Part 1 of 2 Parts

One of the common themes of this blog is that although the design of nuclear power plants and equipment to handle nuclear materials may be superb, in the end, the people operating the equipment must be capable and conscientious. The problem with commercial nuclear power operations is that the prime directive of a corporation is to make money.

A pair of professors in a prestigious business school wrote an article for a journal in which they said that it was the duty of the officers of a corporation to increase the wealth of the shareholders and if they had an opportunity to do that by breaking the law, they were obligated to break the law. If they were caught later, then the fines resulting from illegal activity should just be included in operating expenses for the corporation. This is very bad aspect for U.S. corporations and may be disastrous for operators of a nuclear power plant.

I have written before about the problems that ultimately shut down the San Onofre nuclear power plant in southern California. When a problem with a steam generator prompted Southern California Edison (SCE), the operators of San Onofre, to purchase new generators from Hitachi Heavy Industries, SCE made some design changes that were criticized by the contractor as problematic. Nonetheless, SCE insisted on the changes and failed to tell the Nuclear Regulatory Commission as was required by regulation.

When difficulties arose in the installation and operation of the new steam generators, the ultimate result was that the plant was permanently closed. Now it is being decommissioned which includes the disposal of the spent nuclear fuel from the reactor cooling pool. The plan is to transfer it to dry casks provided by Holtec, one of the leaders in the dry cask industry.

The transfer of the spent nuclear fuel began early last year but has been halted by the NRC because of violation of regulations. In February of 2018, workers discovered a loose four-inch stainless steel bolt inside on of the canisters they were preparing. An investigation found that Holtec had altered the design of the canister without informing the NRC as they were obligated to do. On July 22 of 2018, workers had problems aligning and centering a canister that was being lowered into the storage vault. Ultimately, the canister was successfully lowered into the vault, but the event was not entered into the “corrective action program” which is intended to let the plant operators learn from their mistakes. On August 3rd of 2018, there was another very serious problem with aligning a canister for insertion into the vault. A fifty-ton waste filled canister held by slings was being lowered into the eighteen-foot deep vault. The canister got stuck on a “shield ring” near the top of the vault and the supporting slings went slack but that fact was not noticed by the workers. The canister sat there without being supported by anything but the shield ring for an hour. SCE should have reported the incident to the NRC immediately on the Friday when the event occurred but did not actual notify the NRC until the following Monday.

Please read Part 2

Blog

-

Radioactive Waste 386 – Problems With Spent Nuclear Fuel Canisters At San Onofre – Part 1 of 2 Parts

