The short-lived radioisotope technetium-99m (Tc-99) is used for more than thirty million medical procedures each year for treatment and diagnosis around the world. Tc-99m is the most widely used radioisotope for medical imaging. Tc-99m is generated from molybdenum-99 (MO-99) which also has a short half-life. They have to be used quickly after they are produced. This requires a stable supply of them for the world medical market.

Mo-99 production has been mainly carried out in a small number of research reactors. Many of these reactors were constructed and put into operation in the 1960s. There have often been disruptions in Mo-99 production which has resulted in shortages of this important radioisotope.

BWX Technologies (BWXT) is an American company in the nuclear technology sector. It builds steam generators and other nuclear components and manages “high-consequence nuclear and national security operations.” The company is working on a small modular reactor called the B&W mPower. It also recently announced the development of a special device to generate Mo-99 and Tc-99.

The President and CEO of BWXT says that the current Mo-99 infrastructure is inefficient, scattered around the globe, seriously antiquated, and has “burdensome” logistic. He said that his company has a breakthrough technology that solves the problems of an expensive, unstable supply system that produces complex radioactive waste that could lead to the proliferation of nuclear weapons.

The BWXT Mo-99 production device is based on a neutron capture process. The device will produce Mo-99 from natural molybdenum instead of using enriched uranium targets which is the primary current production method. Tc-99m can be extracted as needed from the device which is still under development.

BWXT will initially focus on the North American market where there is currently no Mo-99 production. Their plans call for the production of sufficient Mo-99 to satisfy all demands in North America. The President and CEO said “We are presently working to finalize agreements that will provide us with a long-term and stable irradiation supply of Mo-99 and other medical radioisotopes from multiple source.”

The Mo-99 Tc-99 generator is being designed to be able to be inserted into the existing configurations and processes of radiopharmacies without the need for any special hardware or adaptions. The U.S. Food and Drug Administration (FDA) will have to approve the device before it can be sold.

BWXT has just signed an agreement to purchase Sotera Health’s Nordian medical isotope business in order to speed up their entry into the medical radioisotope business. The acquisition will reduce risks for BWXT and provide an already licensed infrastructure, one hundred and fifty trained and experienced personnel, and two production centers. If approval can be obtained from U.S. and Canadian regulators, BWXT hopes to finalize the deal by the end of 2018.

The President and CEO of BWXT says that they will use the acquisition of Nordian to help them obtain the approval of the FDA and commercialize their device. Their plans call for adapting the two Nordian facilities to the production of the technetium generators.

