Taiwan’s Executive Yuan agreed today to halt its policy of making the island nuclear-free by 2025, after voters backed a Nov. 24 referendum item supporting nuclear power. International.thenewslens.com

‘

‘

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

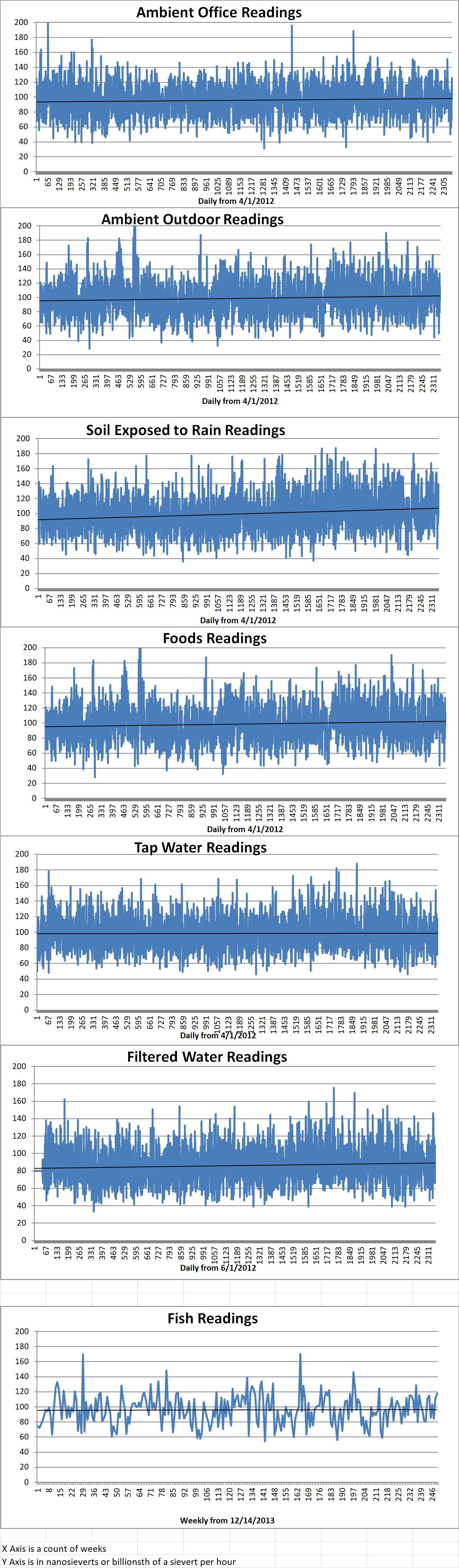

Ambient office = 97 nanosieverts per hour

Ambient outside = 101 nanosieverts per hour

Soil exposed to rain water = 97 nanosieverts per hour

Blueberry from Central Market = 97 nanosieverts per hour

Tap water = 102 nanosieverts per hour

Filter water = 89 nanosieverts per hour

Part 1 of 2 Parts

Two days ago, a broad coalition of fifteen industry groups including labor unions, state public service commissions, clean energy organizations and energy trade associations sent a letter the leaders of the U.S. House and Senate urging them to take swift action on finding a permanent solution to the problem of disposing of spent nuclear fuel. Among the organizations sending the letter were the Nuclear Energy Institute (NEI), the American Public Power Association, the National Rural Electric Cooperative Association, and the Edison Electric Institute—along with the National Association of Regulatory Utility Commissioners, which is a group of state regulators.

The letter pointed out that there had been no progress on the Yucca Mountain repository license application and that consolidated temporary storage was simply “untenable.” The letter said, “It is time for the federal government to meet its statutory and contractual obligations. Utilities and their electricity customers have done their part.” At this time, it is estimated that eight hundred thousand metric tons of spent nuclear fuel are contained in temporary storage at seventy-five reactor sites in thirty-three state.

Under the Nuclear Waste Policy Act of 1982, the U.S. Department of Energy was obligated to create a permanent geologic repository for spent nuclear fuel from U.S. commercial nuclear power reactors. The repository was to be finished and ready to operate by 1999. In anticipation of the availability of this facility, the DoE began collecting a fee from all the operators of commercial nuclear power reactors. The fee was ultimately collected from ratepayers who purchased electricity from nuclear power.

