Construction began on the Bellefonte Nuclear Power Generating Station in Hollywood, Alabama in 1975. The site was owned by the Tennessee Valley Authority. Two reactors were originally planned for the site. Eighty eight percent of reactor 1 construction was accomplished, and fifty eight percent of reactor 2 construction was accomplished with the TVA investing over six billion dollars. But, in 1988, work on the project was halted. Following that, useable equipment was removed from the site and now only fifty five percent of reactor 1 and thirty five percent of reactor 2 remains.

In 2005, the TVA announced that it had selected the Bellefonte site for the construction of two of the new AP1000 pressurized water reactors. The new reactors would be designated as reactor 3 and reactor 4. In 2006, construction permits for reactors 1 and 2 were cancelled. Subsequently, the TVA studied what would be required to finish the two reactors and concluded that reactor 1 could be completed by 2017 and reactor 2 could be completed by 2021. In late 2007, the TVA filed the necessary applications to begin design and construction of reactors 3 and 4. In 2008, the TVA request that the NRC reinstate the construction permits that had been cancelled two years before for reactors 1 and 2. The NRC did reactivate the permits for reactors 1 and 2 in 2009. In the fall of 2009, the TVA encountered “falling electric sales and rising costs from cleaning up a massive coal ash spill in Tennessee”. As a result, the TVA scaled back their plans to the construction of one reactor at the Bellefonte site.

In early fall of 2010, the TVA allocated two hundred and forty-eight million dollars for the development of reactor 1 at Bellefonte. A year later, the Board of Directors at the TVA voted to begin the construction of reactor 1. A plan was approved in 2011 to make the restart of construction at Bellefonte contingent on the completion of the TVA Watts Bar 2 reactor in Tennessee. In 2012, they projected that Watts Bar 2 reactor would be completed in 2015. In the middle of 2013, staffing at Bellefonte was reduced from five hundred and forty to just one hundred and forty. In late 2013, it was announced that a proposal had been drafted to complete the Bellefonte plant with private funds and federal tax credits.

In 2015, the TVA decided that, given power demand projections, it would be at least twenty years until they needed the power that could be provided by the Bellefonte plant. In 2016, the TVA decided that the Bellefonte site was surplus property and that they would put the site up for auction. Nuclear Development LLC (ND) bought the site at auction for one hundred and ten million dollars. They announced that they were going to complete the two reactors at the site with an investment of thirteen billion dollars. ND has paid TVA twenty-two million dollars in earnest money to date and they have applied for more than eight billion dollars in loans from the U.S. Department of Energy.

In January of this year, Memphis Light, Gas & Water (MLGW) signed a non-binding agreement to purchase electricity from the reactors to be constructed at the Bellefonte site. MLGW says that it wants to wait for a regional energy report that is due in December before deciding whether or not to provide a binding letter of intent to ND. ND responded that unless MLGW signs a binding agreement to buy electricity from Bellefonte in the near future, ND may walk away from the purchase deal with the TVA because the terms of the loans from the DoE require that there be a guaranteed market for the electricity generated at the Bellefonte plant.

Alabama state officials are very concerned with the recent developments. They were counting on the income from workers at the plant and the purchase of goods and services by the plant from local businessmen to revitalize the struggling economy of the communies near the site. Supporters of completion of the Bellefonte site say that the price of electricity from the plant would be much cheaper than current sources.

The tortured history of Bellefonte Nuclear Generation Station illustrates why it is so difficult to finance and build nuclear power reactors in the U.S.

Blog

-

Nuclear Reactors 627 – Bellefonte Nuclear Generation Station in Alabama May Never Produce Electricity

