The global demand for minerals just keeps increasing. Such minerals as phosphates, copper and rare earth elements are critical to our high-tech civilization. As the most concentrated and accessible deposits of these minerals become depleted, global mining has to switch to lower grade ore or unconventional resources. Many of these poorer deposits also contain uranium and other valuable minerals. Energy neutral mineral processing is a process that is being developed to extract uranium from these unconventional resources as a byproduct of processing for the primary minerals in the ore. The uranium can then be used to power nuclear reactors.

Energy neutrality occurs when the energy produced by the uranium extracted from the ore is the same as or greater than the energy that was necessary to mine the ore, process the ore, extract the uranium, convert the uranium, enrich the uranium and create the reactor fuel. The extraction of naturally occurring radioactive materials (NORM) occurs along with the extraction of byproduct uranium. In addition to adding to the supply of uranium, this also results in cleaner end products such as phosphoric acid for fertilizers and cleaner mine tailings.

The International Atomic Energy Agency created a research project called Uranium/Thorium Fueled High Temperature Gas Cooled Reactor Applications for Energy Neutral and Sustainable Comprehensive Extraction and Mineral Product Development in 2014. This coordinated research project (CRP) involves seventeen institutes from sixteen of the member states of the IAEA. The first report from the project was published in the journal Sustainability earlier this year. The IAEA will publish a comprehensive technical document next year.

The participants in the CRP studied a wide variety of ores to determine the uranium and thorium content. They tested different extraction processes. They have modelled the coupled system of high temperature gas-cooled reactors (HTRs) and mineral processing plants. Their research illustrates how the heat and electricity from a modular high temperature reactor constructed near the mineral processing plant could be used to process raw material to produce enough uranium byproduct to be energy neutral.

The CRP scientific secretary said, “Using reliable, inexpensive and greenhouse gas lean power from nuclear reactors for mineral development at processing centers but particularly at remote location is something the minerals processing industry long dreams of.”

High temperature gas-cooled reactors have been used for research and as prototypes since the 1960s. There are two HTRs currently in operation. Japan HTTR has been in operation since 1998. China’s HTR-10 was constructed in 2000 and has been in operation since then. China is also constructing a two unit demonstration plant called the HTR-PM at Shidaowan in the Shandong province. They expect the plant to start generating electricity later this year.

The IAEA utilizes CRPs to organize international research efforts to reach specific research objectives consistent with the IAEA program. The results of IAEA CRPs are made available for free to scientists, engineers, and other users from all Member states.

There is currently an oversupply of uranium on the market. Some mines have been shut down to await an increase in prices. This work of the IAEA is interesting, but it is questionable whether or not their new source of uranium is really needed at this time.

Blog

-

Nuclear Reactors 596 – The IAEA Is Working On Extracting Uranium From Ores Mined For Other Minerals

