The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

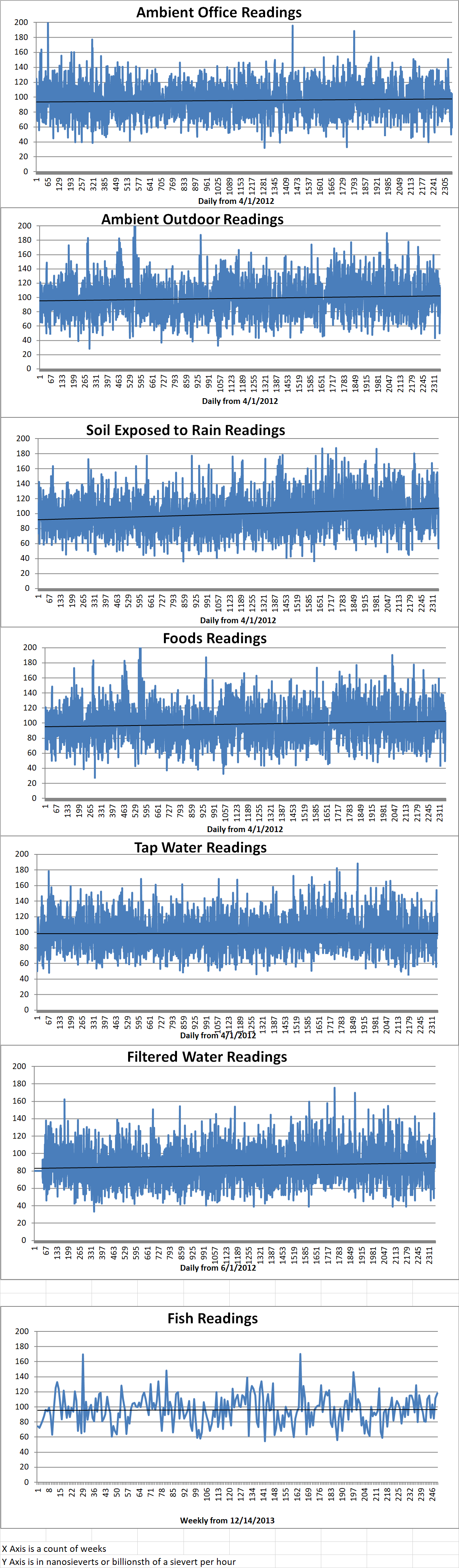

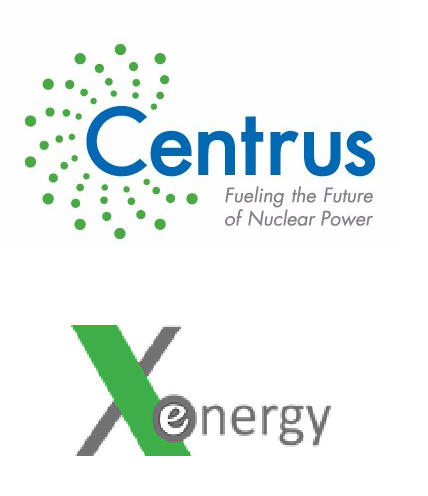

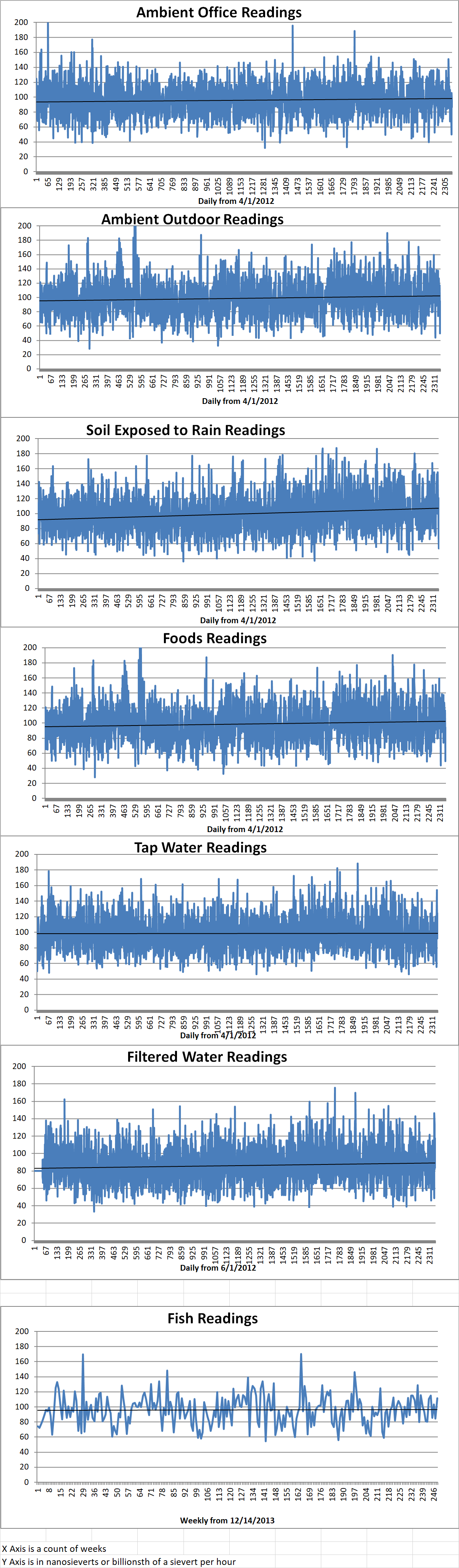

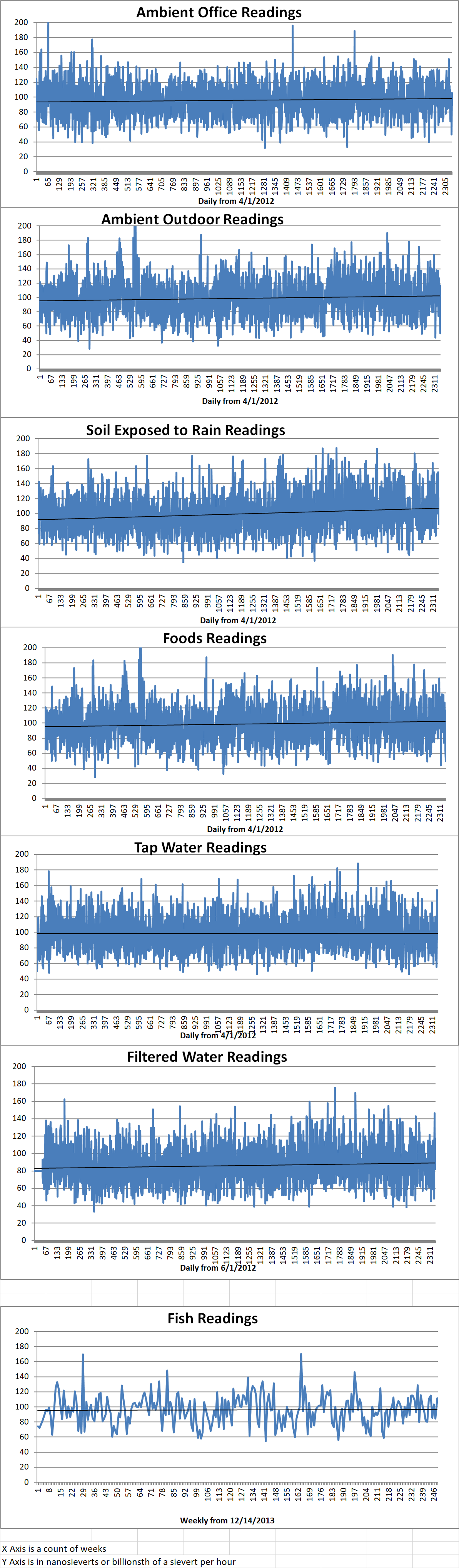

Ambient office = 104 nanosieverts per hour

Ambient outside =89 nanosieverts per hour

Soil exposed to rain water = 89 nanosieverts per hour

Beefstreak tomato from Central Market = 79 nanosieverts per hour

Tap water = 106 nanosieverts per hour

Filter water = 97 nanosieverts per hour

Ambient office = 59 nanosieverts per hour

Ambient outside = 105 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Cauliflower from Central Market = 114 nanosieverts per hour

Tap water = 116 nanosieverts per hour

Filter water = 112 nanosieverts per hour

Dover sole – Caught in USA = 118 nanosieverts per hour

Centrus Energy Corporation and X-energy are working on the preliminary design of a facility dedicated to the fabrication of advanced nuclear fuels. The new fuels will be based on the uranium oxycarbide tristructural isotropic (TRISO) fuel form developed by X-energy.

In 2017, a memorandum of understanding (MoU) was signed for the development of a fuel fabrication facility intended to create TRISO fuels to be used in the X-energy Xe-100 high temperature gas-cooled modular reactors and other advanced reactors. A contract was signed last March to build on the 2017 MoU and develop a conceptual design for the fuel fabrication facility. A new services contract has just been signed.

According to the new services contract between Centrus and X-energy, Centrus will contribute technical expertise and resources for the preliminary facility design. This will include detailed nuclear criticality safety analysis, infrastructure design, balance of plant support systems, and initial work on a license for the new fuel fabrication facility. Centrus will also make space available to X-energy at the Centrus Technology and Manufacturing Center in Oak Ridge, Tennessee.

Daniel Poneman is the president and chief executive officer of Centrus. He said, “We see great promise in this market and believe the advanced TRISO fuel to be produced in this facility will offer an attractive and competitive solution to power advanced reactors around the world.”

Pete Pappano is the principal investigator and vice president of fuels production at X-energy. He said that the working agreement between Centrus and X-energy had already produced a conceptual layout of the of the TRISO-X Fuel Fabrication Facility. He added, “With this new agreement, X-energy and Centrus will complete the preliminary and final designs of the TRISO-X Facility, positioning the companies to be first to market in the sector of high assay low enriched uranium (HALEU) TRISO-based fuel for advanced reactors and, potentially, accident tolerant fuel for the existing light water reactor fleet.”

