Blog

-

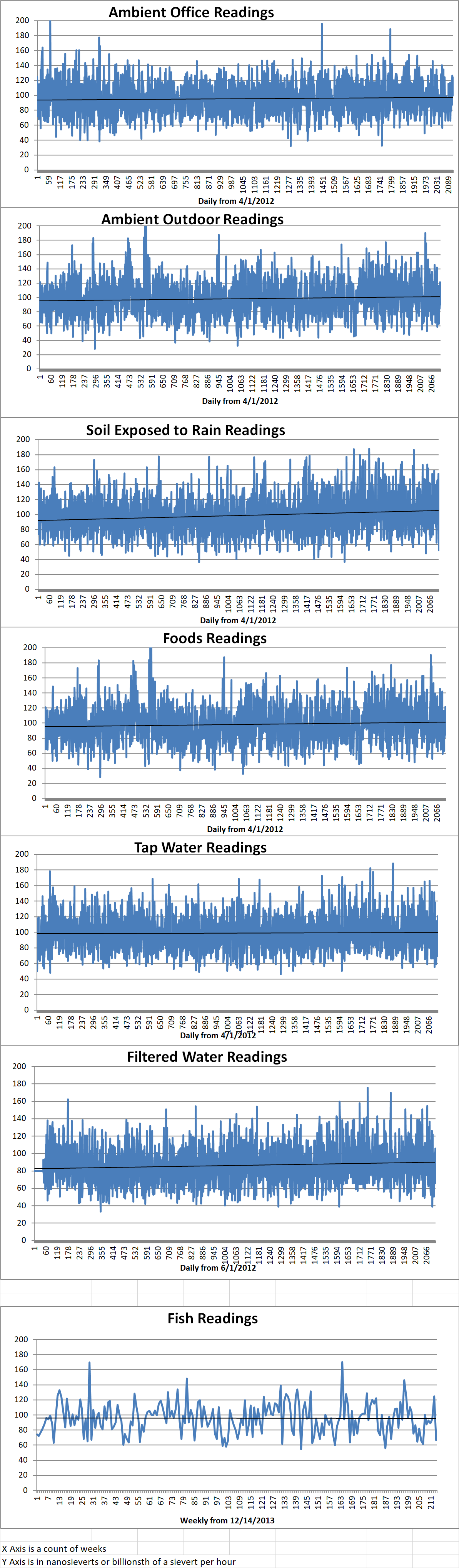

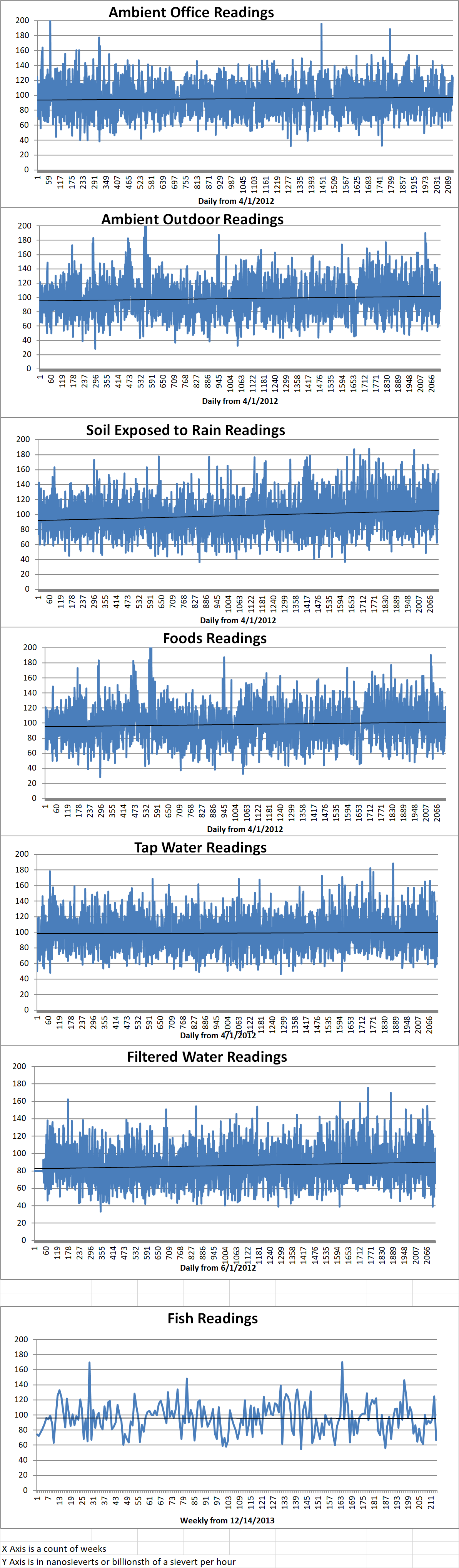

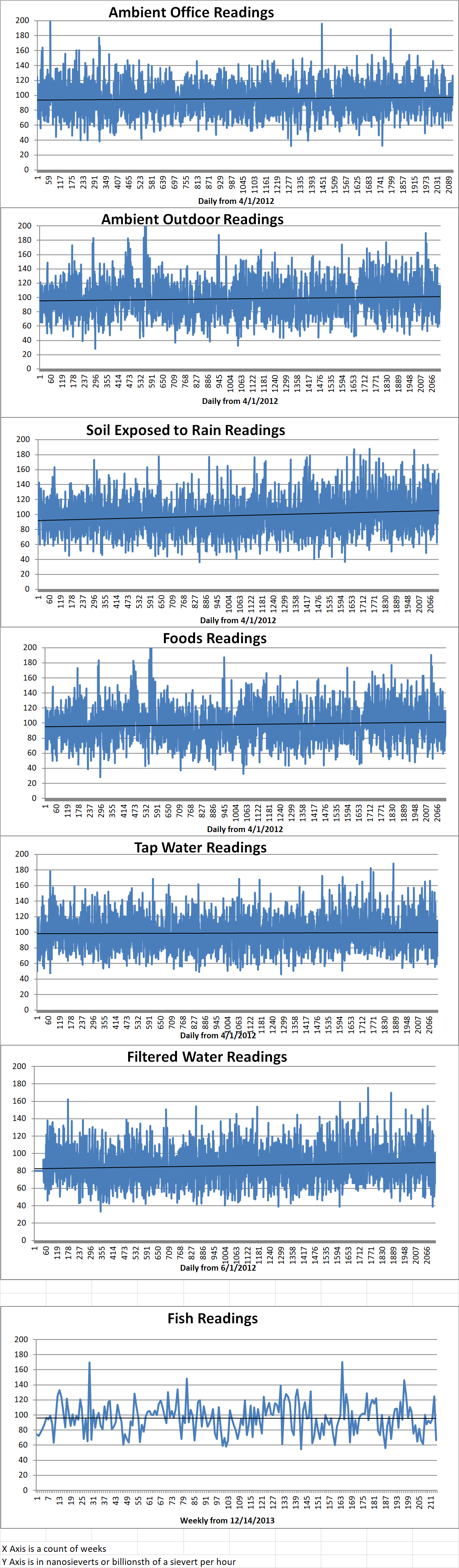

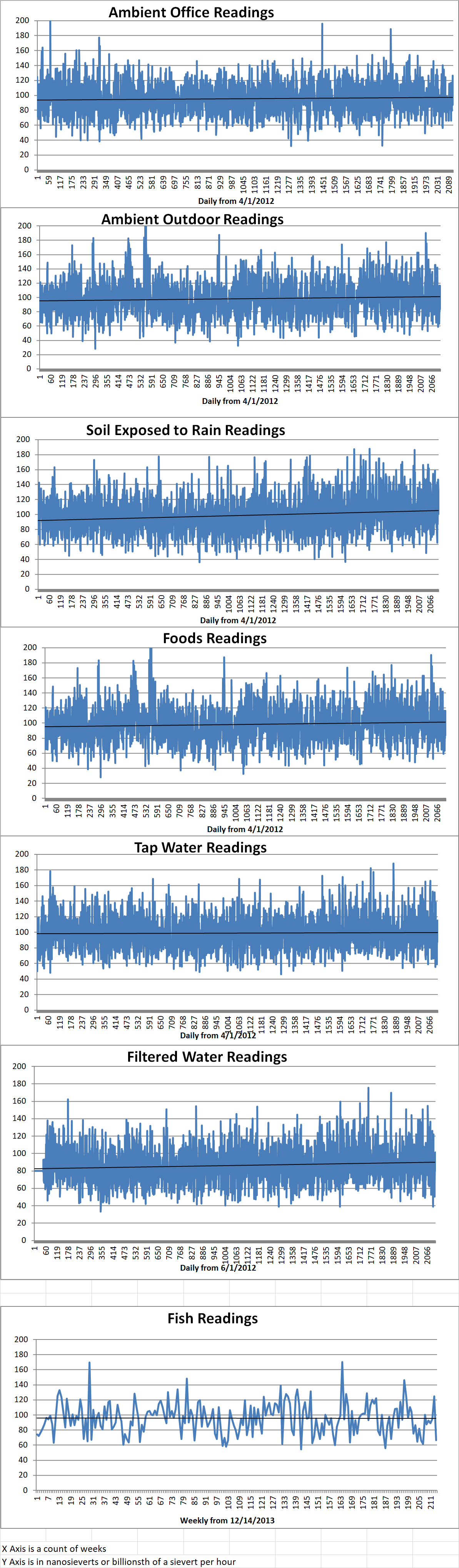

Geiger Readings for Apr 12, 2018

Ambient office = 100 nanosieverts per hourAmbient outside = 111 nanosieverts per hourSoil exposed to rain water = 105 nanosieverts per hourCarrot from Central Market = 121 nanosieverts per hourTap water = 121 nanosieverts per hourFilter water = 106 nanosieverts per hour -

Nuclear Reactors 553 – India Cancels Plans For Fifty Seven Nuclear Power Reactors

India has very serious shortages of electricity. About two hundred million people out of India’s one billion three hundred million citizens do not have any access to electricity. Much of the rest of the country does not have reliable sources of electricity. In July of 2012, India experienced the biggest electrical blackout in world history. About six hundred and seventy million Indian’s had no electricity for three days. This is about half of India’s population. Future growth in the economy and population of India are going to require a major expansion of electrical generation.

Currently, nuclear energy provides less than four percent of the electricity for India. India has been planning to build seventy six new nuclear power reactors that will generate sixty-three megawatts worth of nuclear power. That would provide about twenty-five percent of their electricity.

India had an ambitious three phase plan for the development of nuclear power. The first phase would be the construction of conventional power reactors. The second phase would begin with the construction of four fast breeder reactors to generate plutonium to fuel a fleet of fast breeder reactors. The third phase would be the development of thorium reactors. India has large deposits of thorium.

