A coalition of business, consumer, labor and environmental groups have asked Gov. Phil Murphy to conditionally veto the nuclear subsidy bill that passed the New Jersey legislature last month. Pressofatlanticcity.com

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

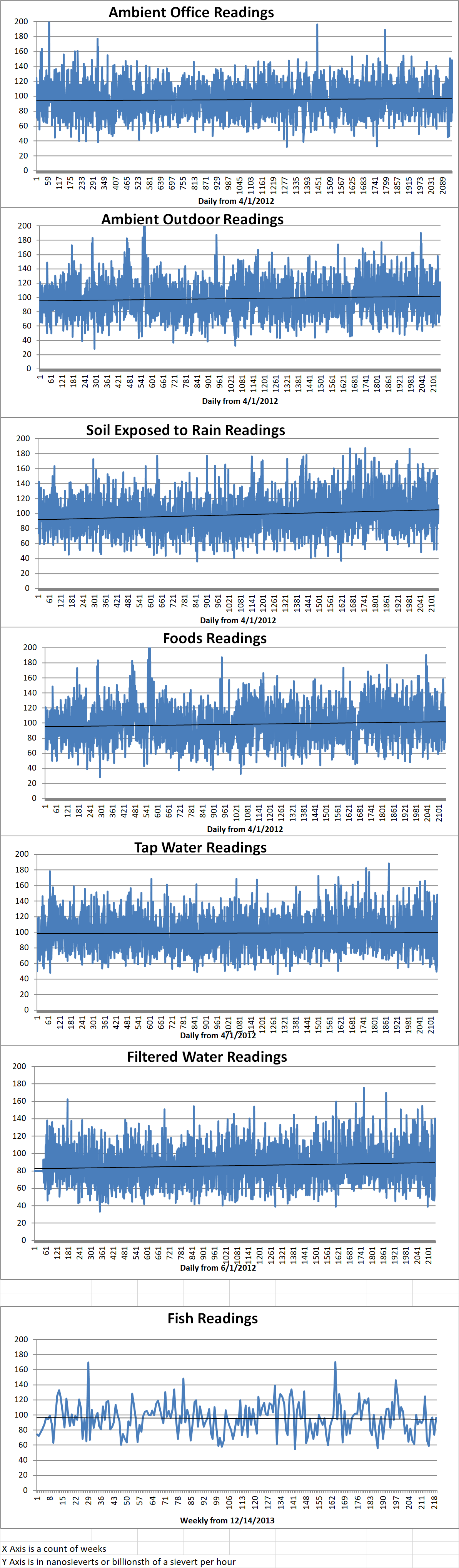

Ambient office = 78 nanosieverts per hour

Ambient outside = 107 nanosieverts per hour

Soil exposed to rain water = 111 nanosieverts per hour

Crimini mushroom from Central Market = 77 nanosieverts per hour

Tap water = 84 nanosieverts per hour

Filter water = 74 nanosieverts per hour

One of the major problems encountered in decommissioning nuclear power reactors is dealing with the radioactivity of the components of the reactor. If the parts of a reactor are too hot for human beings to safely handle, then another way must be found. There has been a great deal of work on adapting robots to assist in decommissioning.

The Winfirth site in Doset, U.K. was the location of nine unique reactors and associated facilities. Decommissioning work began in the 1990s. Currenly, there are only two reactors left at the site; a prototype of a steam generating heavy water reactor and the Dragon prototype of a high-temperature gas-cooled reactor. All that is left of the Dragon plant is the reactor core which is contained in a pressure vessel surrounded by thick concreate shielding, steel plates and an outer containment building. The reactor core is scheduled to be removed by 2021. The remaining facility will be demolished by 2022.

Magnox manages the Winfrith site for the Nuclear Decommissioning Authority (NDA). They subcontracted OC Robotics (OCR) to help them remove a sixteen-inch diameter vessel called the purge gas pre-cooler (PGPC) which is attached to the core of the Dragon reactor at one end and extends outside of the concrete and steel shielding of the reactor.

