The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

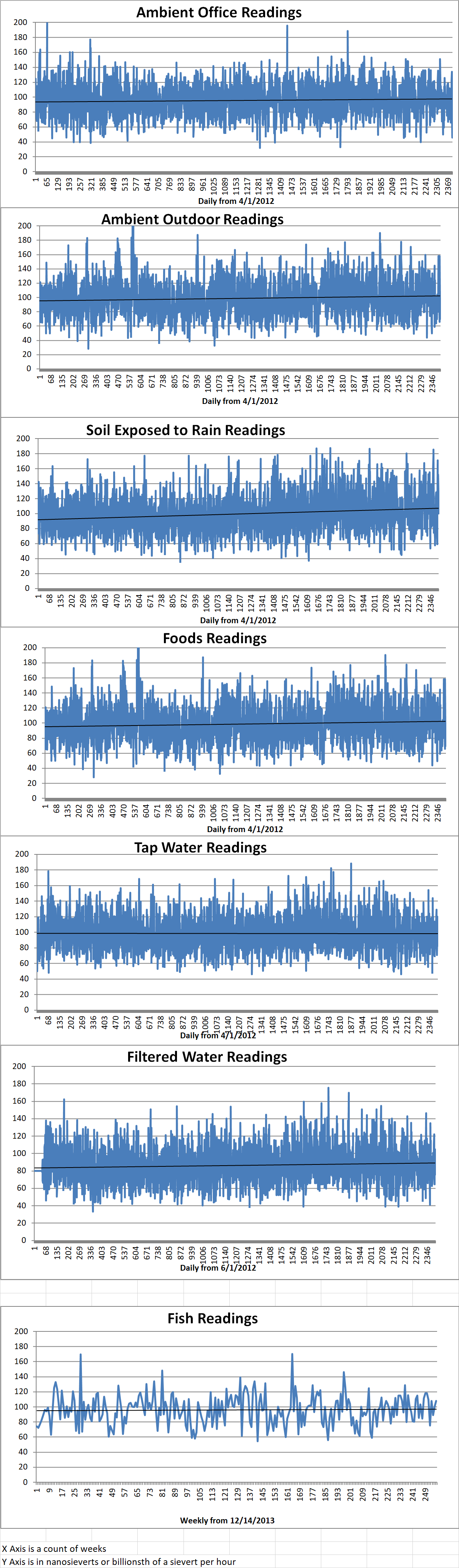

Ambient office = 81 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Yellow bell pepper from Central Market = 92 nanosieverts per hour

Tap water = 90 nanosieverts per hour

Filter water = 81 nanosieverts per hour

Dover sole – Caught in USA = 108 nanosieverts per hour

Part 1 of 2 Parts

The disposal of nuclear waste is an extremely serious problem for the world and an impediment in selling nuclear power to the public and investors. The cooling pools at many U.S. commercial nuclear power reactors are so full of spent nuclear fuel rods that if many of the rods are not removed soon, the reactors will have to be shut down. It is estimated that there are around one hundred and thirty-eight million pounds of nuclear waste accumulating at commercial nuclear power plants around the country.

There was a plan to create a permanent underground repository for spent nuclear fuel under Yucca mountain in Nevada. The development of that repository was suspended in 2009. It is now estimated that there will not be a permanent repository in the U.S. until 2050 at the earliest.

There have been a number of suggestions on ways to handle nuclear waste other than a centralized underground repository. One of those idea is to drill deep holes in the ground and bury the spent fuel rod deep underground. This is not a new idea. Getting rid of nuclear waste by shoving it down deep boreholes drilled into basement rock has been under consideration since the 1950s. There has been research into deep borehole disposal in Denmark, Sweden, Switzerland and the U.S. but so far no one has implemented such a disposal system.

Basement rock is a thick foundation of ancient metamorphic and igneous rock that forms the crust of continents. It lies below sedimentary rock such as sandstone and limestone which are laid down over the basement rock. Generally, sedimentary rock is relatively thin but can be up to three miles think in places. Basement rock can be more than thirty miles thick. It has been geologically stable for tens of millions of years.

In 2016, the Battelle Memorial Institute was selected by the U.S. Department of Energy to drill a sixteen-thousand foot test borehole into a crystalline basement rock formation in North Dakota. This project was carried out as part of a research program to determine whether this could serve as practical and safe way to dispose of spent nuclear fuel. Other plans for deep borehole tests in the U.S. had to be cancelled because of public resistance at the possible test sites.

Also, in 2016, the International Atomic Energy Agency announced that it had successfully carried out “proof of concept” tests for disposal of small amounts of radioactive waste in deep boreholes.

