A special inspection of a nuclear power plant in Mississippi has resulted in two low-level citations, as its operator says it has continued trying to make improvements. Insurancejournal.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

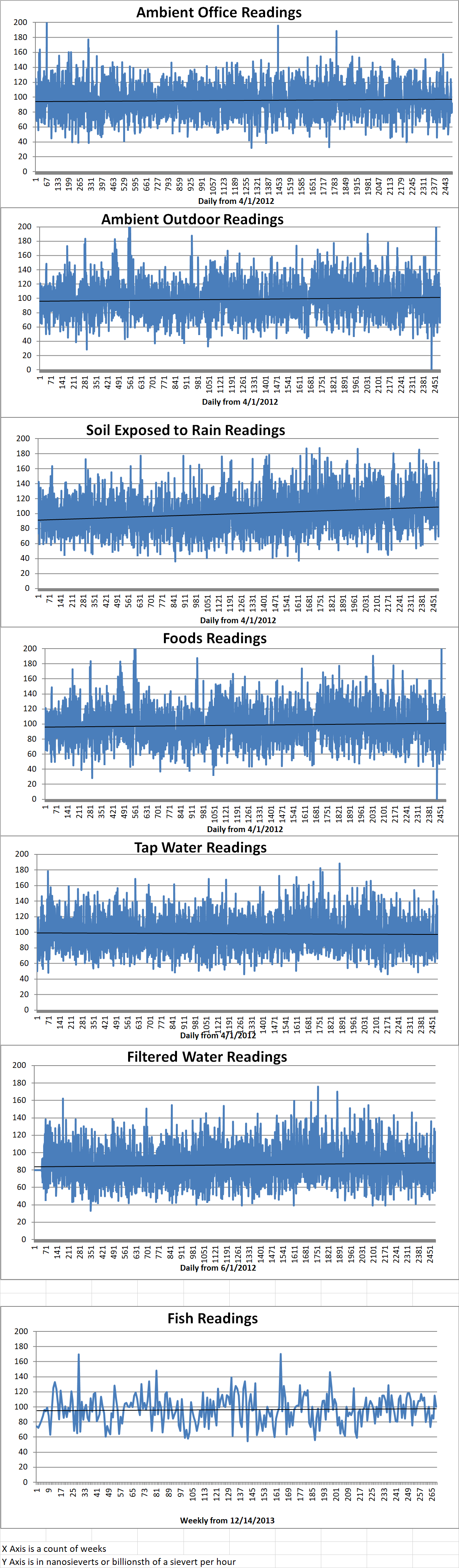

Ambient office = 91 nanosieverts per hour

Ambient outside = 119 nanosieverts per hour

Soil exposed to rain water = 121 nanosieverts per hour

Avocado from Central Market = 66 nanosieverts per hour

Tap water = 89 nanosieverts per hour

Filter water = 84 nanosieverts per hour

One of my big concerns with nuclear power is that government regulators often fail to insure that plant operators comply with government regulations and that corporations operating nuclear power plants often ignore regulations in the name of profit. I have often blogged about this problem. Today I am going to write about a good example of what drives my concern.

The Crystal River Nuclear Plant is located in Crystal River, Florida near Tampa Bay. Plant construction ended in 1976 and the plant operated safely for thirty-three years until it was shut down permanently in 2014. It is currently owned by Duke Power.

Ten years ago, the power was turned off in order to carry out refueling and a complex upgrade plan. Two steam generators were to be replaced and the power output increased by 20 percent. In order to replace the steam generators, it would be necessary to cut a hole in the containment vessel for the reactor.

There were two companies in the U.S. at that time which had the expertise and experience to carry out the replacement of the steam generators. Between the two of these companies, they had successfully carried out similar work at thirty-four other nuclear power plants. Both of these companies bid on the Crystal River project with eighty-one million dollars being the low bid. Instead of contracting either experienced company, Progress Energy, the owners of the Crystal River plant at that time, decided to carry up the work themselves. They estimated that they would save as much as fifteen million dollars by doing it themselves. Although a standard process had been developed as the other thirty-four such upgrades proceeded, Progress Power decided that they would do it their way and ignore the earlier upgrades.

