Boris Johnson calls for new nuclear deal with Iran. Ft.com

Ohio law lets political action groups keep funders secret during drive to let voters get a say on nuclear subsidies. Energynews.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

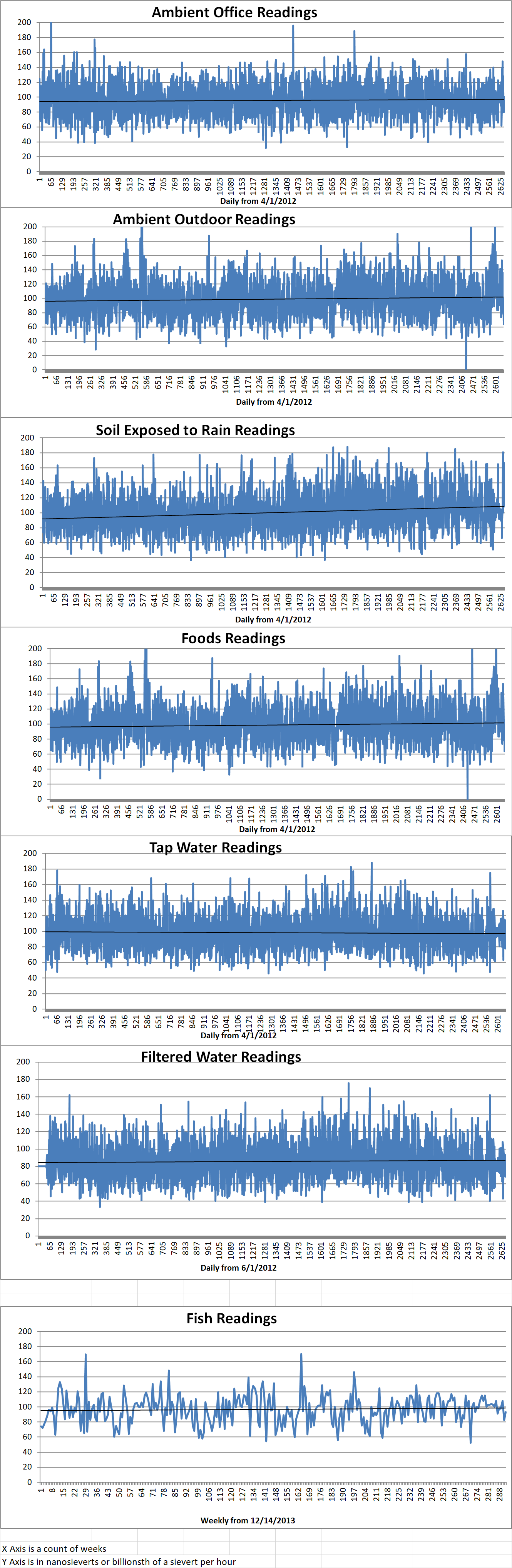

Ambient office = 101 nanosieverts per hour

Ambient outside = 166 nanosieverts per hour

Soil exposed to rain water = 166 nanosieverts per hour

Blueberry from Central Market = 64 nanosieverts per hour

Tap water = 108 nanosieverts per hour

Filtered water = 86 nanosieverts per hour

Dover sole – Caught in USA = 93 nanosieverts per hour

I recently blogged about Congressional hearings that were called to consider problems with new U.S. nuclear weapons programs. It appears that faulty electrical components that were purchased on the retail marked for electronics resulted in huge cost overruns and delays. I now have more details on those problems to share.

Congress and the Trump administration revealed yesterday that a five dollar electrical component used on two types of new nuclear weapons will require at least seven hundred and twenty five million dollars in fixes. Tests in April of this year showed that a glitch in the cheap capacitor used in both the B61-12 gravity bomb program and the program to modify W88 submarine launched warheads. The problem had been made public earlier this year but the low cost of the capacitor and the high cost of dealing with the problem have not been made public before.

This situation makes clear that there are serious problems with the increasing use of the off the shelf components from the retail market being used in highly classified nuclear weapons programs. Congress is worried that the problems encountered in the B61-12 and W88 projects may be recur in other weapons programs.

A problem with a small, simple part in a very complex nuclear weapon can trigger a cascade of effects that require significant and expensive changes. As one official said, “It’s not like changing a spark plug.”

It is estimated that fixing the problem caused by the cheap capacitor for the B61-12 will cost between six hundred million dollars and seven hundred million dollars. The cost for fixing the problem with the W88 program is estimated to cost between one hundred twenty five million dollars and one hundred fifty million dollars. So the total cost for fixes to these two programs will be between seven hundred twenty five million dollars and eight hundred fifty million dollars.

