Blog

-

Geiger Readings for Aug 07, 2017

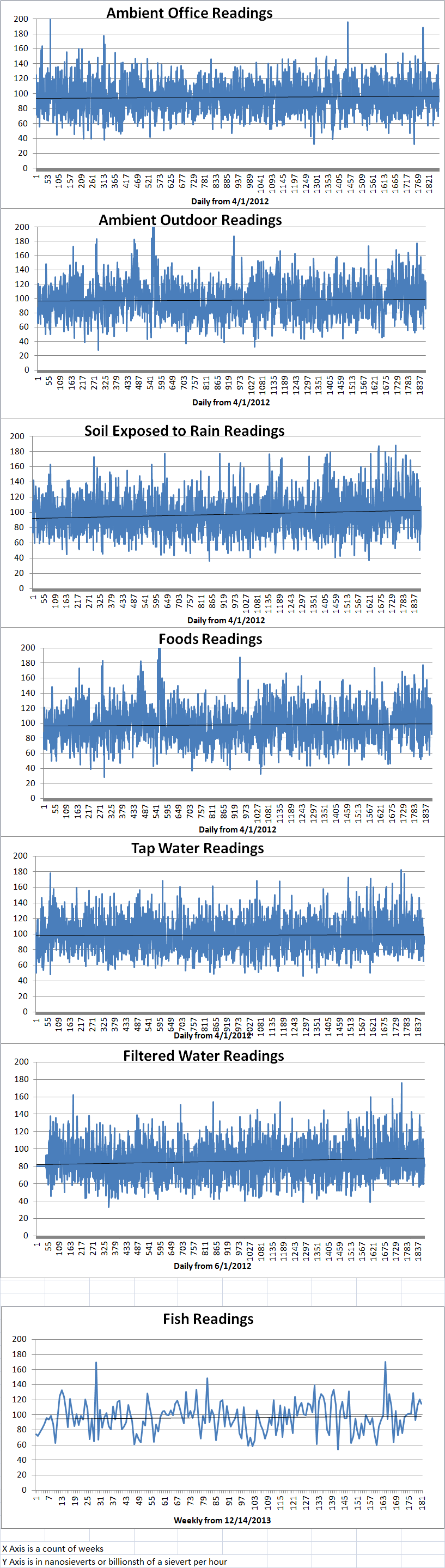

Ambient office = 108 nanosieverts per hourAmbient outside = 135 nanosieverts per hourSoil exposed to rain water = 143 nanosieverts per hourCarrot from Central Market = 93 nanosieverts per hourTap water = 108 nanosieverts per hourFilter water = 94 nanosieverts per hour -

Nuclear News Roundup Aug 06, 2017

-

Geiger Readings for Aug 06, 2017

Ambient office = 100 nanosieverts per hourAmbient outside = 88 nanosieverts per hourSoil exposed to rain water = 105 nanosieverts per hourCelery from Central Market = 138 nanosieverts per hourTap water = 85 nanosieverts per hourFilter water = 75 nanosieverts per hour -

Nuclear News Roundup Aug 05, 2017

-

Geiger Readings for Aug 05, 2017

Ambient office = 89 nanosieverts per hourAmbient outside = 114 nanosieverts per hourSoil exposed to rain water = 108 nanosieverts per hourCrimini mushroom from Central Market = 123 nanosieverts per hourTap water = 87 nanosieverts per hourFilter water = 80 nanosieverts per hourDover sole – Caught in USA = 115 nanosieverts per hour -

New Technologies Are Being Developed For The Production Of Medical Radioisotopes

Most of my blog posts have to do with nuclear reactors, nuclear weapons and/or nuclear waste. But occasionally I blog on other nuclear related issues such as the production of radioisotopes for medical use. The radioisotope market was over eleven billion dollars in 2016 and is estimated to rise to almost twenty billion dollars by 2021. There have been concerns lately that the production of Molybdenum-99 will be sufficient to supply the global demand.

Mo-99 is the precursor for technetium-99m. Tc-99m is the most popular radioisotope used in nuclear medicine. Mo-99 only has a sixty-six hour half-life so it cannot just be manufactured and stockpiled for whenever it is needed. The ability to produce and distribute Mo-99 in a timely fashion is critical to insuring that it will be available when needed. Mo-99 is produced in special reactors, many of which are connected to research organizations. Highly enriched uranium targets are bombarded to produce Mo-99. These targets are of concern to organizations and governmental agencies dedicated to preventing the proliferation of nuclear weapons.

Commercial production of Mo-99 in the U.S. ended in 1989. The U.S. Department of Energy’s National Nuclear Security Administration (NNSA) has been partnering with U.S. private firms to speed up the creation of technologies which can produce Mo-99 without the need for the highly-enriched uranium targets.

Shine Medical Technologies just started the construction of a new radioisotope production plant in Janesville, Wisconsin. They create Mo-99 along with other radioisotopes used in medical diagnosis and treatment. They will produce these isotopes with an accelerator-driven subcritical assembly and will only need low-enriched uranium for targets. They have received twenty five million dollars from the NNSA.

Shine applied to the Nuclear Regulatory Commission for a construction permit in 2013. In 2015, the conclusion of a review of Shine’s safety analysis report prompted the NRC to recommend granting the construction permit. The permit was granted by the NRC in early 2016. Space at the facility will be used to research further refinements in the production technology for radioisotopes. The facility is being construction near an airport to facilitate the rapid shipment of the radioisotopes. The first commercial shipments of Mo-99 are planned for 2020.