Steel rods and four hundred and twenty-six steel bands were embedded in the walls of the containment vessel for reinforcement. Before cutting through the wall of the containment vessel, some of the steel bands needed to be loosed. This was a costly and lengthy process. The usual practice in the past had been to avoid loosening steel bands that were adjacent. In addition, in the other upgrades, the steel bands were partially loosened early in the work and then completely loosened later.

Progress Power decided that they did not need to follow the previous process. They decided that they would not loosen as many steel bands as had been loosened during the other upgrades. They also decided to loosen adjacent bands and to relieve the tensions on the bands all at once. One of the construction foremen on the Crystal River job warned Progress Power that he had never seen such work done in this way.

A few months into the job, workers were cutting a twenty-five by twenty-seven foot hole in the side of the containment vessel when they discovered a big crack. When they repaired the first crack, they created a second crack. Then a third crack appeared. The cost of repairing these cracks which appeared to be the fault of the Progress Power do it yourself approach was estimated to be a billion dollars.

In 2013, the Crystal River nuclear plant was still shut down when it was purchased by Duke Energy. The next year, Duke permanently closed the Crystal River nuclear plant. The closed plant will need to be decommissioned at a cost of around a billion dollars.

Corporate incompetence and greed resulted in the loss of an operational power plant and a great deal of money.

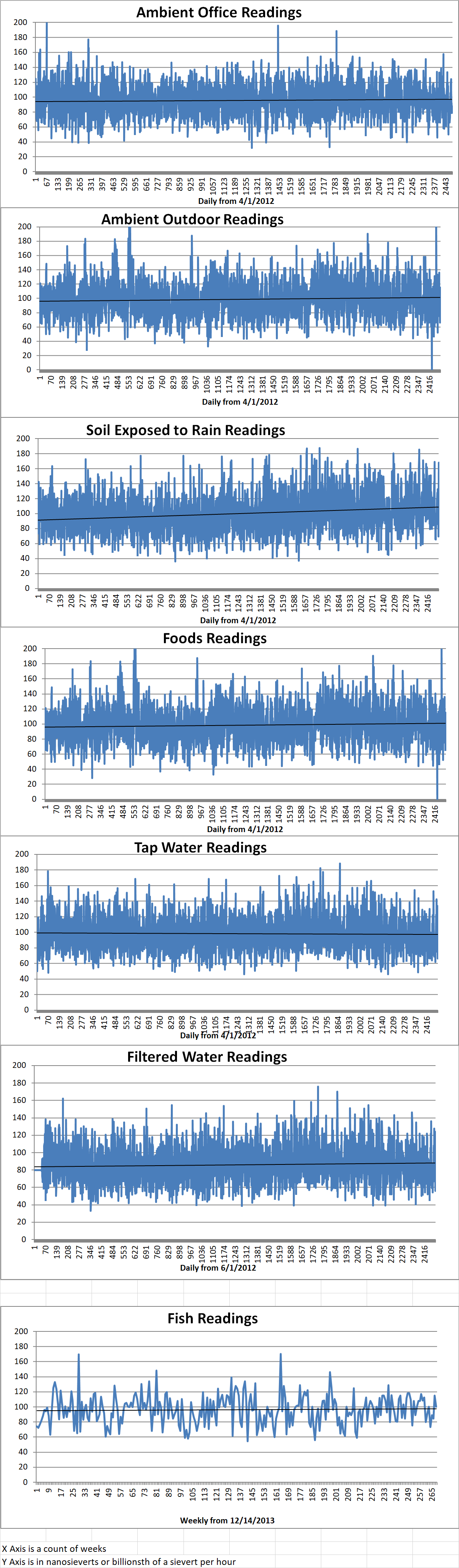

Ambient office = 87 nanosieverts per hour

Ambient outside = 167 nanosieverts per hour

Soil exposed to rain water = 168 nanosieverts per hour

Carrot from Central Market = 115 nanosieverts per hour

Tap water = 85 nanosieverts per hour

Filter water = 73 nanosieverts per hour

Part 2 of 2 Parts (Please read Part 1 first)