OC Robotics and The Welding Institute (TWI) used funding from the NDA to develop the LaserSnake long-reach snake-arm with laser cutting optics. It has previously been employed at the Sellafield site in Cumbria.

The pipes in the reactor are thick, the layout of PGPC is complex and there is limited access to the PGPC. OCR constructed two mock-ups of the section of the reactor that contains the PGPC in order to test the use of the LaserSnake. When they were confident of their preparations, the LaserSnake was inserted through a small hole in the ten-foot thick concrete shielding around the core of the Dragon reactor. The actual work of cutting away the PGPC took under three hours.

A spokesman for OCR said, “The difficult environment of the external core of the Dragon reactor was an ideal challenge to show the full capabilities of laser-cutting technology and snake-arm robots. Cutting something as thick as the 400mm PGPC with its complex internal geometry had never been attempted before.”

The senior project manager for Magnox said: “We believe this is the first time that laser-cutting technology has been deployed directly on the core of a nuclear reactor. The ability of the LaserSnake to carry out ‘keyhole surgery’ on the reactor core meant that the work could be carried out using existing protective shielding.”

The head of technology at the NDA said: “This is an excellent example of how early NDA R&D funding support enabled the technology to grow from an exploration of whether laser-cutting could actually be adapted for nuclear into a system that, with further funding and collaborative working, is now mature and being successfully deployed on a number of our sites.”

As more and more of the old nuclear reactors built in the Seventies are permanently shut down, it will be necessary to employ advanced robotics such as the LaserSnake to safely decommissioning them.

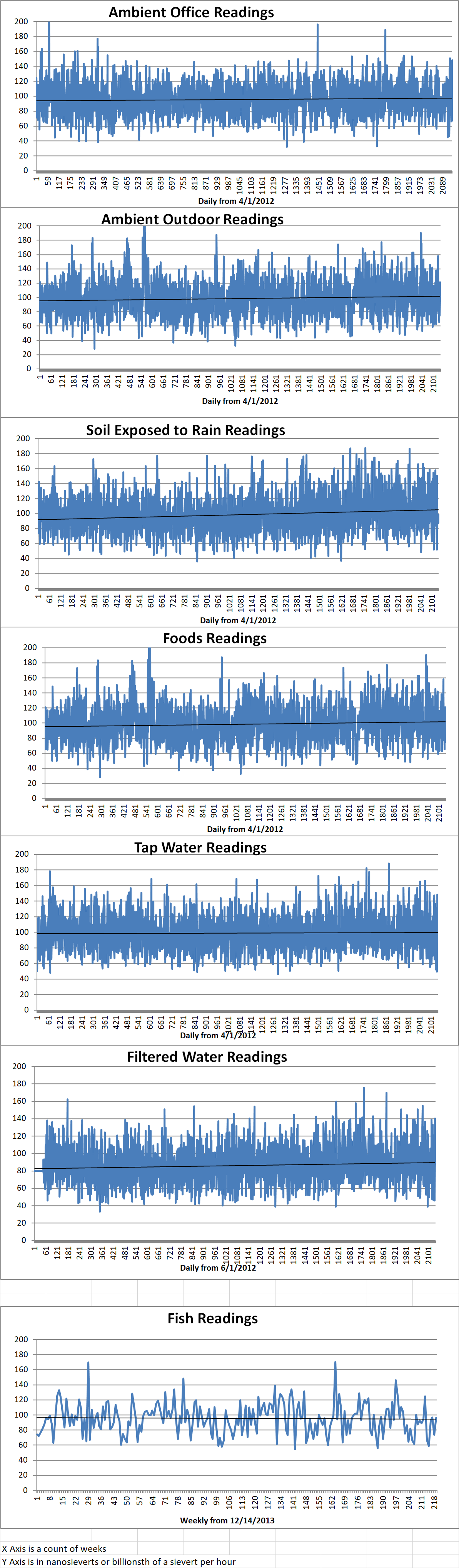

Ambient office = 148 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 98 nanosieverts per hour