The Indian Department of Nuclear Energy (DNE) has just announced that they are cutting way back on their nuclear ambitions. Fifty-seven reactor projects are going to be cancelled leaving only nineteen reactor construction projects. This means that instead of twenty-five percent of electricity being nuclear by 2032, only about ten percent will be nuclear by that date.

The Indian DNE which made the announcement of the cancellations did not give any reason for the decision. Analysts say that it is probably a combination of reasons such as a lack of funding, the absence of a reliable supply chain that could cope with such a huge increase in reactor construction and the lack of a trained workforce to construct and maintain the nuclear reactors.

One major roadblock for India’s nuclear projects has been the fact that India has very stringent supplier liability laws. This is a result of the horrible Bhopal disaster in central India in 1984. Foreign nuclear technology firms are afraid that a nuclear disaster in India could bankrupt them.

Another problem for India is the fact that they have not signed the international treaty to prevent proliferation of nuclear weapons. They are not part of the international organization of nuclear technology suppliers because of the fear that dual use technologies that are sold for the development of nuclear power could be repurposed for the creation of nuclear weapons.

India will rely of coal fired power plants to replace the cancelled nuclear projects. India has huge deposits of coal and is the third largest exporter of coal in the world. This will impact India’s attempts to fight climate change. India’s carbon dioxide emissions rose almost five percent in 2016 as opposed to the drop-in emissions recorded by other nations which are major sources of carbon dioxide.