Unfortunately, 1999 came and went with no facility being completed. The DoE was working on creating such a facility at Yucca Mountain in Nevada, but that plan was cancelled in 2009 by the U.S. President and the U.S. Congress. In the meantime, over forty billion dollars was collected from nuclear plant operators by the DoE. It is accumulating interest of about one and three quarters billion dollars a year from investment in Treasury securities.

When the 1999 deadline passed, owners of commercial nuclear power plants began to file lawsuits to claw back those payments to the DoE. So far, forty lawsuits have been settles with paybacks of seven billion four hundred thousand dollars. Another fifty-seven lawsuits have been resolved.

The letter said, “taxpayers have been saddled with the federal government’s inaction,” and “billions [of dollars] more in liability continuing to mount.” The letter pointed out that the nuclear industry employs about a hundred thousand people directly and almost five hundred thousand people indirectly.

The letter went on to say, “Yet the lack of a strong used fuel management program has stymied public support of nuclear power for the existing fleet as well as advanced reactors currently under development. This is unfortunate as the overwhelming scientific evidence clearly demonstrates that used nuclear fuel can be stored, transported, and disposed of safely.”

Last May, the U.S. House of Representatives passed the Nuclear Waste Policy Amendments Act of 2018. Previously, the condition for a license for the Yucca Mountain repository was dependent on the satisfaction of public land use laws. Under the new bill, the license process would be completely under the control of the DoE. The bill would also permit the temporary storage of spent nuclear fuel at interim storage facilities licensed by the NRC but owned by non-federal entities. Under the bill, the storage capacity of a Yucca Mountain repository would be raised from seventy thousand metric tons to one hundred and ten metric tons. The U.S. Senate has failed to ratify this House bill.

Please read Part 2

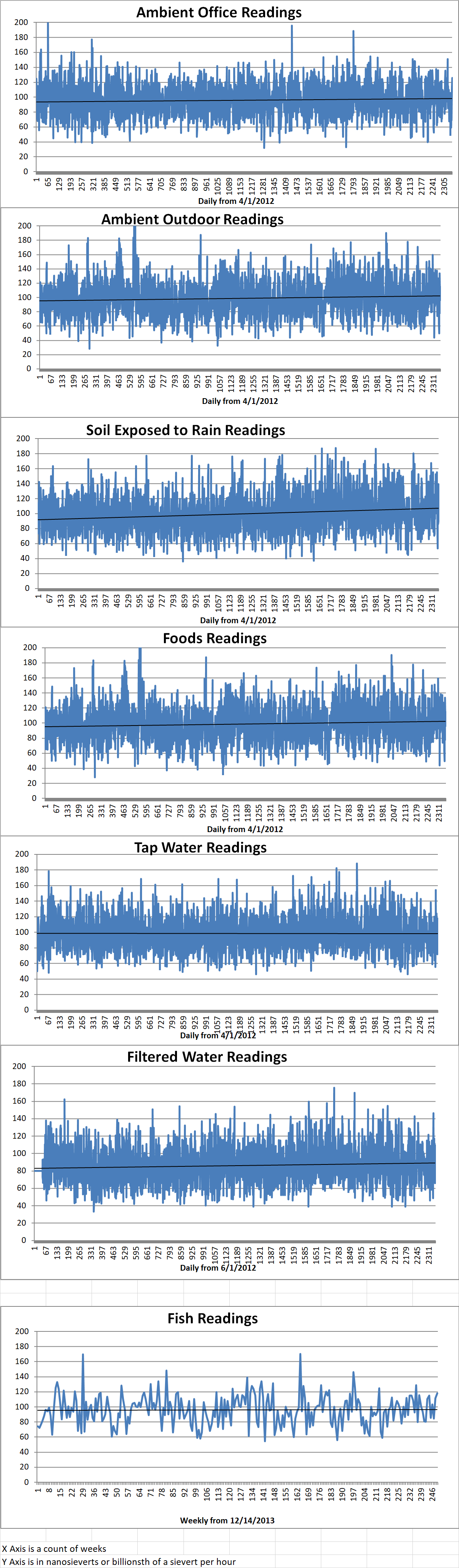

Ambient office = 126 nanosieverts per hour

Ambient outside = 126 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Orange bell pepper from Central Market = 115 nanosieverts per hour

