The company that operates upstate New York’s three nuclear power plants is planning a $20 million push over the next decade to focus on clean energy and environmental technology. spectrumlocalnews.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

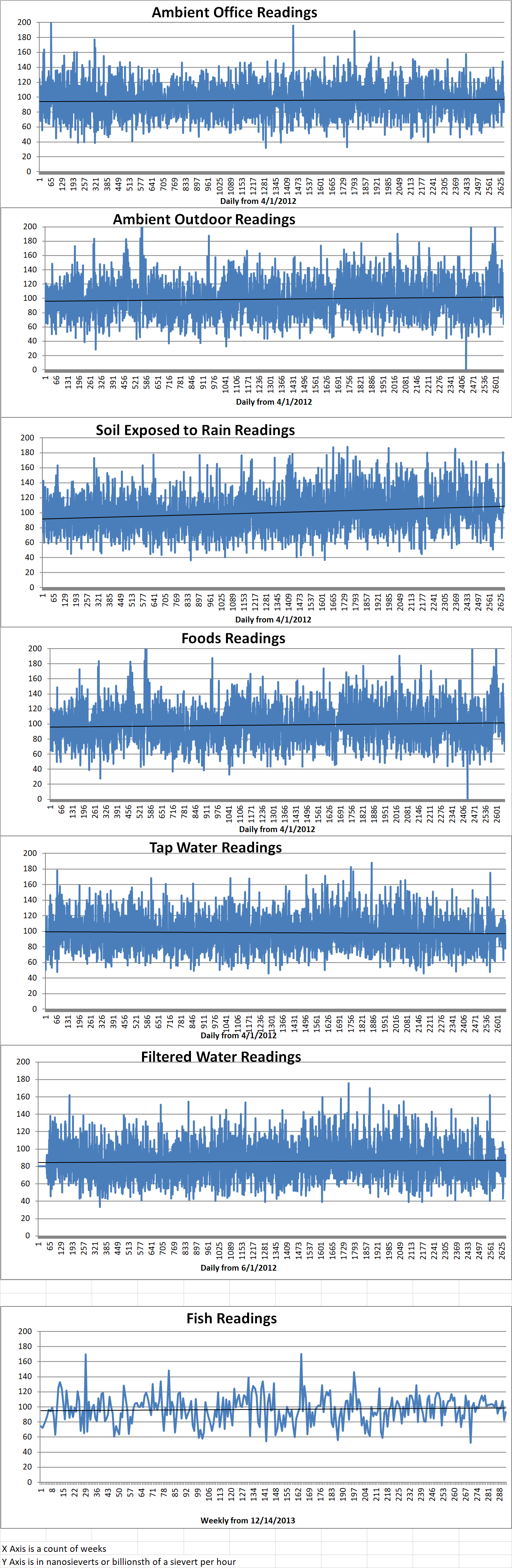

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

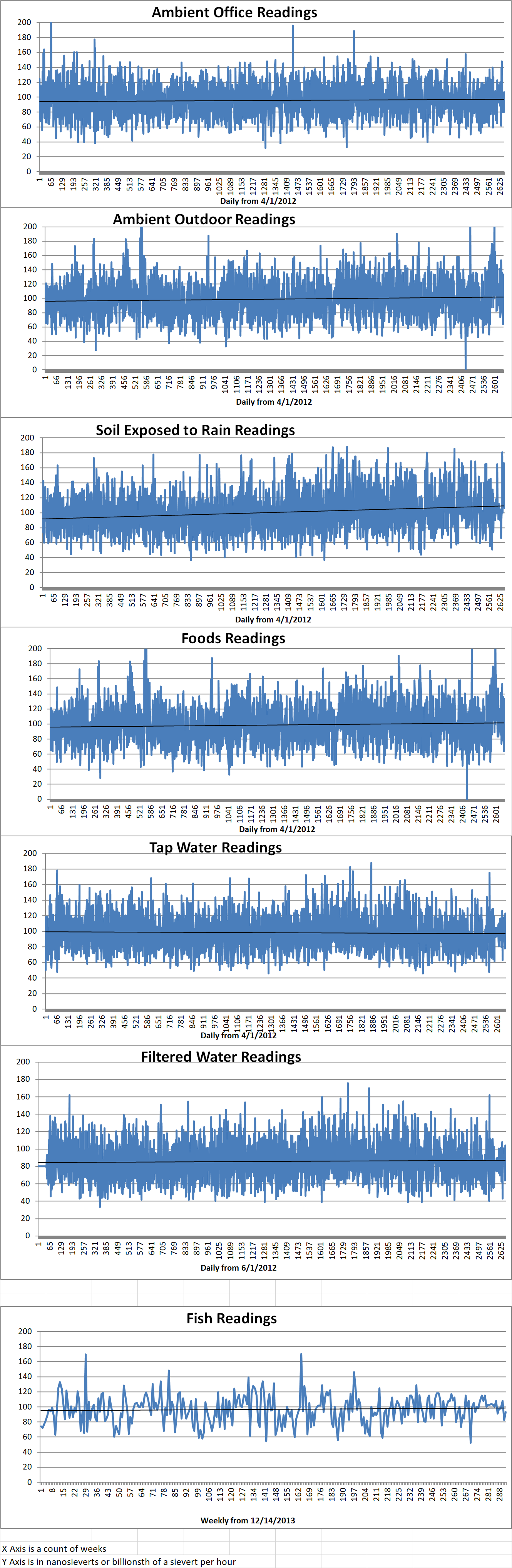

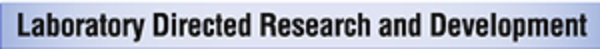

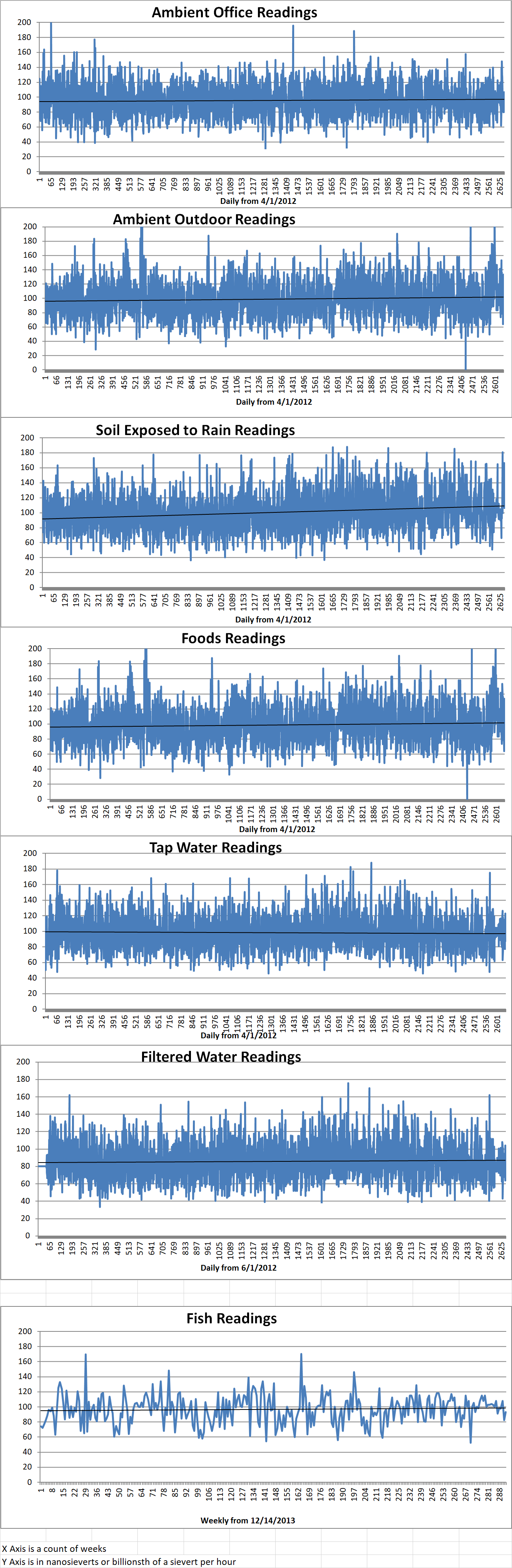

Ambient office = 87 nanosieverts per hour

Ambient outside = 102 nanosieverts per hour

Soil exposed to rain water = 106 nanosieverts per hour

Red bell pepper from Central Market = 89 nanosieverts per hour

Tap water = 115 nanosieverts per hour

Filtered water = 93 nanosieverts per hour

Part 2 of 2 Parts (Please read Part 1 first)

In the first series of tests, a few grams of molten lead oxide power were used to simulate corium in a desktop setup. The lead oxide was heated to eighteen hundred degrees Fahrenheit. When the lead oxide was molten, it was poured over granular calcite. In a control test for the experiment, the molten lead oxide was also poured over sand which is granular silicon dioxide.

Louie said, “We saw that the injectable carbonate minerals work. It reacted chemically to produce a lot of carbon dioxide, which ‘leavened’ the lead oxide into a nice cake-like structure. The reaction itself had a cooling effect, and all the pores in the ‘cake’ allow for further cooling.” In the control test with sand, nothing significant happened which was expected.

Following the first small experiments, kilograms of molten lead oxide and granular calcite were used in more tests. The control tests were also carried out with kilograms of sand. As expected, the expanded tests yielded the same results showing that injecting granular carbonates might be a promising solution that could help prevent the spread of corium in a nuclear accident.

During the final year of the project, Louie, Wang, Alec Kucala, Rekha Rao and Kyle Ross translated the results of their physical experiments into MELCOR models. They constructed an accident scenario in the software in order to model exactly how the injectable carbonates might affect a real nuclear reactor accident that was similar to the Fukushima accident in March of 2011 in Japan.