-

Geiger Readings for Jul 24, 2018

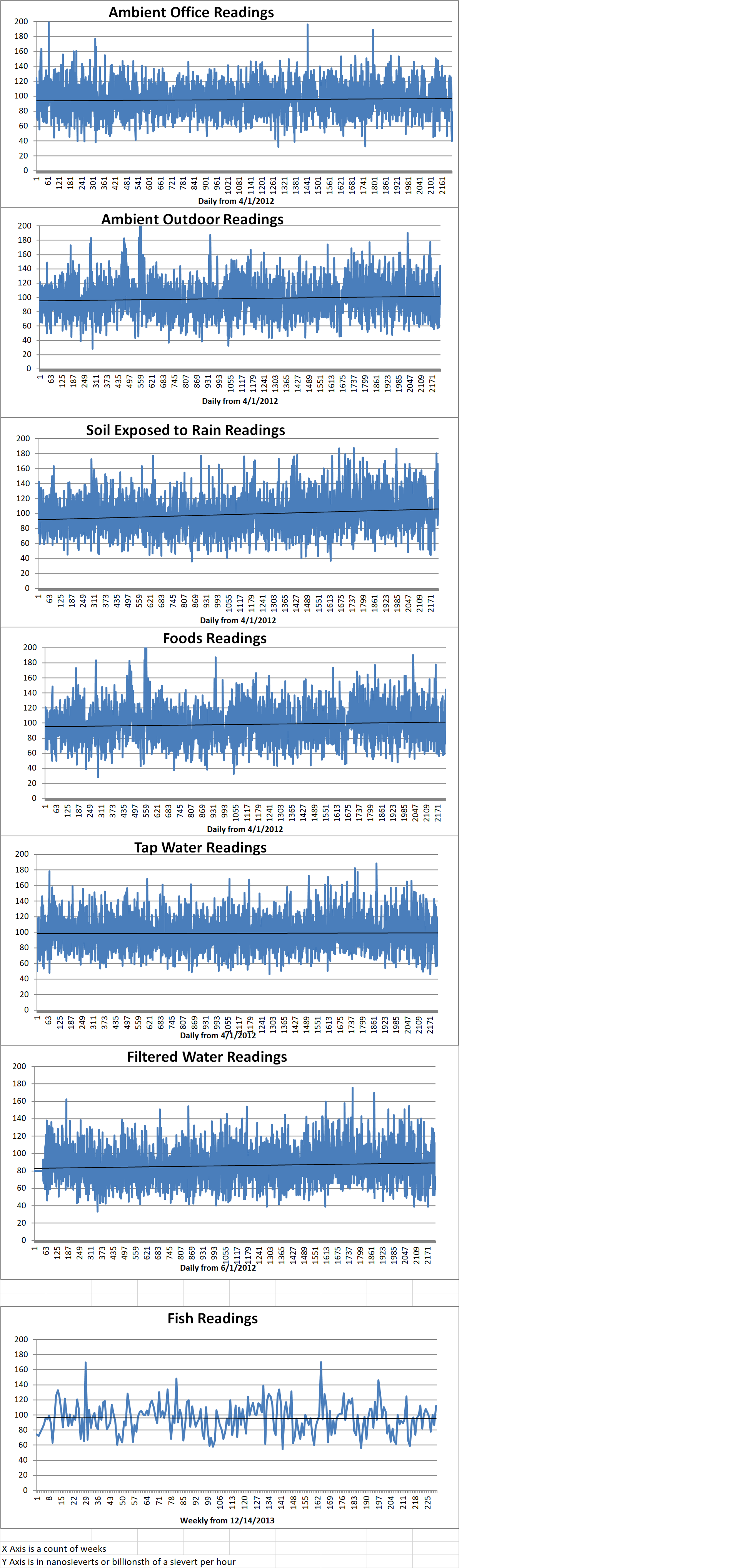

Ambient office = 116 nanosieverts per hour

Ambient outside = 117 nanosieverts per hour

Soil exposed to rain water = 116 nanosieverts per hour

Orange bell pepper from Central Market = 83 nanosieverts per hour

Tap water = 104 nanosieverts per hour

Filter water = 92 nanosieverts per hour

-

Nuclear Reactors 595 – U.S. Is Considering Tariffs On Imported Uranium Reactor Fuel

Since President Trump started imposing tariffs on a variety of imports, other countries have reciprocated with tariffs on U.S. goods. Now the question has been raised of whether or not the U.S. needs to put tariffs on imported uranium destined to fuel U.S. commercial nuclear power reactors in the name of national security.

The U.S. Department of Commerce announced on Wednesday that it will investigate whether uranium imports are a threat to national security. U.S. mining companies Energy Fuels Inc. and Ur-Energy Inc. requested the investigation last January. These two companies are suggesting that it would be prudent for the U.S. to require that at least twenty-five percent of the domestic uranium market should be reserved for domestic producers. Currently, domestic companies only account for less than five percent of U.S. uranium consumption. It is estimated that it would take about three years for domestic uranium miners to increase their production to meet that twenty-five percent target.

