A couple of days ago, I blogged about the San Onofre nuclear power plant where transfer of spent nuclear fuel into dry canisters for underground storage has been halted because there have been multiple violations of NRC regulations. One of the issues raised has been that the surface of some of the stainless-steel canisters have been scratched as they were being lowered into the Holtec International storage bunker. Critics fear that these scratches could result in corrosion and cracks which may release radioactive materials. The NRC has refused to allow the transfer of any more spent fuel into the storage bunker until the possible danger of the scratches can be properly assessed.

The final safety analysis for the Holtec UMAX dry canisters said that when the transfer was carried out, “There will not be scratches on the canisters.” However, the NRC license issued to Southern California Edison, the owner of the San Onofre nuclear power plant, authorizing the use of the Holtec UMAX canisters only says that the system and process must comply with the American Society of Mechanical Engineers specifications. These specifications do permit some scratching on the canisters.

Scott Morris is the Region IV administer for the NRC. He said that, “Clearly, there’s an inconsistency between these two documents that has to be rectified. Edison has to resolve this. But you can’t just say, ‘It’s OK to have scratches.’ There has to be a technical basis for it. You have to have an analysis that says why it is OK. Give me the calculations. Give me the data.”

SCE and Holtec first tried to allay the NRC concerns by providing calculations that showed that the scratches were not a problem. After the NRC rejected that work, SCE and Holtec stress tested the metal of the shells of the canisters but this called into question the original calculations. Linda Howell is the deputy director of the NRC’s Division of Nuclear Materials Safety. She said, “How do you know what you have scratched? You have to actually look. Actually look at an actual canister, instead of at these surrogates.”

Holtec speeded up the development of a robotic inspection system in order to comply with the NRC demands for seeing the actual scratches on the canisters. Last week, a flat square robot equipped with 3D cameras began crawling around on a few of the dry canister and inspecting the scratches to determine how deep and wide they are. So far, the robot has been able to inspect ninety five percent of the chosen canister exteriors. It checked the surface of three of the canisters that have already been loaded into the storage bunker. Two of the inspected canisters were involved in the problems covered in my previous post. The robot also inspected the surface of a random canister.

The 3D camera on the robot can see scratches that are only one one thousandth of an inch deep. The robot has documented scratches that are twenty-six one thousandths of an inch deep. Morris says that if these are the deepest scratches, then they are well within acceptable tolerances. Tom Palmisano works for SCE. He said at a public panel that the deepest scratches are about the width of a credit card. He added that the oxide layer on the exterior of the canisters should reform quickly so there is no danger that there will be any corrosion.

The NRC is waiting for SCE to provide the data on the robotic inspection. They will then decide if the work and analysis of the canister scratches are sufficient to satisfy the requirements of the NRC. There are twenty-nine canisters in the Holtec storage bunker with forty-three more canisters waiting for NRC permission.

Blog

-

Radioactive Waste 388 – Holtec Checking Scratches On Spent Fuel Canister At San Onofre Nuclear Power Plant

