Blog

-

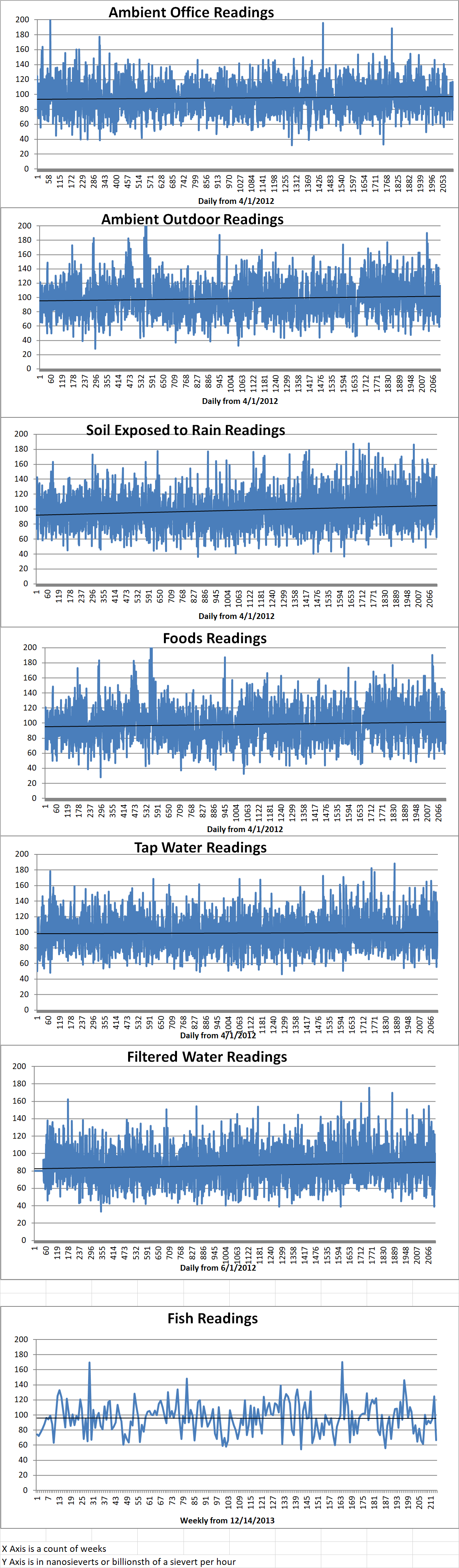

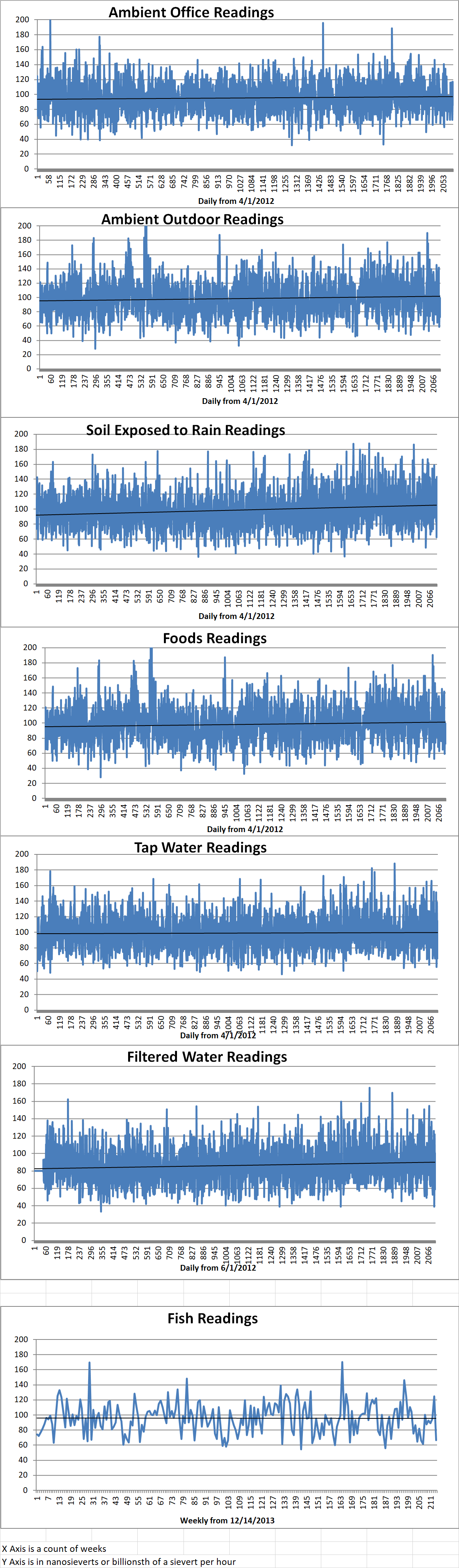

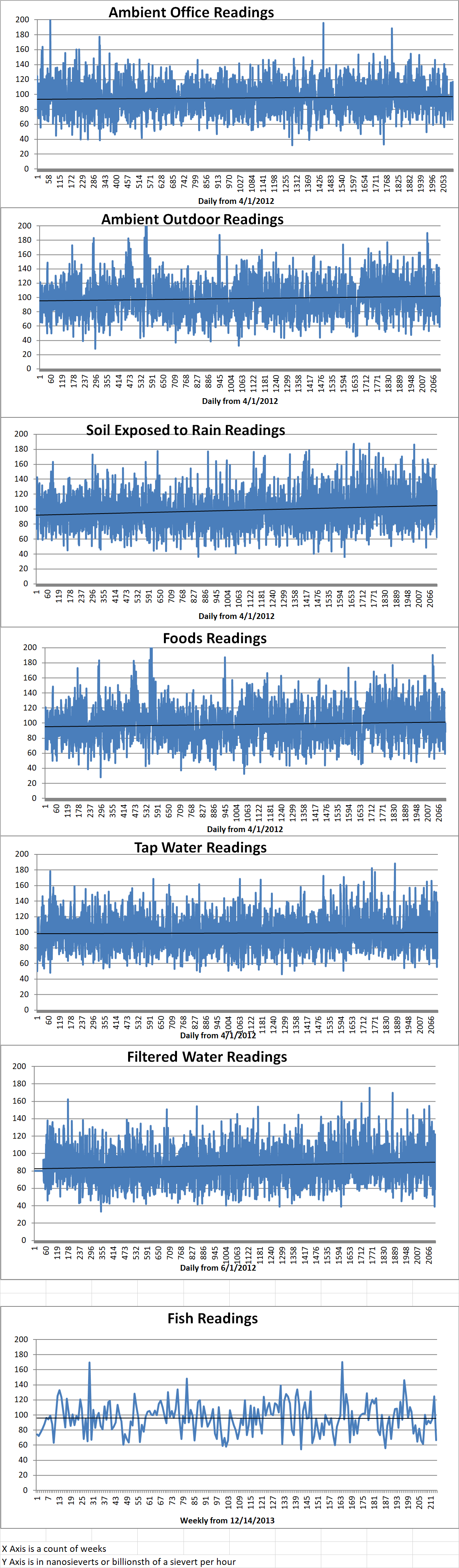

Geiger Readings for Apr 04, 2018

Ambient office = 109 nanosieverts per hourAmbient outside = 83 nanosieverts per hourSoil exposed to rain water = 87 nanosieverts per hourOrange bell pepper from Central Market = 63 nanosieverts per hourTap water = 59 nanosieverts per hourFilter water = 50 nanosieverts per hour -

Nuclear Weapons 352 – Soviet and Russian Systems For Deploying ICBMs On Trains

Towards the end of the Soviet Union, the USSR put intercontinental ballistic missiles on trains. Their Soviet name was RT-23 but the U.S. referred to them as the SS-23 Scalpel. Each missile was seventy-seven feet long and carried ten five-hundred and fifty kiloton multiple-reentry warheads. The trains were referred to as Moldets. The first became operational in 1987. The Soviets ultimately deployed twelve of these trains. After the fall of the Soviet Union in 1991, the Russians entered into the START II treaty with the U.S. and all of the Moldets were decommissioned.

In 2013, the Russian military announced that they were going to create a new generation of rail-mobile ICBMs. These trains would carry the more sophisticated RS-24 Yars missiles. The RS-24 has about the same range as the older RS-23 but is ten feet shorter and half the weight as the RS-23. The RS-24 can also be mounted on a truck and driven around. The intent is to have these mobile missiles constantly roaming around Russia, ready to stop and launch their missiles on demand. The new project was referred to as “Barguzin” and Russia said that the new trains would be ready for testing by 2019.

The benefit of these mobile launchers is that they can travel around Russia and blend in with the regular rail and truck traffic. This makes them much harder to locate and target that missiles that in silos. More U.S. missiles would be required to destroy them which means the there would be fewer missiles for fixed targets.

In 2012, a Russian general had said that they were developing the Barguzin because the U.S. Prompt Global Strike (PGS) program. Part of that program involves the development of hypersonic weapons that can quickly reach any part of the globe. The PGS program still exists and one hundred and eighty million dollars was spent on it in 2017.

In 2015, according to the Rossiyskaya Gazeta, there were tests of part of the Barguzin program. In December of 2017, the Russian government stated that it was going to suspend the Barguzin project because the project was too expensive. Some analysts said that the Russians were never really serious about the Barguzin program and that it was just part of their misinformation and propaganda.

Whether the Russians were serious about Barguzin or not, it is true that mobile missiles are much more expensive that missiles in silos. During periods of peace, the Barguzin program would have required an expensive network of bases where the missiles and launchers could be stored and maintained. The missiles would have to remain in storage under the terms of international arms treaties, so any enemy would know exactly where they were.

In the event of a war, there would have to be major security detachments of troops to guard the mobile launchers as they moved around Russia. And, in the end, the launchers would still be somewhere on the rail system of Russia which would make them easier to locate. Hypersonic missiles travel so rapidly that it is questionable whether or not the missile trains would be able to even make it out of their storage locations before the hypersonic missiles reached them.

While Russia may have cancelled the Barguzin program, they have said that if circumstances require it, the trains and missiles could be quickly reactivated and deployed. Let us hope that circumstances never require it.

RS-24 Yars missile mounted on mobile carrier:

-

Geiger Readings for Apr 03, 2018

Ambient office = 79 nanosieverts per hourAmbient outside = 96 nanosieverts per hourSoil exposed to rain water = 91 nanosieverts per hourCarrot from Central Market = 116 nanosieverts per hourTap water = 93 nanosieverts per hourFilter water = 89 nanosieverts per hour -

Nuclear Reactors 549 – New Accident Tolerant Fuel Assemblies For Nuclear Power Plants Are Being Developed

Current nuclear power reactors are fueled with assemblies of rods. The rods contain pellets of uranium or a uranium-plutonium mixture called MOX. The long thin fuel rods in a nuclear fuel assembly are coated in a process called cladding. Zirconium is widely used for cladding but there are problems with zirconium that have contributed to research for modified or replacement cladding that is safer and more efficient.

Research on accident tolerant fuels (ATF) including new cladding materials and different designs for fuel pellets have been going on since the early 2000s. The nuclear disaster at Fukushima in Japan in March of 2011 created additional pressure on the nuclear industry to find ways to make nuclear power reactors safer.

The U.S. Department of Energy created the Enhanced Accident Tolerant Fuel program in order to develop new fuel assemblies for light water reactors. The program includes U.S. utilities, universities and the Electric Power Research Institute. Projects being supported by the DoE could result in commercial products within ten years.

Three different approaches to ATF are under development by GE’s Global Nuclear Fuel (GNF), AREVA, and Westinghouse. The DoE is providing funding and technical assistance. Lightbridge, a company in Reston, Virgina, is working on its own ATF project with zirconium-alloy cladding and a metallic uranium alloy.

GNF is working on “IronClad” fuel assemblies with help from Oak Ridge National Laboratory. IronClad ATFs utilize an alloy containing iron, chromium and aluminum. The new alloy for the cladding is supposed to improve how the fuel assemblies respond to severe accident scenarios. One of the big dangers in extreme scenarios is the leakage of high temperature steam which can cause cladding to oxidize. The steel in the IronClad coating gives it a much lower oxidation rate than the conventional zirconium alloy cladding.

GNF recently shipped test assemblies with two variations of the IronClad coating to Edwin I. Hatch Nuclear Plant near Baxley in southeastern Georgia. They also shipped a test assembly with a zirconium cladding called ARMOR. After a

planned outage for maintenance, the test assemblies will be installed in the Unit 1 reactor and will remain there for the next twenty-four months.

The Hatch Nuclear Plant is owned and operated by Southern Nuclear Operating Co. (SNO). A spokesperson for SNO said that the ATF technologies have “industry-changing safety and efficiency advantages” that they hope could make nuclear power plants safer and more efficient. They consider the upcoming test of the ATFs “…not a small step, but a leap for our industry.”

This February, the principal deputy assistant secretary for the Office of Nuclear Energy at the U.S. Department of Energy said, “An accident-tolerant fuel is an industry term used to describe new technologies that further enhance the safety and performance of nuclear materials. This can be in the form of new cladding and/or fuel pellet designs.”

The Hatch tests will be the first deployment of the new ATF assemblies but there will be more soon. GNF also plans to test IronClad and ARMOR cladding material at Exelon Generation’s Clinton Power Station in 2019. Areva and Westinghouse ATF assemblies will also be tested in plants owned by Southern Co. and Exelon.

-

Geiger Readings for Apr 02, 2018

Ambient office = 86 nanosieverts per hourAmbient outside = 151 nanosieverts per hourSoil exposed to rain water = 143 nanosieverts per hourCelery from Central Market = 873 nanosieverts per hourTap water = 114 nanosieverts per hourFilter water = 100 nanosieverts per hour -

Geiger Readings for Apr 01, 2018

Ambient office = 117 nanosieverts per hourAmbient outside = 73 nanosieverts per hourSoil exposed to rain water = 63 nanosieverts per hourCrimini mushroom from Central Market = 99 nanosieverts per hourTap water = 105 nanosieverts per hourFilter water = 97 nanosieverts per hour