The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

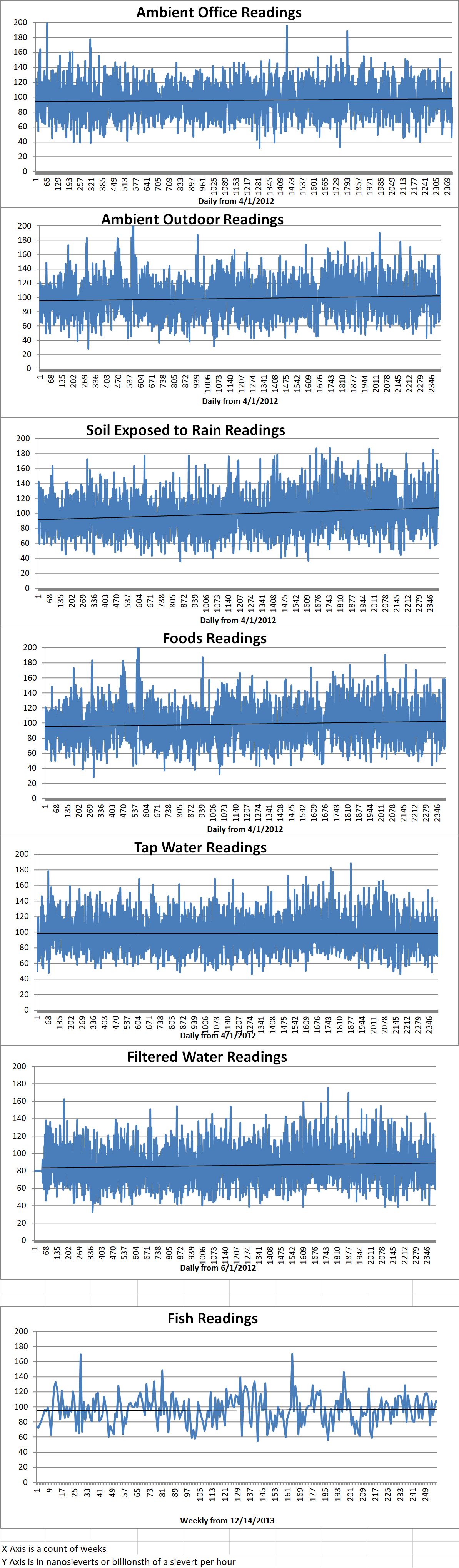

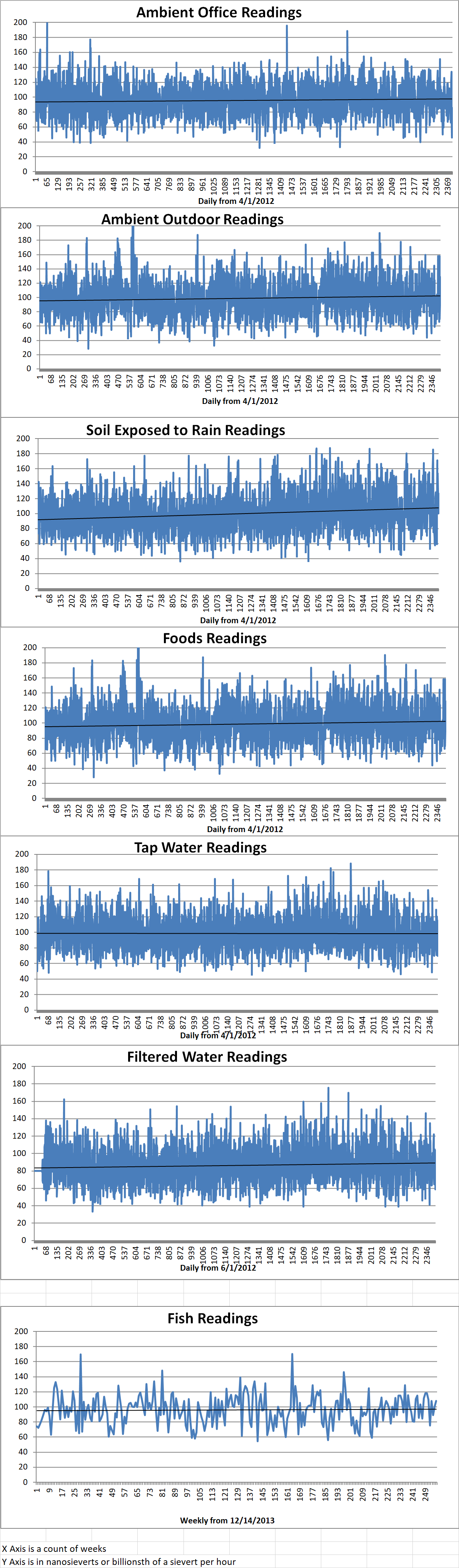

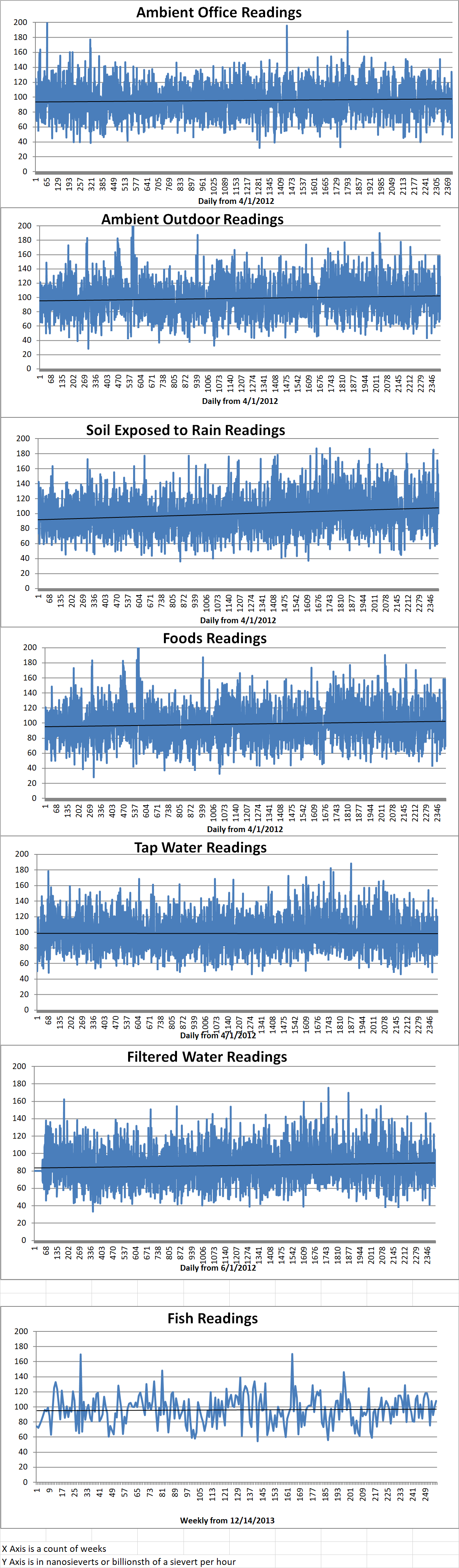

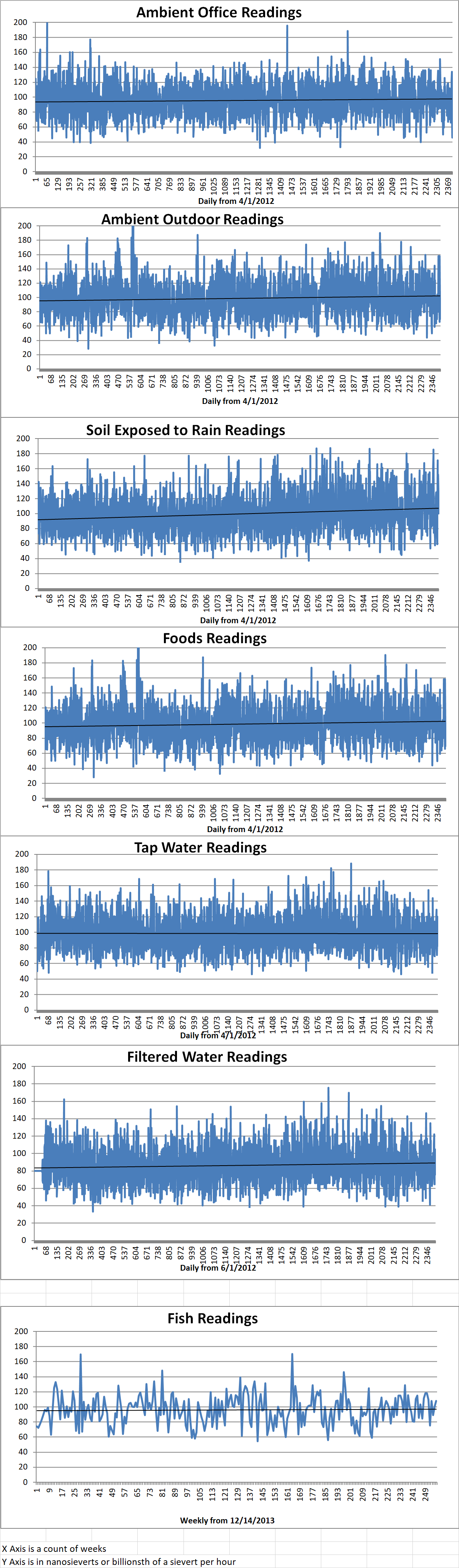

Ambient office = 66 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 98 nanosieverts per hour

Blue from Central Market = 92 nanosieverts per hour

Tap water = 89 nanosieverts per hour

Filter water = 84 nanosieverts per hour

Part 2 of 2 Parts (Pease read Part 1 first)

The DI prototype nuclear waste canister contained a steel rod to simulate the weight of a nuclear fuel rod. It was lowered on a cable two thousand feet into the ground and then moved sideways four hundred feet by an underground “tractor”. The cable was then detached and pulled out of the hole. Later, the cable was reinserted into the hole where it was able to attach to the prototype canister and pull it back out of the hole.

Forty observers were present for the test. These included representatives from the DoE, nuclear, oil and gas industry professionals as well as investors, environmentalists and private citizens. The November test was the first time that the DI system was demonstrated in public.