Blog

-

BWX Technologies Is Working On A New Generator For Mo-99 And Tc-99

-

Geiger Readings for May 08, 2018

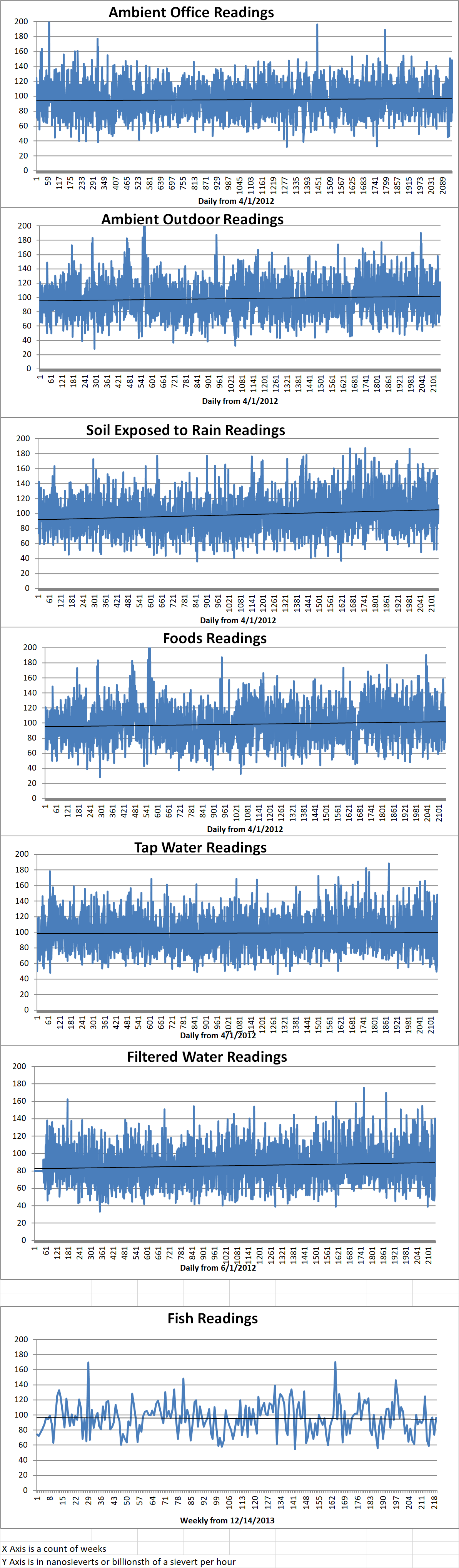

Ambient office = 78 nanosieverts per hour

Ambient outside = 107 nanosieverts per hour

Soil exposed to rain water = 111 nanosieverts per hour

Crimini mushroom from Central Market = 77 nanosieverts per hour

Tap water = 84 nanosieverts per hour

Filter water = 74 nanosieverts per hour

-

Nuclear Reactors 558 – LaserSnake Robot Being Used To Decommission Winfirth Dragon Reactor In U.K.

One of the major problems encountered in decommissioning nuclear power reactors is dealing with the radioactivity of the components of the reactor. If the parts of a reactor are too hot for human beings to safely handle, then another way must be found. There has been a great deal of work on adapting robots to assist in decommissioning.

The Winfirth site in Doset, U.K. was the location of nine unique reactors and associated facilities. Decommissioning work began in the 1990s. Currenly, there are only two reactors left at the site; a prototype of a steam generating heavy water reactor and the Dragon prototype of a high-temperature gas-cooled reactor. All that is left of the Dragon plant is the reactor core which is contained in a pressure vessel surrounded by thick concreate shielding, steel plates and an outer containment building. The reactor core is scheduled to be removed by 2021. The remaining facility will be demolished by 2022.

Magnox manages the Winfrith site for the Nuclear Decommissioning Authority (NDA). They subcontracted OC Robotics (OCR) to help them remove a sixteen-inch diameter vessel called the purge gas pre-cooler (PGPC) which is attached to the core of the Dragon reactor at one end and extends outside of the concrete and steel shielding of the reactor.

OC Robotics and The Welding Institute (TWI) used funding from the NDA to develop the LaserSnake long-reach snake-arm with laser cutting optics. It has previously been employed at the Sellafield site in Cumbria.

The pipes in the reactor are thick, the layout of PGPC is complex and there is limited access to the PGPC. OCR constructed two mock-ups of the section of the reactor that contains the PGPC in order to test the use of the LaserSnake. When they were confident of their preparations, the LaserSnake was inserted through a small hole in the ten-foot thick concrete shielding around the core of the Dragon reactor. The actual work of cutting away the PGPC took under three hours.

A spokesman for OCR said, “The difficult environment of the external core of the Dragon reactor was an ideal challenge to show the full capabilities of laser-cutting technology and snake-arm robots. Cutting something as thick as the 400mm PGPC with its complex internal geometry had never been attempted before.”

The senior project manager for Magnox said: “We believe this is the first time that laser-cutting technology has been deployed directly on the core of a nuclear reactor. The ability of the LaserSnake to carry out ‘keyhole surgery’ on the reactor core meant that the work could be carried out using existing protective shielding.”

The head of technology at the NDA said: “This is an excellent example of how early NDA R&D funding support enabled the technology to grow from an exploration of whether laser-cutting could actually be adapted for nuclear into a system that, with further funding and collaborative working, is now mature and being successfully deployed on a number of our sites.”