The expert consensus has been that using deep boreholes for disposal of large volumes of spent nuclear fuel would be very expensive compared to a centralized underground repository. One issue of concern with respect to borehole disposal is the fact that it was considered impossible to retrieve nuclear waste from such boreholes should it ever be necessary.

Deep Isolation (DI) is a private company located in Berkeley, California. Last November, DI successfully placed a prototype nuclear waste canister into a borehole two thousand feet deep. DI then retrieved the waste canister and brought it back to the surface. DI has patented technology based on off-the-shelf standard drilling technology developed by the oil and gas industry. The tests were carried out at a commercial test facility for gas and oil drilling.

Please read Part 2

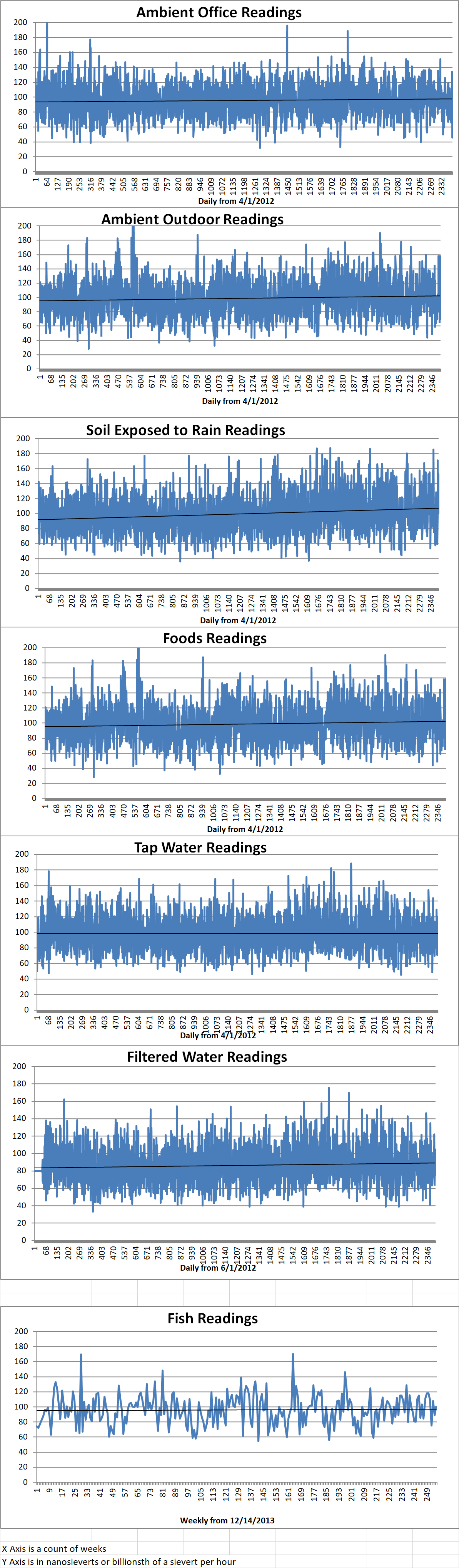

Ambient office = 46 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Avocado from Central Market = 70 nanosieverts per hour

Tap water = 115 nanosieverts per hour

Filter water = 104 nanosieverts per hour

I recently blogged about cutting edge research into stabilizing fusion plasmas being carried out the U.S. Department of Energy Princeton Plasma Physics Laboratory. It turns out that another project at the PPPL is making news.

One of the main current approaches to generating fusion power is the tokamak design. This is a donut shaped chamber surround by powerful magnets. A plasma is subjected to enormous heat and pressure in the tokamak to cause fusion in the plasma. One of the big problems with tokamaks is instabilities in the plasma that may cause it to contact the sides of the chamber and quench any fusion reaction.

There are sudden bursts of heat that can occur in tokamaks that can damage the walls of the confinement chamber. These bursts of heat are called “edge localized modes.” Recently researchers at the PPPL have observed a “possible and previously unknown process” that can trigger ELMs.

An experimental physicist named Ahmed Diallo and a theoretical physicist named Julien Dominski who work at the PPPL have teamed up to analyze data from the DIII-D tokamak at the National Fusion Facility run by General Atomics for the DoE in San Diego. They have found a trigger for a particular type of ELM that does not fit into current models of the ways in which ELMs can destabilize tokamak plasmas.

The findings of this research team could illuminate a variety of mechanisms that can cause ELMs. This, in turn, could lead to new tools for suppressing ELMs. Understanding the physics of ELMs is critical to the development of commercial nuclear fusion reactors which could provide abundant, cheap power.

