Blog

-

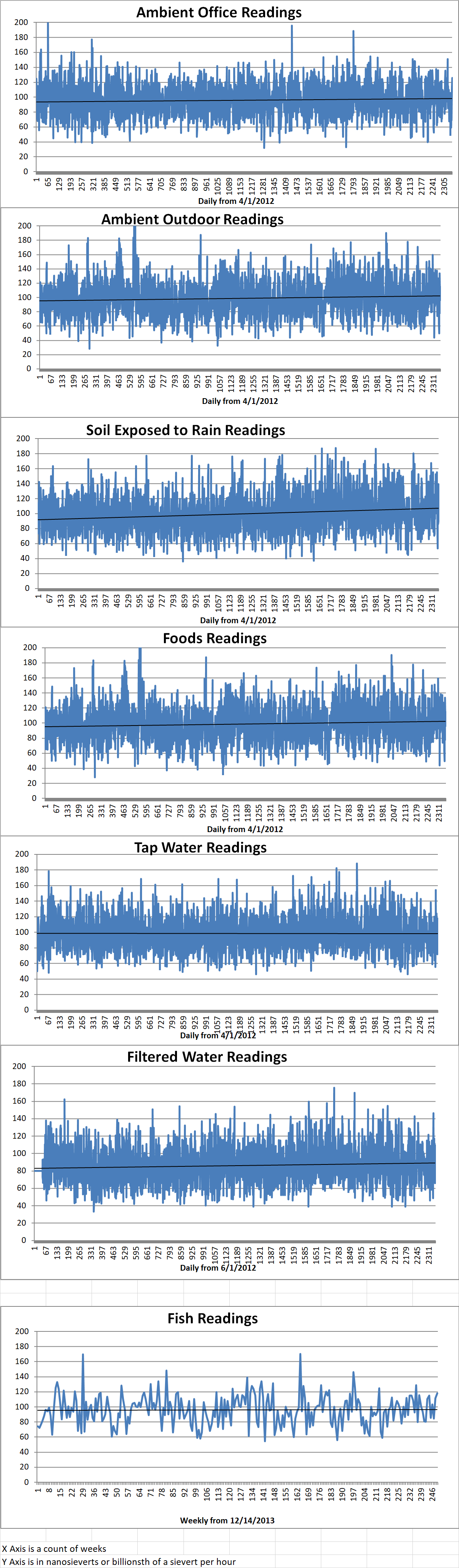

Geiger Readings for Dec 06, 2018

Ambient office = 126 nanosieverts per hour

Ambient outside = 126 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Orange bell pepper from Central Market = 115 nanosieverts per hour

Tap water = 90 nanosieverts per hour

Filter water = 85 nanosieverts per hour

-

Nuclear Reactors 637 – Grand Gulf Nuclear Generating Station Is Not Reliable Base-Load Power

One of the things that supporters of nuclear power always bring up is the fact that nuclear power plants are base-load power. This means that the plants are always running and producing power as opposed to solar and wind installation which are intermittent. Having base-load power sources on the electrical grid to continually supply a minimum amount of electricity is very important. While nuclear power is theoretically base-load, in reality, nuclear power plants are not “always on.” In addition to the scheduled downtime necessary to load new nuclear fuel every twelve to eighteen months, there can be unscheduled shutdowns caused by technical problems in the complex components of plant.

The Grand Gulf Nuclear Generating Station is the largest single-unit nuclear plant in the U.S. It is located near the western border of Alabama and has a maximum capacity of one thousand four hundred and forty-three megawatts. It began operating in 1985. There have been plans to add additional reactors, but they were all abandoned. It is an example of why nuclear power cannot be counted on for base-load power.

A review of federal daily reactor status reports by E&E News found that between 2013 and the present, the Grand Gulf only operated at full power for a little over half the time. It was at zero power about one fifth of the time. The rest of the time, it was operating at reduced power.

Entergy holds a ninety percent stake in Grand Gulf through a company called System Energy Resources, Inc. Utilities in Arkansas, Mississippi and Louisiana all receive electricity from Grand Gulf. When Grand Gulf is shut down, the local grid must find other power sources which can be more expensive and involve the use of fossil fuels with their carbon emissions.