Indian Department of Atomic Energy logo:

-

Geiger Readings for Apr 11, 2018

Ambient office = 124 nanosieverts per hourAmbient outside = 111 nanosieverts per hourSoil exposed to rain water = 105 nanosieverts per hourCelery from Central Market = 121 nanosieverts per hourTap water = 121 nanosieverts per hourFilter water = 106 nanosieverts per hour -

Radioactive Waste 335 – Los Alamos National Laboratory Working On Using Muons To Monitor Contents Of Dry Casks

Most nuclear reactors are powered by pellets of uranium or uranium mixed with plutonium. The pellets are inserted into long thin fuel rods which are then bundled together into fuel assemblies. When fuel assemblies are removed from a reactor, they are placed in a cooling pool for five years to allow heat and radioactivity to dissipate. When the assemblies are removed from the pool, they are stored in massive stainless steel and concrete containers known as dry casks which can hold between twenty and thirty fuel rod assemblies.

Once a dry cask is sealed, there is currently no way to know how many fuel rod assemblies are actually stored in the cask because it cannot be opened once sealed. This is of grave concern to individuals and organizations who are working on insuring the non-proliferation of nuclear weapons. It would be possible for a country to claim that there were more spent fuel rod assembles in their dry casks than were actually in the casks. The missing fuel rod assemblies could be diverted to a nuclear weapons facility for recycling and recovery of U-235 and/or plutonium.

