Part 5 of 5 Parts (Please read Part 1, 2, 3 and 4 first)

The melters are designed for an annual throughput of about one million seven hundred and fifty million to two million gallons of tank waste each year. Each melter has a five-year operating life span. A third melter will be constructed onsite before any treatment of waste begins. The whole low-level treatment facility has an intended life span of forty years. DoE claims that outstanding technical and design issues have been solved and signed off on by the State of Washington.

The high-level waste processing facility remains in the design stage. It is not clear exactly when this facility will be finished or if it ever will be. There are nine major technical challenges which have been resolved, two of them were dealt with last August. Olds says that “I would be jumping ahead to give you a conclusion.”

Adding to the uncertainty, DoE proposed new guidelines last June which would reclassify some of the high-level waste as low-level waste. Hanford watchdog groups adamantly oppose this reclassification and the governor of Washington State says that it is “reckless.” Some local groups support the reclassification scheme because it should speed up the cleanup and further Hanford redevelopment. The reclassification proposal was explicitly banned from the spending bill that passed the U.S. House of Representatives. DoE officials at Hanford state that they have not officially committed to any changes in classification.

The U.S. Corp of Engineers performed an analysis of options and budget scenarios that may be necessary in order to reach key consent decree milestones for the high-level waste treatment facility and the pretreatment plant. The analysis reports that there is a low probability that the deadlines can be met under the current funding levels. The DoE has contracted an independent firm which will develop alternatives by late 2019 in order to aid future decisions.

Tom Carpenter is the executive director of leading site watchdog group Hanford Challenge. He says that no facility at the Vit Plant should be put into operation until there has been a complete and independent inspection that validates and verifies the quality of nuclear treatment in the Vit Plant. He says, “DOE seems to be doing everything in its power to simply walk away from its legal and moral obligations to deal with Hanford’s extraordinary radioactive waste inventories. I seriously doubt the high- level waste facility will ever operate for numerous reasons, and DoE will simply find that the waste is low-level, not high-level, dump concrete on the whole mess and call it good.”

Carpenter does support the vitrification of waste at Hanford. However, he is concerned about what he says are consistent design flaws, a lack of quality control and a “poor nuclear safety culture” at Hanford. He points out that there have been lawsuits involving whistleblowers as well as reassignment of employee who have raised safety concerns. For the moment, DoE and Hanford are focusing on the ninety percent of Hanford tank waste that is low-level. They are confident that they will be able to treat it successfully in the low-level waste treatment facility. McCain says, “There have been quality issues in the past that slowed things, but those have been addressed. Having legacy issues behind us was a big burden off the project.”

He goes on to say that in view of the fact that the vitrification project at Hanford will need hundreds of millions of dollars a year to meet the milestones and agreements that are in effect, it will be “critically important for DOE and its regulators to identify ways to reduce the long-term cost and schedule for Hanford cleanup.”

Blog

-

Radioactive Waste 415- Status Of Vitrification Plant At Hanford – Part 5 of 5 Parts