As more and more of the old nuclear reactors built in the Seventies are permanently shut down, it will be necessary to employ advanced robotics such as the LaserSnake to safely decommissioning them. -

Geiger Readings for May 07, 2018

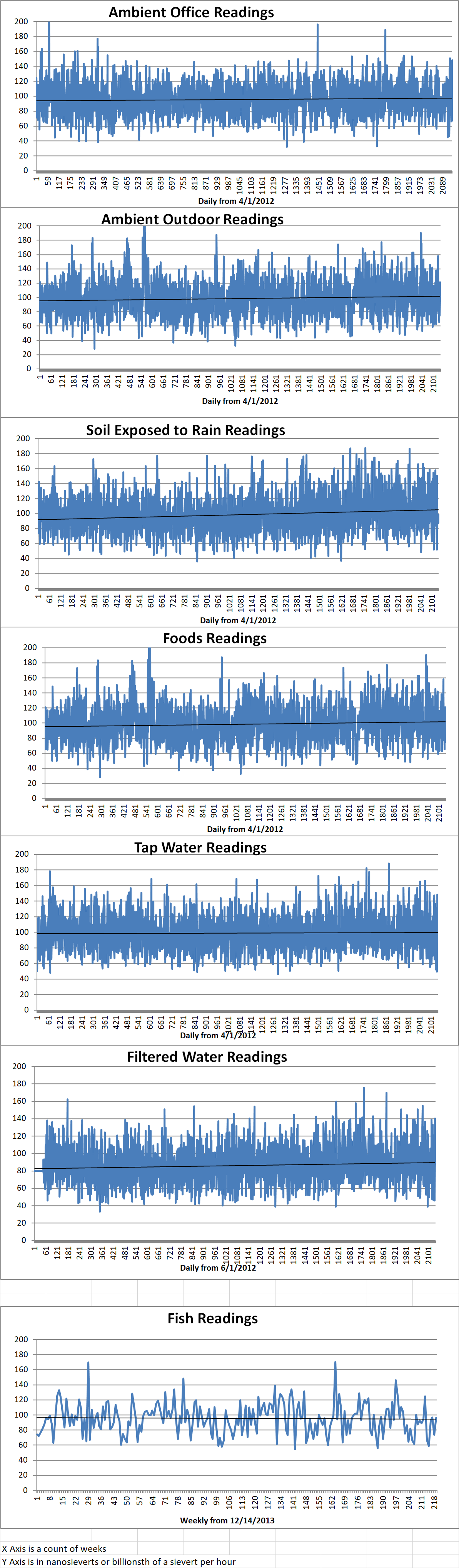

Ambient office = 148 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 98 nanosieverts per hour