Pineapple from Central Market = 121 nanosieverts per hour

Tap water = 100 nanosieverts per hour

Filter water = 88 nanosieverts per hour

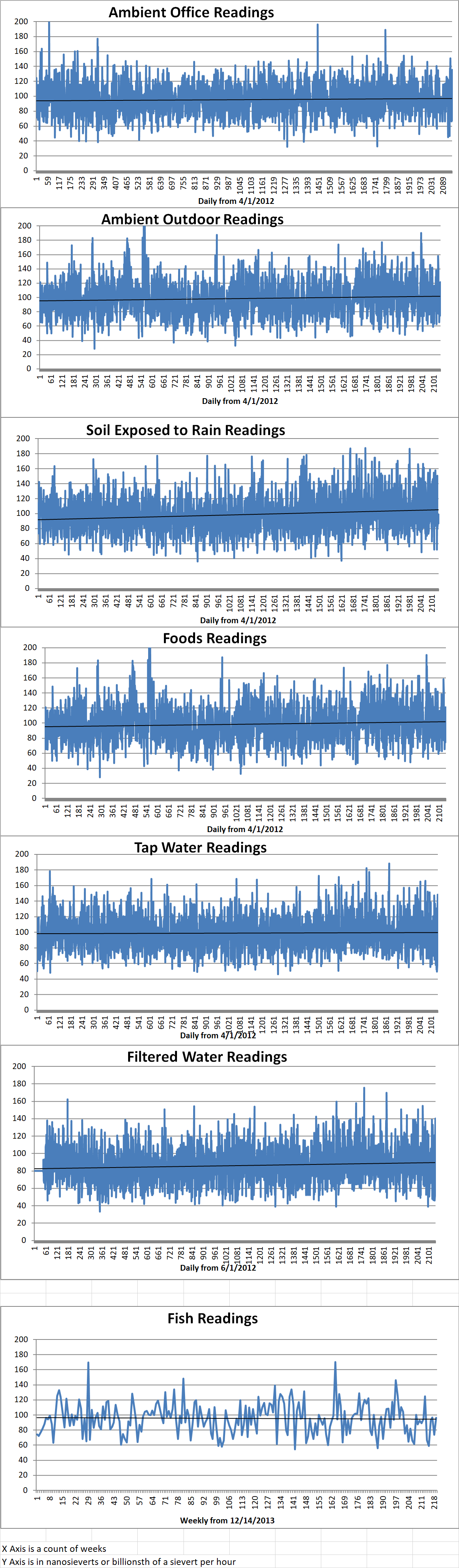

Ambient office = 135 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 99 nanosieverts per hour