-

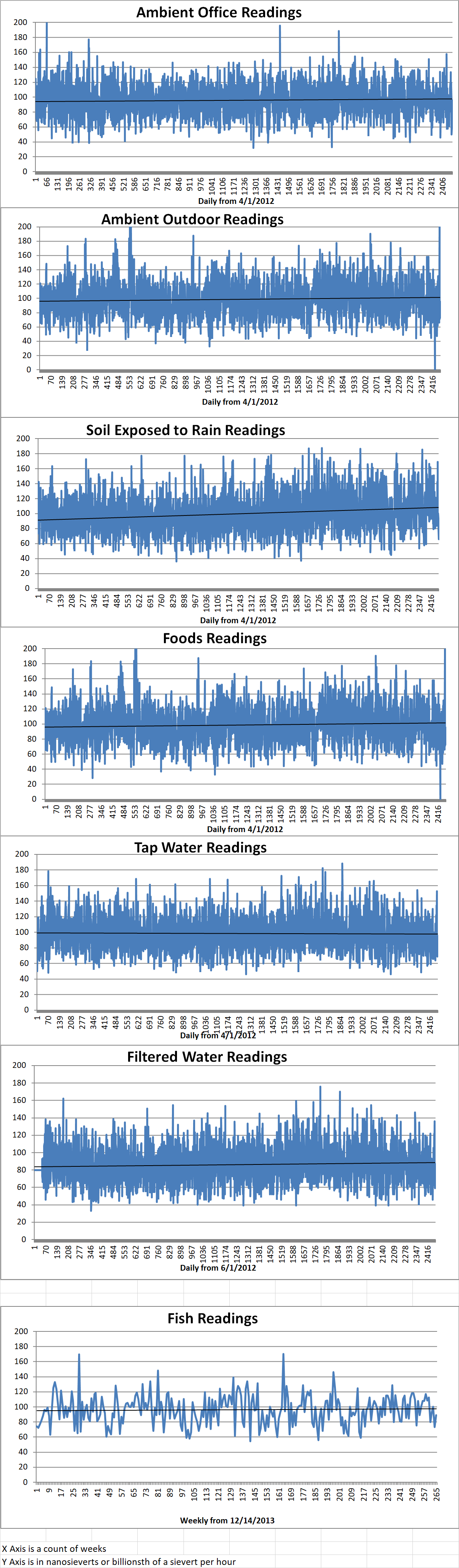

Geiger Readings for Mar 29, 2019

Ambient office = 70 nanosieverts per hour

Ambient outside = 69 nanosieverts per hour

Soil exposed to rain water = 66 nanosieverts per hour

Beefsteak tomato from Central Market = 73 nanosieverts per hour

Tap water = 72 nanosieverts per hour

Filter water = 66 nanosieverts per hour

-

Nuclear Reactors 666 – The U.S. Department Of Energy Has Issued Secret Authorizations To Six Companies Who Seek To Sell Nuclear Technology To Saudi Arabia

I have blogged before about the U.S. interest in selling nuclear power reactors to Saudi Arabia. One of the problems with such sales is the fact that some technologies that can be used to support nuclear power reactors can also be used to help construct nuclear weapons. Saudi Arabia has been reluctant to commit to assurances that it will not use U.S. nuclear technology on any weapons projects. The Crown Prince of Saudi Arabia has said that Saudi Arabia will construction nuclear weapons if Iran restarts its nuclear weapons program. This has impeded progress in U.S. nuclear technology transfer to Saudi Arabia. The Trump administration has pushed strongly for sales to Saudi Arabia while some members of Congress have pushed back against such sales.

It has just been announced that Rick Perry, the U.S. Secretary of Energy, has approved six secret authorization that will permit companies to sell nuclear power technology to Saudi Arabia. These approvals are known as Part 810 Authorizations. They will allow nuclear companies to conduct preliminary work on the construction of nuclear power reactors in Saudi Arabia before contracts are signed but they will not be able to actually ship nuclear power components to Saudi Arabia. The U.S. Department of Energy’s National Nuclear Security Administration (NNSA) reported that it was the nuclear companies that requested that the Trump administration keep the approvals secret. Previously such Part 810 Authorizations had been made available to the public on the Energy Department’s website.

The NNSA said “In this case, each of the companies which received a specific authorization for (Saudi Arabia) have provided us written request that their authorization be withheld from public release.” A spokesperson for the U.S. DoE said that the requests all went through a multi-agency approval process and that one of the reasons for the secrecy was because the authorizations contained proprietary information.

There has been a great deal of opposition to the sale of nuclear technology to Saudi Arabia because there are fears that it may lead to a nuclear weapons race in the Middle East. Following the slaying of Jamal Khashoggi by Saudi Arabia, there has been an international backlash against Saudi Arabia and the Crown Prince. This has had a strong influence on the discussion of nuclear technology sales to Saudi Arabia.

Representative Brad Sherman asked Mike Pompeo, the U.S. Secretary of State, to release the names of the companies which had received the Part 810 Authorizations. Pompeo said that he would “look into it.” Sherman accused the Trump administration of trying to exclude Congress from involvement in the discussions for sale of nuclear technology to Saudi Arabia.

A few weeks ago, Democratic members of the U.S. House of Representatives claimed in a report that they had warned the White House that it might be breaking the law as it worked with a nuclear industry group called IP3 in support of a multibillion dollar plan to build nuclear power reactors in some Middle Eastern countries including Saudi Arabia. The report said that the warnings were ignored.

