Centrus Energy Corporation and X-energy are working on the preliminary design of a facility dedicated to the fabrication of advanced nuclear fuels. The new fuels will be based on the uranium oxycarbide tristructural isotropic (TRISO) fuel form developed by X-energy.

In 2017, a memorandum of understanding (MoU) was signed for the development of a fuel fabrication facility intended to create TRISO fuels to be used in the X-energy Xe-100 high temperature gas-cooled modular reactors and other advanced reactors. A contract was signed last March to build on the 2017 MoU and develop a conceptual design for the fuel fabrication facility. A new services contract has just been signed.

According to the new services contract between Centrus and X-energy, Centrus will contribute technical expertise and resources for the preliminary facility design. This will include detailed nuclear criticality safety analysis, infrastructure design, balance of plant support systems, and initial work on a license for the new fuel fabrication facility. Centrus will also make space available to X-energy at the Centrus Technology and Manufacturing Center in Oak Ridge, Tennessee.

Daniel Poneman is the president and chief executive officer of Centrus. He said, “We see great promise in this market and believe the advanced TRISO fuel to be produced in this facility will offer an attractive and competitive solution to power advanced reactors around the world.”

Pete Pappano is the principal investigator and vice president of fuels production at X-energy. He said that the working agreement between Centrus and X-energy had already produced a conceptual layout of the of the TRISO-X Fuel Fabrication Facility. He added, “With this new agreement, X-energy and Centrus will complete the preliminary and final designs of the TRISO-X Facility, positioning the companies to be first to market in the sector of high assay low enriched uranium (HALEU) TRISO-based fuel for advanced reactors and, potentially, accident tolerant fuel for the existing light water reactor fleet.”

The X-energy Xe-100 is a seventy-five megawatt reactor. X-energy intends to bundle four of them together in a commercial “four-pack” arrangement to produce three hundred megawatts. The TRISO fuel “pebbles” each have a center of enriched uranium carbide. This core is embedded in carbon and ceramic layers which prevent the release of radiation. The layers surrounded the core of each pebble function as a containment system. The graphite around the pebbles moderates the nuclear reaction. It is impossible for these pebbles to melt down.

Last year, at the Oak Ridge National Laboratory, X-energy created its first fuel pebbles using un-enriched natural uranium. Earlier this year, X-energy was awarded four and a half million dollars for the U.S. Department of Energy to match their own investment of four and half million dollars to design a commercial scale fuel fabrication facility. A license application is to be submitted to the Nuclear Regulatory Commission by the middle of 2021.

Harlan Bowers is the president of X-energy. He said last March that he hopes that the new fuel will be in production by 2025. The fuel would then be available to load into new advanced reactors such as the Xe-100 which are expected to be ready in the late 2020s.

Blog

-

Nuclear Reactores 635 – Centrus Energy Corporation and X-energy Are Working On New TRISO Nuclear Fuel Facility