The Grand Gulf had five unplanned downpower events in the past year. One of these outages lasted for three months. There have been other long power outages. An outage that started in September of 2016 lasted for five months. In 2016, Grand Gulf was at zero power for a total of one hundred and seventy-six days.

Turning a nuclear power reactor on and off can make the reactor unstable. Entergy says that it is working on making the plant operation more reliable at Grand Gulf. The NRC says that the plant is still safe to operate. However, the NRC has sent a notice to Entergy that the performance of the Grand Gulf is now outside of what the NRC considers normal.

Other electrical utilities and nuclear plant operators have similar problems as many reactors in the U.S. fleet are nearing the end of their licensed life spans. The operators of many of these aging nuclear plants are applying to the Nuclear Regulatory Commission for twenty-year extensions of their operating licenses.

It is very expensive to build a nuclear power plant but once in operation, they are relatively cheap to operate. The fuel is inexpensive and is not subject to the volatility of other fuels. While in operation, the plants do not emit carbon dioxide and other pollutants. However, as nuclear power plants age, the maintenance costs rise and obtaining replacement parts becomes increasingly difficult. In addition, downtimes increase. -

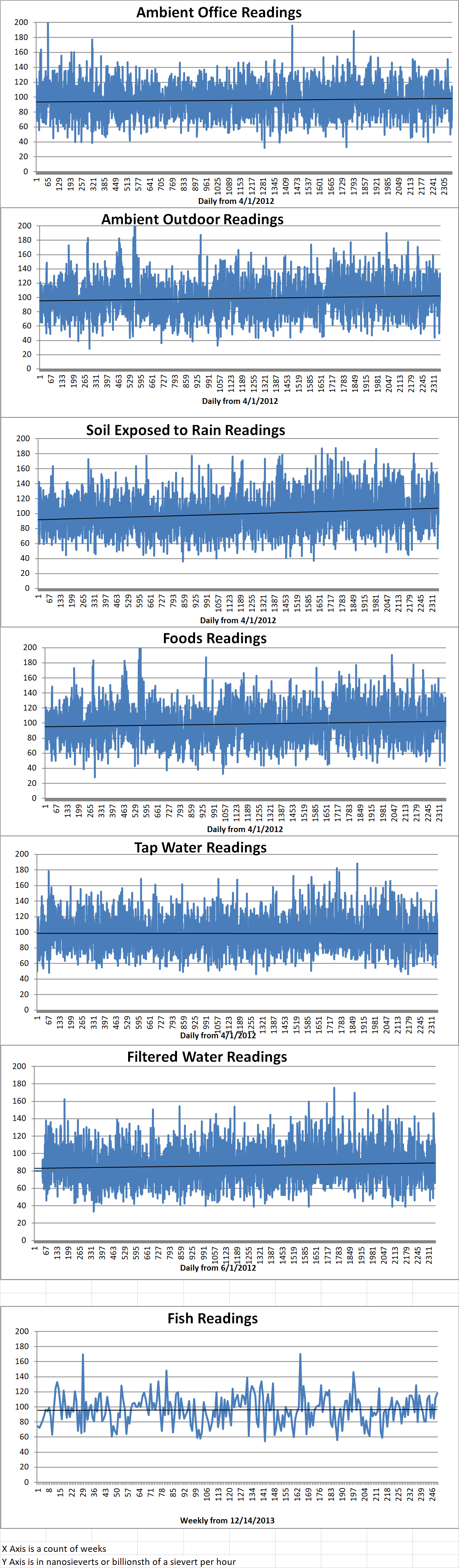

Geiger Readings for Dec 05, 2018

Ambient office = 113 nanosieverts per hour

Ambient outside = 138 nanosieverts per hour

Soil exposed to rain water = 139 nanosieverts per hour

Yellow bell pepper from Central Market = 96 nanosieverts per hour

Tap water = 118 nanosieverts per hour

Filter water = 109 nanosieverts per hour

-

Nuclear Reactors 636 – Three Dimensional Scanning Systems Used To Map Nuclear Reactor Pipe Networks

Nuclear power plants are designed to prevent the escape of radioactive materials. As nuclear power plants age, the danger of release of radioactive materials increases. All nuclear power plants contain a vast network of pipe to carry coolant through the different components of the system. As these pipes age, the danger of corrosion and cracks allowing radioactive materials to leak increases. Monitoring and maintaining the network of pipes in a nuclear power plant is a critical task.

