The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

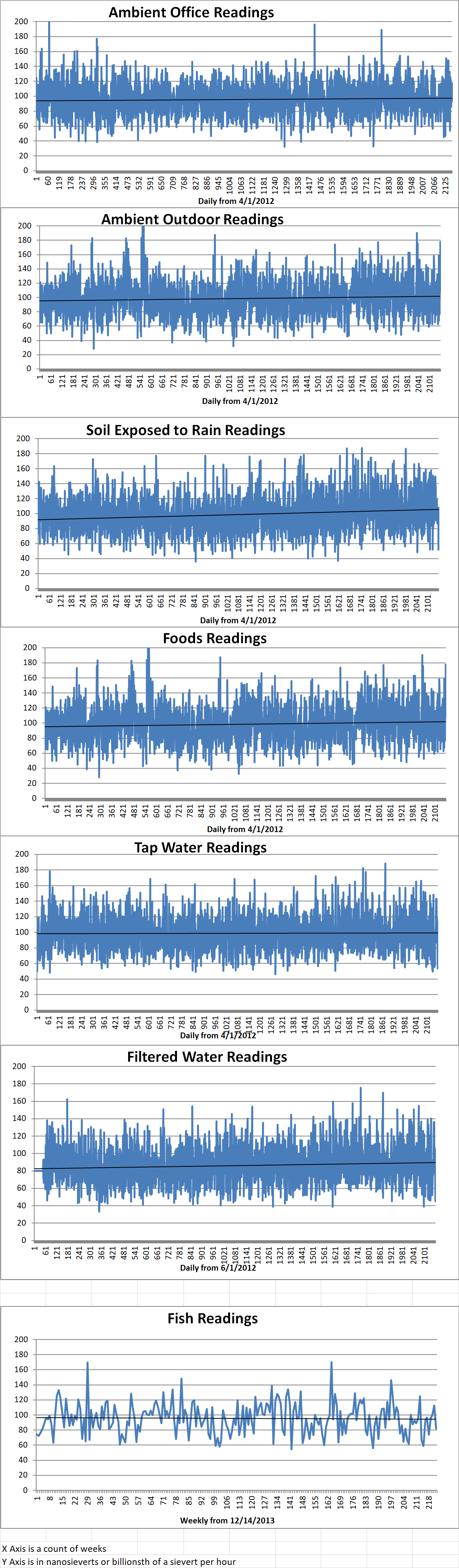

Ambient office = 117 nanosieverts per hour

Ambient outside = 129 nanosieverts per hour

Soil exposed to rain water = 105 nanosieverts per hour

Iceberg lettuce from Central Market = 178 nanosieverts per hour

Tap water = 68 nanosieverts per hour

Filter water = 63 nanosieverts per hour

I have often blogged about the aftereffects of the March 2011 Fukushima nuclear disaster in Japan. When the Fukushima reactors melted down and exploded, a great deal of radioactive materials was thrown into the atmosphere to rain down on Fukushima. Now scientists are saying that a new method of measuring radioactive contamination shows that there was a “significant” distribution of radioactive particles during the disaster which could cause long term health problems it they were inhaled.

The new method of measuring radioactive contamination in soil permitted the researched to easily and quickly count the number of cesium-rich micro-particles in Fukushima soil. They were then able to quantify the amount of radioactivity emitted by these particles. The research was carried out by scientists from Kyushu University, Japan, and The University of Manchester, UK. It was published in the journal Environmental Science and Technology.

Immediately after the nuclear disaster, it was assumed that only volatile, gaseous radionuclides such as cesium and iodine were released from the reactors at the nuclear power plant. In recent years, however, it has become obvious that small radioactive particles called cesium-rich micro-particles were also released. Studies have shown that these particles are composed mostly of glass, but they contain “significant” amounts of radioactive cesium. These particles also contain smaller amounts of other radioisotopes including uranium and technetium. The actual abundance of these micro-particles in the soil and sediments of Japan is not well understood. These particles are very small and they are not easily dissolved. This means that they could be long-term health risks to any human being who inhales them.