-

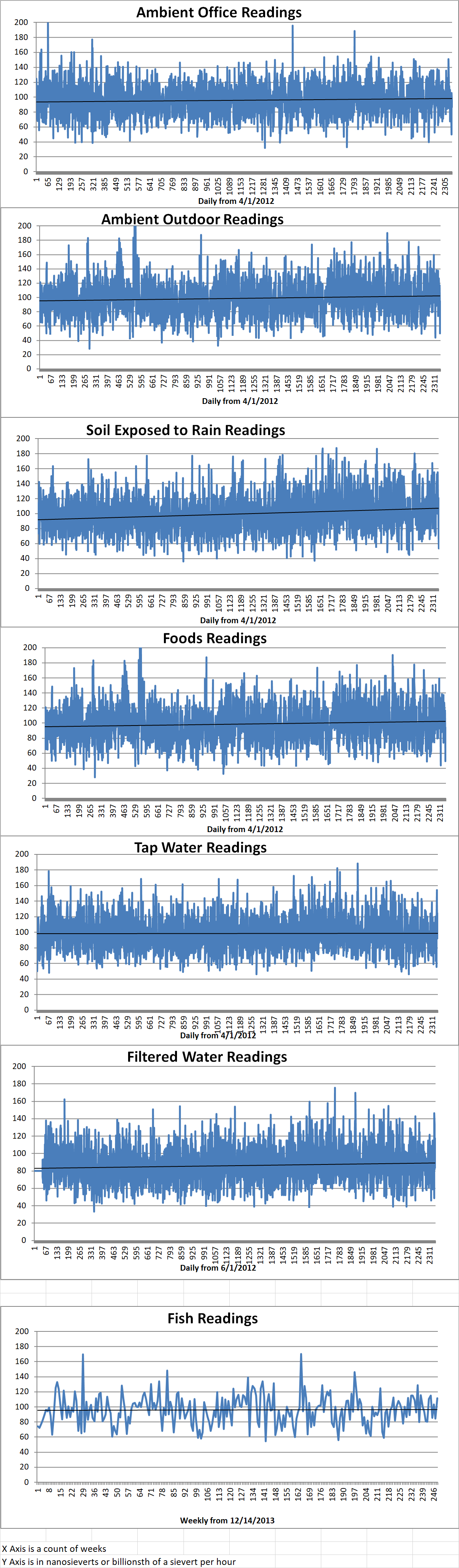

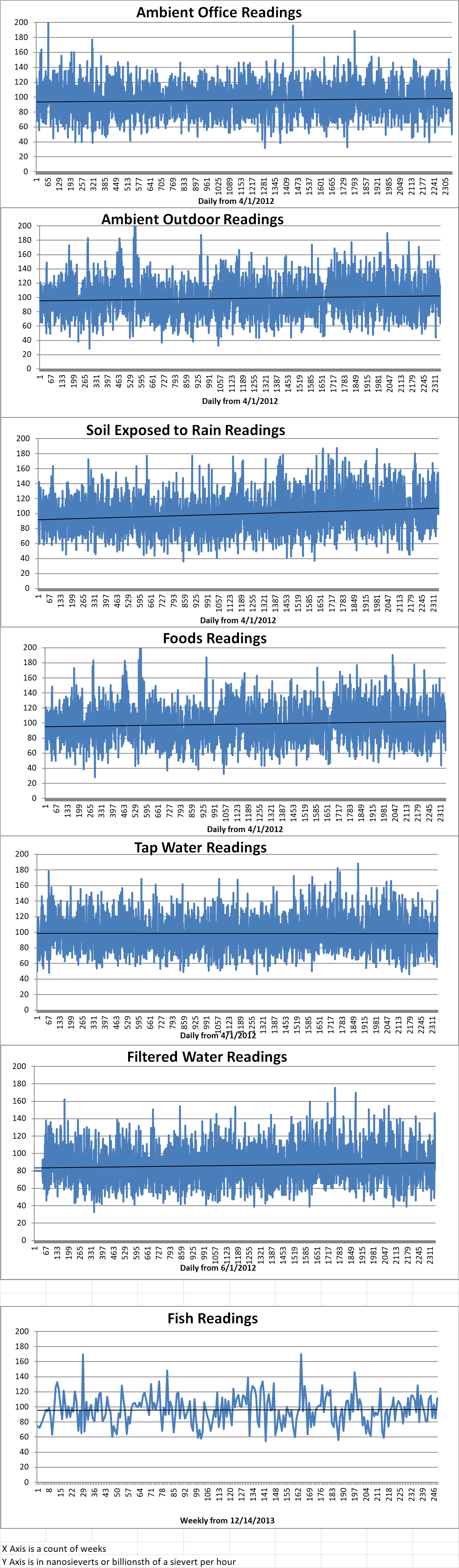

Geiger Readings for Nov 30, 2018

Ambient office = 87 nanosieverts per hour

Ambient outside = 50 nanosieverts per hour

Soil exposed to rain water = 53 nanosieverts per hour

Pineapple from Central Market = 94 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filter water = 84 nanosieverts per hour