Most of the commercial power reactors in the world today are pressurized water reactors (PWR). In a PWR, the primary coolant is water. Radioactive water and steam are pumped through a closed system of pipes that carries them to the core to be heated by the heat released from the nuclear fission reaction. From there they are carried to a heat exchanger that transfers the heat to water circulating in secondary network of pipes. The water in the secondary system is converted to steam that is fed into a turbine to create electricity.

A failure anywhere in the network of pipes could be a major problem. The Nuclear Regulatory Commission is concerned that pipes in nuclear power plants may be undergoing corrosion that could result in leaks and ruptures. This could lead to disasters in which the function of the plant is impaired and/or radioactive materials are released into the environment.

It is difficult to monitor corrosion inside pipes. One source of corrosion is from gases that might be trapped inside the pipe network. Gases mixed with water naturally rises to the highest spot in the container. In a network of pipes, the highest points can become places where gases accumulate, and corrosion occurs. One of the ways to detect potential problems spots is to map the network of pipes.

If highest points can be correctly identified, then vents can be installed in those parts of the pipe network to allow gas to escape and prevent corrosion. The old system to mapping pipe networks utilized hand tools which required staff to spend a lot of time in and around the pipe network. This could result in exposure to dangerous levels of radiation. And, using hand tools is a crude system and could easily miss important information about the pipe network.

Exact Metrology (EM) is a company that specializes in 3D and CT scanning. A few EM technicians can scan the entire pipe network of a nuclear power plant using Leica HDS scanners. These scanners are able to capture full-volume, 360° 3D point clouds for a location in just three minutes. A point cloud is a very accurate digital record of an object or space. Some rooms only require one such scan, while other rooms require multiple scans. Once the scanner is set up and started, the rest of the process is automatic, and the technician can retreat to a safer area if necessary. Once all the scans have been carried out, the separate scans are combined into a single point cloud.

Once the complete point cloud is created, sophisticated computer algorithms are used to identify the pipe sizes, centerlines and positions, even if some section of pipe are concealed from view. The point cloud for nuclear reactor pipe networks is able to identify sections of pipe which are crystalized and leaking.

Once the scanning and point cloud assembly are completed, 3D CAD models are created. Computer snapshot are recorded with elevations descriptors marked on the pipe runs. These snapshots are sent to engineers at the facility to determine if it is necessary to install vents at particular high points.

One big benefit of 3D scanning is that the scans can be carried out at ground level. This means that technicians do not need to climb ladders and scaffolding which reduces the danger to the technicians. Another benefit of 3D scans is that additional measurements can be conducted without the need to return to the actual pipe network. The point cloud assembled in the computer can be accessed to provide the additional measurements.

The development of 3D scanning systems has been of great benefit to the nuclear power industry. -