The X-energy Xe-100 is a seventy-five megawatt reactor. X-energy intends to bundle four of them together in a commercial “four-pack” arrangement to produce three hundred megawatts. The TRISO fuel “pebbles” each have a center of enriched uranium carbide. This core is embedded in carbon and ceramic layers which prevent the release of radiation. The layers surrounded the core of each pebble function as a containment system. The graphite around the pebbles moderates the nuclear reaction. It is impossible for these pebbles to melt down.

Last year, at the Oak Ridge National Laboratory, X-energy created its first fuel pebbles using un-enriched natural uranium. Earlier this year, X-energy was awarded four and a half million dollars for the U.S. Department of Energy to match their own investment of four and half million dollars to design a commercial scale fuel fabrication facility. A license application is to be submitted to the Nuclear Regulatory Commission by the middle of 2021.

Harlan Bowers is the president of X-energy. He said last March that he hopes that the new fuel will be in production by 2025. The fuel would then be available to load into new advanced reactors such as the Xe-100 which are expected to be ready in the late 2020s.

Ambient office = 87 nanosieverts per hour

Ambient outside = 50 nanosieverts per hour

Soil exposed to rain water = 53 nanosieverts per hour

Pineapple from Central Market = 94 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filter water = 84 nanosieverts per hour

I first heard about robotic suits around 1961 in a science fiction novel, Starship Troopers. The infantry in the novel wore metal suits that amplified their strength and protected them from harm. Over the years, a lot of money has been poured into exoskeletons which are pieces of equipment that can be strapped on the body to amplify strength. At the same time, protective suits against fire, chemicals and radiation have been under development. All of these ideas were seen in the popular movie Iron Man. Now a protective suit with strength amplifiers for use in nuclear power plants is being developed.

South West Nuclear Hub at Bristol University in the U.K. is collaborating with Sellafield Ltd, the company that manages the big nuclear facility in Cumbria to create a new type of protective suit for workers in radioactive environments. The Sellafield site receives most of the spent nuclear fuel from U.K. power reactors. It also contains many facilities that handle nuclear materials. Some of its facilities have been decommissioned. Decommissioning is a major problem confronting the global nuclear industry and Sellafield is always working on ways to improve decommissioning.

Currently, workers at Sellafield use air-fed PVC protective suits in areas where there is dangerous radioactivity. While this type of suit may be safe for the workers to use, it can only be worn a few hours at a time because it exposes the wearer to unhealthy heat stress. Now they are working on a suit like the one shown in the Iron Man movies and comic books. The suit would be made of composite materials to protect the wearer. In addition, it would incorporate wearable exoskeletons.

These new suits would minimize any physical stress on the worker wearing them. This would be advantageous when working in awkward or constrained positions that occur when in a confined space or when lifting heavy objects. The new composite materials of the suits would provide more protection against high radiation levels. They would also be much easier to decontaminate.

Professor Tom Scott is the project lead from the University of Bristol. He is also the co-director of the South West Nuclear Hub. He said, “Sellafield is one of the biggest nuclear decommissioning challenges in the world, predicted to last 100 years and costing tens of billions of pounds. Robotic and remotely-deployed technologies are already helping the Sellafield mission, but there will always be some cases where human workers are required to do hands on work in hazardous plant areas. Our wearable suit concept offers the prospect of major improvements in worker protection and enhanced ergonomic capabilities.”

Professor Scott and his collaborators are part of a consortium which includes National Nuclear Laboratory (NNL), DZP Technologies, Imitec and Lightricity. The collaboration was funded by the Sellafield Ltd under the Innovate U.K. project to research the feasibility of wearable technologies. The consortium is also researching eye movement tracking. It is hope that this will help detect fatigue in workers. Printed electronics to be incorporated in the suits are part of their research. Hand-mounted devices for better detection of radiation and nuclear materials are being studied.

Professor Scott said, “Our concept has comparisons with how space suits were developed in the 1950s,” adds Professor Scott. “Space and nuclear are both safety-critical industries. Just as space suits enabled transformational outcomes, making it possible for humans to go into space, further development of our suit could result in game-changing improvements in decommissioning safety and performance at Sellafield. The suit could even be used at other nuclear decommissioning sites across the world, consistent with Government aims for the UK to be a global leader and established exporter of waste management and decommissioning markets solutions.”

A report on the work of the consortium will be delivered to Sellafield Ltd and Innovate U.K. in 2019. Following the delivery of the report, Sellafield will review the results and decide whether or not to proceed further, including the creation of a protype suit.

Ambient office = 89 nanosieverts per hour

Ambient outside = 88 nanosieverts per hour

Soil exposed to rain water = 86 nanosieverts per hour

Carrot from Central Market = 50 nanosieverts per hour

Tap water = 124 nanosieverts per hour

Filter water = 117 nanosieverts per hour