There are four hundred and forty eight operating commercial nuclear power reactors in the world today. Fifty more reactors are under construction. Most of these reactors are water-cooled and water-moderated. The fuel elements in these reactors are mostly zirconium alloys. These alloys are stable and effective up to a temperature of six hundred and sixty-two degrees Fahrenheit. If the heat-removal systems in the reactors are shut down, the temperatures of the fuel containers can reach as high as one thousand six hundred and fifty two degrees Fahrenheit. At these high temperatures, a chemical reaction between zirconium and water vapor can generate explosive hydrogen gas.

The generation of hydrogen gas from the interaction of zirconium in fuel tubes with water vapor at very high temperatures in nuclear power reactors has led to destructive explosions at nuclear power plants in the past.

Boris Kalin is the head of the Moscow Engineering Physics Institute’s (MEPI) Faculty of Physical Problems in Material Science. He leads a team of researchers at the National Research Nuclear University (NRNU) at the MEPI. He recently said “To prevent zirconium-vapor interaction, the researchers propose coating the surface of heat elements with materials (including chromium) that will prevent contact between zirconium and water vapors. We have achieved the science and technological goal of selecting the required compound and coating sections of fuel-element tubes up to 500 mm long with a protective chromium-content substance. This slows the zirconium-oxidization process in water vapors at up to twenty two hundred degrees Fahrenheit.”

The NRNU team says that their ion-beam method requires that the surface of the tubes containing the fuel pellets be polished with argon ions. This insures a very smooth surface. Then alloys acting as electrodes are sprayed onto the surface of the tubes inside the vacuum chamber. This continues until a layer of alloy up to ten micrometers thick is deposited on the surface of the tubes.

After treating the fuel tubes with their process, the NRNU technicians examined the composition, structure and thickness of the alloy coatings with electron and ion microscopes. The wear resistance of the coatings were tested by rubbing them against zirconium components. They also tested the water-oxidation at six hundred and sixty-two degrees Fahrenheit for seventy two hours and then repeated the test at twenty two hundred degrees Fahrenheit.

Kalin said, “We repeated the experiment several times, adjusted the composition of magnetron electrodes and treatment modes, and analyzed each result. This allowed us to choose the optimal composition of coatings and prevent the oxidization of the external surface of zirconium tubes at plus 1,200 degrees Celsius for 400 seconds.”

The results of the work at NRNU are going to be presented at the Sixteenth International school conference: New Materials: Tolerant Nuclear Fuels which was held at the NRNU. The event was initiated by the research school and the Laboratory for the Ion-Beam Treatment of Materials at the Faculty of Physical Problems of Materials Science.

Improving the safety of the fuel assemblies under extreme conditions is a high priority research subject in the nuclear industry.

Blog

-

Nuclear Reactors 638 – Moscow Institute Of Physics and Technology Is Developing A New Coating For Zirconium Alloy Fuel Assemblies

-

Geiger Readings for Dec 11, 2018

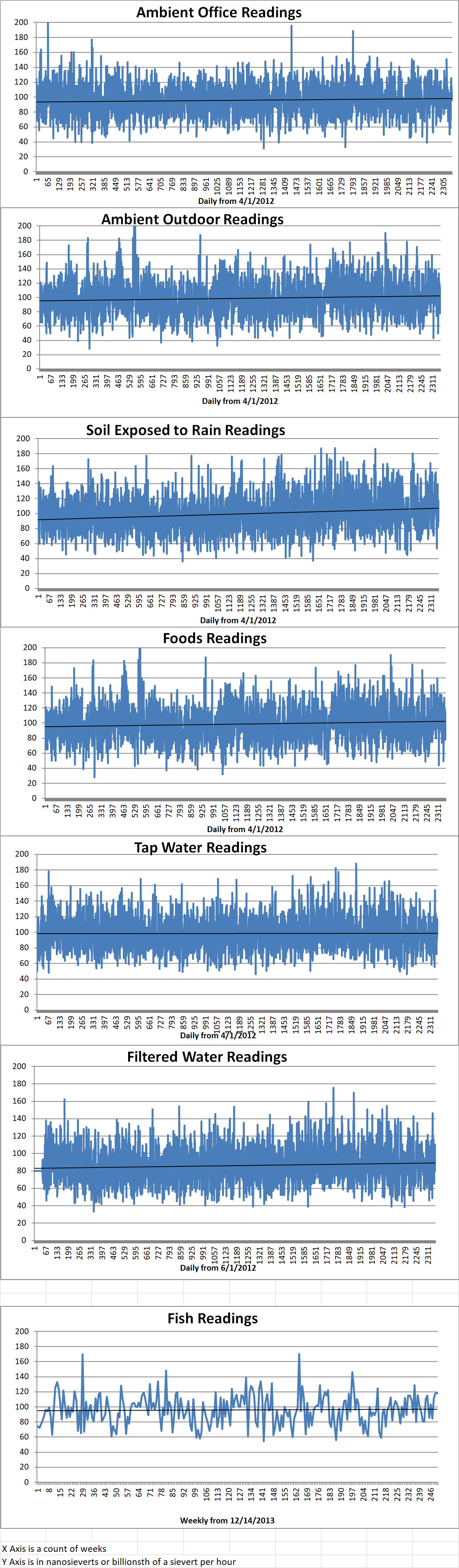

Ambient office = 96 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 117 nanosieverts per hour

Beefsteak tomato from Central Market = 112 nanosieverts per hour

Tap water = 115 nanosieverts per hour

Filter water = 110 nanosieverts per hour

-

Radioactive Waste 370 – The Advanced Mixed Waste Treatment Project At The Idaho National Laboratory Is Being Shut Down

The Hanford Nuclear Reservation was established in 1943 in south central Washington State. The plutonium that was used in World War II to bomb Nagasaki, Japan was produced at the Reservation. During the Cold War, most of the plutonium for the sixty thousand nuclear warheads in the U.S. arsenal was produced at Hanford by the nine reactors and the five plutonium processing facilities constructed on the site.

Nuclear weapons production at Hanford was halted in 1987. Fifty-three million gallons of high-level radioactive waste were left behind by these activities and remain at Hanford in underground tanks, some of which have been leaking.

The high-level radioactive liquid waste at Hanford contains transuranic materials which are man-made unstable radioactive elements such as plutonium that are beyond the natural occurring elements in the periodic table. They will be dangerously radioactive for thousands of years.

The Idaho National Laboratory in south east Idaho was established by the U.S. federal government in 1949 to be a center for nuclear research. Over the years, fifty experimental reactors have been constructed at the INL. Such research continues today with plans to construct one of the first commercial small modular reactors at the INL.

There are more transuranic wastes at the INL than any other federal facility. This waste includes work clothing, rags, machine parts and tools that have been contaminated with plutonium and other radioactive elements. There have been court battles between the State of Idaho and the U.S. Department of Energy over the radioactive waste at the INL site. In 1995 an agreement was reached which required the DoE to clean up the INL site. The Advanced Mixed Waste Treatment Project (AMWTP) was constructed to deal with transuranic wastes.

The Waste Isolation Pilot Plant near Carlsbad New Mexico was opened in 1999 to receive solid transuranic waste from facilities around the U.S. which had been used for research and development of nuclear warheads. A few years ago, an accident closed the WIPP for several years, but it is now back in operation.

The AMWTP at the INL was set up to compact and solidify transuranic wastes which could then be shipped to the WIPP for disposal. The AMWTP is just finishing up the processing of eighty-five thousand cubic yards of transuranic wastes for shipment to the WIPP. The DoE has just announced that the AMWTP will be closed next year.

There have been proposals for keeping the AMWTP open to process liquid transuranic wastes from other national laboratories and other facilities used in the development of nuclear warheads with most of the waste coming from Hanford. A thirty-eight page economic analysis from the DoE was just released that said that “it does not appear to be cost effective due to packaging and transportation challenges in shipping waste” to Idaho.