The Seawolf-class submarines were designed to be stealthier, more heavily armed and able to match the speed and maneuverability of any adversary. As might be expected, these features did not come cheap. The initial cost estimate was thirty-three billion dollars to construct twelve of the new design. In 2018 dollars, the cost would be about five billion dollars per submarine which is three times the cost of one Los Angeles-class sub. It turned out that the HY-100 steel was prone to extensive weld-cracking problems which required massive reconstruction.

Soon after the construction of the Seawolf class of subs began, the Soviet Union fell apart. The Soviet subs were docked and rusting and the massive investment of the U.S. in new expensive powerful subs was called into question. The initial Seawolf-class order was reduced from twelve to three. The Seawolf, the Connecticut and the Jimmy Carter were launched between 1995 and 2004. All three of these new subs are based at the Kitsap-Bangor Naval Base in Washington State.

The Jimmy Carter was modified at an additional cost of more than eight hundred and eighty million dollars. It was made about a hundred feet longer. This was done in order to add a special Multi-Mission Platform which can carry divers or manned or unmanned underwater reconnaissance vehicles which can be deployed through special locks in the hull. The Jimmy Carter also has special thrusters that will allow it to maneuver precisely in dangerous shallow waters or ocean floors. And, finally, it carries special instruments that will allow it to tap undersea cables that carry the Internet and other long-distance communication travel.

The missions of the Jimmy Carter remain secret. It has received multiple unit citations for unreported reasons which indicate that it has been busy. It has been reported that the Jimmy Carter deployed an aerial drone to spy on North Korean coastal artillery.

All of the Seawolf-class subs activities have been kept secret. There have been very few pictures or articles relating to the new class of subs made available to the public. There have been reports that the subs have been traveling under the ice covering the Arctic Ocean. Some of these trips have been used to test special sonar and communication equipment. None of the Seawolf-class subs has been engaged in any combat operations.

The Virginia-class subs being built now are cheaper than the Seawolf-class at one billion eight hundred million dollars each. They do not have some of the bulk and specials fittings of the Seawolf-class, but they do make use of some of the advanced technology on the Seawolf-class. They have stealth pump water jets for propulsions. Some of the latest Virginia-class subs have vertical launch cells for rapid land-attacks.

The Seawolf-class may see its numbers rise as a new underwater arms races has risen between the U.S., Russia and China. China will soon have a bigger fleet but many of their subs are short range diesel subs and even their nuclear subs are much noisier than the Virginia and Seawolf-classes. Russia is developing enhanced successors to their Akula and Borei-classes of subs.

Holtec International said Tuesday it aims to buy a fourth nuclear power plant that is on the verge of retirement, the Indian Point Energy Center in upstate New York. Exchangemonitor.com

Part 2 of 2 Parts (Please read Part 1 first)

The Seawolf-class submarines were designed to be stealthier, more heavily armed and able to match the speed and maneuverability of any adversary. As might be expected, these features did not come cheap. The initial cost estimate was thirty-three billion dollars to construct twelve of the new design. In 2018 dollars, the cost would be about five billion dollars per submarine which is three times the cost of one Los Angeles-class sub. It turned out that the HY-100 steel was prone to extensive weld-cracking problems which required massive reconstruction.

Soon after the construction of the Seawolf class of subs began, the Soviet Union fell apart. The Soviet subs were docked and rusting and the massive investment of the U.S. in new expensive powerful subs was called into question. The initial Seawolf-class order was reduced from twelve to three. The Seawolf, the Connecticut and the Jimmy Carter were launched between 1995 and 2004. All three of these new subs are based at the Kitsap-Bangor Naval Base in Washington State.

