The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

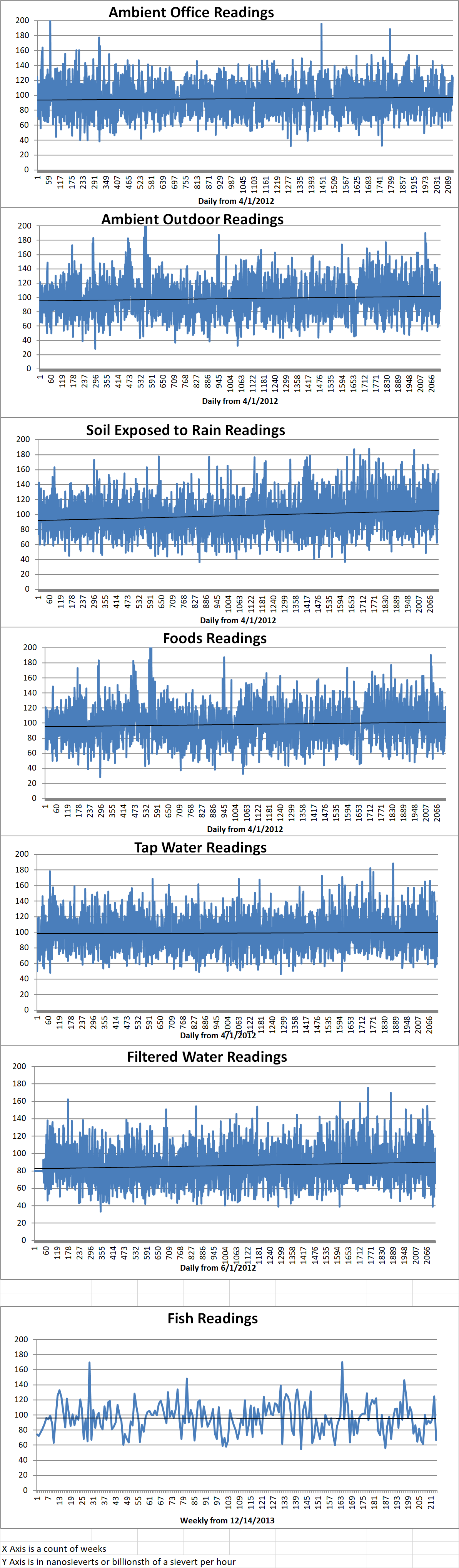

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

Most nuclear reactors are powered by pellets of uranium or uranium mixed with plutonium. The pellets are inserted into long thin fuel rods which are then bundled together into fuel assemblies. When fuel assemblies are removed from a reactor, they are placed in a cooling pool for five years to allow heat and radioactivity to dissipate. When the assemblies are removed from the pool, they are stored in massive stainless steel and concrete containers known as dry casks which can hold between twenty and thirty fuel rod assemblies.

Once a dry cask is sealed, there is currently no way to know how many fuel rod assemblies are actually stored in the cask because it cannot be opened once sealed. This is of grave concern to individuals and organizations who are working on insuring the non-proliferation of nuclear weapons. It would be possible for a country to claim that there were more spent fuel rod assembles in their dry casks than were actually in the casks. The missing fuel rod assemblies could be diverted to a nuclear weapons facility for recycling and recovery of U-235 and/or plutonium.

Scientists at the Los Alamos National Laboratory (LANL) in New Mexico under the leadership of Matthew Durham have developed a method for checking on the contents of dry casks without opening them. Their method relies on monitoring the path through the dry casks of muons generated by cosmic rays. They say that International Atomic Energy Agency inspectors could use the process that LANL researchers have developed to make sure that spent nuclear fuel is not being diverted to a nuclear weapons program.

The LANL process requires muon monitors to be placed on either side of a dry casks. The muons will easily penetrate the concrete and steel of the casks but their paths through the casks will be influenced by the presence of heavy elements such as uranium and plutonium.

The team set up a test cask at the Idaho National Laboratory. The test cask has twenty-four slots that can receive spent fuel rod assemblies. For the test, six of the twenty-four slots were left empty. Previous tests had suggested that the angle of muon scattering was influenced by missing fuel rod assemblies, but the area of the cask tested was too small for the tests to be conclusive.

In the new experiments conducted by the LANL team, sensors were placed all over the test casks in nine different patterns. They found that they could accurately determine when two or more fuel rod assemblies were absent. They say that if they increase measurement time or use larger detectors that can capture more of the passing muons, it should be possible to tell if only one fuel rod assemble is missing.

Considering that the cooling pools at nuclear power plants are quickly filling up, more and more spent fuel rod assemblies will be placed in temporary dry casks storage to await the construction of permanent geological repositories. The new muon monitoring system will be a valuable addition to the tools of nuclear plant inspectors.

Nuclear power reactors are fueled with fuel rod assemblies. The fuel rods in the assemblies are long and thin. They are filled with pellets of enriched uranium or a mixture of uranium and plutonium. The rods are coated with an alloy of zirconium. There are problems with the coating currently used because, at high temperatures, the coating can allow flammable hydrogen gas to escape and might cause explosions. There is a great deal of research into better coatings for fuel rods.

Most metals other than gold will oxidize when exposed to air and water. This process results in rust on an iron surface, tarnish on a silver surface and verdigris on copper and brass surfaces. This process can contribute to a category of failure referred to as stress corrosion cracking. There are three elements that form an oxide that can prevent any further oxidation: aluminum oxide, chromium oxide, and silicon dioxide.

A team of researchers from the Massachusetts Institute of Technology (MIT) led by graduate student Yang Yang just published a paper this week that describes their work with thin layers of solid aluminum oxide coating on metals. These layers of oxide can deform like a liquid which allows them to fill in cracks and gaps that may form in the metal surface they coat. The researchers say that one of the most important potentials uses for the new solid oxide coats is in the coating of nuclear fuel rods. The new coating could prevent the escape of hydrogen gas molecules as the fuel rods age.

The team examined metals coated with solid layers of aluminum oxide, chromium oxide and silicon dioxide with an environmental transmission electron microscope. The microscope allowed the team to examine metal surfaces exposed to gases and liquids such as oxygen and water. They found that these oxides coatings can prevent further oxidation to the surface of the metal.

Only the aluminum oxide flowed like a liquid at room temperatures. In order to flow, the layer of aluminum oxide has to be just two or three billionths of a meter thick. The researchers found that the aluminum oxide coating could be stretched to more than double its original length while still preventing cracks to open in the metal surface. When this coating is present, the typical corrosion process in absent.

The press release from the MIT team said, “Even with a solid protective layer, cracks can form that allow the oxygen to penetrate to the bare metal surface, where it can then penetrate into interfaces between the metal grains that make up a bulk metal material, causing further corrosion that can penetrate deeper and lead to structural failure.” However, the thin aluminum oxide coating “…is almost as deformable as a comparably thin layer of aluminum metal — a layer much thinner than aluminum foil. When the aluminum oxide is coated onto a surface of a bulk piece of aluminum, the liquid-like flow keeps the aluminum covered with its protective layer.”

MIT NSE logo: