There is increasing demand for sustainable electricity across the world and scientists are focusing on the development of very small nuclear reactors. These are called microreactors (MR). To make these reactors safer, researchers have turned to a new technology powered by AI that can detect potential hazards in these reactors in seconds.

This technology is referred to as smart component systems and it can provide remote surveillance of MR. Developed by researchers at the Ulsan National Institute of Science and Technology (UNIST) in South Korea, the system includes embedded optical fiber sensors to monitor components in the reactor and send alerts during abnormal conditions.

The UNIST breakthrough involves a novel technology that combines 3D printing with AI, allowing the rapid processing of multiple continuous variables from optical fiber sensors. The team successfully manufactured smart nuclear parts using a Directed Energy Deposition (DED) printing method. They seamlessly integrated fiber optic sensors within the metal components.

MR designs vary, but most of them would be able to produce one to twenty megawatts of thermal energy that could be used directly as heat or converted to electric power. They can be used to generate clean and reliable electricity for commercial use. They could also be used for non-electric applications such as district heating, water desalination and hydrogen fuel production. These MRs are compact enough to be transported by truck and could help solve energy challenges in a number of areas.

Most MR designs will require nuclear fuel with a higher concentration of uranium-235 than is currently used in today’s full-sized reactors. However, some MRs may benefit from the use of high temperature moderating materials that would reduce fuel enrichment requirements while maintaining the small system size.

The recent study proposes a novel DED approach to incorporate an optical fiber sensor into MR components, enabling real-time monitoring with artificial intelligence.

Researchers conducting the study said, “The embedded optical fiber generates real-time data that allows for AI-driven in-vivo thermal deformation analysis. Our smart MR component can detect structural anomalies, identify abnormal operations, and assess operational conditions through augmented reality interfaces and AI technology.”

Im Doo Jung is a Professor from the Department of Mechanical Engineering, UNIST. He stated that researchers tackled the challenges associated with traditional inspection methods through AI convergence technology. This can greatly enhance the stable and efficient operation of next-generation small nuclear power plants.

Jung continued, “This convergence technology could extend its applications beyond nuclear power, potentially benefiting diverse industries such as autonomous manufacturing systems, aerospace, and advanced defense. We introduced a novel method for producing smart micro reactor components by embedding optical fiber sensors during the DED process. This method includes an optimized DED process for metal components of MR systems.”

Researchers emphasized that the proposed process, involving sensor embedding within metal components, could be applied to create smart metal components with various sensors with the DED process.

This research will also allow expanded applications in a variety of industries and research fields which require digitalization and AI within additively manufactured component.

Blog

-

Nuclear Reactors 1451 – The Ulsan National Institute of Science and Technology Is Embedding Sensors In Metal Components To Monitor Microreactors

-

Nuclear News Roundup Nov 28, 2024

Life extensions announced for four UK plants world-nuclear-news.org

Bruce Power signs long-term Master Services Agreement world-nuclear-news.org

Incentives would make Michigan the most ‘pro-nuclear’ state, lawmakers say mlive.com

Meta seeks up to 4 GW of new nuclear power to help meet AI, sustainability objectives utilitydive.com

-

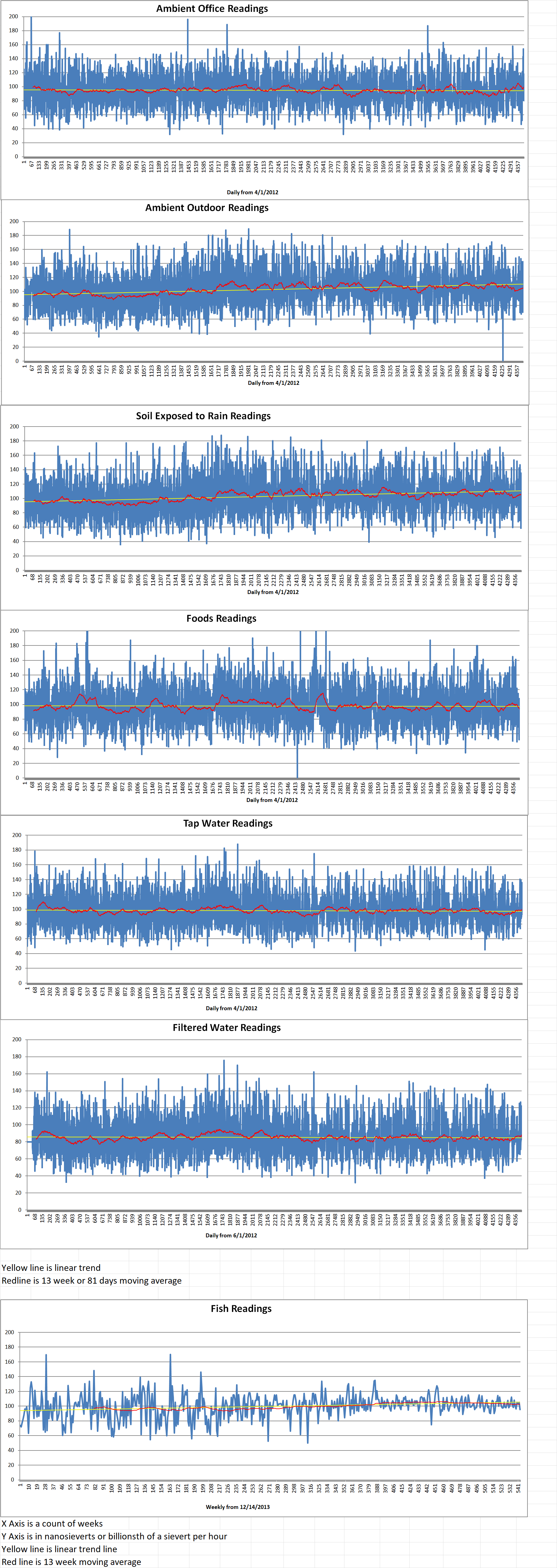

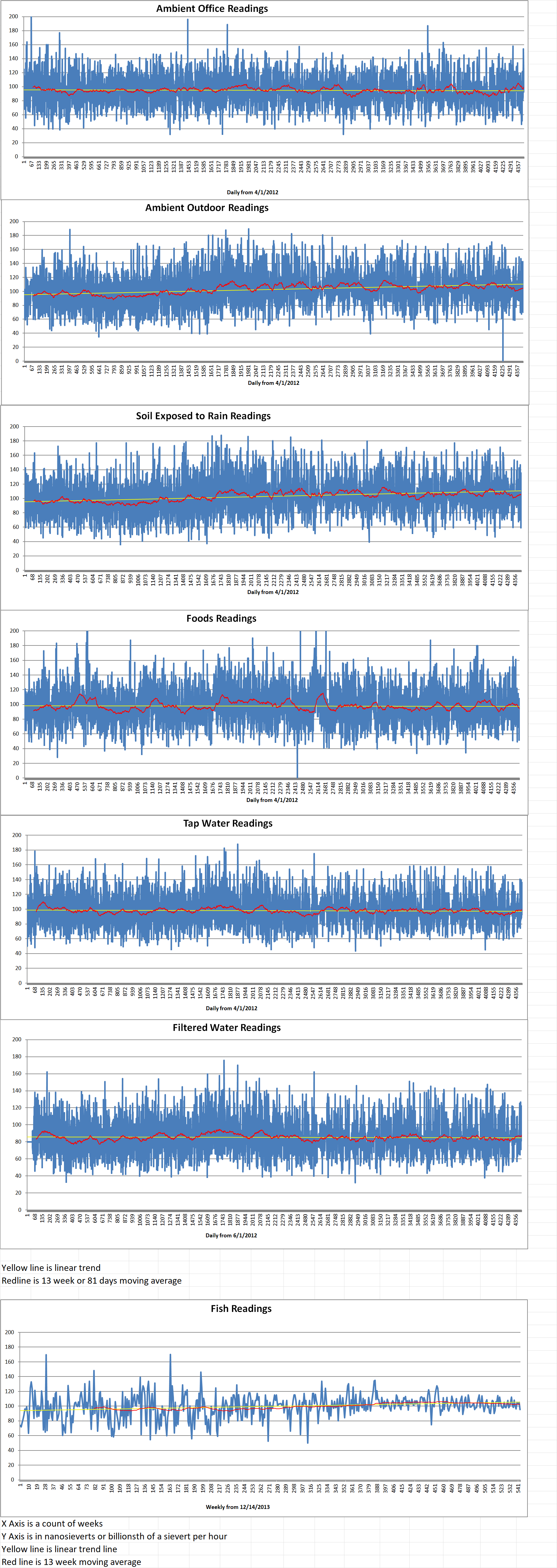

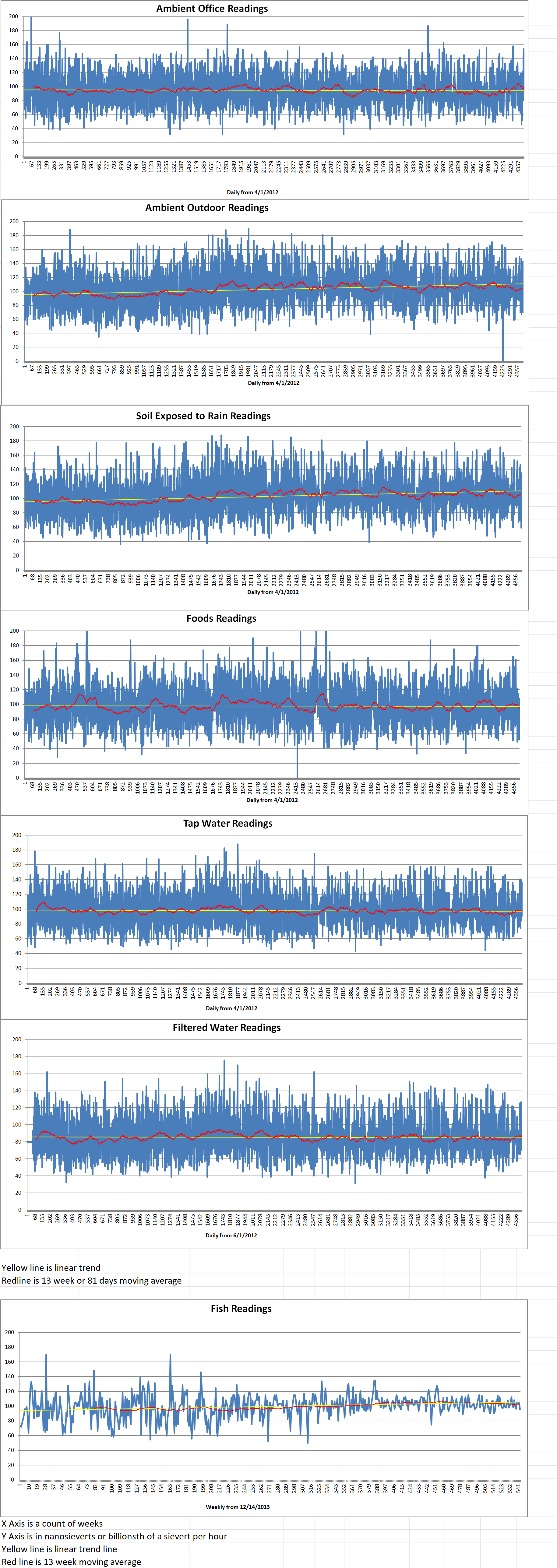

Geiger Readings for Nov 28, 2024

Ambient office = 80 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 104 nanosieverts per hour

Hydroponic tomato from Central Market = 80 nanosieverts per hour

Tap water = 93 nanosieverts per hour

Filter water = 83 nanosieverts per hour

-

Nuclear Fusion 90 – Japanese FAST Project Intends To Create Commercial Fusion Reactors By The Late 2030s

The Fusion by Advanced Superconducting Tokamak (FAST) project has been launched in Japan with the goal of achieving fusion-based commercial power generation by the end of the 2030s.

The FAST project, to be sited in Japan, intends to generate and sustain a plasma of deuterium-tritium (D-T) fusion reactions. This will demonstrate an integrated fusion energy system that combines energy conversion, including electricity generation and fuel technologies. The Project will employ a tokamak configuration which was chosen for its well-established data and scalability. The FAST Project has collected top researchers from prominent institutions, along with industrial and international partners from Japan, the UK, the USA and Canada.

The FAST Project Office is targeting a power generation demonstration by the end of the 2030s. It will address remaining technical challenges on the way to commercial fusion power plants. The FAST Project points out that power generation refers to producing energy from fusion reactions. However, it does not imply net positive power production where electricity output exceeds electricity consumption.

The FAST Project Office said, “While previous or near-term planned fusion experiments have achieved, or will soon achieve, medium-pulse plasma discharges to de-risk the plasma confinement and control for a fusion pilot plant, critical obstacles remain in harnessing the energy transport for sustained external use, establishing the tritium fuel cycle, including tritium breeding, and integrating these advances into a configuration that represents a commercially viable fusion power plant. At present, no experimental device worldwide is capable of creating the necessary fusion environment – the fusion neutron flux and relevant thermal loads – to bridge the gap between the advanced plasma experiments of today and the desired end goal of practical energy extraction.”

FAST intends to fill these gaps by “providing a comprehensive and unique platform to develop technologies applicable to practical fusion power plants worldwide, including demonstration devices and fusion pilot plants”.

The FAST design is a tokamak configuration, which the Project Office says is “a well-established plasma confinement method with the most extensive database and specifically employs a low-aspect-ratio tokamak design, and high-temperature superconducting (HTS) coils, which enables a compact design allowing lower costs and a shorter construction time”.The system aims for a power generation of fifty to one hundred megawatts and a discharge duration of one thousand seconds of D-T fusion burn. High-temperature blankets allow testing of multipurpose uses for thermal power and neutrons. The device will function for a cumulative one thousand hours of full-power operation.

The Project Office said, “The FAST project will advance through collaboration with key universities and research institutions both domestically and internationally. Moving forward, a conceptual design team will be organized, composed of plasma researchers and power plant engineering researchers. The preliminary design is expected to be completed within the year 2025. A thorough evaluation of the internal and external environment, including technology, funding, regulation and policy, will be conducted at the transition to detailed design, where a decision will be made on the feasibility of execution.”

The Project Office continued, “In parallel, led by Kyoto Fusioneering, we will accelerate technology development in key systems, engineering design, site selection, and regulatory efforts in collaboration with industrial partners such as Mitsui & Co Ltd, Mitsui Fudosan Co Ltd, Mitsubishi Corporation, Marubeni Corporation, Fujikura Ltd, Kajima Corporation and Furukawa Electric Co Ltd. We will continue to actively welcome researchers, industrial partners, including companies participating in J-Fusion, and international collaborators to join and contribute to the project.”Fusion Energy Power Generation Demonstration Project

-

Nuclear News Roundup Nov 27, 2024

NANO Nuclear (NNE) Expands in Africa With Togo Deal: What’s Going On? Benzinga.com

How emergency testing works at Arizona’s Palo Verde nuclear plant azfamily.com

Lawmaker needles Michigan nuclear plant owner over cuts to taxes flowing to schools mlive.com

Nigerien authorities in control of SOMAÏR operations – Orano world-nuclear-news.org

-

Geiger Readings for Nov 27, 2024

Ambient office = 107 nanosieverts per hour

Ambient outside = 92 nanosieverts per hour

Soil exposed to rain water = 90 nanosieverts per hour

Green onion from Central Market = 100 nanosieverts per hour

Tap water = 93 nanosieverts per hour

Filter water = 83 nanosieverts per hour

-

Nuclear Fusion 89 – OpenStar Technologies Is Exploring A Levitating Dipole Reactor For Commercial Nuclear Fusion

OpenStar Technologies, a New Zealand-based fusion research company, has reached a key milestone by generating its first plasma. Nuclear fusion research is exploding across the globe. OpenStar has adopted a novel approach to achieving commercial fusion energy that does not utilize a tokamak or stellarator design for its device. It is working on a levitated dipole reactor (LDR).

Nuclear fusion on Earth works by replicating the process that stars use to generate energy. Inside a star, high temperature and pressure force nuclei of lighter atoms to fuse into larger atoms and release tremendous amounts of energy.

Replicating the stellar fusion process on Earth would generate energy without any carbon emissions or radioactive waste. Nuclear fusion research has been going on for decades but has recently accelerated. Multiple approaches are being attempted to attain a net energy gain from this process.

Tokamaks and stellarators are popular designs for nuclear fusion reactors and have shown great promise. However, OpenStar has taken a riskier approach by opting for an LDR design.

A dipole system contains separated positive and negative charges. Such systems can be built in the lab, and they also occur naturally in nature. Nuclear fusion reactions require temperatures of several hundred million degrees. OpenStar researchers believe that dipoles can accommodate this heat and be scaled to build a fusion machine.

Many fusion researchers utilize a magnetic field to confine the high-temperature plasma in a fusion reactor from hitting the walls. OpenStar’s approach achieves the same goal by constructing a magnetosphere similar to the one that exists around planets.

In the magnetosphere, the highest-energy particles find their way toward the poles (in this case, the support system of the reactor). OpenStar avoids this problem by using levitation to keep the plasma within its doughnut-shaped reactor. The advantage of the LDR is that it does not have a lot of stored energy or “plasma current” that can potentially blow up the reactor in the case of other designs.

OpenStar magnets utilize high-temperature superconductors (HTS). These are made of rare earth barium and copper oxides (REBCO) and can produce magnetic fields as strong as 20 Tesla. The Earth’s natural magnetic field is about fifty microteslas.

