Yesterday, I wrote about work at the University of Bonn in Germany on a teleoperated robot called CENTAURO for use in irradiated environments such as nuclear reactors and nuclear waste sites. Today, I am going to write about another project to develop robots for use in the nuclear industry.

Up to the present, all the robots used in nuclear environments have been teleoperated by a human being in a remote location. While these robots are able to handle complex tasks in hostile environments, they would be too slow to deal with the huge amount of radioactive materials with unpredictable shapes, sizes and consistencies that are scattered around the world.

Professor Rustam Stolkin is a robotics expert at the University of Birmingham in the U.K. He coordinates the Robotic Manipulation For Nuclear Sort And Segregation (RoMaNs) project to develop robots capable of autonomous actions which can be used to sort radioactive waste according various levels of contamination.

Stolkin’s team is collaborating with the French Alternative Energies and Atomic Energy Commission (CEA). CEA has developed a radiation-resistant robot arm that has a hand and fingers. This arm is controlled by a robotic glove or haptic exoskeleton which is worn by a human operator. Stolkin said, This now is a bit like a fancy joystick. So as you move your arm and your fingers, the slave arm in the radioactive zone moves its arm and its fingers.” The RoMaNs system incorporates the CEA robot arm. It uses artificial intelligence (AI) for its automatic vision system to allow the robot to detect, recognize and pick up many different kinds of objects.

The human operator and the robot share control of the robotic arm. As the operator moves the arm around and reaches to grasp an object, the robot can automatically control the orientation of the robotic hand to make it easier to grasp the object. The robot can also show the human operator what it is planning to do so it can be approved, cancelled or altered by the operator. The operator can simply place a cursor over an object and click on it to send the arm to pick up the object without further guidance.

The operator can feel the forces that the robotic hand encounters as it touches or grasps an object. This virtual sense of touch is very important to the operation of the robot in the irradiated environment. In order to control the arm in such a hostile environment, the researchers had to design mechanical systems that are more resistant to radiation than typical electronic circuitry that is usually found in robots.

The RoMaNs team has tested one of the CEA robotic arms along with their AI control system in a radioactive environment in 2017. The test was carried out within the U.K. nuclear safety and national security regulations at a site in northern England that is run by the National Nuclear Laboratory. This marked the first time that an AI controlled robot was tested in a real-world, radioactive environment.

Stolkin had previously said that it might take another decade of research and development before such robots could be deployed but now there are plans to deploy them at decommissioning sites in the near future. Stolkin said, “When we proposed this, the idea of AI-controlled robots, it was considered absurd by this industry.”

Blog

-

Radioactive Waste 654 – RoMaNs Robot Being Developed To Operate In Radioactive Environments