Currently, there are efforts to reclassify some of the high-level radioactive waste at Hanford to low-level radioactive waste. This would allow some of the waste currently stored in disintegrating underground tanks to remain in the tanks. The tanks would be topped off with grout and permanently buried. This might result in leakage of some wastes into the Columbia River. Unfortunately, the better solution of treatment at the INL and shipment to WIPP seems to be dead. -

Geiger Readings for Dec 10, 2018

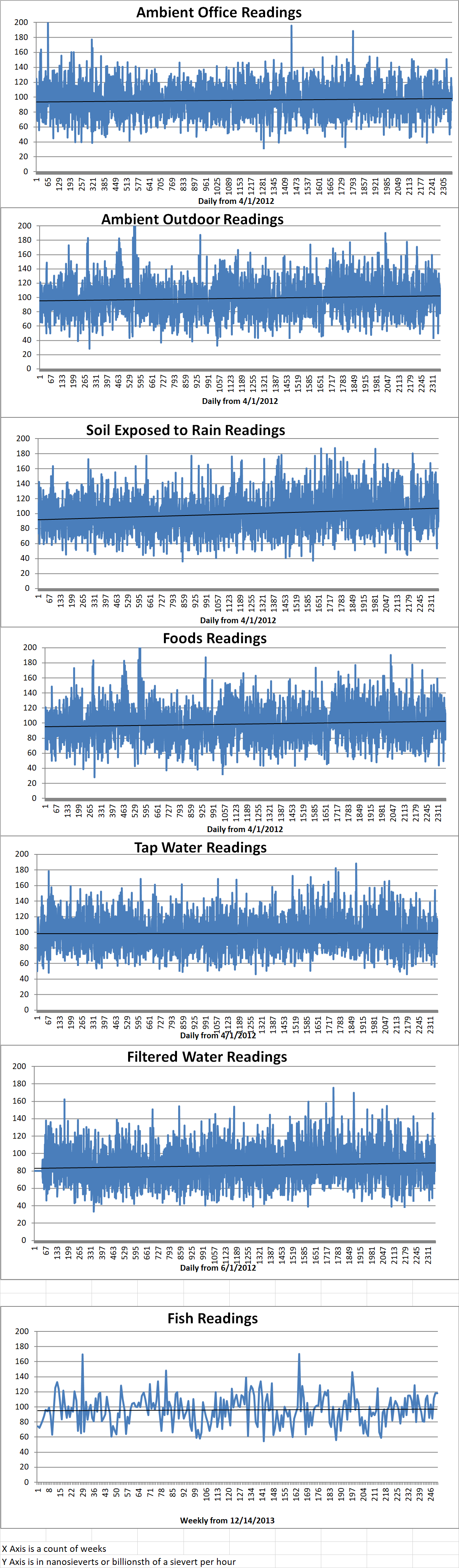

Ambient office = 103 nanosieverts per hour

Ambient outside = 92 nanosieverts per hour

Soil exposed to rain water = 89 nanosieverts per hour

Carrot from Central Market = 78 nanosieverts per hour

Tap water = 100 nanosieverts per hour