On Wednesday of this week, the U.S. General Accountability Office received a request from a Republican Senator and a Democratic Senator for a probe of the Trump administration’s negotiations over a nuclear deal with Saudi Arabia. -

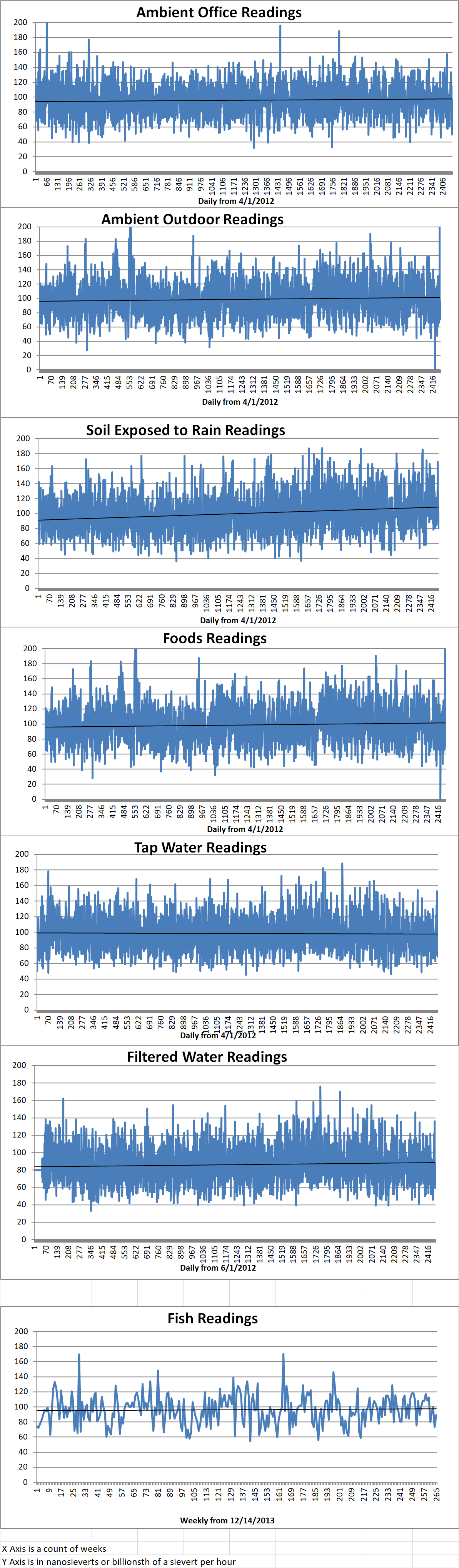

Geiger Readings for Mar 28, 2019

Ambient office = 96 nanosieverts per hour

Ambient outside = 80 nanosieverts per hour

Soil exposed to rain water = 80 nanosieverts per hour

Bartlett pear from Central Market = 96 nanosieverts per hour

Tap water = 95 nanosieverts per hour

Filter water = 87 nanosieverts per hour

-

Radioactive Waste 387 – Problems With Spent Nuclear Fuel Canisters At San Onofre – Part 2 of 2 Parts

Part 2 of 2 Parts (Please read Part 1)

Following the NRC notification, all transfers of waste canisters were stopped until the situation at San Onofre could be investigated and step taken to prevent any repeat. SCE decided that the problem occurred because of inadequate training, oversight and supervision. Since August 3rd, SCE has put many new checks and balances in place to prevent repeats of the event under investigation.

Cameras will be aimed at the canisters and transfers will be monitored in real time. Alarms have been installed to trigger if there is a sudden major change in the weight begin held by the canister-lowering machinery. Two people were monitoring the transfers before the incident but that will be increased to eight. Two of those observers will be above the operation in lift baskets to get a different perspective.