-

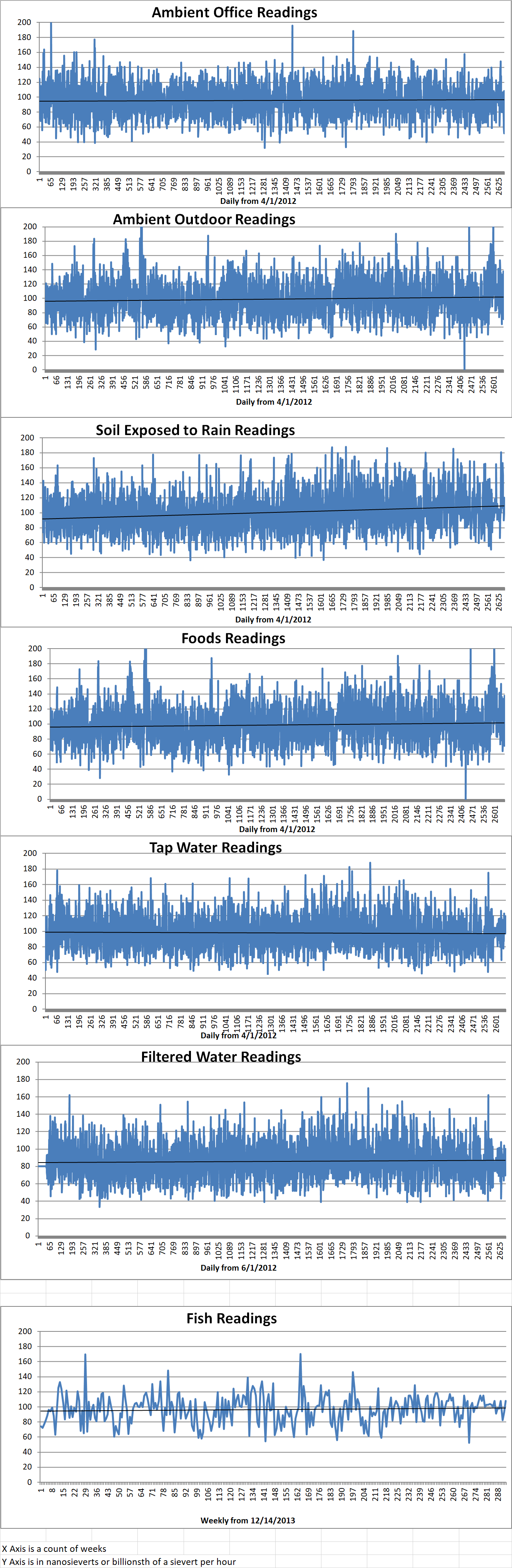

Geiger Readings for Oct 09, 2019

Ambient office = 108 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 102 nanosieverts per hour

Bartlett pear from Central Market = 71 nanosieverts per hour

Tap water = 119 nanosieverts per hour

Filtered water = 100 nanosieverts per hour

-

Radioactive Waste 414- Status Of Vitrification Plant At Hanford – Part 4 of 5 Parts

Part 4 of 5 Parts (Please read Part 1, 2 and 3 first)

The next major test will be what is called a “loss of power” test. This is a critical test needed in order to start the two vitrification melters. Once these melters reach their operating temperature, they can never be shut down. This test will take twenty-eight days. It is intended to determine whether the system has sufficient backup power to weather an emergency situation where normal power has been lost. The test is scheduled for late 2020. It must take place ahead of the 2021 commissioning deadline and the 2022 glass manufacturing. The control room for the Vit Plant is already operating twenty-four hours a day, seven days a week. The analytical lab staff is able to operate offsite on the same equipment that will be moved onsite next year.

About eleven million gallons of waste are currently staged to be pumped into the facility. Olds says “To have actual discussions about operations … on site is a great place to be.” The Hanford tank farm is run by AECOM-led Washington River Protection Solutions. They will stage the waste and deliver it to a separation process tank.

Rick Holmes is the general manager for the Waste Treatment Completion Company. This is a joint venture between AECOM and Bechtel. Holmes says that the task of sending semi-liquid waste from the tanks across the Hanford site to the Vit Plant poses some serious technical challenges. Once the waste stream arrives at the Vit Plant which is managed by Bechtel, it will be analyzed in the onsite laboratory and then processed into vitrified glass.

Holmes says that one concern in the turnover and handover phase is the fact that some of the equipment was installed in 2002 and it must meet current protocol standards. This will require extensive testing and probably some alterations. The final step in the vitrification system will be to transport the vitrified waste to a one million cubic yard on-site disposal facility that cost twenty-five million dollars. It is operated by CH2M Plateau Remediation Ltd., a Hanford contractor.

The new approach with separation of the waste into two streams required the construction of both a new effluent management facility as well as the low-level waste facility. The effluent management facility will deal with secondary waste liquid that will be generated during treatment of the original waste stream. The low-level treatment facility is a three hundred and thirty feet long, two hundred and forty feet wide and ninety feet high concrete structure. It is designed to mix the waste with silica and other materials needed to make glass before it reached the two three-hundred-ton melters.

The worlds biggest waste glass melters are twenty feet by thirty feet by sixteen feet tall. They will make vitrified glass in containers that are seven feet long and four feet in diameter. Each container will weigh over seven tons. During operation of the Vit Plat, the melters will produce thirty tons of glass daily. This is ten times the capacity of the melters used at the DoE Savannah River site.

Holmes says that DoE and Pacific Northwest National Laboratory scientists will custom tailor the mixture recipe for each batch of waste that is processed. He goes on to say, “Nothing I have ever done has prepared me for this. The scale is a pretty significant leap.”