In order to improve understanding of the nature and prevalence of these micro-particles, it has been necessary to develop new methods of detection and measurement. A technique called Autoradiography that is used in Radiochemistry laboratories was chosen. In this procedure, a sample of soil is covered by plastic wrap and then an imaging plate is placed on top of the sample. The radioactive decay in the soil sample leaves traces on the plate which are then input into a computer. The scientists claim that it is possible to differentiate between the cesium-rich micro-particles and other types of cesium contamination in the soil.

Soil samples were obtained from rice paddies at different locations around the Fukushima prefecture. The distance of the soil sampling sites from the Fukushima nuclear power plant varied between about two and a half miles and twenty-six miles. All of the samples contained the cesium-rich micro-particles and they were more abundant that originally assumed.

The lead author of the study said “when we first started to find cesium-rich micro-particles in Fukushima soil samples, we thought they would turn out to be relatively rare. Now, using this method, we find there are lots of cesium-rich microparticles in exclusion zone soils and also in the soils collected from outside of the exclusion zone”. He added that “we hope that our method will allow scientists to quickly measure the abundance of cesium-rich micro-particles at other locations and estimate the amount of cesium radioactivity associated with the particles. This information can then inform cost effective, safe management and clean-up of soils contaminated by the nuclear accident”.

Another one of the authors of the study said, “This particle form of cesium behaves differently to the other, more soluble forms of cesium in the environment. We now need to push forward and better understand if cesium micro-particles are abundant throughout not only the exclusion zone, but also elsewhere in the Fukushima prefecture; then we can start to gauge their impact”.