Filter water = 80 nanosieverts per hour

-

Geiger Readings for Dec 09, 2018

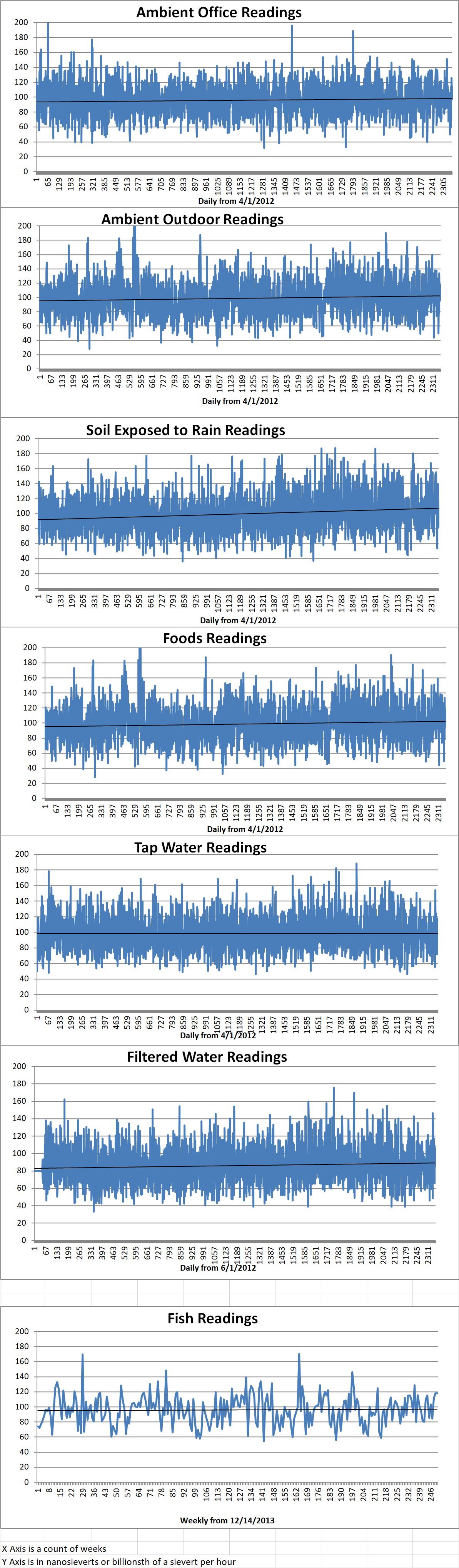

Ambient office = 98 nanosieverts per hour

Ambient outside = 105 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Pineapple from Central Market = 109 nanosieverts per hour

Tap water = 110 nanosieverts per hour

Filter water = 99 nanosieverts per hour

-

Geiger Readings for Dec 08, 2018

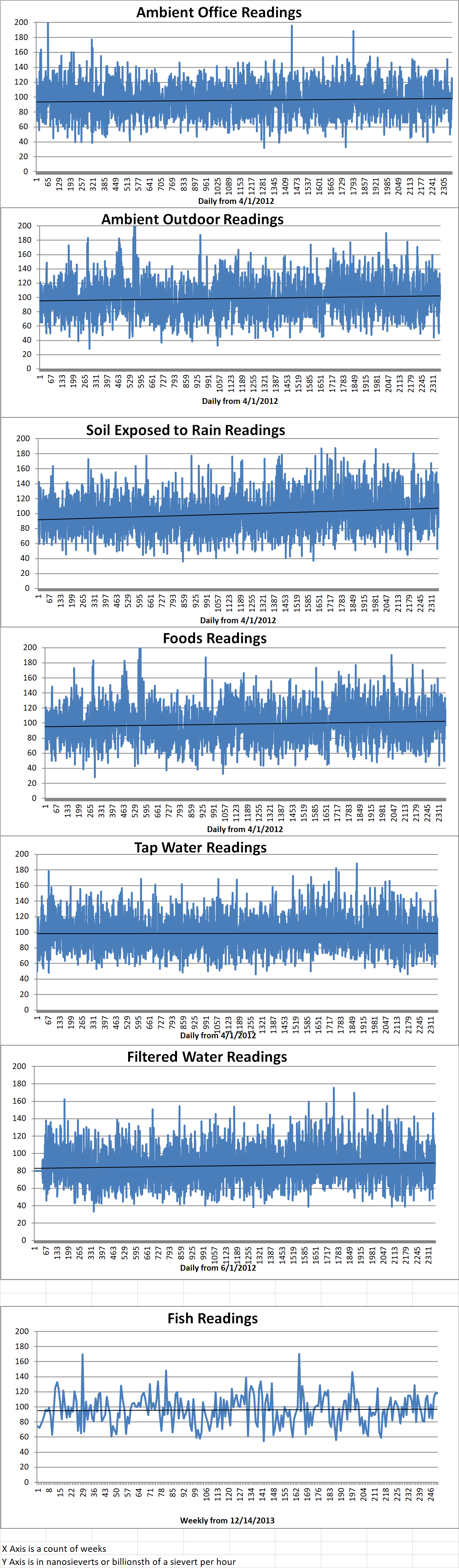

Ambient office = 9114 nanosieverts per hour

Ambient outside = 81 nanosieverts per hour

Soil exposed to rain water = 82 nanosieverts per hour

Crimini mushroom from Central Market = 118 nanosieverts per hour

Tap water = 111 nanosieverts per hour

Filter water = 106 nanosieverts per hour

Dover sole – Caught in USA = 118 nanosieverts per hour