The Jimmy Carter was modified at an additional cost of more than eight hundred and eighty million dollars. It was made about a hundred feet longer. This was done in order to add a special Multi-Mission Platform which can carry divers or manned or unmanned underwater reconnaissance vehicles which can be deployed through special locks in the hull. The Jimmy Carter also has special thrusters that will allow it to maneuver precisely in dangerous shallow waters or ocean floors. And, finally, it carries special instruments that will allow it to tap undersea cables that carry the Internet and other long-distance communication travel.

The missions of the Jimmy Carter remain secret. It has received multiple unit citations for unreported reasons which indicate that it has been busy. It has been reported that the Jimmy Carter deployed an aerial drone to spy on North Korean coastal artillery.

All of the Seawolf-class subs activities have been kept secret. There have been very few pictures or articles relating to the new class of subs made available to the public. There have been reports that the subs have been traveling under the ice covering the Arctic Ocean. Some of these trips have been used to test special sonar and communication equipment. None of the Seawolf-class subs has been engaged in any combat operations.

The Virginia-class subs being built now are cheaper than the Seawolf-class at one billion eight hundred million dollars each. They do not have some of the bulk and specials fittings of the Seawolf-class, but they do make use of some of the advanced technology on the Seawolf-class. They have stealth pump water jets for propulsions. Some of the latest Virginia-class subs have vertical launch cells for rapid land-attacks.

The Seawolf-class may see its numbers rise as a new underwater arms races has risen between the U.S., Russia and China. China will soon have a bigger fleet but many of their subs are short range diesel subs and even their nuclear subs are much noisier than the Virginia and Seawolf-classes. Russia is developing enhanced successors to their Akula and Borei-classes of subs.