The research team at PPPL made their discoveries when they were studying puzzling data returned by probes that detect the fluctuation of magnetic fields and plasma density during DIII-D tokamak experiments. It turned out that ELMs appeared during periods when the plasma was unusually quiet. Diallo said that “These were special cases that didn’t follow the standard models.” Dominski said, “It was a most interesting collaboration.

During six months of research, the two physicists at the PPPL discovered correlations of fluctuations in the DIII-D that had not been seen before. These correlations showed the formation of two modes or waves at the edge the plasma coupled together to create a third mode. This new mode moved towards the wall of tokamak which resulted in bursts of low-frequency ELMs.

This type of ELM has also been seen in the Joint European Torus (JET) in the United Kingdom. It has also been seen in the ASDEX Upgrade in Germany and other tokomaks following quiet periods. It is possible that these results could also be applied to systems such as solar flares and geomagnetic storms.

The research team at PPPL have discovered and reported on a method for triggering ELMs but they did not completely explain the process they discovered. They need to analyze more data from tokamaks. Diallo said, “If we can fully understand how the triggering works, we can block and reverse it.”

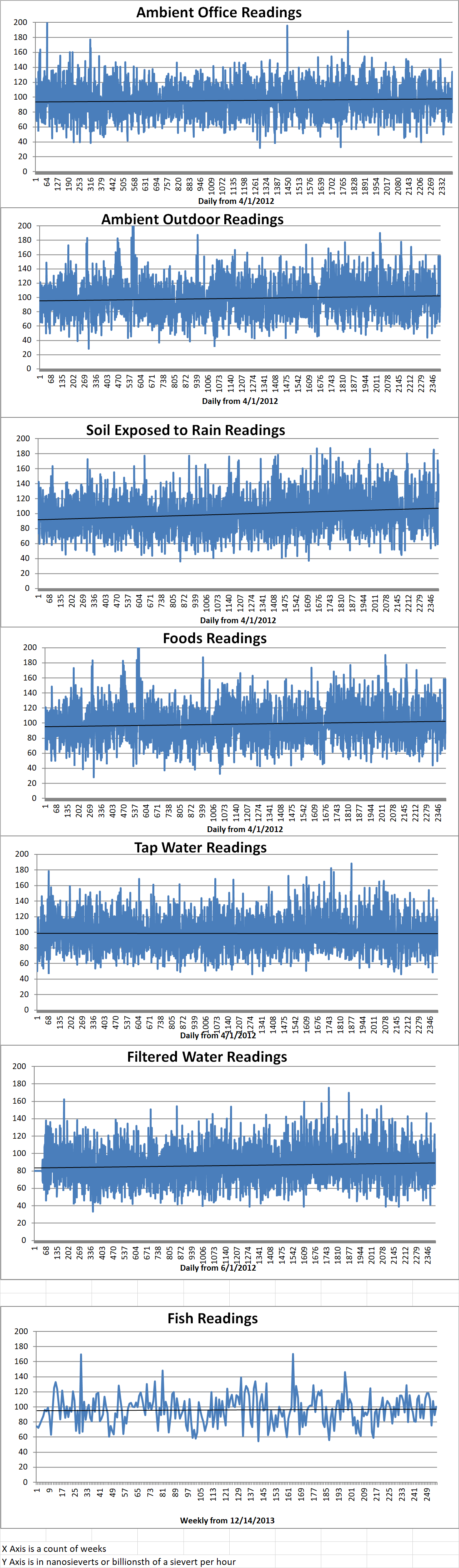

Ambient office = 80 nanosieverts per hour

Ambient outside = 126 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Butternut Squash from Central Market = 87 nanosieverts per hour

Tap water = 82 nanosieverts per hour

Filter water = 76 nanosieverts per hour

Framatome is a French company that manufactures nuclear reactors and nuclear reactor fuel. It was created in 2018 when Areva, another French company, went bankrupt. Seventy five percent is owned by EDF, the French utility company. Twenty percent is owned by Mitsubishi Heavy Industry, a Japanese company, and five percent is owned by Assystem, an international engineering services firm.

Framatome has just received a forty-nine million dollar grant from the U.S. Department of Energy (DoE) for a twenty eight month project. The purpose of the grant is to accelerate the development and commercial production of enhanced accident tolerant fuel (EATF) for nuclear power reactors. The new grant will allow Framatome to continue work that was begun with a ten-million dollar grant from DoE in 2016. EATFs are being created to improve normal performance in nuclear reactors and to give nuclear plant operators more time to deal with the loss of active cooling in reactors.