-

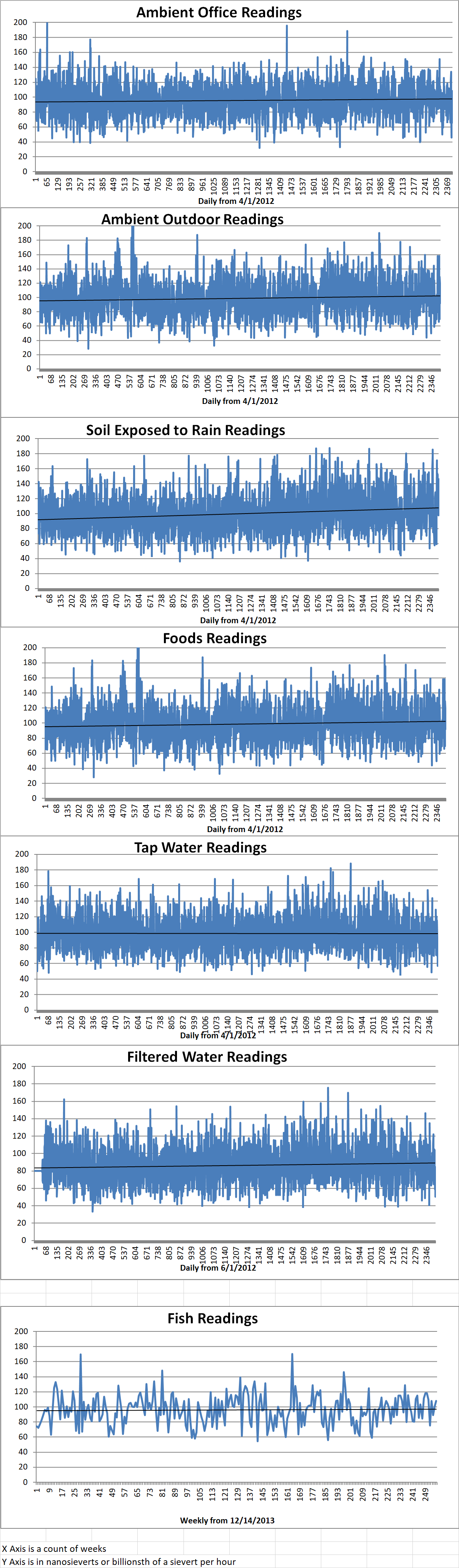

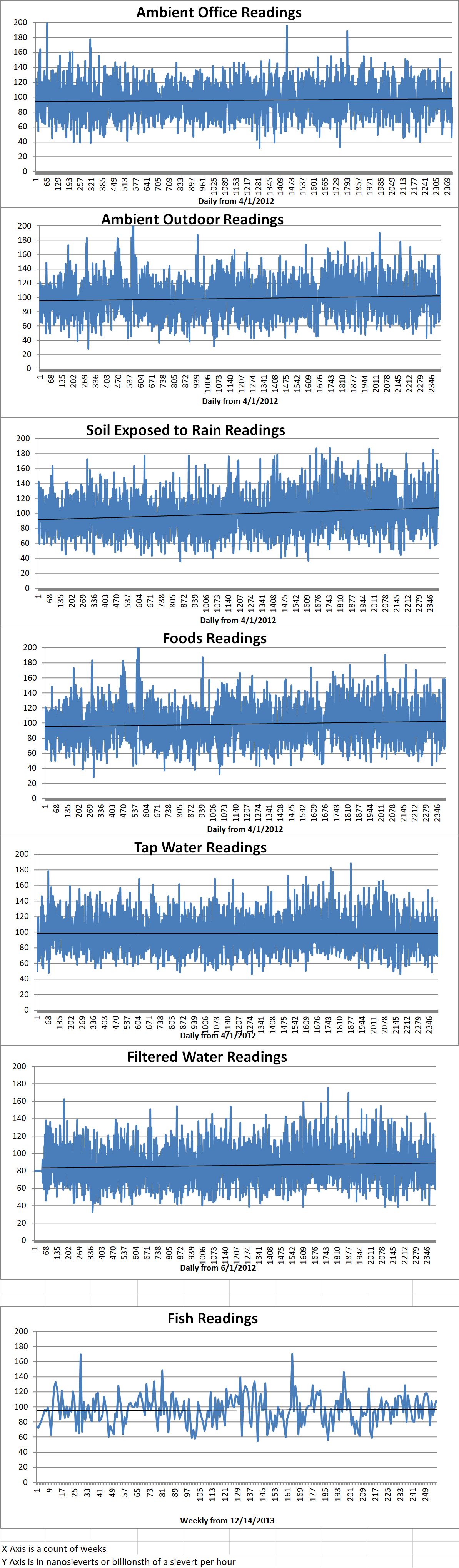

Geiger Readings for Jan 24, 2019

Ambient office = 103 nanosieverts per hour

Ambient outside = 137 nanosieverts per hour

Soil exposed to rain water = 136 nanosieverts per hour

Carrot from Central Market = 87 nanosieverts per hour

Tap water = 91 nanosieverts per hour

Filter water = 87 nanosieverts per hour

-

Radioactive Waste 653 – CENTAURO Robot Being Developed To Operate In Radioactive Environments

Handling radioactive materials is dangerous for human beings. I have mentioned work on various robots in the past that are intended for use in nuclear reactors and nuclear waste facilities. Following the March 2011 nuclear disaster in Japan, some robots were deployed to deal with the aftermath. These robots were primitive and often ineffective. Some were damaged and rendered inoperable by radioactivity. However, work has continued and robots for the nuclear industry are rapidly evolving.