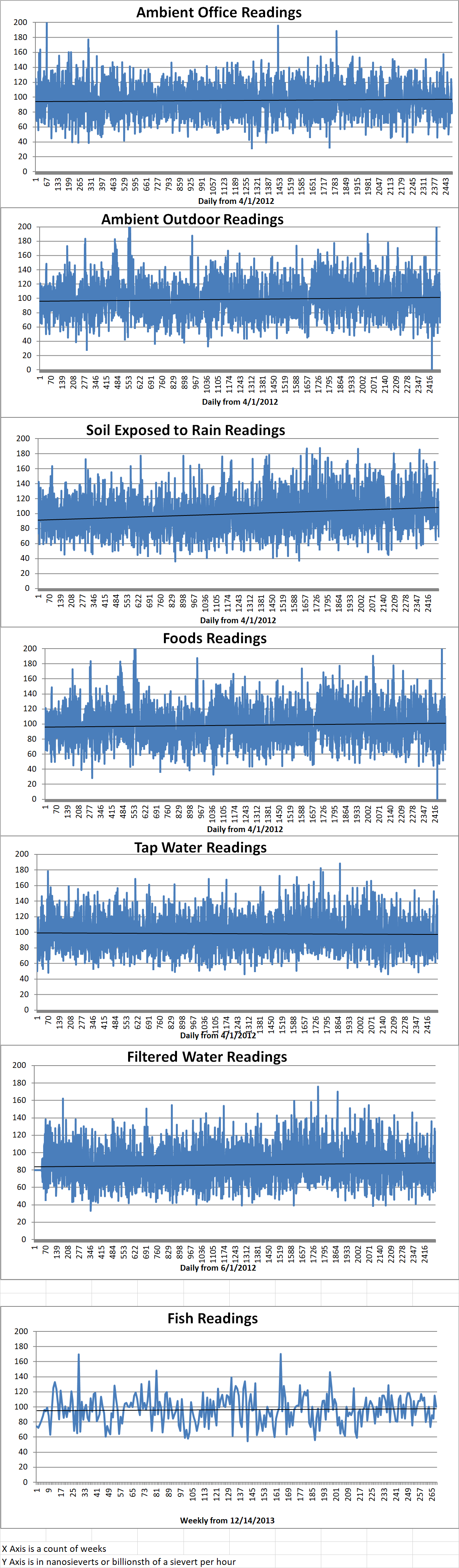

Ambient office = 84 nanosieverts per hour

Ambient outside = 72 nanosieverts per hour

Soil exposed to rain water = 70 nanosieverts per hour

Beefsteak tomato from Central Market = 76 nanosieverts per hour

Tap water = 66 nanosieverts per hour

Filter water = 56 nanosieverts per hour

Part 1 of 2 Parts

I have blogged about nuclear submarines in the arsenals of nuclear-armed nations before. The Chinese, Russians, U.K, France, the U.S., Pakistan and India all have nuclear submarines that can launch nuclear-tipped missiles. These constitute a leg of what is called the nuclear triad. The other two legs are nuclear bombers and ICBM with nuclear warheads. The nuclear submarines are seen as providing the ultimate retaliation capability if the other two legs of the nuclear triad have been destroyed by an enemy. Today, I am going to talk about the most advanced nuclear submarine possessed by the U.S. Navy.

By the late 1950s, the Soviet navy had nuclear powered submarines that could reach twice the maximum depth of most of the U.S. subs. Often the Soviet subs had a higher maximum speed. However, despite these advantages, they had a very significant disadvantage against U.S. subs. The Soviet subs were a lot noisier.

U.S. subs were able to easily detect and trail Soviet subs from a distance that made the U.S. subs undetectable by the Soviet subs. However, by the 1980s, the Soviets were improving their acoustic stealth technology. The Soviet Navy had acquired propeller-milling technology from Toshiba and Kongsberg companies. This allowed the Soviets to create a much quieter seven bladed propeller on their new Akula-class subs.

The Pentagon concluded that the Akula-class subs had superior specification to most of the Los Angles-class subs that constituted the majority of operational U.S. subs. In 1983, the U.S. began development of the biggest, fastest, and quietest attack submarine they could imagine to regain U.S. superiority over Soviet Subs.

The construction of the U.S.S. Seawolf began at Electric Boats in October of 1989. It would be about three hundred and fifty feet long which is more than a football field and displace over nine thousand tons when submerged. The Los Angeles-class subs carried thirty seven torpedoes in four tubes. The Seawolf was armed with fifty heavy-weight 533-millimeter Mark 48 torpedoes or Harpoon anti-ship missiles. These could be launched from eight extra-large 660 mm torpedo tubes. Surface-attack Tomahawk missiles could also be launched from these tubes.

The Seawolf-class of subs is made of a special high strength steel called HY-100. Its conning tower is reinforced so it can cope with operations in Arctic Ice. The S6W pressurized water reactor gives the Seawolf-class an incredible forty miles per hour top speed that allow it to chase down any sub currently in the arsenal of any other country.

The most important advanced technology incorporated in the Seawolf-class involved acoustic stealth. The Seawolf-class generates one tenth of the noise of the quietest Los Angeles-class subs. The Seawolf-class generates about ninety-five decibels in the ocean where the background noise is ninety decibels.

In addition, the Seawolf-class utilizes a jet propulsion pump system instead of the standard propellers that powered the Los Angeles-class. This means that the Seawolf-class can maintain its super quiet operation even traveling at twenty-three miles per hour which is much faster than other subs could travel while remaining in stealth mode.

The Seawolf-class has a twenty-four-foot diameter spherical sonar array on its bow. It also has wide-aperture flank arrays and can tow TB-16D and TB-29 sonar arrays. The information gained by these sensors is fed to the BSY-2 combat system on the Seawolf-class. The Seawolf-class can engage multiple targets simultaneously with their Mark 48 torpedoes. The Mark 48 can be guided by wire from the sub or with their own sonar.

Please read Part 2 next