Scientists at the Los Alamos National Laboratory (LANL) in New Mexico under the leadership of Matthew Durham have developed a method for checking on the contents of dry casks without opening them. Their method relies on monitoring the path through the dry casks of muons generated by cosmic rays. They say that International Atomic Energy Agency inspectors could use the process that LANL researchers have developed to make sure that spent nuclear fuel is not being diverted to a nuclear weapons program.

The LANL process requires muon monitors to be placed on either side of a dry casks. The muons will easily penetrate the concrete and steel of the casks but their paths through the casks will be influenced by the presence of heavy elements such as uranium and plutonium.

The team set up a test cask at the Idaho National Laboratory. The test cask has twenty-four slots that can receive spent fuel rod assemblies. For the test, six of the twenty-four slots were left empty. Previous tests had suggested that the angle of muon scattering was influenced by missing fuel rod assemblies, but the area of the cask tested was too small for the tests to be conclusive.

In the new experiments conducted by the LANL team, sensors were placed all over the test casks in nine different patterns. They found that they could accurately determine when two or more fuel rod assemblies were absent. They say that if they increase measurement time or use larger detectors that can capture more of the passing muons, it should be possible to tell if only one fuel rod assemble is missing.

Considering that the cooling pools at nuclear power plants are quickly filling up, more and more spent fuel rod assemblies will be placed in temporary dry casks storage to await the construction of permanent geological repositories. The new muon monitoring system will be a valuable addition to the tools of nuclear plant inspectors.

-

Geiger Readings for Apr 10, 2018

Ambient office = 100 nanosieverts per hourAmbient outside = 162 nanosieverts per hourSoil exposed to rain water = 155 nanosieverts per hourBeefsteak tomato from Central Market = 99 nanosieverts per hourTap water = 70 nanosieverts per hourFilter water = 66 nanosieverts per hour -

Nuclear Reactors 552 – MIT Researchers Find That Thin Layer Of Aluminum Oxide Forms Self-Healing Coating For Nuclear Fuel Rods

Nuclear power reactors are fueled with fuel rod assemblies. The fuel rods in the assemblies are long and thin. They are filled with pellets of enriched uranium or a mixture of uranium and plutonium. The rods are coated with an alloy of zirconium. There are problems with the coating currently used because, at high temperatures, the coating can allow flammable hydrogen gas to escape and might cause explosions. There is a great deal of research into better coatings for fuel rods.

Most metals other than gold will oxidize when exposed to air and water. This process results in rust on an iron surface, tarnish on a silver surface and verdigris on copper and brass surfaces. This process can contribute to a category of failure referred to as stress corrosion cracking. There are three elements that form an oxide that can prevent any further oxidation: aluminum oxide, chromium oxide, and silicon dioxide.

A team of researchers from the Massachusetts Institute of Technology (MIT) led by graduate student Yang Yang just published a paper this week that describes their work with thin layers of solid aluminum oxide coating on metals. These layers of oxide can deform like a liquid which allows them to fill in cracks and gaps that may form in the metal surface they coat. The researchers say that one of the most important potentials uses for the new solid oxide coats is in the coating of nuclear fuel rods. The new coating could prevent the escape of hydrogen gas molecules as the fuel rods age.

The team examined metals coated with solid layers of aluminum oxide, chromium oxide and silicon dioxide with an environmental transmission electron microscope. The microscope allowed the team to examine metal surfaces exposed to gases and liquids such as oxygen and water. They found that these oxides coatings can prevent further oxidation to the surface of the metal.

Only the aluminum oxide flowed like a liquid at room temperatures. In order to flow, the layer of aluminum oxide has to be just two or three billionths of a meter thick. The researchers found that the aluminum oxide coating could be stretched to more than double its original length while still preventing cracks to open in the metal surface. When this coating is present, the typical corrosion process in absent.

The press release from the MIT team said, “Even with a solid protective layer, cracks can form that allow the oxygen to penetrate to the bare metal surface, where it can then penetrate into interfaces between the metal grains that make up a bulk metal material, causing further corrosion that can penetrate deeper and lead to structural failure.” However, the thin aluminum oxide coating “…is almost as deformable as a comparably thin layer of aluminum metal — a layer much thinner than aluminum foil. When the aluminum oxide is coated onto a surface of a bulk piece of aluminum, the liquid-like flow keeps the aluminum covered with its protective layer.”

MIT NSE logo:

-

Geiger Readings for Apr 09, 2018

Ambient office = 100 nanosieverts per hourAmbient outside = 130 nanosieverts per hourSoil exposed to rain water = 101 nanosieverts per hourBartlett pear from Central Market = 84 nanosieverts per hourTap water = 115 nanosieverts per hourFilter water = 101 nanosieverts per hour