-

Radioactive Waste 366 – Sellafield Ltd. In The U.K. Is Researching A Better Suit For Radiation Protection

I first heard about robotic suits around 1961 in a science fiction novel, Starship Troopers. The infantry in the novel wore metal suits that amplified their strength and protected them from harm. Over the years, a lot of money has been poured into exoskeletons which are pieces of equipment that can be strapped on the body to amplify strength. At the same time, protective suits against fire, chemicals and radiation have been under development. All of these ideas were seen in the popular movie Iron Man. Now a protective suit with strength amplifiers for use in nuclear power plants is being developed.

South West Nuclear Hub at Bristol University in the U.K. is collaborating with Sellafield Ltd, the company that manages the big nuclear facility in Cumbria to create a new type of protective suit for workers in radioactive environments. The Sellafield site receives most of the spent nuclear fuel from U.K. power reactors. It also contains many facilities that handle nuclear materials. Some of its facilities have been decommissioned. Decommissioning is a major problem confronting the global nuclear industry and Sellafield is always working on ways to improve decommissioning.

Currently, workers at Sellafield use air-fed PVC protective suits in areas where there is dangerous radioactivity. While this type of suit may be safe for the workers to use, it can only be worn a few hours at a time because it exposes the wearer to unhealthy heat stress. Now they are working on a suit like the one shown in the Iron Man movies and comic books. The suit would be made of composite materials to protect the wearer. In addition, it would incorporate wearable exoskeletons.

These new suits would minimize any physical stress on the worker wearing them. This would be advantageous when working in awkward or constrained positions that occur when in a confined space or when lifting heavy objects. The new composite materials of the suits would provide more protection against high radiation levels. They would also be much easier to decontaminate.

Professor Tom Scott is the project lead from the University of Bristol. He is also the co-director of the South West Nuclear Hub. He said, “Sellafield is one of the biggest nuclear decommissioning challenges in the world, predicted to last 100 years and costing tens of billions of pounds. Robotic and remotely-deployed technologies are already helping the Sellafield mission, but there will always be some cases where human workers are required to do hands on work in hazardous plant areas. Our wearable suit concept offers the prospect of major improvements in worker protection and enhanced ergonomic capabilities.”

Professor Scott and his collaborators are part of a consortium which includes National Nuclear Laboratory (NNL), DZP Technologies, Imitec and Lightricity. The collaboration was funded by the Sellafield Ltd under the Innovate U.K. project to research the feasibility of wearable technologies. The consortium is also researching eye movement tracking. It is hope that this will help detect fatigue in workers. Printed electronics to be incorporated in the suits are part of their research. Hand-mounted devices for better detection of radiation and nuclear materials are being studied.

Professor Scott said, “Our concept has comparisons with how space suits were developed in the 1950s,” adds Professor Scott. “Space and nuclear are both safety-critical industries. Just as space suits enabled transformational outcomes, making it possible for humans to go into space, further development of our suit could result in game-changing improvements in decommissioning safety and performance at Sellafield. The suit could even be used at other nuclear decommissioning sites across the world, consistent with Government aims for the UK to be a global leader and established exporter of waste management and decommissioning markets solutions.”

A report on the work of the consortium will be delivered to Sellafield Ltd and Innovate U.K. in 2019. Following the delivery of the report, Sellafield will review the results and decide whether or not to proceed further, including the creation of a protype suit. -