Tap water = 90 nanosieverts per hour

Filter water = 85 nanosieverts per hour

One of the things that supporters of nuclear power always bring up is the fact that nuclear power plants are base-load power. This means that the plants are always running and producing power as opposed to solar and wind installation which are intermittent. Having base-load power sources on the electrical grid to continually supply a minimum amount of electricity is very important. While nuclear power is theoretically base-load, in reality, nuclear power plants are not “always on.” In addition to the scheduled downtime necessary to load new nuclear fuel every twelve to eighteen months, there can be unscheduled shutdowns caused by technical problems in the complex components of plant.

The Grand Gulf Nuclear Generating Station is the largest single-unit nuclear plant in the U.S. It is located near the western border of Alabama and has a maximum capacity of one thousand four hundred and forty-three megawatts. It began operating in 1985. There have been plans to add additional reactors, but they were all abandoned. It is an example of why nuclear power cannot be counted on for base-load power.

A review of federal daily reactor status reports by E&E News found that between 2013 and the present, the Grand Gulf only operated at full power for a little over half the time. It was at zero power about one fifth of the time. The rest of the time, it was operating at reduced power.

Entergy holds a ninety percent stake in Grand Gulf through a company called System Energy Resources, Inc. Utilities in Arkansas, Mississippi and Louisiana all receive electricity from Grand Gulf. When Grand Gulf is shut down, the local grid must find other power sources which can be more expensive and involve the use of fossil fuels with their carbon emissions.

The Grand Gulf had five unplanned downpower events in the past year. One of these outages lasted for three months. There have been other long power outages. An outage that started in September of 2016 lasted for five months. In 2016, Grand Gulf was at zero power for a total of one hundred and seventy-six days.

Turning a nuclear power reactor on and off can make the reactor unstable. Entergy says that it is working on making the plant operation more reliable at Grand Gulf. The NRC says that the plant is still safe to operate. However, the NRC has sent a notice to Entergy that the performance of the Grand Gulf is now outside of what the NRC considers normal.

Other electrical utilities and nuclear plant operators have similar problems as many reactors in the U.S. fleet are nearing the end of their licensed life spans. The operators of many of these aging nuclear plants are applying to the Nuclear Regulatory Commission for twenty-year extensions of their operating licenses.

It is very expensive to build a nuclear power plant but once in operation, they are relatively cheap to operate. The fuel is inexpensive and is not subject to the volatility of other fuels. While in operation, the plants do not emit carbon dioxide and other pollutants. However, as nuclear power plants age, the maintenance costs rise and obtaining replacement parts becomes increasingly difficult. In addition, downtimes increase.

