The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

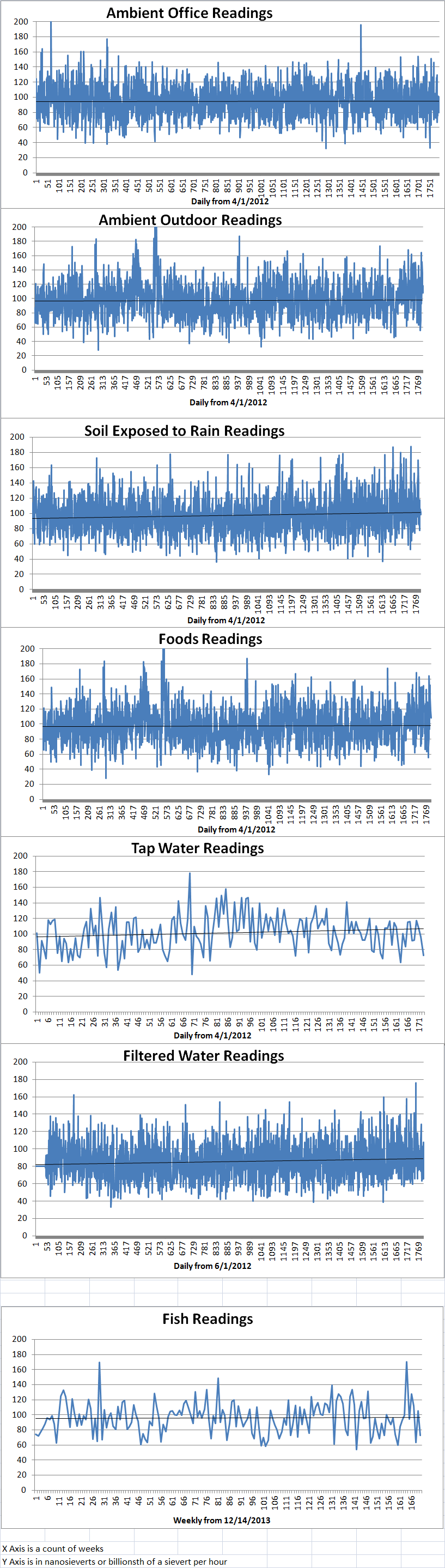

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

The newly elected French president Emmanuel Macron is busy assembling his cabinet these days, but it looks like he made a misstep in his choice for the country’s new energy minister. The-american-interest.com

Jeremy Corbyn refused to promise Labour would keep all four Trident submarines on Saturday as the party’s nuclear stance descended into chaos. Telegraph.co.uk

I have been blogging lately about the railroad tunnel cave in at the Hanford Nuclear Reservation. The ceiling of an old railroad tunnel containing highly radioactive railway cars and contaminated waste spontaneously collapsed. The U.S. Department of Energy had been warned for decades that the intense radiation was weakening the structure of the tunnel and that a cave in was inevitable.

It turns out that Hanford is not the only national nuclear waste site that is having problems with underground nuclear waste storage. It has just been reported that there has been a cave in at the Idaho National Laboratory (INL) during excavation of nuclear waste.

The accident occurred in the nuclear landfill called the Subsurface Disposal Area (SDA) at the INL. The site contains radioactive waste from nuclear research at the INL during the 1950s. During the 1950s and 1960s, the site received nuclear waste from nuclear weapons research and development at the Rocky Flats nuclear weapons plant near Denver, Colorado. Spent nuclear fuel was also sent to the SDA from commercial power reactors for decades.

Eventually the State of Idaho sued the Federal government to stop the shipments of spent nuclear fuel and to clean up the SDA. The Federal government is bound by a legal agreement signed in 1995 to remove all transuranic waste from the INL. Transuranic wastes include plutonium, americium and other highly radioactive elements that lie above uranium in the periodic table and are man-made.

An excavator was digging inside a large building at the ninety seven acre SDA when the side of the pit collapsed. The entire two acre excavation site is enclosed in a soft-sided building designed to prevent any escape of any radioactive materials. At the time of the collapse, the depth of the excavated pit was about twenty one feet.