If this system is implemented for national spent nuclear fuel disposal, the nuclear waste would be placed in corrosion-resistant canisters. These canisters would be about a foot in diameter and fourteen feet long. The drill hole, lined with a steel casing, would be vertical at first and then would curve gradually until it was horizontal with a slight upward tilt. The horizontal section would be as much as two miles long and would be anywhere from a few thousand feet to two miles deep. Once the waste canisters are in place, the vertical section of the hole would be filled with rock, bentonite and possibly other materials.

Drilling technology is well-developed and drilling rigs can be easily transported to the site of nuclear reactors. Most of the nuclear reactors in the U.S. are in the eastern half of the U.S. which contains many basement rock formations.

One of the benefits of the deep drill holes is that the waste is stored in stable rock far below the water table. Another benefit is that it is far less expensive to drill small holes down to basement rock than to excavate shallower geological repositories. A third benefit is that these holes could be drilled as needed on the site of nuclear power plants which means that there would be no need to transport the dangerous spent nuclear fuel. A fourth benefit is that they could be drilled a few at a time over a periods of years and be immediately used as opposed to the difficulty of having to build a centralized nuclear waste repository which could not be used until it was completely finished.

Richard Muller is the Chief Technology Officer of Deep Isolation. He said, “Right now, the US is holding 80,000 tons of highly radioactive nuclear waste. Something must be done with this, and every major scientific group that has studied the challenge concluded that putting it deep underground is the safest solution for the present and future generations. A drilled repository allows you to go deeper while disturbing less rock. It is both safer and less expensive than a mined repository.”