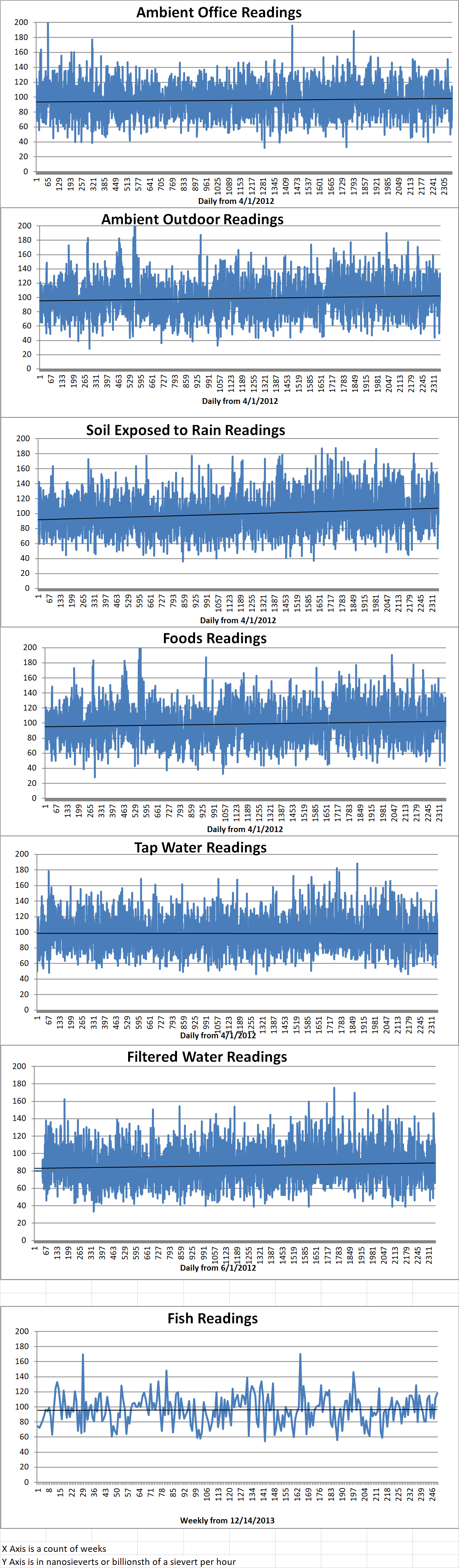

Ambient office = 113 nanosieverts per hour

Ambient outside = 138 nanosieverts per hour

Soil exposed to rain water = 139 nanosieverts per hour

Yellow bell pepper from Central Market = 96 nanosieverts per hour

Tap water = 118 nanosieverts per hour

Filter water = 109 nanosieverts per hour

Nuclear power plants are designed to prevent the escape of radioactive materials. As nuclear power plants age, the danger of release of radioactive materials increases. All nuclear power plants contain a vast network of pipe to carry coolant through the different components of the system. As these pipes age, the danger of corrosion and cracks allowing radioactive materials to leak increases. Monitoring and maintaining the network of pipes in a nuclear power plant is a critical task.

Most of the commercial power reactors in the world today are pressurized water reactors (PWR). In a PWR, the primary coolant is water. Radioactive water and steam are pumped through a closed system of pipes that carries them to the core to be heated by the heat released from the nuclear fission reaction. From there they are carried to a heat exchanger that transfers the heat to water circulating in secondary network of pipes. The water in the secondary system is converted to steam that is fed into a turbine to create electricity.

A failure anywhere in the network of pipes could be a major problem. The Nuclear Regulatory Commission is concerned that pipes in nuclear power plants may be undergoing corrosion that could result in leaks and ruptures. This could lead to disasters in which the function of the plant is impaired and/or radioactive materials are released into the environment.

It is difficult to monitor corrosion inside pipes. One source of corrosion is from gases that might be trapped inside the pipe network. Gases mixed with water naturally rises to the highest spot in the container. In a network of pipes, the highest points can become places where gases accumulate, and corrosion occurs. One of the ways to detect potential problems spots is to map the network of pipes.

If highest points can be correctly identified, then vents can be installed in those parts of the pipe network to allow gas to escape and prevent corrosion. The old system to mapping pipe networks utilized hand tools which required staff to spend a lot of time in and around the pipe network. This could result in exposure to dangerous levels of radiation. And, using hand tools is a crude system and could easily miss important information about the pipe network.

Exact Metrology (EM) is a company that specializes in 3D and CT scanning. A few EM technicians can scan the entire pipe network of a nuclear power plant using Leica HDS scanners. These scanners are able to capture full-volume, 360° 3D point clouds for a location in just three minutes. A point cloud is a very accurate digital record of an object or space. Some rooms only require one such scan, while other rooms require multiple scans. Once the scanner is set up and started, the rest of the process is automatic, and the technician can retreat to a safer area if necessary. Once all the scans have been carried out, the separate scans are combined into a single point cloud.

Once the complete point cloud is created, sophisticated computer algorithms are used to identify the pipe sizes, centerlines and positions, even if some section of pipe are concealed from view. The point cloud for nuclear reactor pipe networks is able to identify sections of pipe which are crystalized and leaking.

Once the scanning and point cloud assembly are completed, 3D CAD models are created. Computer snapshot are recorded with elevations descriptors marked on the pipe runs. These snapshots are sent to engineers at the facility to determine if it is necessary to install vents at particular high points.

One big benefit of 3D scanning is that the scans can be carried out at ground level. This means that technicians do not need to climb ladders and scaffolding which reduces the danger to the technicians. Another benefit of 3D scans is that additional measurements can be conducted without the need to return to the actual pipe network. The point cloud assembled in the computer can be accessed to provide the additional measurements.

The development of 3D scanning systems has been of great benefit to the nuclear power industry.