Please read Part 5 -

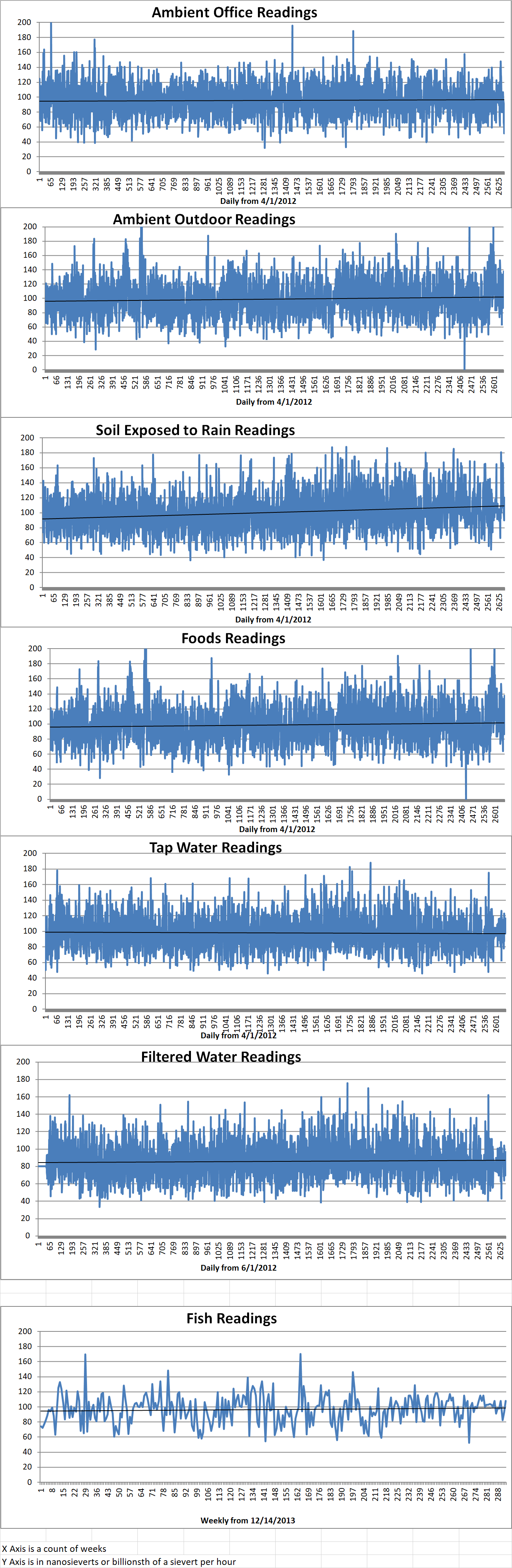

Geiger Readings for Oct 08, 2019

Ambient office = 52 nanosieverts per hour

Ambient outside = 106 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Blueberry from Central Market = 138 nanosieverts per hour

Tap water = 116 nanosieverts per hour

Filtered water = 97 nanosieverts per hour

-

Radioactive Waste 413- Status Of Vitrification Plant At Hanford – Part 3 of 5 Parts

Part 3 of 5 Parts (Please read Part 1 and 2 first)

The draft study laid out options that might help the project such as expanding the plant which could push costs to twenty billion dollars or more. They also suggested that perhaps a cheaper treatment system could be utilized such as using grout or fluidized-bed stream reforming that would result in a ceramic-like material instead of glass. Unfortunately, these alternatives have not been fully developed or tested. If they are attempted, the cost could rise even further. DoE and Washington State announced in September that they would hold a new round of talks in November to discuss cleanup strategies and deadlines. It has been suggested that a professional mediator could be employed for the talks which could extend into next summer.

While work on the high-level waste facility remains stalled, the DoE says that it is tightly focused on starting up the low-level waste treatment by 2023. Once it is turned on, it will be able to function twenty four hours a day, seven days a week, three hundred and sixty five days a year. Valerie McCain is the Bechtel principle vice president and Vit Plant project director. She said that “We are really at a stage we have never been at before. People can see the end is in sight.”