These estimates were delivered at a House Armed Services panel hearing by Charles Verdon, deputy administrator for defense programs at the Energy Department’s National Nuclear Security Administration. The five dollar commercial capacitor that cost five dollars will be replaced by a better capacitor that cost seventy five dollars. Jim Cooper is a Tennessee Democrat who is the chairman of the Subcommittee on Strategic Forces was at the hearing. He said, “In rough figures, due to the effect of a failure in a component that costs less than $100, taxpayers will face charges on the order of close to $1 billion.”

Fixing the problems caused by the use of the cheap capacitor will take between eighteen and twenty months additional time before the first production models of these new weapons systems. First estimates of the delay were between one year and eighteen months.

The B61-12 nuclear gravity bomb is intended to replace four different types of nuclear bottoms now in the U.S. nuclear arsenal. The W88 Alteration 370 upgrade is intended to replace a subsystem that helps detonate the W88 submarine launched nuclear warhead. The total estimated cost for these two programs is now twelve billion dollars. Verdon commented that he hopes that his agency will be able to divert funding from other nuclear weapons programs in the future to pay for the fixes to the B61-12 and W88 upgrade programs.

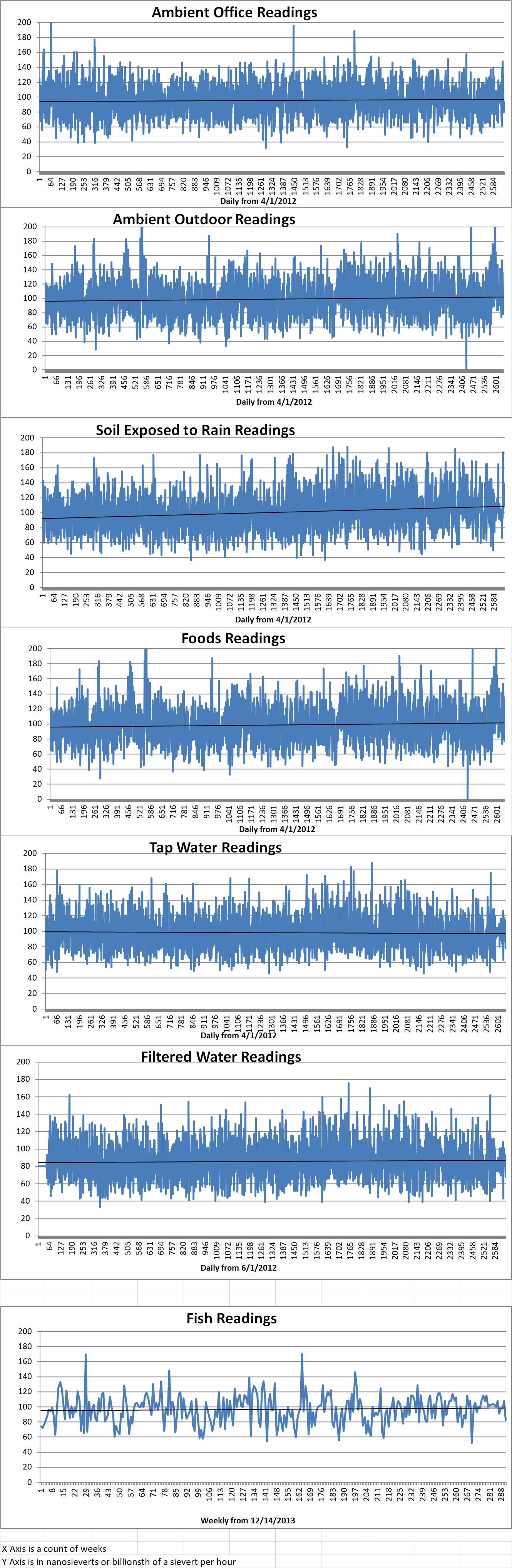

Ambient office = 89 nanosieverts per hour

Ambient outside = 126 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Blueberry from Central Market = 100 nanosieverts per hour

Tap water = 78 nanosieverts per hour

Filtered water = 68 nanosieverts per hour

Part 2 of 2 Parts

Once the Finnish plant is completed, spent nuclear fuel will arrive in transportation canisters at the receiving area of the plant. Empty final disposal canisters will also be delivered to the receiving area. At the encapsulation plant, the transportation canisters and the empty disposal canisters will be tightly docked inside the fuel handling cell. Inside the cell, the spent fuel will be moved from a transportation canister to the drying area and then to a final disposal canister. When all the fuel assemblies from the transportation canister have been dried and placed in the final disposal canister, the final disposal canister will be filled with argon gas and tightly sealed with an inner steel cover.