-

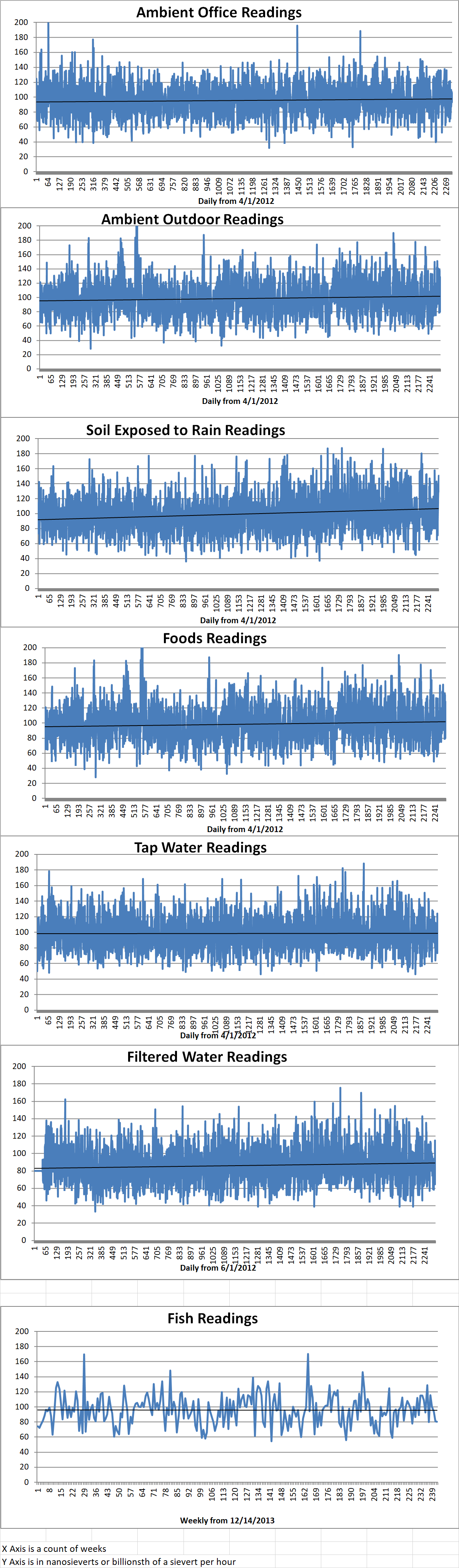

Geiger Readings for Oct 19, 2018

Ambient office = 105 nanosieverts per hour

Ambient outside = 140 nanosieverts per hour

Soil exposed to rain water = 151 nanosieverts per hour

Crimini mushroom from Central Market = 128 nanosieverts per hour

Tap water = 80 nanosieverts per hour

Filter water = 72 nanosieverts per hour

-

Nuclear Reactors 626 – Toshiba and IHI Dissolve Joint Nuclear Venture.

IHI Corporation is a Japanese company which produces ships, aircraft engines, turbochargers for automobiles, industrial machines, power station boilers and other facilities, suspension bridges and other transport-related machinery.

Toshiba Corporation is a Japanese multinational conglomerate headquartered in Tokyo, Japan. Its diversified products and services include information technology and communications equipment and systems, electronic components and materials, power systems, industrial and social infrastructure systems, consumer electronics, household appliances, medical equipment, office equipment, as well as lighting and logistics.

These two companies have been partners in the development and sale of nuclear equipment since the 1960s. IHI supplied important components to Toshiba which assembled them into finished systems. IHI wanted to expand sales in the nuclear business. In the first decade of the Twenty First Century, it looked as if the global nuclear industry was starting to expand again after decades of stagnation. Many countries were talking about building nuclear power reactors. Toshiba acquired Westinghouse Electric in 2006 in anticipation of this expanding market with investment assistance from IHI.

In January of 2011, Toshiba and IHI formed Toshiba IHI Power Systems. The joint venture was created to manufacture steam turbine parts for nuclear power plants for the domestic and overseas markets. They formed the JV with the intent of strengthening their partnership to take advantage of the renewed interest in nuclear power.

The JV was intended to allow IHI to extend its operations to major components of turbines, alongside the manufacture of nuclear reactor pressure vessels and containment vessels, while Toshiba would enhance its turbine manufacturing capacity and strengthen its nuclear power plant business supply chain.

Just two months after the joint partnership was formed, in March 2011, the Fukushima nuclear disaster happened. The bottom dropped out of the global nuclear power reactor market. The factory of the JV had to start making parts with no relation to nuclear reactors just to keep the lights on.

In December of 2016, it was revealed that Westinghouse had suffered huge losses and eventually filled for bankruptcy. This hit Toshiba hard and they sold of their shares in Westinghouse in 2018.