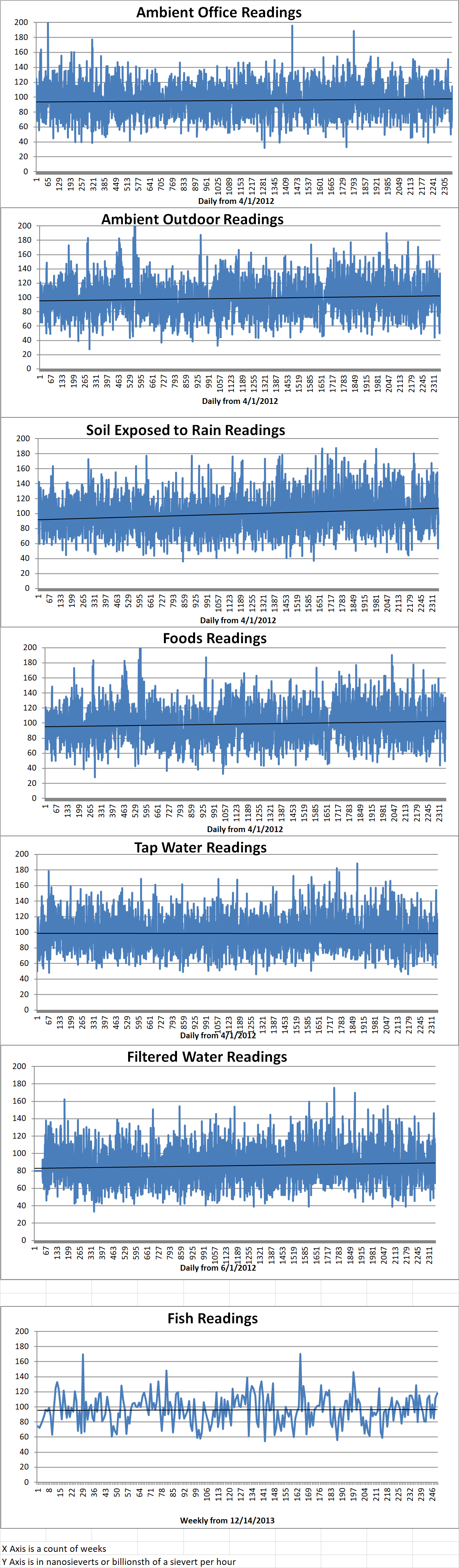

Geiger Readings for Dec 04, 2018

Ambient office = 69 nanosieverts per hour

Ambient outside = 88 nanosieverts per hour

Soil exposed to rain water = 86 nanosieverts per hour

Bartlett pear from Central Market = 134 nanosieverts per hour

Tap water = 73 nanosieverts per hour

Filter water = 67 nanosieverts per hour

-

Radioactive Waste 367 – Southern California Edison And Holtec International Are Using Inadequate Dry Casks To Store Spent Nuclear Fuel From The San Onofre Nuclear Generating Station

I have blogged about the San Onofre Generating Station near San Diego before. This plant is owned and was operated by the Southern California Edison (SCE) utility. The plant was shut down in 2013 after replacement steam generators failed. SCE redesigned the replacement generators but were told by the manufacturer that the new designs might not work correctly. SCE told the manufacture to go ahead and build the redesigned generators. SCE also told the U.S. Nuclear Regulatory Commission (NRC) that they had made no changes to the generators and did not need to get approval from the NRC.

As with all shuttered nuclear power plants, there was a question of what to do with all the spent fuel. Some California activists wanted it removed from the site. The operators decided that they would lease land at the Navy’s nearby San Onofre Camp Pendleton for their underground storage facility. They put spent fuel rods into Holtec dry cask containers made of concrete and steel and moved them under ground. Activist fought this decision but lost.

Now the NRC has just issued a report that states that every Holtec dry cask that has been lowered into the ground is damaged. Apparently, there is not enough clearance between the dry casks and the divider shell in the storage hole. The sides of the dry casks already show signs of wear. As a result of such wear, cracks form in the walls of the dry casks. Over time, these cracks will grow and multiply. This could result in the leakage of radioactive materials in casks as well as explosions.

The NRC says that SCE and Holtec have known about this problem since January of 2018 but continued to lower twenty nine dry casks into the storage hole. The NRC has ordered SCE and Holtec to stop loading dry casks into the storage hole until this problem is dealt with. SCE and Holtec say that there is no way to inspect and repair dry casks once they are in the storage hole.

Activists say that the NRC should admit that the Holtec dry casks are based on a faulty design and that the NRC should revoke the licenses of SCE and Holtec to carry out their current dry cask storage plan. They say that the NRC should mandate that all the thin-walled Holtec dry casks should be removed from the storage hole and the spent nuclear fuel in them should be transferred to new thick-walled transportable dry casks. These transportable casks are the only temporary storage system for spent nuclear fuel that can be inspected, maintained, repaired and monitored sufficiently to reduce the risk of explosions and the release of radioactive materials. There are calls for responsible California state agencies to cancel the permits for San Onofre dry cask storage and to withhold Decommissioning Trust Funds until these problems have been solved.

Critics of the work done so far by SCE and Holtec say that the leases for Navy land should be cancelled and that the Navy should bring in their own nuclear experts to deal with what the critics consider to be a national security issue. They say that the thin-walled dry casks being used by SCE and Holtec are a clear and imminent danger to the health and lives of the citizens, and pose potential financial, security and ecological disaster for the state of California, and beyond.

San Onofre Nuclear Generating Station: