Blog

-

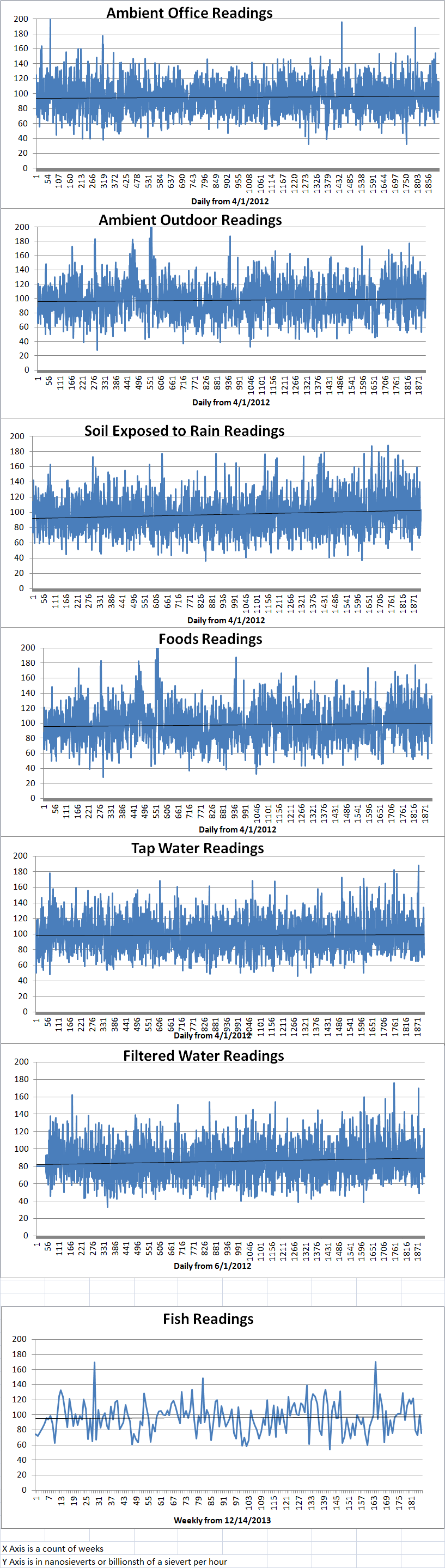

Geiger Readings for Sep 13, 2017

Ambient office = 103 nanosieverts per hourAmbient outside = 109 nanosieverts per hourSoil exposed to rain water = 119 nanosieverts per hourCherry tomato from Central Market = 143 nanosieverts per hourTap water = 102 nanosieverts per hourFilter water = 84 nanosieverts per hour -

Nuclear Reactors 301 – The NRC Performs Properly In Dealing With A Problem With Critical Valves At Nuclear Power Plants – Part 2 of 2 Parts

Part 2 of 2 parts (Please read Part 1 first.)

On February 11 of this year, the Unit 2 reactor at LaSalle was shut down for refueling. The operators used this shutdown as an opportunity to inspect and maintain emergency systems such as the HPCS. They tried to fill the HPCS system with water but were unable to fill the piping that led from the HPCS valve to the reactor vessel. Upon inspection of the gate valve, they discovered that one of the disks in the gate valve had broken free from the stem of the valve and was blocking the flow path. This valve is normally closed in the standby mode and it only opens when the HPCS system is turned on in an emergency. The motor turns the stem which raises the disk to open the pipe and lowers the disk to close the pipe. The disk that broke loose was in the closed position so the motor was unable to open it and permit the flow of water. The workers replaced the internal parts of the gate valve and restarted the Unit 2 reactor when the refueling was finished.

In April of 2017, Exelon contacted the NRC and informed them of the problem with the HPCS gate valve. A Special Inspection Team (SIT) was dispatched to carry out an investigation of the cause of the gate valve failure and the response that followed the discovery of the problem.

The SIT agreed with the conclusions of the LaSalle operators. A part inside the gate valve had broken due to severe stress. The broken part allowed the connection of the stem to the disks to become so misaligned that the disk separate from the stem. Anchor Darling has redesigned the internal parts of the gate valve to prevent such occurrences in the future.

Exelon to the NRC in early June that it intended to fix sixteen other problems with Anchor Darling gate valves that may suffer the same sort of failure of the HPCS system for Unit 2 the next time they shut down the two reactors for refueling. The SIT considered the explanations given by Exelon for waiting until the next refueling outage to repair the valve problems at their plant. The SIT agreed with their reasoning in fifteen of the sixteen problems. Exelon said that the Unit 1 gate valve in the HPCS system was much newer than the gate valve for Unit 2 and they felt that it would be safe to wait until they shut down the plant for refueling to check on it. The SIT said that there were significant differences between the two gate valves including how they were originally tested, some differences in design, unknown material strength properties and differences in thread wear that caused them to reject the delay in replacing the gate valve for Unit 1. They said that they felt confident that the gate valve would fail and that it would be dangerous to delay replacement. Unit 1 at the LaSalle plant was shut down on June 22 to replace the internal components of the valve for the HPCS system.