OpenStar uses a helium gas loop to achieve temperatures of fifty Kelvin (-223 degrees Celsius) for the HTS magnets to operate in and create dipoles for the fusion reaction. The advantage of using an HTS magnet in this design is that it can be built faster and iterated quickly.

Since the plasma in an LDR is stable and turbulence is not much of an issue, the team at OpenStar can create long pulse lengths for it. In the five trial shots they recently ran, the pulse length was between five and twenty seconds.

Limiting pulse lengths to this time was necessary to gather the data required for their analysis. The LDR reactor is only at a prototype stage. However, achieving first plasma sets the stage for further technological advances in the years to come.

OpenStar is hopeful that its LDR reactor can begin generating electricity as early as 2030. -

Nuclear News Roundup Nov 26, 2024

Putin Ally Predicts Nuclear ‘Radiation Zone’ Could End War in Ukraine newsweek.com

South Africa ‘committed to new nuclear and PBMR’ world-nuclear-news.org

‘Third nuclear age’ threatens the West, armed forces chief warns bbc.com

Backfilling of Gorleben mine starts world-nucleawr-news.org

-

Geiger Readings for Nov 26, 2024

Ambient office = 93 nanosieverts per hour

Ambient outside = 143 nanosieverts per hour

Soil exposed to rain water = 135 nanosieverts per hour

Blueberry from Central Market = 108 nanosieverts per hour

Tap water = 136 nanosieverts per hour

Filter water = 122 nanosieverts per hour

-

Nuclear Fusion 88 – The Princeton Plasma Physics Laboratory Has Completed New Magnets For It’s Prototype Nuclear Fusion Reactor

The Princeton Plasma Physics Laboratory (PPPL) has just announced the completion of the complex process of building the first quadrant of the magnet at the heart of the National Spherical Torus Experiment-Upgrade (NSTX-U) nuclear fusion reactor. This is a major milestone for the PPPL’s nuclear fusion project, which comes under the U.S. Department of Energy (DOE).

PPPL said that “it is assembling two high-current magnets to create the toroidal field-ohmic heating coil (TF-OH) bundle. The magnets make up the core of the NSTX-U, similar to the core of an apple. They are designed to produce the highest magnetic field strength of any large spherical torus.”

The toroidal field (TF) coil is a nineteen-foot-tall inner magnet which resembles a telephone pole. The TF carries up to four million amps of electric current to stabilize and confine the hot plasma in fusion experiments, according to a press release by PPPL.

There will also be an outer magnet called the ohmic heating (OH) coil. It is a four-kilovolt magnet that wraps around the TF coil like thread around a bobbin.

The press release stated that “It uses up to twenty four thousand amps to induce an electric field that drives an electric current within the vessel and helps heat the plasma”.

Steve Cowley is the PPPL director. He said that “These magnets are critical to the NSTX-U experiment, and the team has been laser focused on this assembly. Constructing the first quadrant is a big achievement.”

The PPPL states that the quadrants are going through a process called vacuum pressure impregnation (VPI). In this process, pieces of the TF coil “pie” are baked together into one very tall, solid piece of pie.

The quadrant was constructed by technicians at Elytt Energy in Bilbao, Spain in July. Preliminary electrical tests conducted on the quadrant in August showed that the process was successful.

Dave Micheletti is the division director of major science and engineering projects at the PPPL. He said that the team is now looking forward to the time “when the entire magnet is complete.”

The NSXT-U recovery team has completed many critical components of the nuclear fusion device. Once the center stack magnets are installed, the team can start focusing on reassembling and testing the NSTX-U.

Engineers have designed the TF coil and OH coil so the strong magnets will be powerful enough to confine the plasma during nuclear fusion experiments, which can occur every 20 minutes while the experiment is operating.

The NSTX-U is currently the primary nuclear fusion experiment at PPPL. The spherical fusion device is shaped more like a cored apple than the doughnut-like shape of conventional tokamaks. It can produce high-pressure plasmas with relatively low and cost-effective magnetic fields.

Using both neutral beams and high-power radio waves, the NSTX-U will heat the plasma to one hundred million degrees Celsius. This is seven times hotter than the Sun.

According to the PPPL, the NSTX-U’s compact design makes it an ideal candidate to serve as the model for a nuclear fusion pilot plant followed by a commercial fusion reactor.

The NSTX-U recovery project is eighty-four percent complete, and it has seen participation from scientists around the globe.

PPPL’s end goal is to seek assistance from around the globe to help PPPL and the world figure out the best way to build commercial nuclear fusion reactors.