Now it has been announced that Toshiba and IHI are dissolving Toshiba IHI Power Systems. IHI will remain in the nuclear component business but they will move their operations towards biomass fuels and other renewable energy sources including hydrogen. Toshiba is currently considering the sale of its share of a nuclear power reactor project in the U.K. Toshiba hopes to be able to continue work on maintaining, repairing and decommissioning existing plants in Japan but will not be vigorously pursuing the construction of new nuclear power plants. This means that Toshiba and IHI will probably be less involved with each other in the future.

Although other Japanese companies continue to be involved in the manufacture of nuclear plant components and the construction of nuclear power reactors, the international market for nuclear power reactors is in decline. Russia and China are working hard to export nuclear power reactors to developing countries, but they are forced to offer very attractive financing terms including long term loans at low interest to attract customers. Some of these announced deals have recently been cancelled.

As I have repeatedly said, it will not be the danger of nuclear power plant accidents or the possible proliferation of nuclear weapons that will ultimately sink the use of nuclear power but the cold hard facts of international economics. -

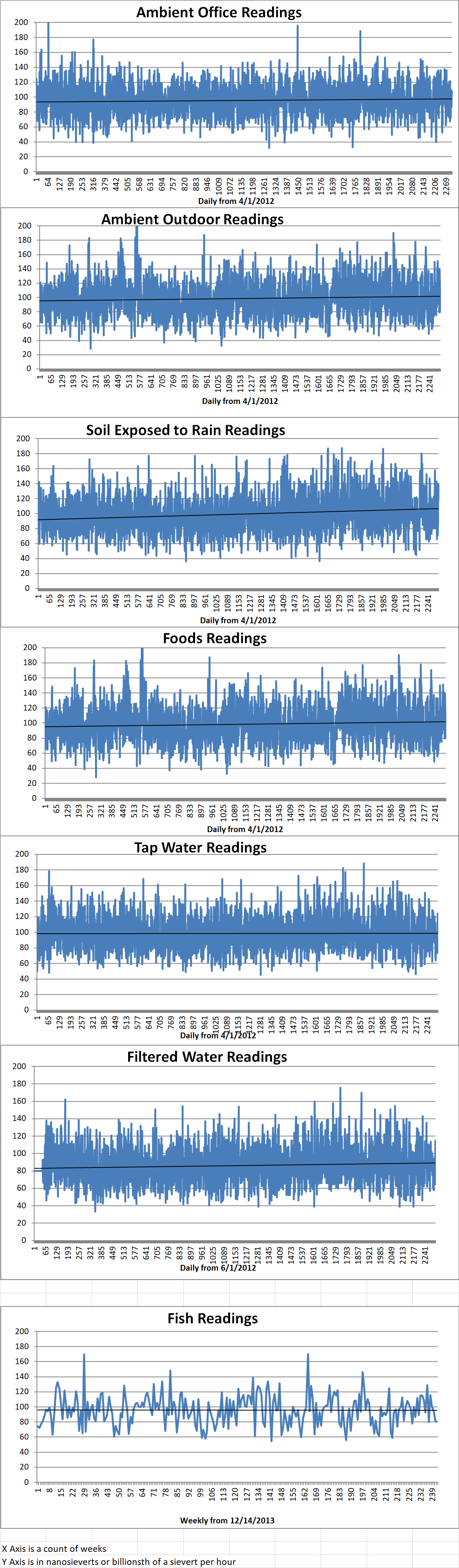

Geiger Readings for Oct 18, 2018

Ambient office = 93 nanosieverts per hour

Ambient outside = 129 nanosieverts per hour

Soil exposed to rain water = 1129 nanosieverts per hour

Beefsteak tomato from Central Market = 118 nanosieverts per hour

Tap water = 120 nanosieverts per hour

Filter water = 102 nanosieverts per hour

-

Radioactive Waste 354 – Duke University Researchers Studying Geophysical Process Which Might Affect Underground Repositories

Thomas Hueckel is a professor of civil and environmental engineering at Duke University. He is an expert in the study of the mechanics of earthen materials and the way that they react to everything else including water, gases, fossil fuels, and structures. This field of research is called multi-physics geomechanics. Hueckel has teamed with Manolis Veveakis, another Duke University researcher with similar expertise. The two of them have just received an eight hundred thousand dollar grant from the U.S. Department of Energy to study how physical and chemical processes underground might interacted with or degrade nuclear waste storage facilities. They will also try to find ways of dealing with such potential problems.