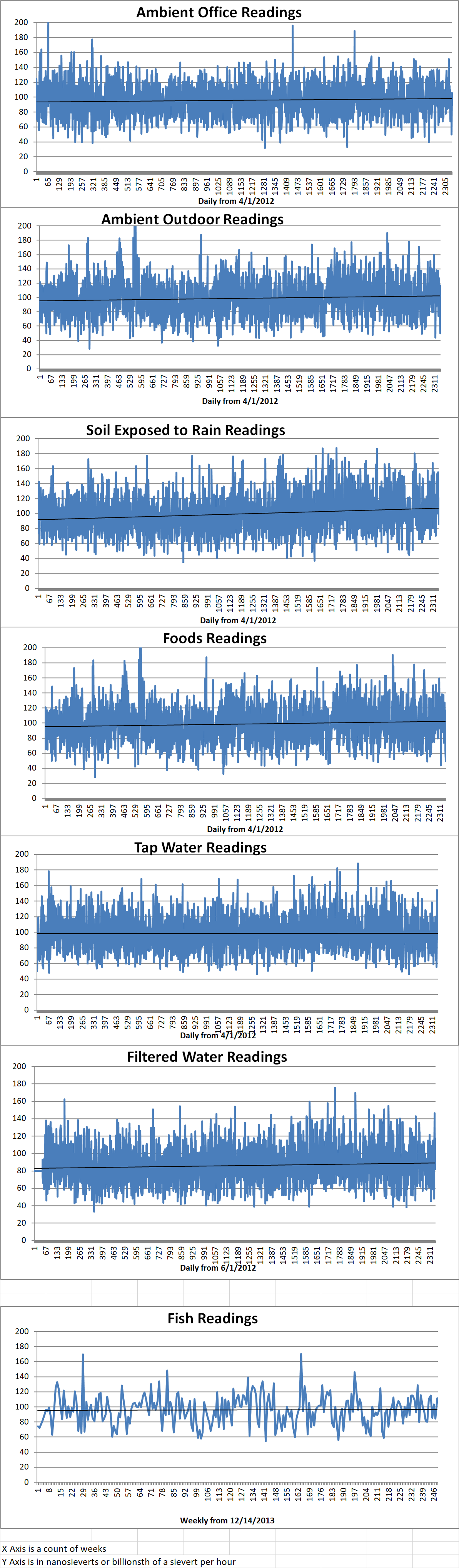

Geiger Readings for Nov 29, 2018

Ambient office = 89 nanosieverts per hour

Ambient outside = 88 nanosieverts per hour

Soil exposed to rain water = 86 nanosieverts per hour

Carrot from Central Market = 50 nanosieverts per hour

Tap water = 124 nanosieverts per hour

Filter water = 117 nanosieverts per hour

-

Nuclear Reactors 634 – NuScale Partnering With Canadian Bruce Power On SMRs

The U.S. nuclear industry is not doing well. The U.S. had about one hundred nuclear reactors in operation for the commercial generation of electric power. Six reactors have been retired in the past few years and there are plans to retire another sixteen reactors in the next ten years. Attempts to build two new reactors in South Carolina have collapses. The project to build new reactors in Georgia is having serious problems.

One of the proposed ways to expand the use of nuclear power in the U.S. is the creation of factory-made small modular reactors (SMR) that generate three hundred megawatts or less. It is claimed that this new type of reactor will be safer and cheaper than the current gigawatt plus conventional nuclear reactors.

NuScale Power is a private limited liability company with headquarters in Tigard, Oregon. NuScale was founded based on research on SMRs funded by the Department of Energy carried out between 2000 to 2003. The company was set up in 2007. NuScale has announced plans to construct its first reactor at the Idaho National Laboratory. A Utah utility is in talks with NuScale to build a NuScale reactor in Utah. It has been projected that the first commercial NuScale reactor will be on the market around 2025. Earlier this month, NuScale signed a memorandum of understanding with Ontario Power Generation, Inc. (OPG) that OPG would assist NuScale with its vendor design review that will be evaluated by the Canadian Nuclear Safety Commission.

Bruce Power is a privately-owned utility company in Canada. It provides about thirty percent of the electricity in the Ontario province. About six and a half gigawatts of the electricity from Bruce power come from commercial nuclear power reactors.

Last May, Bruce Power and the County of Bruce announced that they were entering into a partnership to create the Nuclear Innovation Institute (NII). This institute is intended to be an international center of excellence for applied research and training. This mission will include evaluating application for new nuclear technologies such as SMRs.