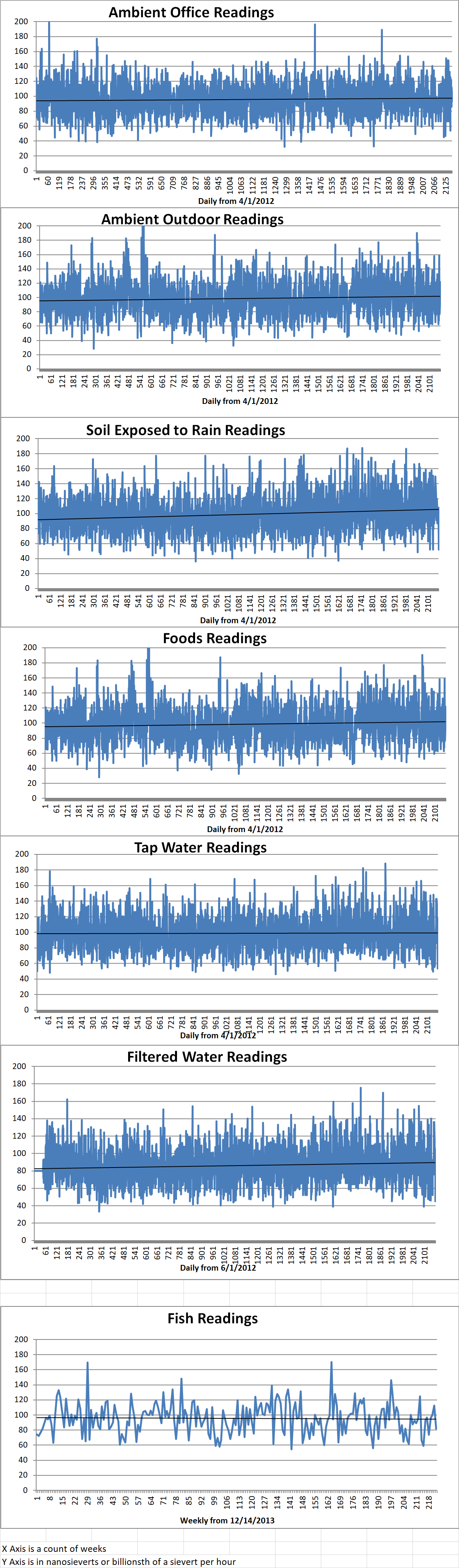

Ambient office = 93 nanosieverts per hour

Ambient outside = 52 nanosieverts per hour

Soil exposed to rain water = 52 nanosieverts per hour

Organic carrot from Central Market = 107 nanosieverts per hour

Tap water = 54 nanosieverts per hour

Filter water = 45 nanosieverts per hour

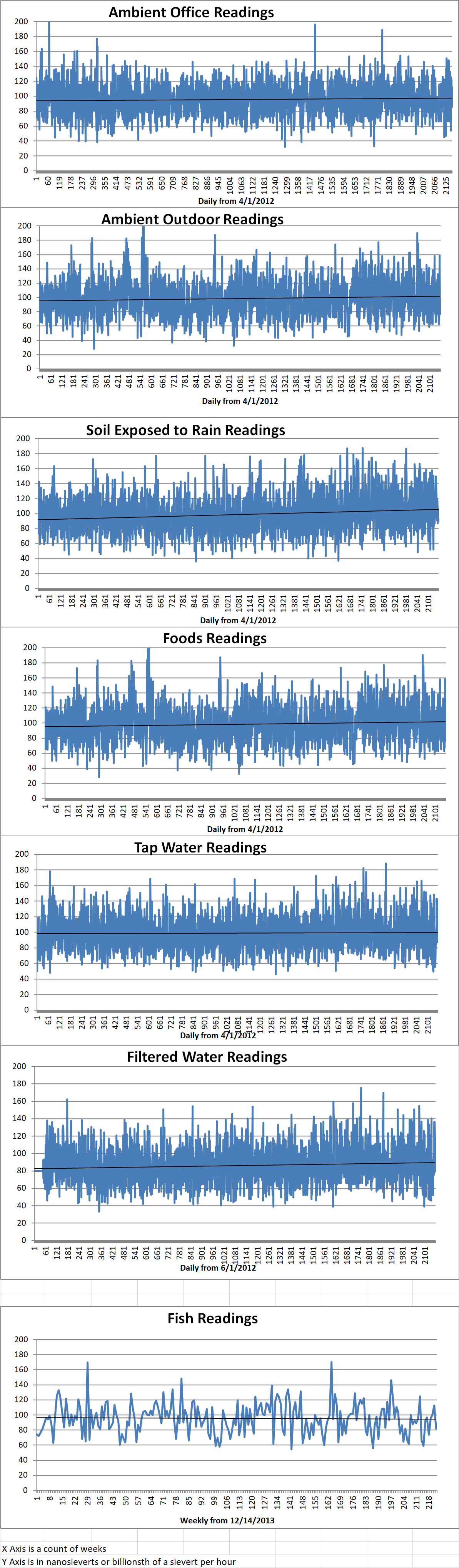

Ambient office = 93 nanosieverts per hour

Ambient outside = 108 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Bartlett pear from Central Market = 122 nanosieverts per hour

