The electrification of transport could potentially offer many opportunities for nuclear generation, Brandon Munro told the World Nuclear Association Symposium 2018 in London today. World-nuclear-news.org

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

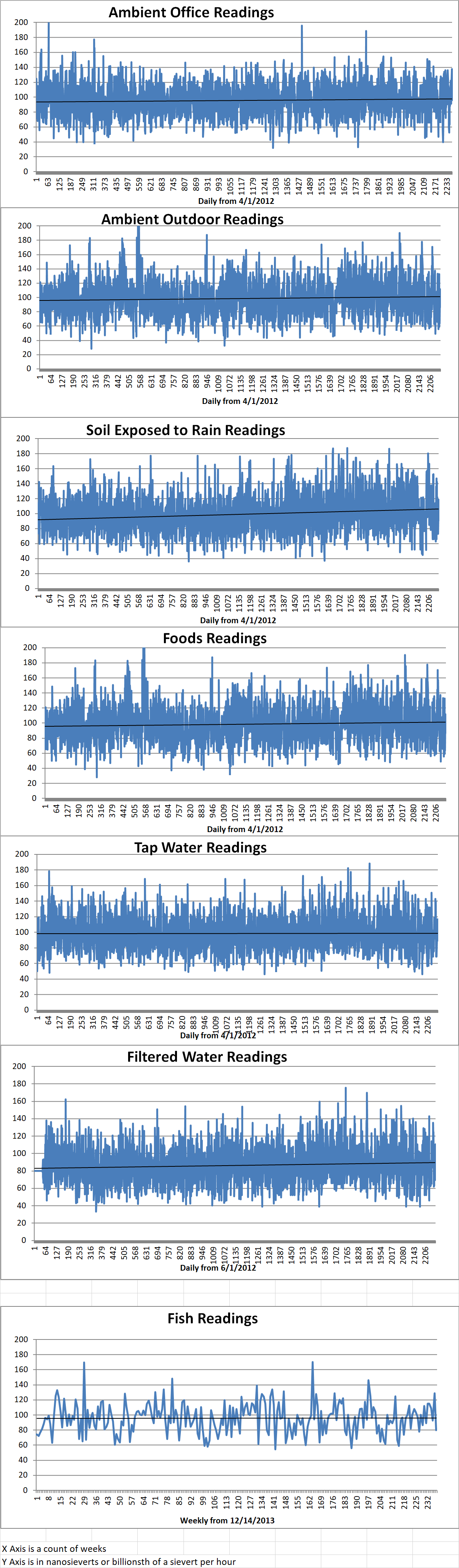

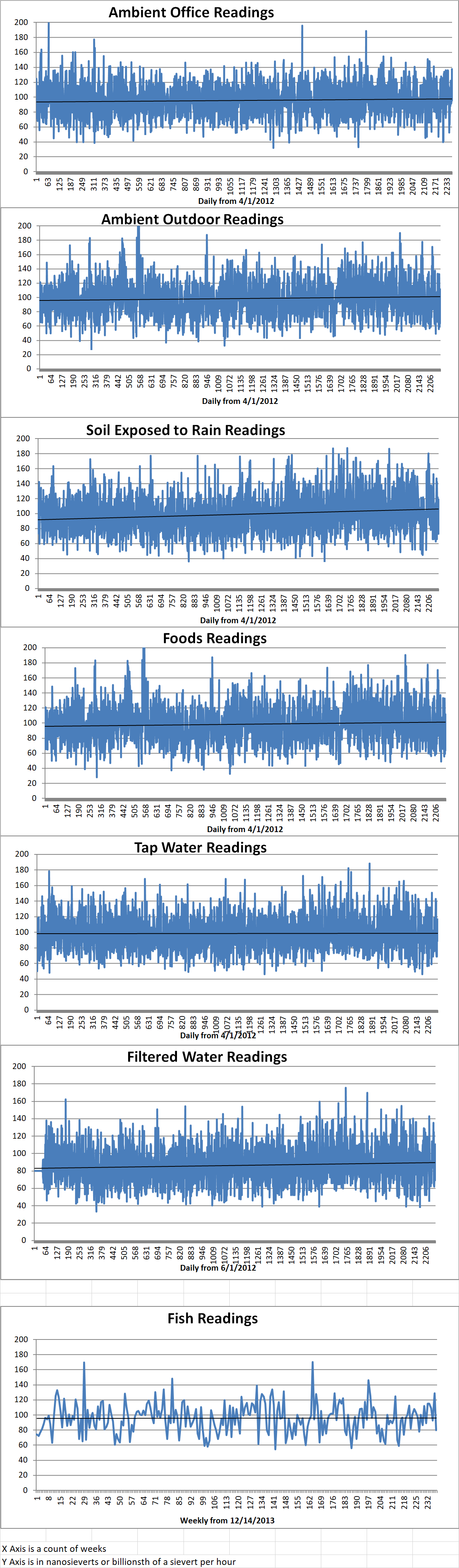

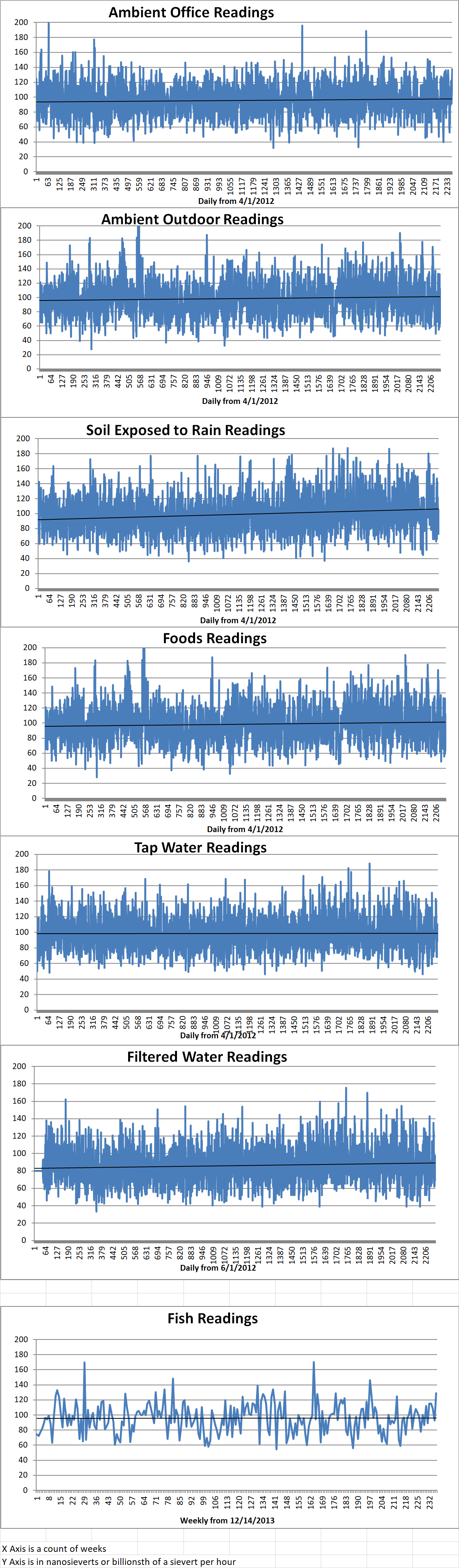

Ambient office = 85 nanosieverts per hour

Ambient outside = 87 nanosieverts per hour

Soil exposed to rain water = 78 nanosieverts per hour

White mushroom from Central Market = 116 nanosieverts per hour

Tap water = 77 nanosieverts per hour

Filter water = 73 nanosieverts per hour

Ambient office = 114 nanosieverts per hour

Ambient outside = 92 nanosieverts per hour

Soil exposed to rain water = 91 nanosieverts per hour

Snap pea from Central Market = 87 nanosieverts per hour

Tap water = 96 nanosieverts per hour

Filter water = 90 nanosieverts per hour

Ambient office = 96 nanosieverts per hour

Ambient outside = 121 nanosieverts per hour

Soil exposed to rain water = 119 nanosieverts per hour

Banana from Central Market = 107 nanosieverts per hour

Tap water = 116 nanosieverts per hour

Filter water = 111 nanosieverts per hour

Dover sole – Caught in USA = 80 nanosieverts per hour

My blogging about commercial nuclear reactors has focused on the generation of electricity from such reactors. In addition to generating electricity, the heat given off by nuclear reactors can also be used directly for industry and district heating. District heating is a system that distributes heat generated in a central location through a network of insulated pipes to residential and industrial consumers. Residences use the heat for space heating and to heat water. There are two values assigned to the output of a commercial power plant. Watts can be a measure of both electricity and heat.

Pool-type light water nuclear reactors (also called swimming pool reactors) feature a core immersed in an open pool of normal water. The water serves as a neutron moderator, coolant and radiation shield. One of the benefits of a pool reactor is that the cooling system is operating at normal air pressure and temperature. This makes the reactor much safer to work around. These reactors burn enriched uranium that is less than twenty percent U-235 which is considered highly enriched uranium. Pool reactors are not used to generated electricity but have been used as heat sources. They cannot meltdown as commercial power reactors may do. And they have very low emissions of radioactive materials which makes them desirable for use in urban areas.