Problems with corium spread have been highlighted by what happened following the Fukushima accident. There was a major earthquake to the northeast of Japan in March of 2011. The earthquake resulted in a tsunami that hit the coast of Fukushima and flooded the emergency generators at the Fukushima nuclear power plant on the coast of Fukushima. Unable to cool the reactors following the accident, the operators could not stop the meltdown of three reactors. Corium formed in all three reactor cores and proceeded to meltdown through the bottom of the reactor vessels. A great deal to time, technology, manpower and money has been expended in the eight years since the Fukushima nuclear disaster and knowledge of the current location of the corium from the three reactors that experienced the meltdowns is still uncertain.

The situation at Fukushima underscores how important results of the research project at Scandia into retarding the spread of corium following a major nuclear accident are. If the patented carbonate minerals patented recently at Scandia had been available at Fukushima in 2011, the custodians of the damaged reactors would not still be searching for the corium.

The Scandia research team has what is called a “non-provisional” patent for the injectable minerals that they developed and tested. A provisional patent is simple, informal and quick to file. It allows the patentor to take measure to protect their patent as quickly as possible. A non-provisional patent is long, complicated and difficult to follow. Unlike a provisional patent, a non-provisional patent can be used to issue an enforceable claim. Provisional patents applications are usually followed by non-provisional patent applications.

Louie says, “After that, we’d be ready to commercialize the technology. These materials could be retrofitted into any existing nuclear reactor design.”

Iran’s president rejects nuclear talks before sanctions are lifted theguardian.com

Japan high court rejects residents’ appeal to halt nuclear reactors. English.kyodonews.net

An “undeclared phaseout” of the nuclear industry. Thebulletin.org

Ambient office = 107 nanosieverts per hour

Ambient outside = 109 nanosieverts per hour

Soil exposed to rain water = 106 nanosieverts per hour

Blueberry from Central Market = 134 nanosieverts per hour

Tap water = 114 nanosieverts per hour

Filtered water = 91 nanosieverts per hour

Part 1 of 2 Parts

When a nuclear reactor melts down, a substance is formed called corium which is composed of nuclear fuel, fission products, control rods, structural materials and other components forms. The corium proceeds to melt through the reactor vessel and continues melting through the soil and rock below the reactor building.

The Sandia National Laboratory researches all aspects of nuclear energy. This extends from uranium production, fuel rod manufacture, transportation, reactor design, and disposal of spent nuclear fuel. One of their goals is to be sure that all of these activities can be carried out as safely as possible. MELCOR software was developed as part of Scandia’s mission. It allows the modeling of nuclear accidents and the spread of corium. Scandia seeks to model catastrophic accidents to identify the causes and to study how changes to the scenarios might result in different outcomes.

During a three-year Laboratory Directed Research and Development project at the Scandia National Laboratory, a team of researchers discovered and patented a new process for creating a special sand-like mixture of minerals that can be injected into the core of a nuclear reactor during an accident. The result is that the spread of corium is slowed considerably, and the meltdown will be less severe.

The researchers on the project created computer models with software called MELCOR mentioned above that tracks the formation and spread of corium during a meltdown. David Louie is a nuclear engineer at Scandia. He said, “During a severe reactor accident, the vessel that contained the fuel melts and ruptures, and then all that stuff falls out on the containment floor and starts spreading.” He went on to say that although nuclear accidents are very rare, the consequences can be very extreme for people and the environment. In addition, there is a very negative impact on the public trust in nuclear safety.

When corium spreads during a meltdown, it increases the release of radioactive materials. Corium melts through the reactor building floor and seeps into the soil. It chemically reacts with any materials that it comes into contact with. One example is what happens when corium comes into contact with concrete. The chemical reaction releases hydrogen gas which could lead to a serious explosions.

During actual nuclear reactor meltdowns and in computer modeling of accidents, the usual procedure is to inject water into the reactor to try to cool the corium. Unfortunately, this procedure does not cool the corium fast enough to prevent the radioactive contamination from spreading beyond the reactor core. Louie said, “Eventually corium stops spreading because water will cool it down. But you don’t want the accident to get worse and worse while you’re working to bring water in. The water also provides a source of explosive hydrogen.”

Louie, Yifeng Wang, Jessica Kruichak and other members of the Scandia team researched and tested natural carbonate minerals such as calcite and dolomite. Their research was aimed at determining whether any of the tested minerals could help contain the corium and slow or eliminate the progress of it spreading.

Please read Part 2

The US uranium industry awaits President Trump’s Nuclear Fuel Working Group findings. Investorintel.com

In a war that never happened, formations of heavy and rather odd-looking Soviet tanks would have powered through atomic explosions in breakthrough attacks into West Germany. Nationalinterest.org

Estonia Startup Hopes to Build First Small Modular Nuclear Reactor bloombergenvironment.com

Ambient office = 91 nanosieverts per hour

Ambient outside = 147 nanosieverts per hour

Soil exposed to rain water = 150 nanosieverts per hour

Blueberry from Central Market = 119 nanosieverts per hour

Tap water = 123 nanosieverts per hour

Filtered water = 104 nanosieverts per hour

Ambient office = 80 nanosieverts per hour

Ambient outside = 159 nanosieverts per hour

Soil exposed to rain water = 164 nanosieverts per hour

Blueberry from Central Market = 81 nanosieverts per hour

Tap water = 87 nanosieverts per hour

Filtered water = 64 nanosieverts per hour