Tap water = 114 nanosieverts per hour

Filter water = 105 nanosieverts per hour

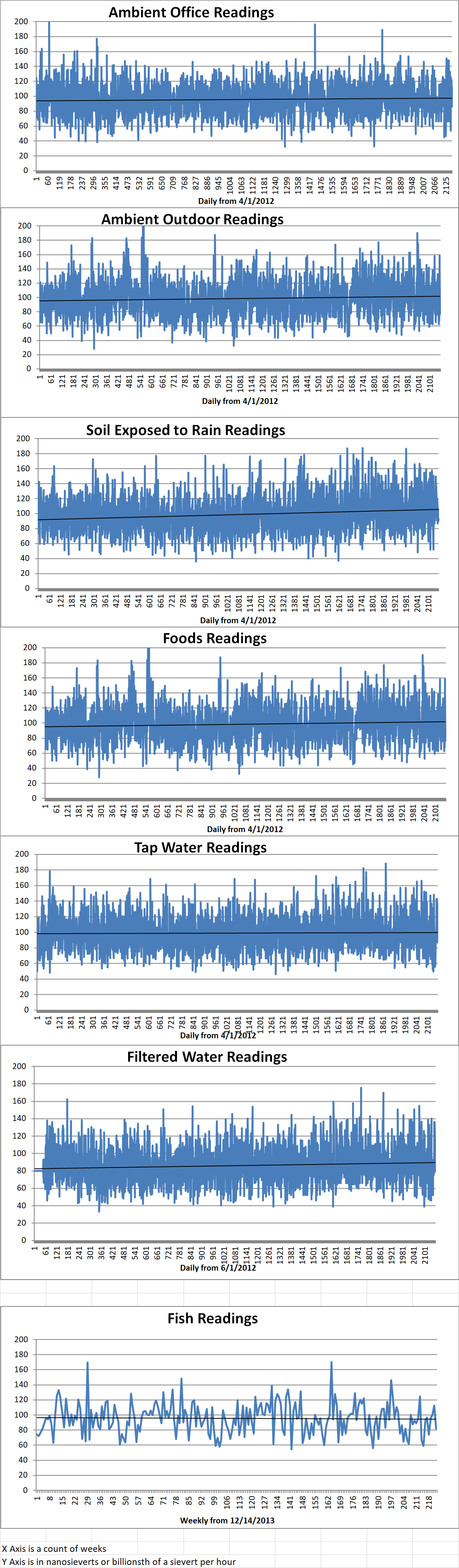

Ambient office = 105 nanosieverts per hour

Ambient outside = 89 nanosieverts per hour

Soil exposed to rain water = 92 nanosieverts per hour

Beefsteak tomato from Central Market = 93 nanosieverts per hour

Tap water = 108 nanosieverts per hour

Filter water = 88 nanosieverts per hour

Dover Sole = 82 nanosieverts per hour

The U.S. manufactured nuclear weapons at the Hanford Nuclear Reservation in south central Washington State. Approximately fifty-six million gallons of liquid waste left over from the production of nuclear warheads is currently stored in one hundred and seventy seven buried tanks. The liquid in the tanks is a witches’ brew of toxic chemicals and radioactive waste. Some of the tanks are leaking and a more permanent solution to the storage of the liquid wastes is being developed.

In 2000, the Department of Energy chose Bechtel as the recipient of a $4.3 billion grant to construct a vitrification plant. The facility is intended to take the liquid wastes from the tanks and combine it with the ingredients of glass. When the mixture is heated, the glass solidifies and traps the radioactive materials. The glass, in the form of logs can then be safely buried.

Bechtel began construction of the vitrification plant in 2002 and it was scheduled to be in operation by 2011. The intention was to vitrify all the contents of the tanks by 2028. In 2012, the U.S. Government Accountability Office issued a report that detailed a variety of unresolved technical and managerial problems at the facility.

One major problem involved the need to keep the plutonium and enriched uranium in the liquids from creating a criticality accident before it was turned into glass. Another problem had to do with the generation of hydrogen gas which could cause an explosion and fire. A third problem involved vibration in the pipes caused by variations in the liquids being treated that could cause ruptures and spills of the liquids.

Currently the vitrification plant is being subjected to “ongoing” reviews by the Government Accounting Office, Office of Inspector General, Defense Nuclear Facilities Safety Board and other agencies. The new estimate for total cost is about $16.18 billion with an expected completion date of 2023.

Researchers at the U.S. Department of Energy’s (DOE) Pacific Northwest National Laboratory (PNNL) have just announced the successful demonstration of the continuous conversion of three gallons of liquid wastes from the buried tanks at Hanford into glass. This is the first time that liquid waste has been converted into glass in a continuous process as opposed to a batch process. It is an important milestone in the development of the process that will be used during full scale operation.

The radioactive waste liquid was slowly pumped into a mixture of the materials used to make glass and heated to over two thousand degrees Fahrenheit. The test produced about twenty pounds of glass. The radioactive materials in the original liquid are chemically bound and sealed to the glass. If the lump of glass were broken, each piece of glass would still prevent the radioactivity from escaping. The vitrification test at the PNNL will assist in the development of the Direct Feed Low-Activity Waste (DFLAW) system that will be used during full operation of the facility when it is completed.

Kris Colosi is the Washington River Protection Solutions project manager. He said that “Being able to run real tank waste instead of simulant through these tests provides valuable input for validating and refining our approach to the treatment of low-activity waste. It’s another important step toward the removal and disposal of a large portion of Hanford’s tank waste.”