Professor Sven Behnke is a robotics expert at the University of Bonn who is working on a robot called Centauro because it has four legs and two arms. He and his team are developing a robust teleoperated disaster response system. Their robot is remotely operated by a human being in a safe remote location. It has a suite of sensors that gather detailed information about its environment and relay that information back to its operator.

Behnke said, “The main operator controls the robot through a telepresence suit which measures the motions of the operator’s arms, wrists and fingers and transfers them to the robot. A head-mounted display worn by the operator allows them to see in 3D what the robot sees from its own perspective. The robot has a centaur-like body plan with four articulated legs ending in steerable wheels.”

Centauro weights about two hundred pounds and is about five feet tall. It has frame made of light-weight materials such as aluminum and a plastic skin that was 3-D printed. The robot’s four legs make it more stable than a bipedal robot. It is able to rotate at the hip, the knee and the ankle. This means that the robot can assume various postures and can navigate in a complex and challenging environment.

Centauro has two arms attached to its upper body. Each arm ends in a multi-figured hand. The robot is able to pick up objects, manipulate tools and open and close doors. The robot is tele-operated, but it does have some degree of autonomy. It can be given simple orders such as to move to a particular location or to pick up a particular object. The robot is able to plan and execute the requested actions without further instruction or remote control.

Last year Centauro was tested in real-world situations. The nuclear disaster response provider Kerntechnische Hilfsdienst GmbH set up challenging scenarios for the robot. It was able to climb stairs, move around debris, overcome gaps, unlock a door, operate valves, manipulate tools and handle other tasks. Behnke said, “The Centauro disaster-response system provided the high degree of flexibility needed for realistic missions.” Behnke is confident that his robotic technology will eventually play a major role in disaster relief efforts, but it has not had to deal with high radiation levels yet in its tests.

More than ninety nuclear reactors have been permanently shut down across the European Union. More reactors are scheduled to be decommissioned. The E.U. Commissions has proposed the allocation of one billion three hundred and sixty-seven million dollars for nuclear safety. There are nearly five million tons of legacy nuclear waste in the U.K. alone. Cleaning it up is the biggest and most complicated environmental remediation challenge in the E.U. -

Geiger Readings for Jan 23, 2019

Ambient office = 108 nanosieverts per hour

Ambient outside = 145 nanosieverts per hour

Soil exposed to rain water = 146 nanosieverts per hour

Avocado from Central Market = 114 nanosieverts per hour

Tap water = 57 nanosieverts per hour

Filter water = 50 nanosieverts per hour

-

Nuclear Reactors 652 – Petntagon Seeking Help To Develop Small Mobile Nuclear Reactors For Military Deployments

The U.S. military often has to rush men and supplies to a remote area which may not have any conventional infrastructure. The military has to provide buildings, roads and bridges, food and water, weapons and munitions for thousands of men in such remote locations. There is a need for a reliable and portable energy sources which are currently diesel generators. U.S. military researchers are currently trying to find companies that are interested in developing a small mobile nuclear reactor. This reactor would be used to supply energy to forward-deployed fighting forces on land and sea.

The Washington Headquarters Services Acquisition Directorate (WHSAD) in Arlington, Va., issued a request for information (RFI) last Friday for the Small Mobile Nuclear Reactor (SMNR) project. The WHSAD issued this RFI on behalf of the U.S. Office of the Under Secretary of Defense for Research and Engineering, OUSD(R&E).

The RFI states that the deployable SMNR should be able to produce from one to ten megawatts of power. It should weigh no more than forty tons and be deployable by truck, ship or C-17 cargo plane. The reactor should use passive air cooling. It should be designed so that if power and cooling are lost, a meltdown would be impossible. The reactor should not require more than three days to set up and start operating. It should not require more than seven days to shut down and remove from the operational site. The reactor should be able to operate for three years without needing to be refueled. It should be able to operate semiautonomously without needing manual controls. The reactor should burn high-assay low enriched uranium advanced gas reactor tristructural isotropic fuel.