The possibility of a trade war affecting the U.S. uranium market follows President Trump’s order last month to his Energy Secretary to provide funding to extend the life of uneconomical coal and nuclear power plants. These fossil and nuclear plants are suffering from the competition with cheap natural gas and renewable sources with steadily dropping costs. If tariffs are attached to imported uranium, then these nuclear power reactor operators will have even more difficulty competing in the U.S. energy market.

The director for fuel cycle programs at the Nuclear Energy Institute in Washington said, “The administration is searching for ways to help nuclear power plants that are financially struggling right now. We wouldn’t want to see counterproductive action to their stated goal of saving nuclear power.”

Uranium prices have fallen since the nuclear disaster at Fukushima, Japan in March of 2011. Japan shut down all of their reactors following the disaster and is only now beginning to turn some of the back on. Germany decided that it would abandon nuclear power and began closing nuclear power plants. In addition to the loss of these customers, there is also a global oversupply of uranium that caused Kazakhstan, the biggest uranium supplier in the world, to cut back production last year. Cameco Corporation, a Canadian company, is the biggest supplier of uranium in North America. Last November they also cut production.

Commercial nuclear power reactors supply about twenty percent of the electricity in the U.S. Uranium to fuel the reactors accounts for about twenty percent of the cost of operation. Most U.S. utilities that operate nuclear power plants have contracts for uranium fuel through 2021. It is not clear what effect new tariffs would have on these existing contracts.

A utility analyst at Bloomberg Intelligence said, “Clearly the purpose of a tariff is to raise the price. Ultimately, in most states, it would end up being borne by the end consumer.”

There have been reports that the price of uranium will inevitably rise as the prime deposits are depleted and more costly deposits will have to be mined. On the other hand, there is a new process for extracting uranium from sea water that the developers claim will soon be competitive with the cost of uranium mined and extracted from land-based sources. There are many uncertainties ahead for the uranium market. -

Geiger Readings for Jul 23, 2018

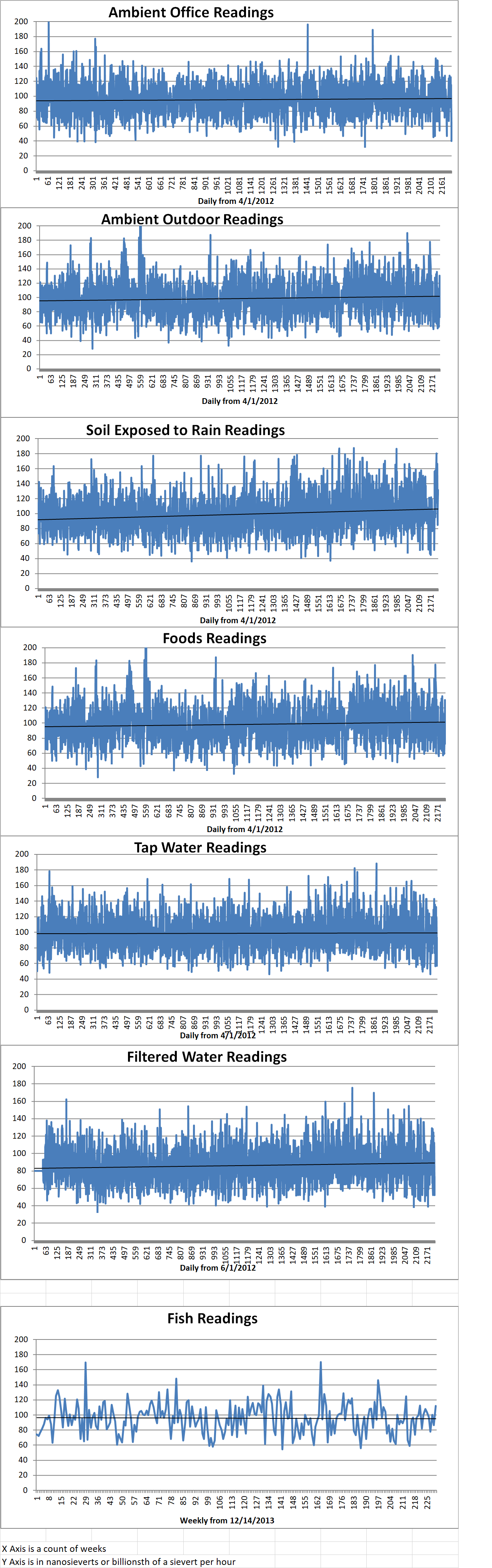

Ambient office = 79 nanosieverts per hour

Ambient outside = 128 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Strawberry pear from Central Market = 145 nanosieverts per hour