The final disposal canisters that have been filled and sealed will then be moved to a welding station where the canister lid will be sealed with electron beam welding. This type of welding results in a strong, tight seam. The integrity of the weld will be checked with non-destructive testing such as x-ray or ultrasonic tests.

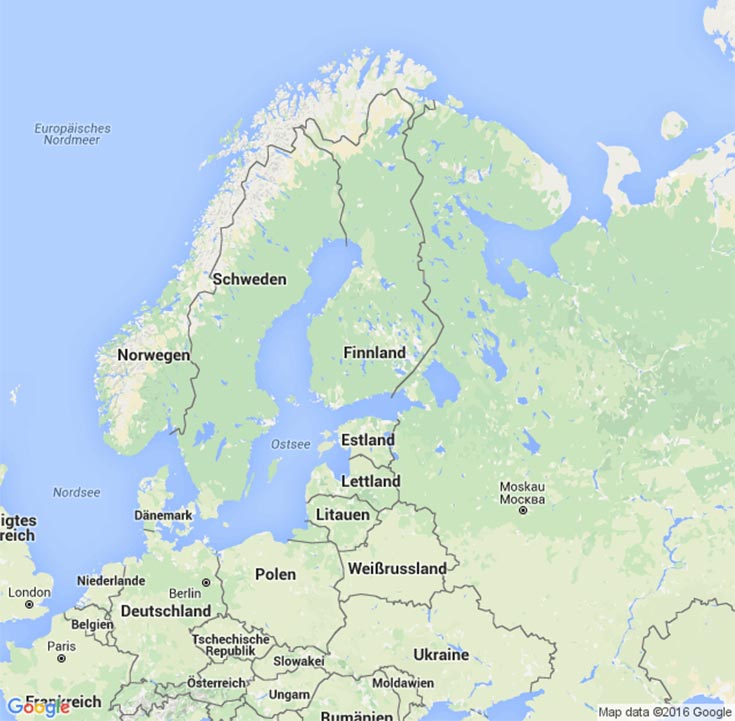

Sweden is also planning a spent nuclear fuel similar to the Finnish Posiva project that will use the same type of encapsulation and disposal system. The current timetable calls for the Swedish national radioactive waste management company Svensk Kärnbränslehantering AB is scheduled to begin construction of their spent nuclear fuel encapsulation plant and permanent geological repository sometime in the early 2020s. The project should take about ten years to complete.

The U.S. selected a site for a permanent geological repository in an old salt mine under Yucca Mountain in Nevada. The repository was supposed to open in 1999 to take spent nuclear fuel from U.S. nuclear power plants but was delayed by legal and environmental challenges. In 2009, preparations for the project were underway when the Obama administration with support from the Nevada Congressional delegation cancelled the project. Later, some remaining funds were used to finish the environmental report.

Now the U.S. government is trying to find a new location for a permanent underground spent nuclear fuel repository but is running into a lot of public opposition to such a repository. Even if a new site were selected tomorrow, it is estimated that it would take until 2050 at the soonest before a U.S. permanent underground geological repository could be opened to take spent nuclear fuel from U.S. nuclear power plants.

In the meantime, the spent nuclear fuel assemblies are piling up in the cooling pools at U.S. nuclear power plants. The pools are getting so full that unless some of the fuel assemblies are removed, the reactors will have to be shut down because there will be no way to refuel the reactors. There are dry storage casks made of steel and concrete that can be used to temporarily store spent nuclear fuel but there are technical problems with these casks. Another possibility being considered is to drill deep holes in basement rock to store spent nuclear fuel assemblies. Other countries are exploring ways to dispose of spent nuclear fuel.