China began researching the possible application of nuclear power to heating in the early 1980s. During 1983 and 1984, the Institute of Nuclear Energy and Technology (INET) at Tsinghua University used its experimental pool-type reactor to provide heating for nearby buildings. Also during that time, INET constructed two nuclear heating reactors. One of those reactors was a deep pool-type and the other one was a regular vessel-type reactor. INET built a five Megawatt experimental thermal pool-type reactor called the NHR5 between 1986 and 1989. The larger production prototype NHR200-II was constructed based on the design of the NHR5.

The China National Nuclear Corporation (CNNC) has been constructing and studying experimental pool reactors for over fifty years. The China Institute of Atomic Energy recently operated a pool-type reactor for one hundred sixty-eight hours. Following this success, the CNNC started an independent research and development program with their Yanlong pool-type reactor (also known as DHR-400) in November of 2017.

CNNC said, “The Yanlong reactor is an effective way to improve China’s energy resource structure by utilizing nuclear energy for district heating, and to ease the increasing pressures on energy supplies. Nuclear energy heating could also reduce emissions, especially as a key technological measure to combat haze during winter in northern China. Thus, it can benefit the environment and people’s health in the long run.”

The Yanlong reactor “can be constructed either inner land or on the coast, making it an especially good fit for northern inland areas, and it has an expected lifespan of around 60 years. In terms of costs, the thermal price is far superior to gas, and is comparably economical with coal and combined heat and power.”

China General Nuclear and Tsinghua University are working on a feasibility study for the first commercial nuclear plant dedicated to district heating. The plant would use the technology developed for the NHR200-II. The president of Shanghai Nuclear Engineering Research & Design Institute and senior vice president of State Nuclear Power Technology Company said that using fossil fuels for heating is creating terrible pollution in China during winter months. He also said, “To prevent air pollution and to enhance human life, we think that nuclear power, especially the use of nuclear energy to supply district heating, is very important.”

Ambient office = 137 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 103 nanosieverts per hour

Brussell sprout from Central Market = 112 nanosieverts per hour

Tap water = 89 nanosieverts per hour

Filter water = 70 nanosieverts per hour

I have blogged about molten salt reactors (MSR). In a MSR, nuclear materials are dissolved in a molten fluoride or chloride salt. The molten salt becomes both the fuel for the reactor and the coolant for the fission reaction. The meltdowns feared in conventional power reactors are impossible in MSRs.

Terrestrial Energy USA (TE) is a startup working on what they refer to as an Integral Molten Salt Reactor (IMSR). In the TE design, the primary reactor components which include primary heat exchangers are integrated with a secondary clean salt circuit in a sealed and replaceable core vessel. It is a small modular reactor designed for fabrication in a factory. It can be used to generate one hundred and ninety megawatts of electricity or as a source for industrial heat generation. TE hopes to be able to produce a commercial version of the IMSR in the 2020s.

TE started a feasibility study in June of 2017 for the siting of the first commercial IMSR at the Canadian Nuclear Laboratory facility at Chalk River, Ontario. Last March, TE signed a memorandum of understanding with respect to possible siting, construction and operation of an IMSR at the Idaho National Laboratory in southern Idaho.

TE has announced that it is going to partner with Southern Energy Company and several U.S. Department of Energy national laboratories to utilize the ISMR for the production of hydrogen. Southern Energy Company (SE) is an U.S. independent oil and gas company that invested in oil and gas. It operates primarily in Texas and Oklahoma.

The Savanah River National Laboratory (SRNL) has been researching such technology for twenty years. SRNL will lead the development of technology for the TE project with assistance from Sandia National Laboratories and Idaho National Laboratory.

Hydrogen is used in the production of ammonia, petroleum refining, the production of other industrial chemicals and other industrial applications. In the future, it is expected that hydrogen will play an increasing role in energy storage. Applications will include being used as fuel for all forms of transportation. The hydrogen market is projected to reach over two hundred billion dollars by 2020.

Hydrogen is currently produced by high-temperature steam electrolysis. TE and SE hope that their new process will be more efficient than electrolysis. In their new approach, the hybrid sulfur process will be combined with an IMSR plant for large scale hydrogen production. The hybrid sulfur process is a two-step thermochemical cycle for decomposing water into hydrogen and oxygen. They claim that their process will emit zero greenhouse gas.

A project manager at S.C. said, “This is a potentially high-impact project that couples the benefits of molten salt reactors with the development of an advanced water-splitting process for hydrogen generation.”

The CEO of TE said, “By combining forces with an energy leader such as Southern Company, we can bring this revolutionary technology to industrial markets. Using an IMSR power plant to produce hydrogen more efficiently and economically is just one of many industrial applications of IMSR power plants beyond electricity generation. Removing carbon from the production of hydrogen helps bring deep decarbonization into reach. It points the way to the production of carbon-neutral transport fuels and zero-emissions fertilizers.”