When a spent nuclear fuel rod is removed from a reactor core, it is still highly radioactive. Rods are left in a cooling pool filled with water for ten years to allow them to dissipate some of their radioactivity. Even after that, a typical fuel rod will have a temperature of about two hundred and fifteen degrees Fahrenheit. It will still require at least ten thousand years before it is no dangerous.

Currently, most of these spent fuel rods are stored at the site where they were used. Cooling pools are rapidly filling up at many nuclear power stations and, if some of the spent fuel rods are not removed, the reactors at the site may have to be shut down. Some spent fuel rods which have cooled for ten years are removed from pools and stored in concreate and steel cylinders called dry casks.

The disaster at Fukushima clearly illustrated that storage of spent fuel rods in cooling pools is dangerous. When the cooling pool lost water in one of the reactor building, the rods burst into flame and burned down the building. Hueckel says that spent nuclear fuel should be stored at least a quarter of a mile beneath the Earth’s surface.

Countries that use nuclear power have been working on designs for decades for deep underground repositories for spent nuclear fuel. Many of the features of such designs are similar. In these designs, a vertical shaft opens on an underground cavern full of separated chambers. The walls of the chambers are lined with bentonite clay or other types of crushed rocks. Cracks between the materials in the linings are then filled in with clay and spayed with water to form a sealed lining. The waste is placed in dry casks and each cask is then inserted into a single chamber which is sealed with multiple barriers to prevent access by human beings or leaks that could allow the radioactive material to migrate out of the storage facility. While some test facilities have been dug, there is no major functioning facility anywhere in the world yet for spent nuclear fuel. The U.S. will not have such a national geological repository until at least 2050.

While this sounds like an excellent system to isolate spent nuclear fuel for thousands of years, Hueckel says that the steady emission of heat by the spent nuclear fuel rods has a deleterious effect on the rock around the repository. The rock may dry, crack and disintegrate, removing the solid barrier around the waste and allowing it to migrate into the ecosystem. Other geological processes might adversely impact the repository such as corroding the material used to construct the dry casks or changing the chemical composition of the clay in the walls.

Hueckel said, “With the new grant, we are charged with understanding how temperature and pressure contribute to drying and cracking in the planned repository, and what kinds of remedies we can.”

One way to improve the integrity of the walls of the repositories is to incorporate fibers into the clay used to seal the walls. This is an ancient technique which utilized animal hair to improve the strength of construction materials. Hueckel will experiment with nano- or micro-sized fibers of various materials. He will also investigate designs that increase the probability of the formation of shear cracking as opposed to tensile cracking. He says, “In many places where you see inclined cracks in materials, like in an iceberg, the two surfaces slide past one another—but they don’t open up. It could reduce the potential for radionuclide migration.” -