Avocado from Central Market = 121 nanosieverts per hour

Tap water = 107 nanosieverts per hour

Filter water = 99 nanosieverts per hour

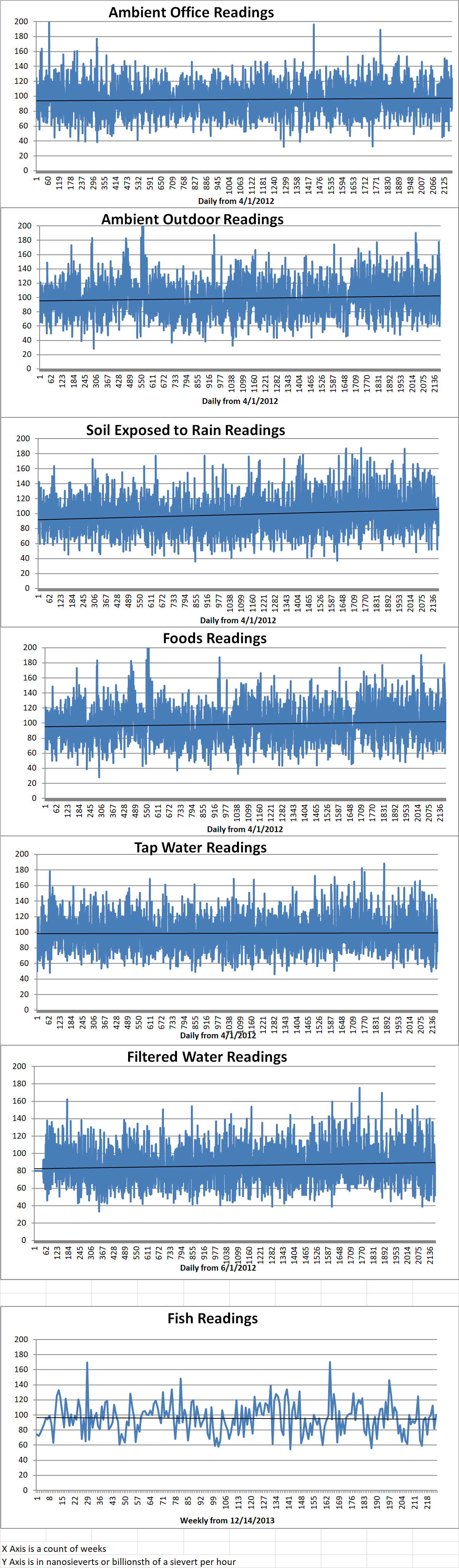

Ambient office = 67 nanosieverts per hour

Ambient outside = 89 nanosieverts per hour

Soil exposed to rain water = 89 nanosieverts per hour

Pineapple from Central Market = 98 nanosieverts per hour

Tap water = 148 nanosieverts per hour

Filter water = 140 nanosieverts per hour

Dover sole – Caught in USA = 96 nanosieverts per hour

The U.S. is planning on spending a trillion dollars over the next ten years on upgrading the U.S. nuclear arsenal. Part of this project will be the construction on new nuclear warheads. The plutonium cores of warhead are called “pits”. The Pentagon expects to be producing eighty pits a year by 2030. In the past twenty-five years, the U.S. has only produced thirty pits.

In the next few days, the U.S. Department of Energy will select one of two possible sites to manufacture the plutonium pits. The two sites are the Los Alamos National Laboratory and the Savannah River Site in South Carolina. However, there are serious concerns for both potential sites about the safety of their operations. There are charges that employees at both sites were sloppy in the handling of nuclear materials and/or failed to monitor safety issues aggressively.

The Los Alamos National Laboratory in New Mexico is the place where plutonium pits have been manufactured in the past. In the month of March alone, errors in the handling of plutonium by LANL workers caused three work stoppages. Workers confused the words “staging” and “storage” twice in recent weeks which resulted in plutonium being placed in containers and areas which were prohibited and unsafe. These mistakes follow three years during which work at LANL was halted because they were unable to meet safety standards for handling plutonium. They have resumed most such work since the three-year hiatus which began in 2013 and ended in 2016.

The Savannah River Site has produced materials for nuclear warheads since the Fifties. In January of 2015, the stirring mechanism for a tank of plutonium solution failed. Flakes of plutonium sank to the bottom of the tank and began to interact with each other. If there had been enough to form a critical mass, a chain reaction would have taken place that would have killed everyone in the room and released radioactive materials into the environment.

Since the incident with the plutonium tank, operations at the SRS have been overseen by the National Nuclear Security Administration. A recent report from senior DoE engineers and physicists concluded that while there had been some improvement at the SRS from the NNSA oversight, there were still problems that needed to be fixed. During a week-long inspection in the month of January, were still “alarmingly inattentive to safety and were not adequately heeding the advice of their safety experts.”

The principal assistant deputy secretary of defense of the U.S. National Nuclear Security Administration’s stated that nuclear rivals of the U.S. are taking notice of our problems in the production of nuclear warheads. He said, “I’m sure they’re watching that. It’s not lost on anyone that there are nations out there that produce more pits than we do, including the North Koreans. That’s one of the reasons why we need to get moving in terms of our capability.”

During the Cold War, nuclear armed nations paid little attention to safety and the environment when they were working on nuclear weapons. There has been some improvement in the past twenty years since the fall of the Soviet Union, but it appears that there are still significant problems at U.S. nuclear weapons manufacturing sites.