The operator of the excavator stayed inside his sealed cabin for an hour and a half while his crew made sure that it would be safe for him to climb out of the pit. The excavator cab has its own air supply and the rest of the crew working at the site have respirators to protect them from airborne radioactive particles.

Ed Simpson is with Fluor Idaho, the contractor hired to clean up the Subsurface Disposal Area. He reported that there was no radiation released into the environment and that no one was injured in the accident. He said “Our crews had been exhuming waste for about 30 minutes when a portion of the pit wall where the excavator was operating sloughed off and the excavator slid into the pit. We’re working on a path to remove the excavator from the edge of the pit and basically make some additional enhancements to protect the operators and the excavators from this point forward.”

Flour Idaho procedures call for excavators to never be closer to the side of the pit they are working on than two feet. The excavator that slid into the excavation was more than four feet from the edge of the pit before it collapsed so correct procedures were being followed. Fluor Idaho is studying the cause of the accident and may revise their procedures to stay further from the edge of a pit being excavated.

One of the biggest problems with nuclear power is how to dispose of the spent nuclear fuel produced by nuclear power reactors. One solution is to reprocess the fuel to recover uranium and plutonium which can be used to make more nuclear fuel but can also be used to make nuclear weapons. Nuclear fuel reprocessing is complex and dangerous. Another solution is to store it in a deep geological repository which is a good solution except that there are only a few national repositories and this solution is not available for most of spent nuclear fuel.

A temporary solution is to store the spent nuclear fuel in dry cask currently made of steel and concrete. This is a solution that has been adopted by some nuclear plant operators. The canisters can either be stored on the same site as the reactors or they can be transported to an interim storage facility. It is hoped that such canisters can last at least a hundred years by which time it is hoped that a better alternative for disposal will have been found and implemented.

Holtec International is an equipment supplier for the nuclear power industry. They manufacture dry casks. They have plants in Pittsburgh, Pennsylvania, Orrville, Ohio and Camden New Jersey. In January of this year, Holtec announced a new fuel basket for fast track decommissioning. Fuel baskets hold the spent fuel assemblies in the dry casks.

The new baskets are made of Metamic HT which is an aluminium boron carbide metal matrix composite. The baskets are welded with a technique called friction-stir welding. This type of welding is superior to conventional welding and does not have the distortion typical of a regular weld. The new baskets have over ten times the thermal conductivity of conventional stainless steel fuel baskets. This means that instead of waiting seven years for spent fuel to cool enough to be transported, the fuel will typically be cool enough in two and one half years. Holtec estimates that a closed nuclear power plant site could be restored to its original condition in about five and a half years.

Ukraine currently has fifteen nuclear power reactors which provide about half of its electricity. They pay Russia about two hundred million dollars a year to remove, transport and reprocess their spent nuclear fuel.

In 2004, Energoatom, the Ukrainian nuclear power agency, contracted with Holtec to build a Central Spent Fuel Storage Facility (CSFSF). The project was repeatedly stalled due to the political instability in Ukraine but work resumed in 2014 after things calmed down. In 2015, it was announced that the technology necessary to construct the dry casks would eventually be transferred to Ukraine’s Turboatom under a memorandum of understanding between the two companies and Energoatom. The contract was amended in 2016 to have the CSFSF built at the site of the Chernobyl nuclear power plant. Initial plans call for the CSFSF to store spent nuclear fuel from three Ukrainian nuclear power plants: Khmelnitsky, Rovno and South Ukraine. Ultimately, Holtec will deliver ninety four dry cask storage systems to Ukraine by 2020.

In early May of this year, Energoatom officials took a tour of Holtec’s Orrville plant. The President of Energoatom said “We’re very pleased with what we saw. The quality of the individual items of equipment that have already been manufactured by the American specialists for our order convincingly demonstrates that Ukraine will receive one of the most modern and safest storage facilities for used nuclear fuel in the world.”