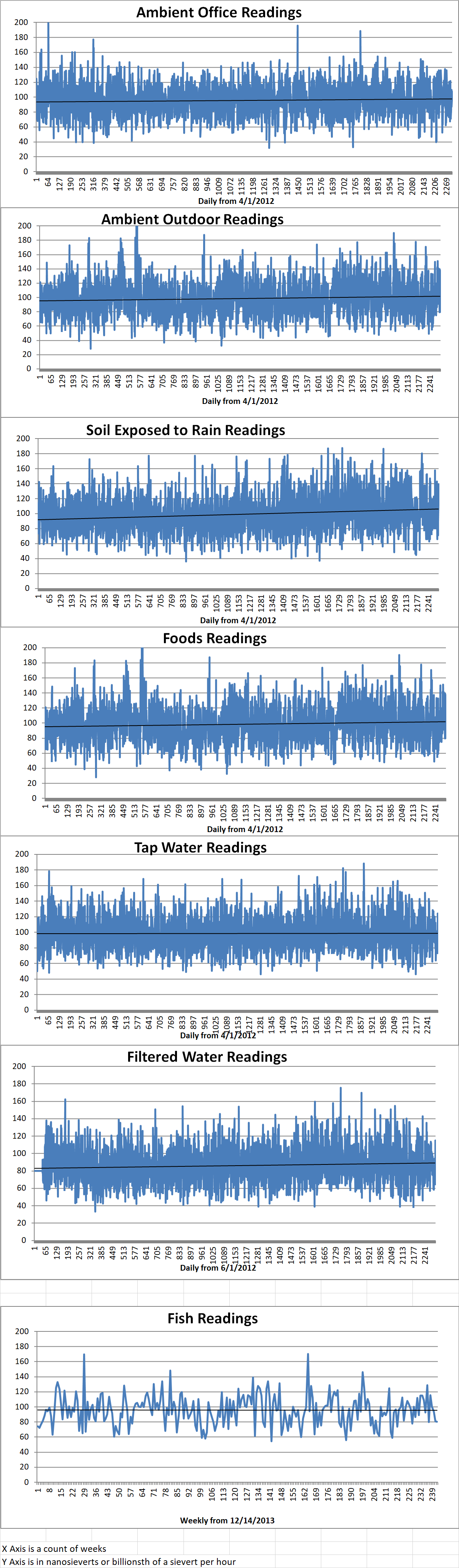

Geiger Readings for Oct 17, 2018

Ambient office = 105 nanosieverts per hour

Ambient outside = 136 nanosieverts per hour

Soil exposed to rain water = 140 nanosieverts per hour

Orange bell pepper from Central Market = 80 nanosieverts per hour

Tap water = 124 nanosieverts per hour

Filter water = 115 nanosieverts per hour

-

Nuclear Reactors 625 – BWXT Nuclear Engineering Is Working Under A NASA Grant To Develop Nuclear Thermal Propulsion

The idea of using nuclear power for spaceflight has been around for decades. Different designs have been proposed but not built. It looks as if technology has caught up reality and NASA is seriously considering the use of nuclear propulsion systems to power spacecraft.

BWX Technologies Nuclear Technology, Inc. (BWXT NE) is a U.S. company headquartered in Charlotte, North Carolina. It manufactures nuclear components and provides engineering, design, construction, inspection and repair services.

Last year, BEXT NE announced an eighteen million eight hundred thousand dollar that it had been granted an award under the Game Changing Development Program at NASA for work on a nuclear thermal propulsion (NTP) system. This three-year grant will enable the company to manufacture and test prototype nuclear fuel elements.

BWXT NE will also assist NASA in figuring out how to address and resolve nuclear licensing and regulatory requirements. BWXT NE’s goal is to help NASA refine the feasibility of and affordability of the development of an NTP rocket engine. They will deliver the technical and programmatic data required to actually implement this new technology.

BTXT NE just held an event for officials from the Space Technology Mission Directorate (STMD) of NASA yesterday. BWXT NE gave the NASA representatives updates and technology demonstrations of their nuclear thermal propulsion (NTP) project to build a reactor that could be incorporated into a rocket engine to carry a crew to Mars and back.

Rex Geveden is the BWXT NE president and CEO He said, “We believe that NTP is an ideal propulsion system to take humans to Mars, and our scientists and engineers are working every day to make that a reality.”

James Reuter is the NASA acting administrator of STMD. He toured the BWXT NE Advanced Technology Lab in Lynchburg, Virginia to review progress on the new BWXT NE reactor. BWXT NE staff demonstrated three new technologies that they are working on for the project. The three areas of research are advanced welding, metallography and fuel element filling. Metallography is the study of the physical structure and components of metals, by using microscopy.

BWXT NE says that its compact reactor design which burns low-enriched uranium can be incorporated into a rocket engine which has significant advantages over current chemical-based rocket engines. NTPs have double the efficiency of the most powerful chemical rockets and much greater power density.

Sonny Mitchell is the Nuclear Thermal Propulsion manager at NASA’s Marshall Space Flight Center. He said “As we push out into the solar system, nuclear propulsion may offer the only truly viable technology option to extend human reach to the surface of Mars and to worlds beyond. We’re excited to be working on technologies that could open up deep space for human exploration.”

It is hoped that a NTP engine could cut the travel time to Mars from six months to just four months. This would result reducing the exposure of astronauts to dangerous radiation in space. It will also reduce the mass of the space vehicle which means that it can carry addition payloads of fuel and supplies.