This week, NuScale signed a memorandum of understanding (MOU) with Bruce Power to develop a business case for the introduction of a NuScale SMR to the Canadian power market. The agreement says that Bruce Power will assist in evaluation, planning and licensing activities. Bruce Power said, “all of which will serve an important role in demonstrating the business case for why NuScale’s technology is the right choice for Ontario and Canada.” The agreement also included carrying out studies on the impact of deployment of a NuScale plant in Ontario Province. There will be feasibility studies for proposed SMR sites and other risk evaluation activities to demonstrate how the deployment of SMRs can be of use in Canada.

Mike Rencheck is the President and Chief Executive Officer of Bruce Power President. He remarked that the development of the NuScale SMR had reached the point “where Bruce Power can participate in understanding and developing a conceptual business case” for making SMRs a power source in Canada. He also said that “We look forward to working with NuScale.”

NuScale also has two laboratories in Italy and is working with the U.K. government on the possibility of building SMRs there. -

Geiger Readings for Nov 28, 2018

Ambient office = 93 nanosieverts per hour

Ambient outside = 118 nanosieverts per hour

Soil exposed to rain water = 121 nanosieverts per hour

Crimini mushroom from Central Market = 64 nanosieverts per hour

Tap water = 112 nanosieverts per hour

Filter water = 95 nanosieverts per hour

-

Radioactive Waste 365 – UK Hopes To Use Experience With Decommissioning At Sellafield To Launch Decommisioning Business Abroad

The Thorp nuclear fuel reprocessing plant at Sellafield, Cumbria, in the U.K. has been closed. No more spent nuclear fuel will be reprocessed there. Now the plant will undergo decommissioning which will require decades and billions of dollars. In order to successfully and safely dismantle and decontaminate the plant, it will be necessary to develop some new technology.

Five sieverts of radiation absorbed in an hour is considered enough to kill a human being. The Head End Shear Cave (HESC) section of the Thorp facility is where the spent nuclear fuel rods are removed from their fuel rod assemblies and cut into sections. Then the sections are dissolved in hot nitric acid. The radiation level in the HESC is two hundred and eighty sieverts per hour, far above a lethal dose of radiation.

The only way to dismantle and remove this equipment is with the use of robots. Once that has been accomplished, water and acids will be used to wash out the room and lower the level of radiation. It is hoped that it can be made safe enough for human beings to enter. New decontamination washing agents may have to be developed.

It will require robots and remotely operated vehicles to clean up other parts of the plant. It is hoped that such systems in use in other industries such as oil and gas, car manufacturing and even space industries can be adapted for the Thorp decommissioning. However, some of the needed systems will have to be developed from scratch. Very small robots which are able to change shape may be needed to go through small apertures to get into some of the contaminated areas. On the other extreme, very large mobile platforms might be needed to move around other equipment.

There other facilities that have been or are being closed in the Sellafield site. These other facilities are also very heavily contaminated. The equipment being developed for the Cave decommissioning will be of use in the dismantling and decommissioning the other facilities.

A flying drone has already been used to map radiation contamination in parts of the site that are difficult or impossible to access via usual methods. Remotely operated robot submarines have also been used to explore and begin cleaning up old storage ponds that contain radioactive materials.

There is a large network of specialist companies which will be developing the machines necessary to decommission the Thorp facility and other facilities on the Sellafield site. Many of these companies are located in Cumbria.

There is a growing business in the U.K. to decommission old nuclear reactors and other facilities such as Sellafield. Almost five hundred nuclear facilities scattered around the U.K. are slated to be decommissioned in the next forty years.

The Centre for Innovative Nuclear Decommissioning Engineering was just opened in Workington, a community in Cumbria. The Center will assist in the research and development of new decommissioning technologies to help with the decommissioning work at Sellafield. It is hope that research at the Centre and experience at Sellafield will help the U.K. export decommissioning services to other countries.