The availability of electricity is a critical part of military operations. Demand for power will just increase as military technology evolves. The global projection of U.S. military power has increased the need for alternative sources of energy that can enhance the mobility of forward land and maritime military operations in remote locations.

In order to improve mobility, military planners are seeking help from private industry to create innovative power sources. They seek demonstration of SMNR prototypes. These prototypes must be safe, reliable and provide an almost unlimited supply of power for rapid response deployments.

SMNRs would make major changes to the logistics of supplying energy to our forward operating bases. It would significantly simplify complex fuel logistical supply lines which are currently required for diesel generators. In addition to supplying power for remote deployments, small mobile nuclear reactors could also make our domestic military infrastructure able to resist an electrical grid attack which took down our civilian electrical systems.

Companies such as General Atomics in San Diego, California and NuScale Power LLC in Portland, Oregon are currently working on SMNR for industry and humanitarian relief operations in remote and/or devastated locations. Pentagon officials are gathering information so they can decide whether they should give up the idea of SMNRs for military use or continue with a multi-stage project to develop a SMNR to support our military energy needs.

If they decide to further explore the utility of SMNRs, they will fund up to three different SMNR designs in the year-long first phase of the project. The second project phase would select one out of the three designs for further work. A decision to move forward or abandon such SMNRs may be made as early as spring of 2019. -

Geiger Readings for Jan 22, 2019

Ambient office = 66 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 98 nanosieverts per hour

Blue from Central Market = 92 nanosieverts per hour

Tap water = 89 nanosieverts per hour

Filter water = 84 nanosieverts per hour

-

Radioactive Waste 372 – Deep Isolation Tests Drilling Deep Boreholes To Dispose of Spent Nuclear Fuel – Part 2 of 2 Parts

Part 2 of 2 Parts (Pease read Part 1 first)

The DI prototype nuclear waste canister contained a steel rod to simulate the weight of a nuclear fuel rod. It was lowered on a cable two thousand feet into the ground and then moved sideways four hundred feet by an underground “tractor”. The cable was then detached and pulled out of the hole. Later, the cable was reinserted into the hole where it was able to attach to the prototype canister and pull it back out of the hole.

Forty observers were present for the test. These included representatives from the DoE, nuclear, oil and gas industry professionals as well as investors, environmentalists and private citizens. The November test was the first time that the DI system was demonstrated in public.

If this system is implemented for national spent nuclear fuel disposal, the nuclear waste would be placed in corrosion-resistant canisters. These canisters would be about a foot in diameter and fourteen feet long. The drill hole, lined with a steel casing, would be vertical at first and then would curve gradually until it was horizontal with a slight upward tilt. The horizontal section would be as much as two miles long and would be anywhere from a few thousand feet to two miles deep. Once the waste canisters are in place, the vertical section of the hole would be filled with rock, bentonite and possibly other materials.

Drilling technology is well-developed and drilling rigs can be easily transported to the site of nuclear reactors. Most of the nuclear reactors in the U.S. are in the eastern half of the U.S. which contains many basement rock formations.

One of the benefits of the deep drill holes is that the waste is stored in stable rock far below the water table. Another benefit is that it is far less expensive to drill small holes down to basement rock than to excavate shallower geological repositories. A third benefit is that these holes could be drilled as needed on the site of nuclear power plants which means that there would be no need to transport the dangerous spent nuclear fuel. A fourth benefit is that they could be drilled a few at a time over a periods of years and be immediately used as opposed to the difficulty of having to build a centralized nuclear waste repository which could not be used until it was completely finished.

Richard Muller is the Chief Technology Officer of Deep Isolation. He said, “Right now, the US is holding 80,000 tons of highly radioactive nuclear waste. Something must be done with this, and every major scientific group that has studied the challenge concluded that putting it deep underground is the safest solution for the present and future generations. A drilled repository allows you to go deeper while disturbing less rock. It is both safer and less expensive than a mined repository.”

Of all of the systems proposed for the disposal of spent nuclear fuel that I have researched, it has always seemed to me that drilling deep boreholes in basement rock is the most practical.