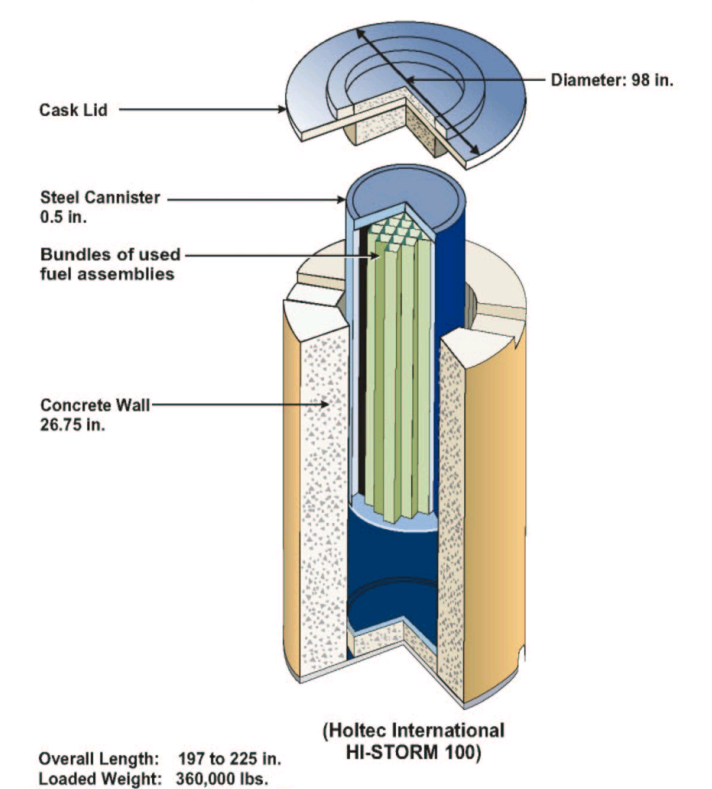

SCE workers at all levels have received much more rigorous training in the process of loading canisters into the Holtec Hi-Storm UMAX system and supervising the process. The design of the canisters has been changed since the workers were trained. The new canisters are bigger than the canisters that the workers originally trained on, so they are a tighter fit in the vault and harder to get into place.

There have been personnel changes throughout the whole chain of command from the top to the low levels workers. There are sixteen more managers for oversight and six are dedicated exclusively to monitoring Holtec activities. SCE says that their management will be much more “intrusively engaged” in keeping the contractors under observation.

During the investigation, it was found that the steel canisters being loaded into the Holtec system were likely scratched as they were lowered into the vault because of the change of design and the tighter fit. SCE and Holtec say that the scratches pose no problem in the “short term.” This is troubling because it implies that there may be problems in the long term and these canisters are supposed to safely store spent nuclear fuel for decades.

The NRC is concerned about the possible long term impact that those scratches may have. They were also critical of SCE management in their apparent failure to plan adequately given the complexity and risks of such canister loading. Some activists monitoring the canister loading are worried that scratches could lead to cracks which could compromise the integrity of the canisters in the long term and post a safety threat.

Donna Gilmore is a retired systems analyst who is the director of SanOnofreSafety.org. She said, “The question is, ‘How bad are the gouges?’ And since there is no method to find or repair the gouges, this is an unacceptable situation. This system must be recalled. It’s clearly a lemon.”

An inspection-and-maintenance program for loading the canisters is being developed and it is scheduled for completion in 2020. Mini-robots with cameras that can crawl down into the vaults and examine the canister closely may be used. The loading of the canisters should never have been done without such a plan already available.

So here we have a company decommissioning a nuclear power plant displaying incompetence, failing to follow nuclear regulations, failure to inform the NRC of regulation violations, inadequate training, and other bad behavior. This is a perfect illustration of why I say that current corporate culture is simply not up to the task of safely and competently constructing and operating nuclear power plants. -