Of all of the systems proposed for the disposal of spent nuclear fuel that I have researched, it has always seemed to me that drilling deep boreholes in basement rock is the most practical.

Ambient office = 86 nanosieverts per hour

Ambient outside = 111 nanosieverts per hour

Soil exposed to rain water = 112 nanosieverts per hour

Beefsteak tomato from Central Market = 119 nanosieverts per hour

Tap water = 70 nanosieverts per hour

Filter water = 59 nanosieverts per hour

Ambient office = 72 nanosieverts per hour

Ambient outside = 124 nanosieverts per hour

Soil exposed to rain water = 127 nanosieverts per hour

Orange bell pepper from Central Market = 129 nanosieverts per hour

Tap water = 73 nanosieverts per hour

Filter water = 63 nanosieverts per hour

Ambient office = 81 nanosieverts per hour

Ambient outside = 100 nanosieverts per hour

Soil exposed to rain water = 100 nanosieverts per hour

Yellow bell pepper from Central Market = 92 nanosieverts per hour

Tap water = 90 nanosieverts per hour

Filter water = 81 nanosieverts per hour

Dover sole – Caught in USA = 108 nanosieverts per hour

Part 1 of 2 Parts

The disposal of nuclear waste is an extremely serious problem for the world and an impediment in selling nuclear power to the public and investors. The cooling pools at many U.S. commercial nuclear power reactors are so full of spent nuclear fuel rods that if many of the rods are not removed soon, the reactors will have to be shut down. It is estimated that there are around one hundred and thirty-eight million pounds of nuclear waste accumulating at commercial nuclear power plants around the country.

There was a plan to create a permanent underground repository for spent nuclear fuel under Yucca mountain in Nevada. The development of that repository was suspended in 2009. It is now estimated that there will not be a permanent repository in the U.S. until 2050 at the earliest.

There have been a number of suggestions on ways to handle nuclear waste other than a centralized underground repository. One of those idea is to drill deep holes in the ground and bury the spent fuel rod deep underground. This is not a new idea. Getting rid of nuclear waste by shoving it down deep boreholes drilled into basement rock has been under consideration since the 1950s. There has been research into deep borehole disposal in Denmark, Sweden, Switzerland and the U.S. but so far no one has implemented such a disposal system.

Basement rock is a thick foundation of ancient metamorphic and igneous rock that forms the crust of continents. It lies below sedimentary rock such as sandstone and limestone which are laid down over the basement rock. Generally, sedimentary rock is relatively thin but can be up to three miles think in places. Basement rock can be more than thirty miles thick. It has been geologically stable for tens of millions of years.

In 2016, the Battelle Memorial Institute was selected by the U.S. Department of Energy to drill a sixteen-thousand foot test borehole into a crystalline basement rock formation in North Dakota. This project was carried out as part of a research program to determine whether this could serve as practical and safe way to dispose of spent nuclear fuel. Other plans for deep borehole tests in the U.S. had to be cancelled because of public resistance at the possible test sites.

Also, in 2016, the International Atomic Energy Agency announced that it had successfully carried out “proof of concept” tests for disposal of small amounts of radioactive waste in deep boreholes.

The expert consensus has been that using deep boreholes for disposal of large volumes of spent nuclear fuel would be very expensive compared to a centralized underground repository. One issue of concern with respect to borehole disposal is the fact that it was considered impossible to retrieve nuclear waste from such boreholes should it ever be necessary.

Deep Isolation (DI) is a private company located in Berkeley, California. Last November, DI successfully placed a prototype nuclear waste canister into a borehole two thousand feet deep. DI then retrieved the waste canister and brought it back to the surface. DI has patented technology based on off-the-shelf standard drilling technology developed by the oil and gas industry. The tests were carried out at a commercial test facility for gas and oil drilling.

Please read Part 2