The SIT said that Exelon had violated Criterion III, Design Control, of Appendix B to 10 CFR Part 50 that involved torque values for the motors of the HPCS gate valves. Exelon mistakenly assumed that the weakest part of the gate valve was the stem and made sure that the torque of the motor would not overstress the stem. However, it turned out that another part was the weakest and the permitted torque of the motor damaged that part, permitting the disk to separate from the stem. Although the NRC considered the Exelon mistake to be a violation of their regulations, they did not issue a citation because they decided that the problem with the valve was so subtle that Exelon could be forgiven for missing it.

Looking this sequence of events and responses to them, how did the system perform in the case of the problem with these valves? First of all, the TVA reported a serious problem that they found. The manufacture investigated and found design flaws. The NRC sent out an advisory to the nuclear industry members that operated nuclear power plants. The NRC subsequently sent out a special team to investigate. They concluded that the owner of the nuclear power plant had performed properly given the subtly of the problem.

-

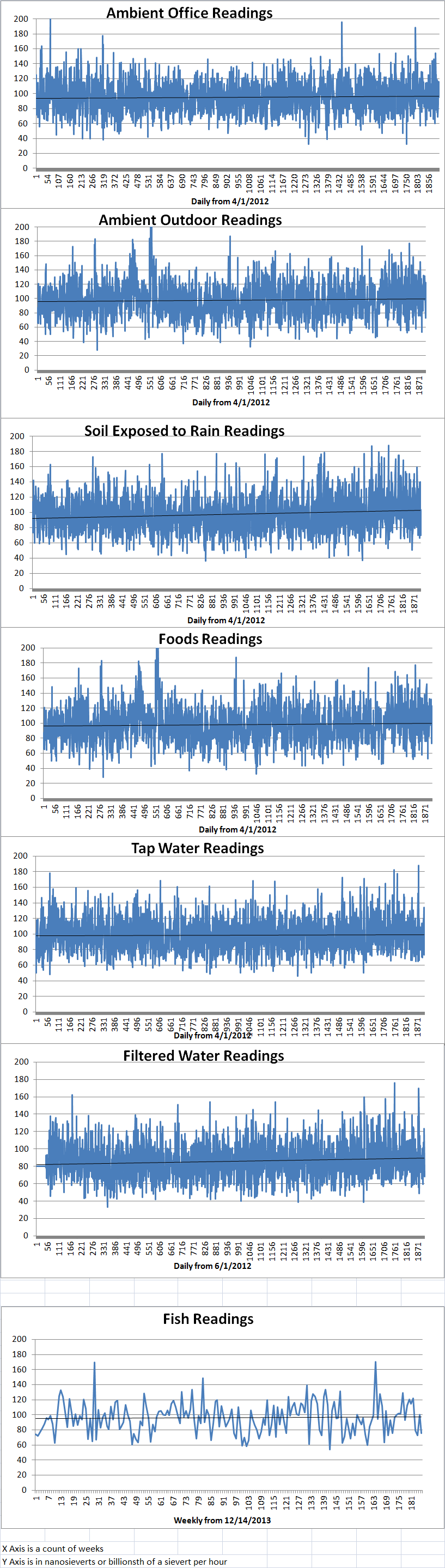

Geiger Readings for Sep 12, 2017

Ambient office = 78 nanosieverts per hourAmbient outside = 100 nanosieverts per hourSoil exposed to rain water = 88 nanosieverts per hourOrganic carrot from Central Market = 136 nanosieverts per hourTap water = 77 nanosieverts per hourFilter water = 69 nanosieverts per hour -

Nuclear Reactors 300 – The NRC Performs Properly In Dealing With A Problem With Critical Valves At Nuclear Power Plants – Part 1 of 2 Parts

Part 1 of 2 parts

I have blogged about many accidents at nuclear power plants from minor problems to major disasters. Sometimes the problems are handled professionally and other times there are serious issues with the responses of the operators of the nuclear power plants. I have often complained of incompetence and dishonesty on the part of the Nuclear Regulatory Commission, the nuclear industry and the owners of nuclear power plants. Today I am going to talk about a problem with valves in emergency cooling systems and the response of various groups to those problems.