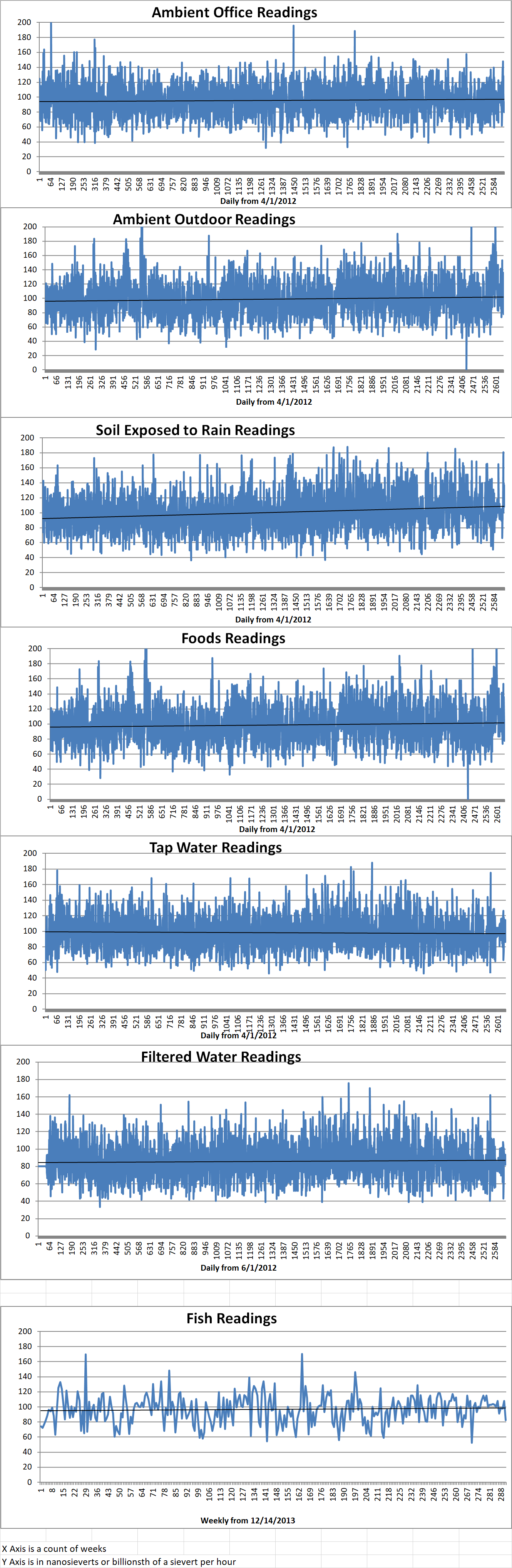

Ambient office = 93 nanosieverts per hour

Ambient outside = 137 nanosieverts per hour

Soil exposed to rain water = 134 nanosieverts per hour

Bartlett pear from Central Market = 78 nanosieverts per hour

Tap water = 108 nanosieverts per hour

Filtered water = 93 nanosieverts per hour

Part 1 of 2 Parts

One of the biggest problems with nuclear power generation is the accumulation of hundreds of tons of spent nuclear fuel with no system of permanently disposal. All nations using nuclear power have a problem with disposing of spent nuclear fuel.

Finland is working on a permanent disposal system for spent nuclear fuel. A site was chosen for the Posiva permanent geological nuclear repository at Eurajoki near the Finnish Olkiluoto nuclear power plant in 2000. The next year, the Finnish Parliament approved the “decision-in-principle” for the permanent repository project. Posiva is jointly owned by two Finnish nuclear utilities, Fortum and Teollisuuden Voima Oyj.

A construction license application was submitted to the Finnish Ministry of Employment and the Economy in December 2013. The Onkalo underground laboratory was created to study the rock formations at Olkiluoto in order to serve as the basis for the repository. A construction license was granted by the Finnish government in November of 2015. Construction work began in 2016. Posiva must obtain a separate operational license for the repository before it can open.

The Posiva plan is to encapsulate spent nuclear fuel in copper-steel canisters in a facility above ground. Then the canisters will be moved to the tunnels of the repository which will be between thirteen hundred and fifteen hundred feet underground. The canisters will be placed in special deposition holes lined with a bentonite buffer. Posiva expects to open the repository in 2023. The cost of the repository construction project is estimated to be about five hundred and fifty million dollars. The employment impact will be about twenty-five hundred person years.

Posiva made an announcement in June of 2019 that it was prepared to start construction on the encapsulation plant. Following the announcement, Skansa, a Finnish construction firm, was awarded a contract for the implementation phase of the project. The Skansa contract is worth about fifty million dollars. Posiva and Skansa signed a contract in November of 2018 for the preparation phase of the project.

Posiva announced in September of this year that the foundation stone for the encapsulation plant had been put into place with a ceremony that was attended by : Finnish Prime Minister Antti Rinne; Posiva CEO and President Janne Mokka; Chairman of the Municipal Board of Eurajoki, Vesa Jalonen; Chairperson of the Eurajoki Municipal Council, Ilona Sjöman; and the CEO of Finnish construction company Skanska, Tuomas Särkilahti.

According to Mokka, he believes that the placing of the foundation stone is a serious first step in the long prepertory phase of the disposal facility. He said “This demonstrates that we are proceeding in accordance with the plan defined already in the 1980s. The entire nuclear energy sector in Finland can take pride of the solution we have for the final disposal of used fuel, enabling us to start final disposal in a responsible manner. The laying of the foundation stone is perhaps a small step in terms of worksite progress, but a giant leap for final disposal, nuclear power and climate. We are now about to take the preparations for final disposal to the implementation stage of the facilities; a stage which is unique on the global scale. I feel particularly proud of Posiva’s personnel who can boast world-class expertise in final disposal. Together with our competent partners we are making history in our industry.”

Please read Part 2