Tap water = 79 nanosieverts per hour

Filter water = 64 nanosieverts per hour

-

Geiger Readings for Jul 22, 2018

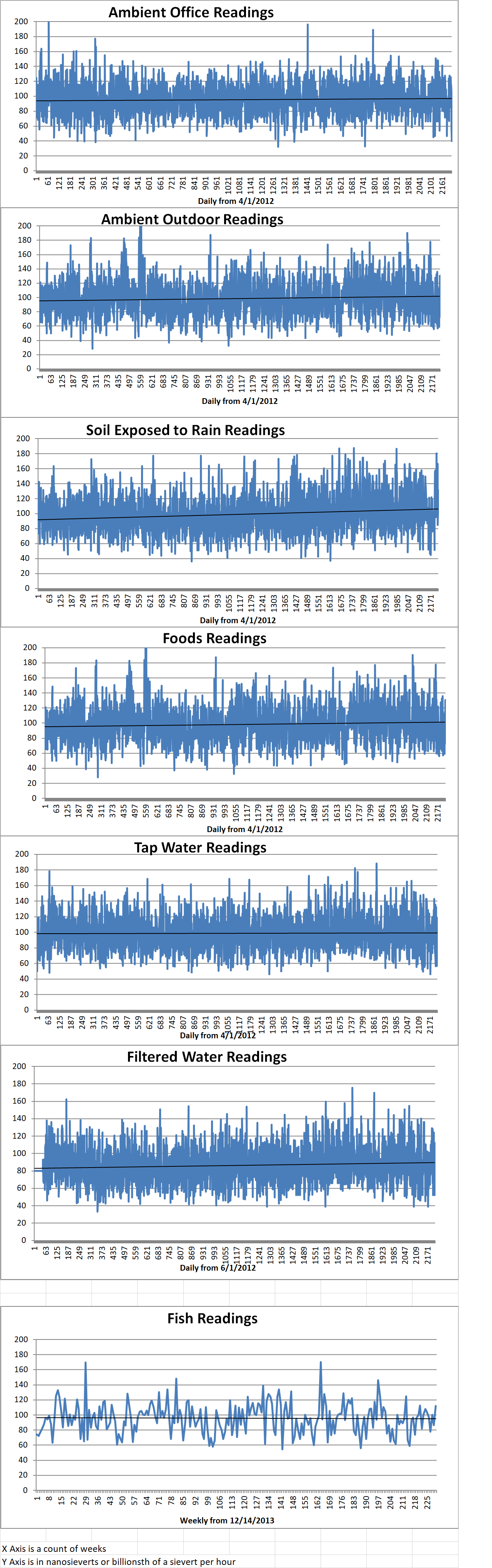

Ambient office = 104 nanosieverts per hour

Ambient outside = 105 nanosieverts per hour

Soil exposed to rain water = 104 nanosieverts per hour

Carrot from Central Market = 113 nanosieverts per hour

Tap water = 57 nanosieverts per hour

Filter water = 52 nanosieverts per hour

-

Geiger Readings for Jul 21, 2018

Ambient office = 104 nanosieverts per hour

Ambient outside = 105 nanosieverts per hour

Soil exposed to rain water = 104 nanosieverts per hour

Orange bell pepper from Central Market = 113 nanosieverts per hour

Tap water = 57 nanosieverts per hour

Filter water = 52 nanosieverts per hour

Dover sole – Caught in USA = 112 nanosieverts per hour