Framatome is working on EATF for all types of nuclear power reactors. In the near term, Framatome is experimenting with the use of chromium in nuclear fuel assemblies. Chromium can be used to coat fuel pellets in fuel rods or to clad the entire fuel rod. These new fuel designs should improve fuel efficiency and give operators more flexibility.

Adding chromium to the existing cladding alloys use in nuclear fuel assemblies provides a number of advantages over existing nuclear fuels such as improved resistance to oxidation at high temperatures, the reduction of hydrogen gas generation caused by accidents and increased resistance to wear and debris production in normal operation.

Framatome has been developing chromium cladding for nuclear fuel for several years as part of the DoE’s EATF program. It was announced in July of 2017 that chromium clad fuel pellets and fuel rods would be loaded into the Unit 2 reactor at the Vogtle nuclear power plant in Georgia for testing early in 2018.

In the long term, Framatome will develop the use of silicon-carbide based cladding for nuclear fuel assemblies. It is hoped that silicon-carbide cladding will offer even more improvements than chromium cladding.

Bob Freeman is the vice president of Contracts and Services for Framatome Fuel Commercial and Customer Center in North America. He said, “EATF designs represent the next evolution in technologies that will support today’s and tomorrow’s nuclear reactors and unlock value in Framatome’s

products and the existing nuclear fleet. With the support of DOE, Congress and our industry partners, we are ahead of schedule in making this fuel technology available to nuclear power plants so that they can continue to provide clean, efficient electricity.”

Framatome is one of three companies working with DoE to commercialize EATF. The other two companies are Global Nuclear Fuel (GNF) and Westinghouse. The DoE accident tolerant fuels project was launched in response to the Fukushima nuclear disaster in 2011. The DoE intends to test EATFs in a commercial power reactor by 2022. The DoE is following an accelerated timetable in order to have EATFs available by 2025 for use in the current fleet of commercial nuclear power reactors, many of which are licensed to operate into the 2030s.

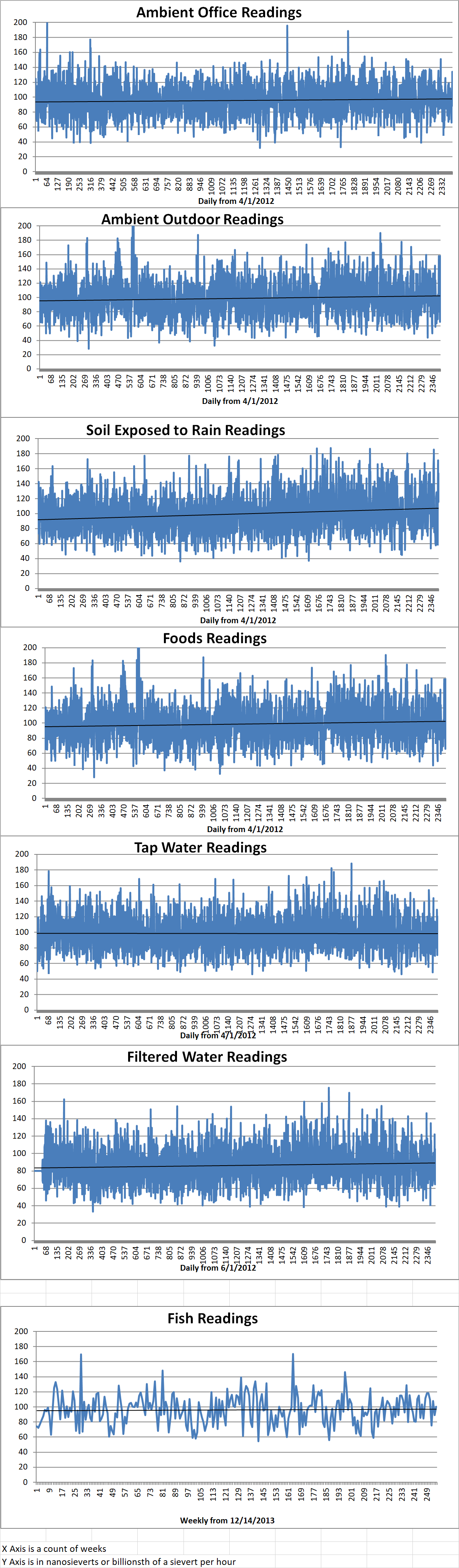

Ambient office = 134 nanosieverts per hour

Ambient outside = 156 nanosieverts per hour

Soil exposed to rain water = 152 nanosieverts per hour

Cauliflower from Central Market = 158 nanosieverts per hour

Tap water = 120 nanosieverts per hour

Filter water = 105 nanosieverts per hour