It may be premature to talk about the end being in sight. It is now estimated that it may take until 2100 to completely clean up Hanford. Future cost estimates span the range from three hundred billion dollars to almost seven hundred billion dollars. About seven hundred million of that is dedicated to the low-level waste facility each year. However, uncertainty about annual funding levels for the Vit Plant is impeding progress.

The 2020 budget submitted by the Trump administration cut about three hundred and eighty million dollars from the overall Hanford site cleanup. The House of representatives 2020 spending bill restored the funds cut in the Presidents budget request. Still, that is about thirty-seven million dollars less than the cleanup funding for 2019. The Senate 2020 spending bill is still in committee, but it does suggest that more money than the House spending bill be dedicated to Hanford cleanup.

Republican Washington State Representative Dan Newhouse serves the district where Hanford is located. He says that he is constantly monitoring the cleanup and is confident that the low-level waste facility will be operational within the deadline. He said, “The federal government has a legal and moral obligation to complete the cleanup, and we must ensure the significant resources going toward the effort.”

There has been a great deal of progress in connecting the Vit Plant facilities. Supporting facilities and systems have been constructed. A large amount of the interlocking piping system, as well as electrical and utilities infrastructure have been completed. There are one hundred and eighty subsystems in the low-level waste management facility. Of those, about sixty have been completed and startup and testing are underway. Another ninety-two systems are in startup, and the last twenty-four systems are nearing the point in construction where they will be turned over to startup.

Please read Part 4 -

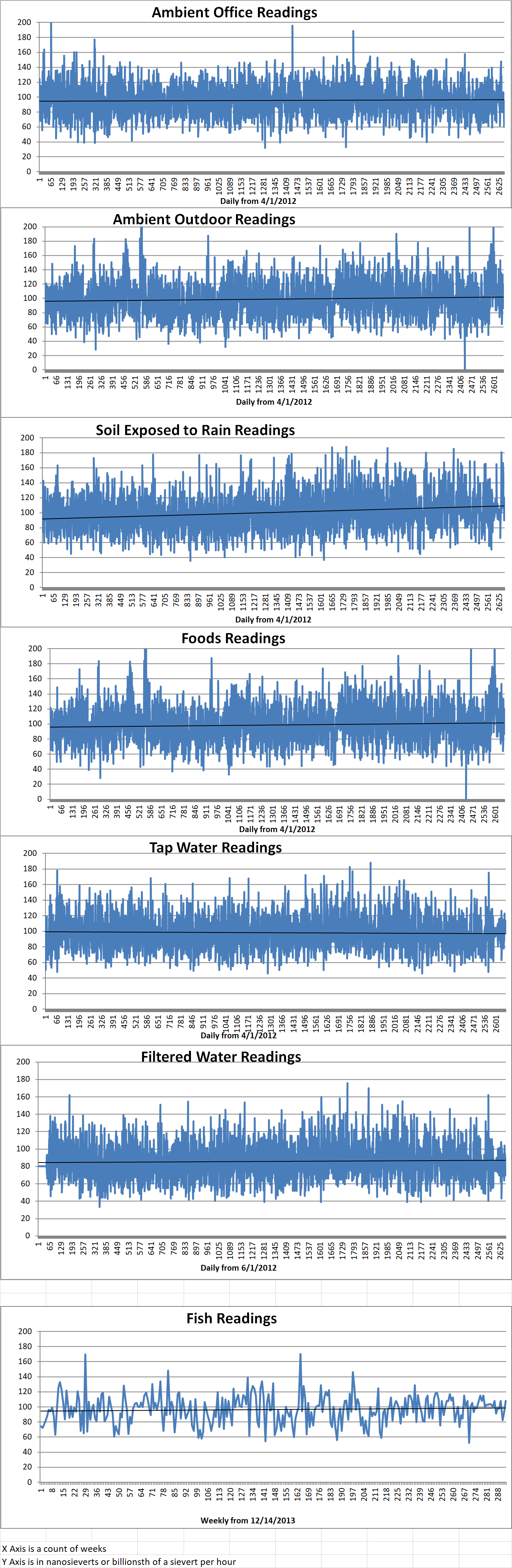

Geiger Readings for Oct 07, 2019

Ambient office = 60 nanosieverts per hour

Ambient outside = 119 nanosieverts per hour

Soil exposed to rain water = 120 nanosieverts per hour

English cucumber from Central Market = 102 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filtered water = 70 nanosieverts per hour