Northstar Medical Radioisotopes is also working with the NNSA. They are developing a production method for radioisotopes that involves the use of a linear accelerator. Another participant in the NNSA project is General Atomics. GA is working on technology that utilizes a low-enriched uranium target for radioisotope production.

NTP Radioisotopes SOC Ltd is a subsidiary of the South African Nuclear Energy Corporation. It claims that it currently supplies between twenty five and thirty three percent of the global demand for Mo-99. The NTP finance director said, “We have managed to grow our market share for Mo-99 through continued investment in our production, and by working with our partners to cover the supply gap.”

The OECD-Nuclear Energy Agency published a report about the supply of medical radioisotopes in April of this year. They said that “additional reactor capacity and associated processing capacity from existing radioisotope producers were added during 2016.” In addition, the report said “Overall, the current irradiator and processor supply chain capacity should be sufficient and if well maintained, planned and scheduled, be able to manage an unplanned outage of a reactor, or a processor throughout the whole period to 2022. If no additional capacity is added, then from mid-2018, the level of capability to manage adverse events falls, in particular when considering processing capacity.” The report went on to say, “The supply situation will continue to require “careful and well considered planning”, to minimize security of supply risks, with a high degree of cooperation between producers being essential for the foreseeable future.” The NEA stated that regular monitoring of the market will be required as well as periodic reviews of the progress in bringing new production capacity online.

-

Geiger Readings for Aug 04, 2017

Ambient office = 106 nanosieverts per hourAmbient outside = 80 nanosieverts per hourSoil exposed to rain water = 82 nanosieverts per hourOrange bell pepper from Central Market = 86 nanosieverts per hourTap water = 97 nanosieverts per hourFilter water = 82 nanosieverts per hour -

Radioactive Waste 293 – Melted Fuel May Have Been Located In The Ruins Of The Number 3 Reactor At Fukushima

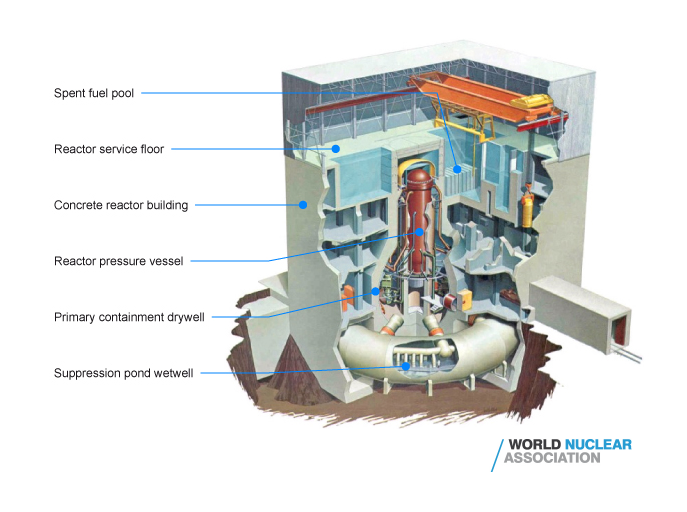

In March of 2011, there was an earthquake northeast of Japan. It created a tsunami that flooded the Fukushima nuclear power plant on the coast of the Japanese island of Honshu. The tsunami flooded the emergency generators which provided power for the cooling pumps in the reactors. Without the emergency generators, the cooling systems failed and three of the six reactors melted down. There was a huge explosion in reactor Three that destroyed the building that contained reactor Four. The ruined reactor buildings were very radioactive and, in some areas, impossible to inspect.

Years have passed and the buildings have cooled off a bit. There have been a succession of attempts, mostly unsuccessful, to send robots in to inspect the damage and try to find out what has happened to the fuel in the reactor cores. There is an estimated six hundred metric tons of melted fuel mixed with debris called “corium” between the three reactors that melted down. The meltdowns ruptured the pressure vessel containing the reactors cores and poured corium down into the bottom of the reactor buildings.

The most recent robot has returned pictures that show globs of molten corium in the lower levels ruins of reactor Three. It has been estimated that the cleanup of the three reactors may take forty years and cost over seventy two billion dollars. Different approaches are being considered for cleaning up the corium although some may require technology that does not exist yet.

An adviser to Tepco, the company that owns and operated the Fukushima nuclear power plant, said “Special tools and techniques will have to be developed to undertake such a task that has never been attempted before anywhere in the world. Once Tepco has identified the characteristics of this material, then they can develop a plan to remove this material in a safe manner.” Three different possible ways to get the corium out of the ruined reactor are being explored.

An existing access hatch could be easily modified to allow the corium to be removed through the side of the reactor without extensive construction or excavation. One problem with this approach is that while it makes it relatively easy to get to the corium in the lower levels of the reactor building, it will be more difficult to remove corium that stayed in the pressure vessel higher up in the building.

A containment building could be constructed above the ruined reactor to limit radiation release. Then the top of the reactor would be removed and the entire reactor including the pressure vessel and the lower levels would be flooded with water to cool the radioactivity. The corium could be removed as the radiation level is controlled by the water.

A tunnel could be dug under the reactor building. Then all the water would be drained out of the ruins. Following that, the corium would be removed. A big problem with this approach is the fact that without cooling water, the level of radiation would be higher and more dangerous as the corium was removed than the other approaches.

The Nuclear Damage Compensation & Decommissioning Facilitation Corporation is a Japanese government agency with a major stake in Tepco. They say that work on decommissioning Fukushima should concentrate of the creation of technology and procedures for removing the corium through the side of the reactors. A decision on what approach to take will be made in September of this year according to an Industry Minister.