-

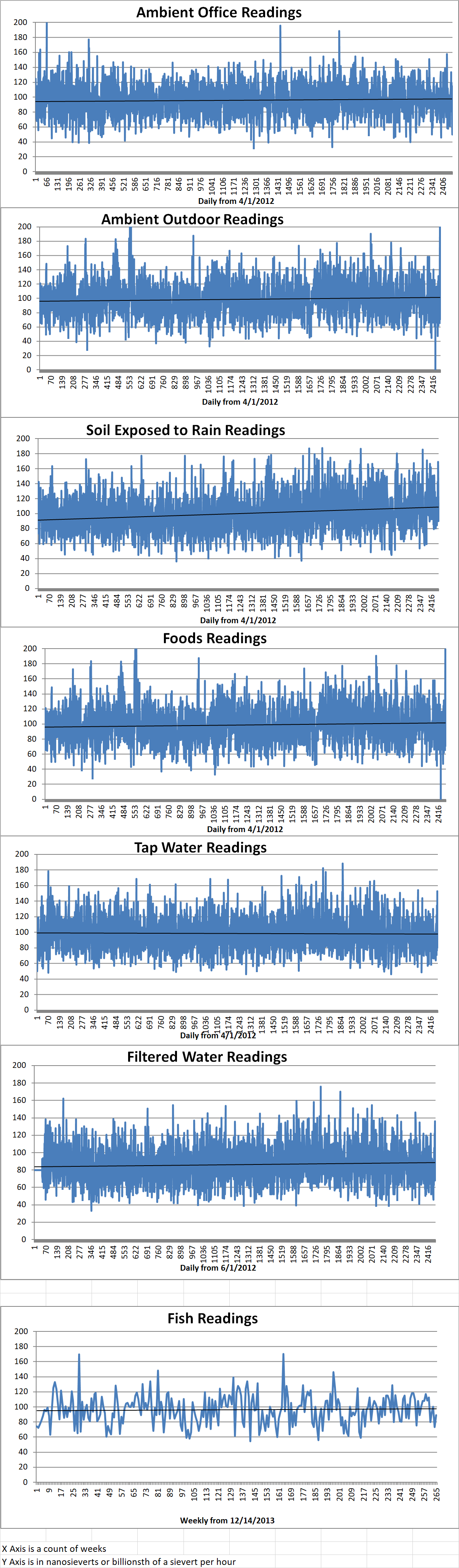

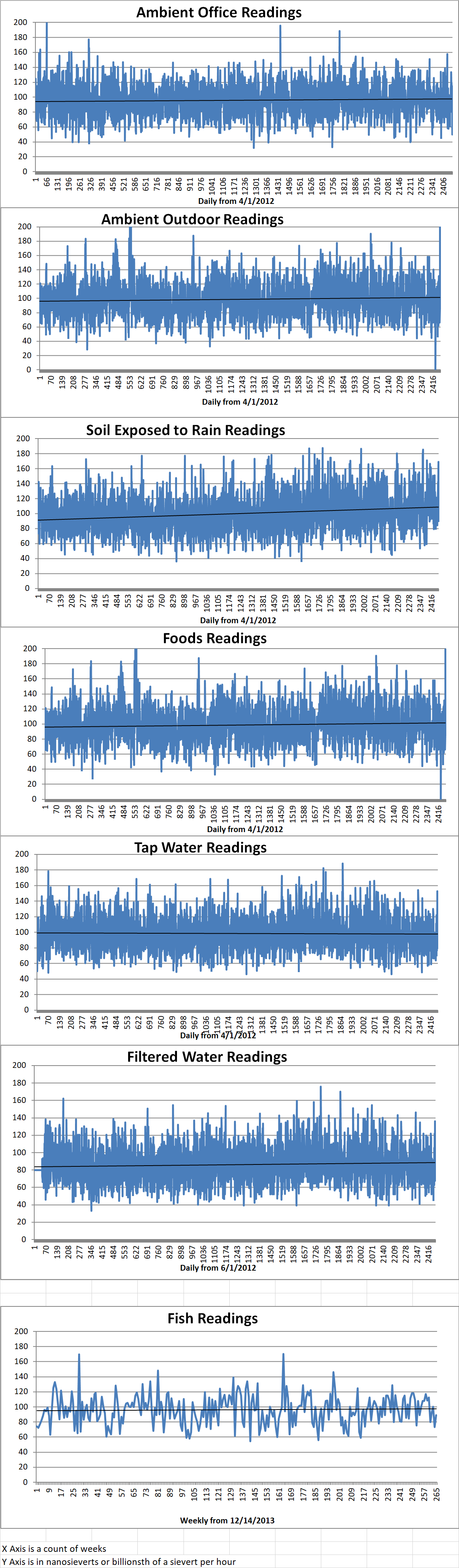

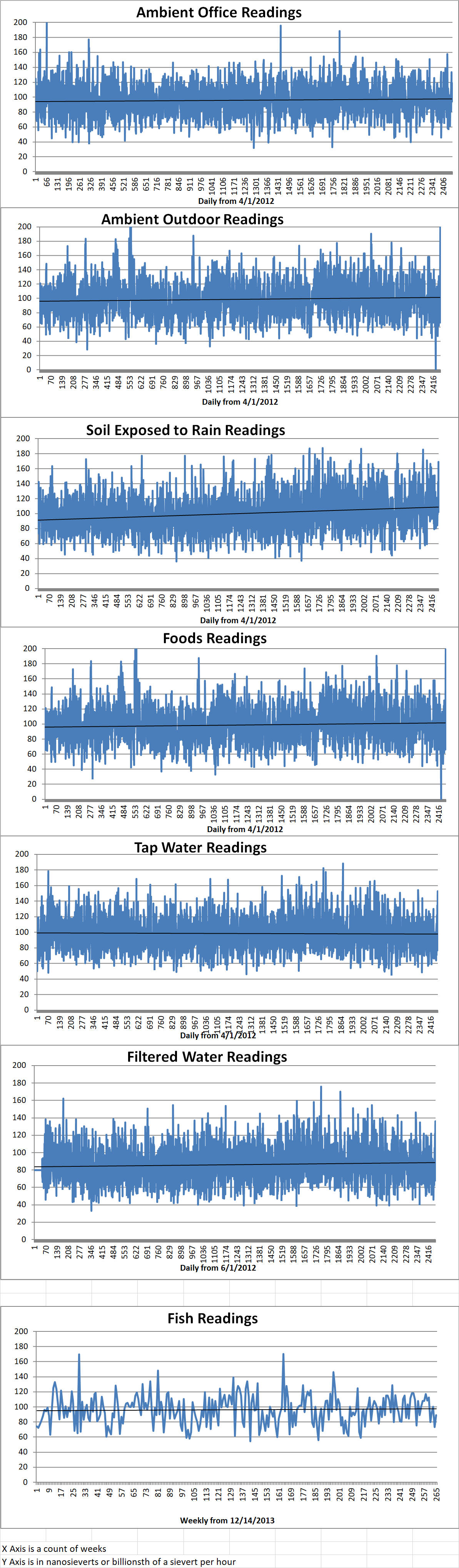

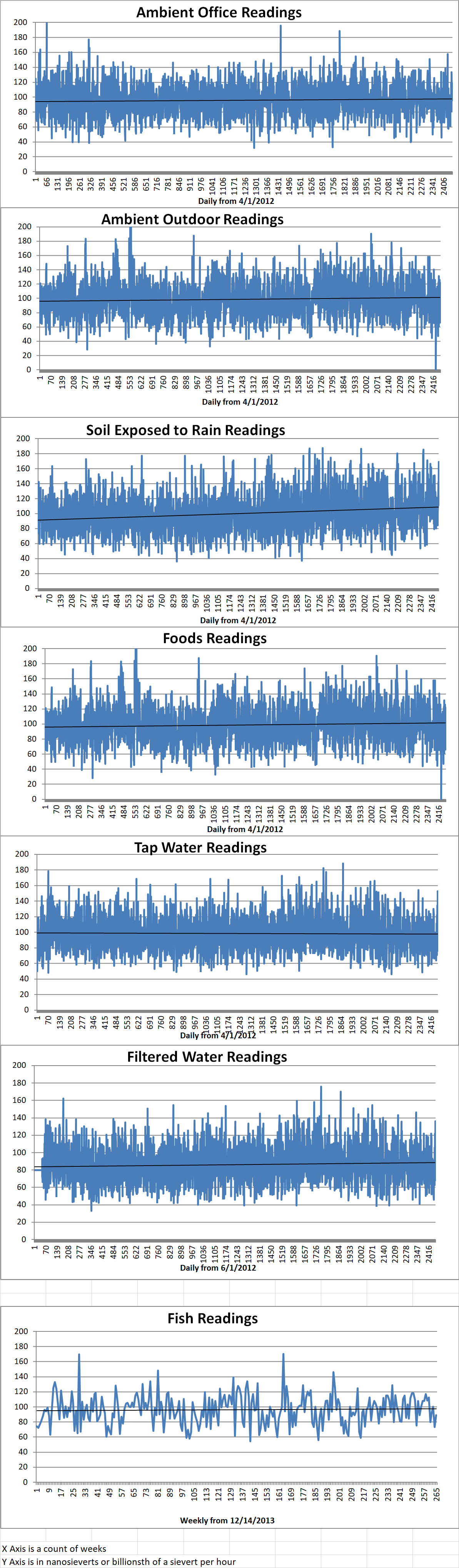

Geiger Readings for Mar 26, 2019

Ambient office = 60 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Pineapple from Central Market = 71 nanosieverts per hour

Tap water = 94 nanosieverts per hour

Filter water = 69 nanosieverts per hour

-

Nuclear Weapons 375 – University of Maryland Researchers Are Working On A New Technique For Detecting Radioactive Materials In Shipping Containers

The possible smuggling of nuclear materials across national borders for a dirty bomb is a great concern to agencies fighting terrorism. Less than four percent of the containers being shipped into the United States are inspected. Any improvement in techniques for checking shipping containers for nuclear materials will improve the chances of stopping such materials from coming into the U.S.

