shut Down nucnet.org

EDF to Simplify Small Nuclear Reactor After Design Setback bnnbloomberg.ca

US taking steps to clear hurdles for civil nuclear partnership with Indian firms economictimes.indiatimes.com

Zhangzhou unit 1 enters commercial operation world-nuclear-news.org

-

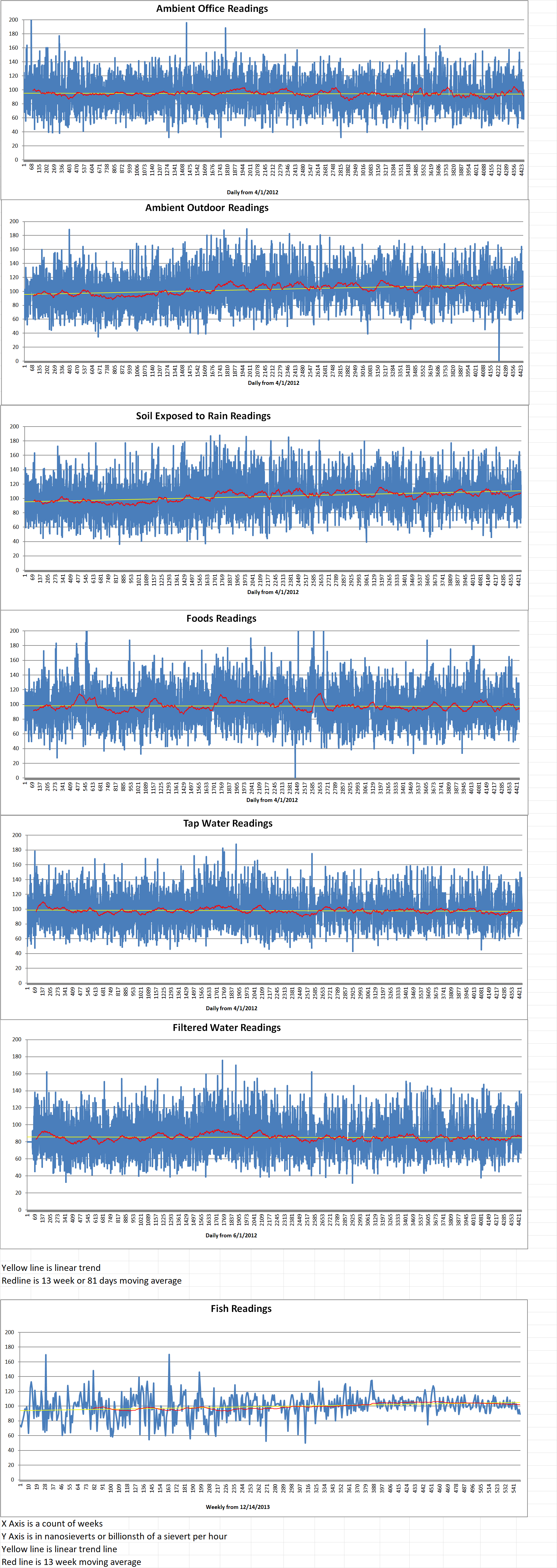

Geiger Readings for Jan 01, 2025

Ambient office = 59 nanosieverts per hour

Ambient outside = 86 nanosieverts per hour

Soil exposed to rain water = 79 nanosieverts per hour

Savoy cabbage from Central Market = 84 nanosieverts per hour

Tap water = 98 nanosieverts per hour

Filter water = 87 nanosieverts per hour

-

Nuclear Fusion 102- A Collaborations Of U.S. Laboratories Is Working On Making An Alloy Of Vanadium For Fusion Reactor Cores – Part 1 of 3 Parts

Part 1 of 3 Parts

Researchers at the U. S. Department of Energy (DoE) Ames National Laboratory and Iowa State University are leading efforts to overcome material challenges to making commercial fusion a reality. The research teams are part of a DoE Advanced Research Projects Agency-Energy (ARPA-E) program referred to as “Creating Hardened And Durable fusion first Wall Incorporating Centralized Knowledge” (CHADWICK). They will research materials for the first wall of a fusion reactor. The first wall is the part of the reactor that surrounds the fusion reaction. It bears the brunt of the extreme heat and pressure in the fusion reactor core.

ARPA-E recently selected thirteen projects under the CHADWICK program. Of those thirteen, Ames Lab leads one of the projects. It is also collaborating with Iowa State on another project, which is led by Pacific Northwest National Laboratory (PNNL).

Nicolas Argibay is a scientist at the Ames Lab and the lead of one project. One of his key challenges in harnessing fusion-based power is containing the plasma core that generates the energy. The plasma is like a miniature sun that needs to be contained by materials that can survive a combination of extreme temperature, extreme pressure, irradiation, and magnetic fields while efficiently extracting heat for conversion to electricity.

Argibay explained that in the reactor core, the plasma is contained by a strong magnetic field, and the first wall surrounds this environment. The first wall has two layers of material. One layer is closest to the strong magnetic and plasma environments. The other layer will help move the energy along to other parts of the system.

The first layer material needs to be structurally sound, and able to resist cracking and erosion over time. Argibay also said that it cannot stay radioactive for very long because the reactor needs to be turned on and off for maintenance without endangering anyone working on it. The project that Argibay is leading is focused on the first layer material.

Argibay said, “I think one of the things we [at Ames Lab] bring is a unique capability for materials design, but also, very importantly, for processing them. It is hard to make and manage these materials. On the project I’m leading, we’re using tungsten as a major constituent, and with the exception of some forms of carbon, like diamond, that’s the highest melting temperature element on the periodic table.”

Special equipment is required to process and test refractory materials, which have extremely high melting temperatures. In Argibay’s lab, the first piece of equipment installed was a commercial, modular, customizable, open-architecture platform for making refractory materials. The lab will explore advanced and smart manufacturing methods to make the process more efficient and reliable.

Argibay added, “Basically, we can make castings and powders of alloys up to and including pure tungsten, which is the highest melting temperature element other than diamond.”

By spring of 2025, Argibay said that they intend to have two additional systems in place for creating these refractory materials at both lab-scale and pilot-scale quantities. He explained it is easier to make small quantities (lab-scale) than larger quantities (pilot-scale). However, larger quantities are important for collecting meaningful and useful data that can translate into a real-world application.

Argibay’s team also has the ability to examine the mechanical properties of refractory materials at relevant temperatures. Systems able to make measurements well above eighteen hundred degrees Fahrenheit are rare. Ames Lab has one of the only commercial thermal testers in the country that can measure tensile properties of alloys at temperatures up to twenty-seven hundred degrees Fahrenheit. This puts the lab in a unique position to support process science and alloy design.

Please read Part 2 next