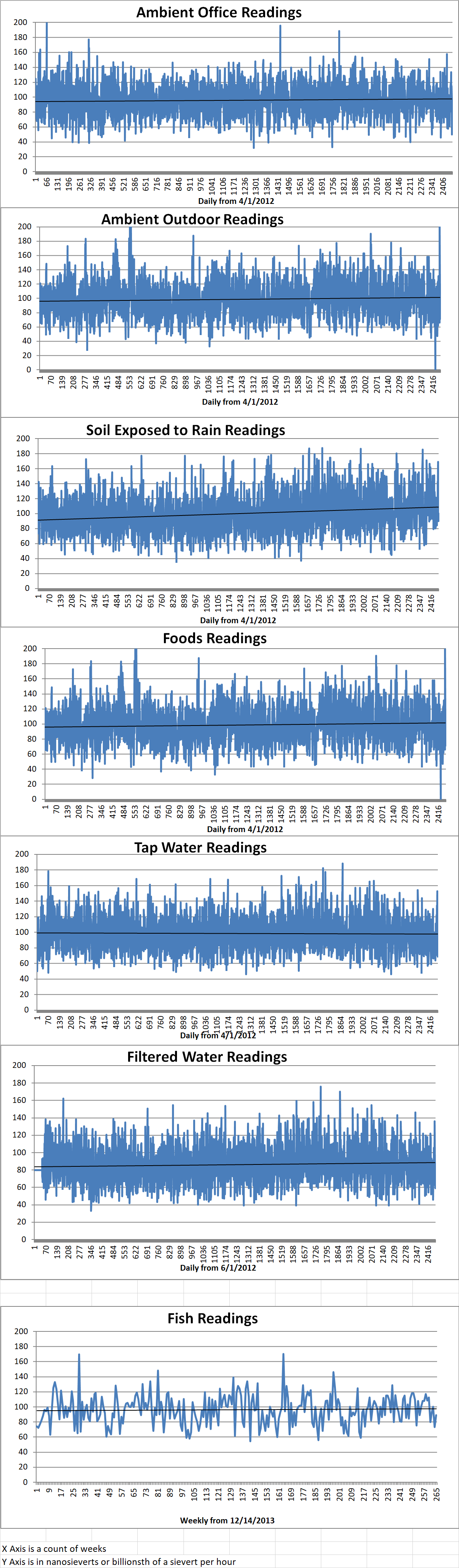

Geiger Readings for Mar 27, 2019

Ambient office = 90 nanosieverts per hour

Ambient outside = 96 nanosieverts per hour

Soil exposed to rain water = 93 nanosieverts per hour

Roma tomato from Central Market = 79 nanosieverts per hour

Tap water = 69 nanosieverts per hour

Filter water = 59 nanosieverts per hour

-

Radioactive Waste 386 – Problems With Spent Nuclear Fuel Canisters At San Onofre – Part 1 of 2 Parts

Part 1 of 2 Parts

One of the common themes of this blog is that although the design of nuclear power plants and equipment to handle nuclear materials may be superb, in the end, the people operating the equipment must be capable and conscientious. The problem with commercial nuclear power operations is that the prime directive of a corporation is to make money.

A pair of professors in a prestigious business school wrote an article for a journal in which they said that it was the duty of the officers of a corporation to increase the wealth of the shareholders and if they had an opportunity to do that by breaking the law, they were obligated to break the law. If they were caught later, then the fines resulting from illegal activity should just be included in operating expenses for the corporation. This is very bad aspect for U.S. corporations and may be disastrous for operators of a nuclear power plant.

I have written before about the problems that ultimately shut down the San Onofre nuclear power plant in southern California. When a problem with a steam generator prompted Southern California Edison (SCE), the operators of San Onofre, to purchase new generators from Hitachi Heavy Industries, SCE made some design changes that were criticized by the contractor as problematic. Nonetheless, SCE insisted on the changes and failed to tell the Nuclear Regulatory Commission as was required by regulation.

When difficulties arose in the installation and operation of the new steam generators, the ultimate result was that the plant was permanently closed. Now it is being decommissioned which includes the disposal of the spent nuclear fuel from the reactor cooling pool. The plan is to transfer it to dry casks provided by Holtec, one of the leaders in the dry cask industry.

The transfer of the spent nuclear fuel began early last year but has been halted by the NRC because of violation of regulations. In February of 2018, workers discovered a loose four-inch stainless steel bolt inside on of the canisters they were preparing. An investigation found that Holtec had altered the design of the canister without informing the NRC as they were obligated to do. On July 22 of 2018, workers had problems aligning and centering a canister that was being lowered into the storage vault. Ultimately, the canister was successfully lowered into the vault, but the event was not entered into the “corrective action program” which is intended to let the plant operators learn from their mistakes. On August 3rd of 2018, there was another very serious problem with aligning a canister for insertion into the vault. A fifty-ton waste filled canister held by slings was being lowered into the eighteen-foot deep vault. The canister got stuck on a “shield ring” near the top of the vault and the supporting slings went slack but that fact was not noticed by the workers. The canister sat there without being supported by anything but the shield ring for an hour. SCE should have reported the incident to the NRC immediately on the Friday when the event occurred but did not actual notify the NRC until the following Monday.

Please read Part 2