Pineapple from Central Market = 121 nanosieverts per hour

Tap water = 100 nanosieverts per hour

Filter water = 88 nanosieverts per hour

-

Geiger Readings for May 06, 2018

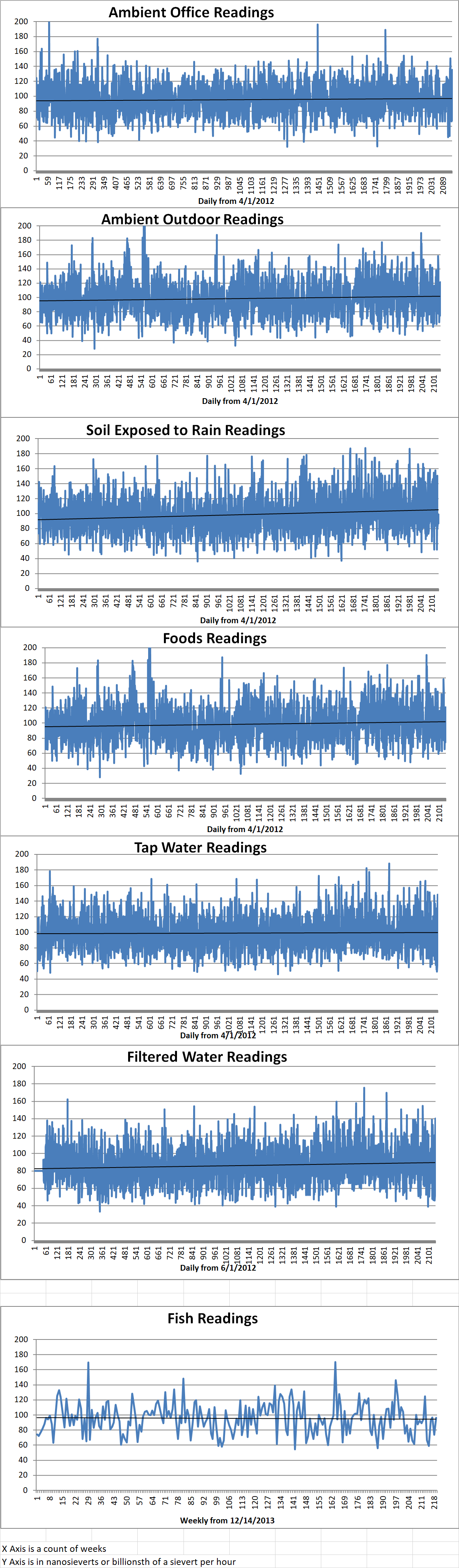

Ambient office = 135 nanosieverts per hour

Ambient outside = 103 nanosieverts per hour

Soil exposed to rain water = 99 nanosieverts per hour

Avocado from Central Market = 121 nanosieverts per hour

Tap water = 107 nanosieverts per hour

Filter water = 99 nanosieverts per hour

-

Geiger Readings for May 05, 2018

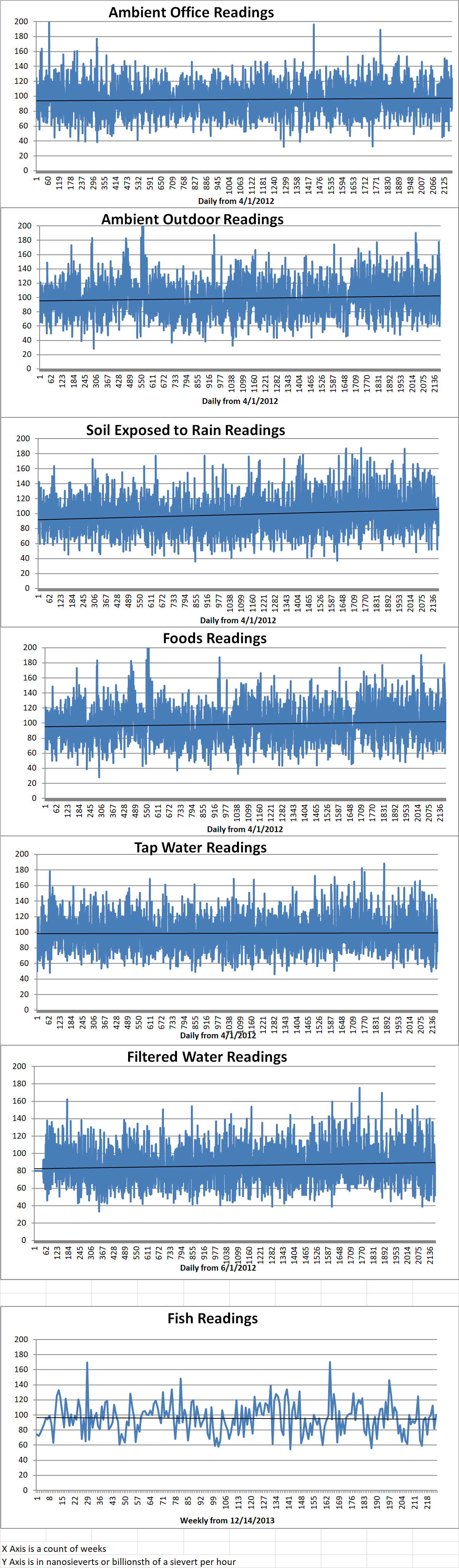

Ambient office = 67 nanosieverts per hour

Ambient outside = 89 nanosieverts per hour

Soil exposed to rain water = 89 nanosieverts per hour

Pineapple from Central Market = 98 nanosieverts per hour

Tap water = 148 nanosieverts per hour

Filter water = 140 nanosieverts per hour

Dover sole – Caught in USA = 96 nanosieverts per hour