Researchers at the University of Maryland (UMD) have announced the development of a new method for detecting radioactive materials. An infrared laser beam is used to induce a phenomenon called “electron avalanche breakdown” near the suspected material. This technique can detect shielded radioactive materials at a greater distance that current methods.

It is hoped that with advancements in this technology, the new method could be scaled up to scan trucks and shipping containers at U.S. ports of entry. The proof-of-concept work done on this new process was published n Science Advances in March of this year.

Robert Schwartz is a physics graduate student at the UMD and is the lead author of the paper. He said, “Traditional detection methods rely on a radioactive decay particle interacting directly with a detector. All of these methods decline in sensitivity with distance. The benefit of our method is that it is inherently a remote process. With further development, it could detect radioactive material inside a box from the length of a football field.”

When radioactive materials decay, they emit particles which remove the electrons from atmospheric gas atoms. This process is referred to as ionization. These free electrons are quickly captured by oxygen atoms. The researchers found that when an infrared laser beam is sent into the area of ionization, the captured electrons are torn from the oxygen atoms. This triggers an avalanche or rapid increase of free electrons. This increased volume of free electrons is fairly easy to detect.

Howard Milchberg is a professor of physics and electrical and computer engineering at UMD and senior author of the paper that was just published. He said, “An electron avalanche can start with a single seed electron. Because the air near a radioactive source has some charged oxygen molecules—even outside a shielded container—it provides an opportunity to seed an avalanche by applying an intense laser field. Electron avalanches were among the first demonstrations after the laser was invented. This is not a new phenomenon, but we are the first to use an infrared laser to seed an avalanche breakdown for radiation detection. The laser’s infrared wavelength is important, because it can easily and specifically detach electrons from oxygen ions.”

The application of an intense infrared laser beam results in the free electrons oscillating and colliding with nearby atoms. As these collisions become more frequent and energetic, more electrons are torn from atoms increasing the avalanche. Milchberg explains that, “A simple view of avalanche is that after one collision, you have two electrons. Then, this happens again and you have four. Then the whole thing cascades until you have full ionization, where all atoms in the system have at least one electron removed.”

As the atmospheric gases in the laser’s beam begin to ionize, it has an effect on the reflected infrared laser light known as backscattering. This reflected light is captured by a nearby detector. The reflected light can be analyzed to determine when the air began to ionize and how long the air took to fully ionize. The timing of the ionization process or electron avalanche indicated how many seed electrons started the whole process. This can show the amount of radioactive material that triggered the avalanche.

David Woodbury is a physics graduate student at UMD and a co-author on the research paper. He said, “We’re using a relatively weak probe laser pulse, but it’s ‘chirped,’ meaning that shorter wavelengths pass though the avalanching air first, then longer ones. By measuring the spectral components of the infrared light that passes through versus what is reflected, we can determine when ionization starts and reaches its endpoint.”

The researchers say that their new method is very specific and sensitive to the detection of radioactive material. Radioactive material alone will not trigger an avalanche without the infrared laser beam. A laser pulse by itself without the presence of radioactive materials will not trigger an avalanche.

Swartz said, “Right now we’re working with a lab-sized laser, but in 10 years or so, engineers may be able to fit a system like this inside a van. Anywhere you can park a truck, you can deploy such a system. This would provide a very powerful tool to monitor activity at ports.” -

Geiger Readings for Mar 25, 2019

Ambient office = 50 nanosieverts per hour

Ambient outside = 89 nanosieverts per hour

Soil exposed to rain water = 90 nanosieverts per hour

Celery from Central Market = 100 nanosieverts per hour

Tap water = 93 nanosieverts per hour

Filter water = 88 nanosieverts per hour

-

Geiger Readings for Mar 24, 2019

Ambient office = 94 nanosieverts per hour

Ambient outside = 106 nanosieverts per hour

Soil exposed to rain water = 102 nanosieverts per hour

Red potato from Central Market = 80 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filter water = 93 nanosieverts per hour

-

Geiger Readings for Mar 23, 2019

Ambient office = 115 nanosieverts per hour

Ambient outside = 171 nanosieverts per hour

Soil exposed to rain water = 169 nanosieverts per hour

Beefsteak tomato from Central Market = 89 nanosieverts per hour

Tap water = 153 nanosieverts per hour

Filter water = 136 nanosieverts per hour

Dover sole – Caught in USA = 89 nanosieverts per hour