The two reactors at LaSalle are boiling water reactors (BWRs) which were put into operation in the early 1980s. The LaSalle reactors were an evolution of BWR/4 that had what is referred to as Mark I containment systems. The new reactors at LaSalle are known as BWR/5 with Mark II containment systems. In BWR/4 reactors utilize steam-driven high pressure coolant injection (HPCI) to supply “makeup” cooling water to the core in case a spall pipe connected to the reactor vessel breaks, the BWR/5 reactors use a high pressure core spray system (HPCS) powered by a motor to supply such makeup cooling water in case a pipe breaks.

The HPCS is not normally operating. It stays in standby mode as long as reactor operations are normal. The system has a motor driven pump that can pump water into the reactor vessel at a rate of seven thousand gallons per minute if necessary. There is a “suppression” pool inside the containment vessel that supplies water to the pump. In the event of a major drop in pressure in the reactor vessel, there are low pressure emergency systems such as the residual head removal and low pressure core spray pumps. However, if a small pipe breaks and leaks, the drop in pressure is not enough to trigger the low pressure emergency systems. When a small pipe breaks, the water drains into the suppression pool that supplies the HPSC pump. The motor for the HPCS can either be powered from the electrical grid outside the power plant or from onsite emergency diesel generators.

In January of 2013, the Tennessee Valley Authority turned a report in to the Nuclear Regulatory Commission under 10 Code of Federal Regulation Part 21 concerning a defect in an Anchor Darling double disk gate valve in the HPCI system at their Browns Ferry nuclear power plant. The next month, Anchor Darling, the manufacturer of the valve, turned in their own report under 10 Code of Federal Regulation Part 21 which stated that there was a design problems in their valve that could cause the lower disk to separate from the valve stem.

In April of 2013, the Boiling Water Reactor Owners’ Group (BWROG) sent a report to their members about the problems with the gate valve. The report suggested what could be done to monitor the valve and insure that it was operating correctly. In 2015, operators at LaSalle carried out the recommended monitoring of their gate valves operations and found not problems. In 2016, the (BWROG) sent out a revision of their 2013 report on the gate valves based on the work of a nuclear plant owner. Workers at the plant had disassembled twenty six gate valves and found problems in twenty four of them. In February of 2017, LaSalle workers tested the HPCS gate valve in Unit 2 and found no problems.

(Please read Part 2)

-

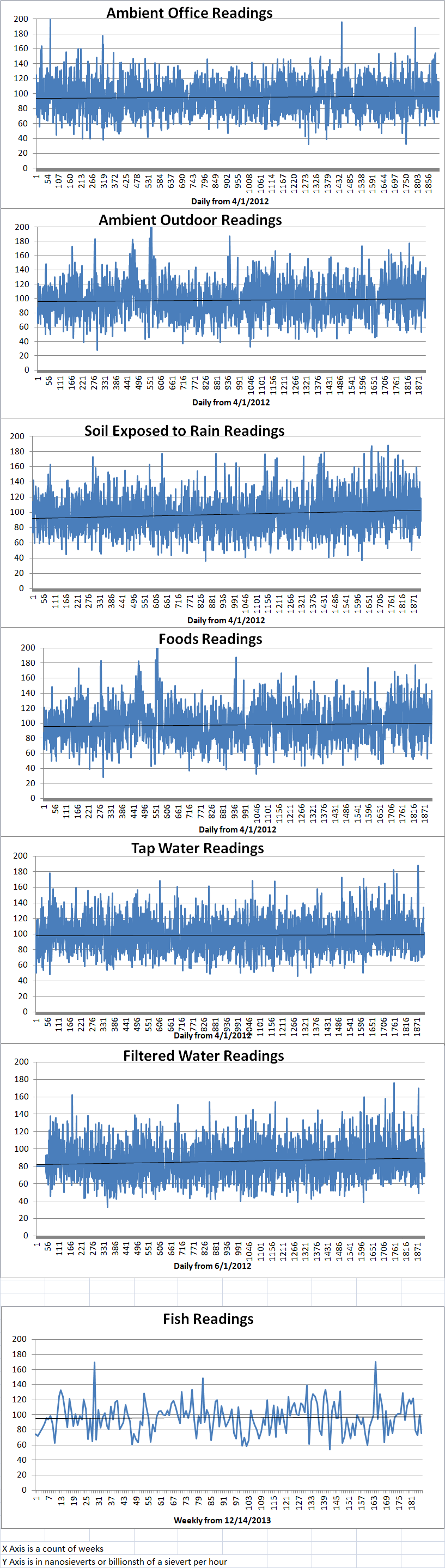

Geiger Readings for Sep 11, 2017

Ambient office =116 nanosieverts per hourAmbient outside = 86 nanosieverts per hourSoil exposed to rain water = 103 nanosieverts per hourCrimini mushroom from Central Market = 123 nanosieverts per hourTap water = 75 nanosieverts per hourFilter water = 68 nanosieverts per hour