Blog

-

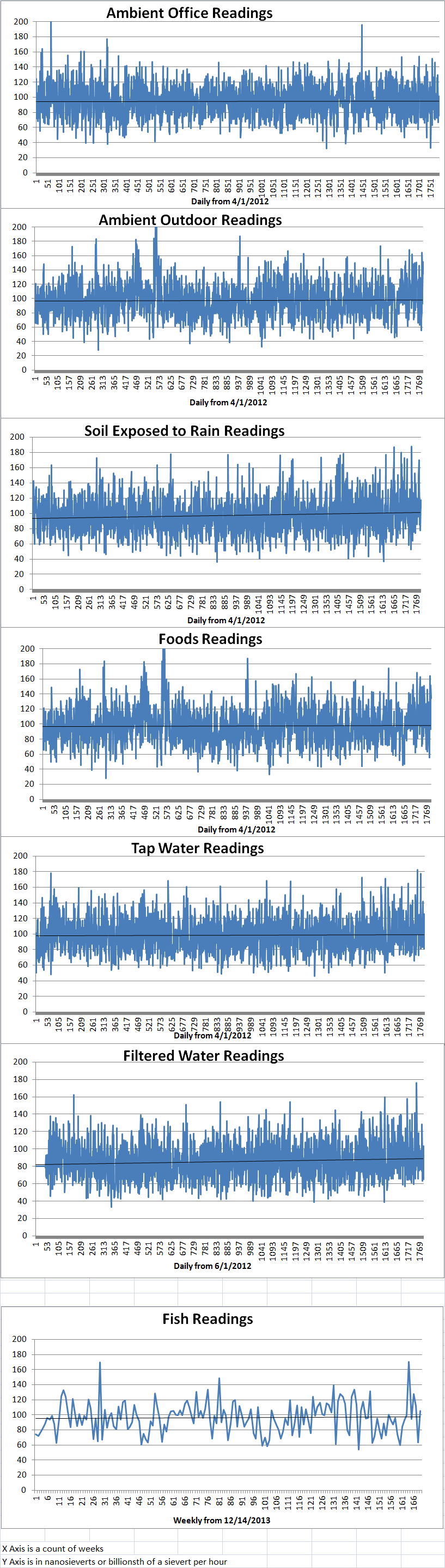

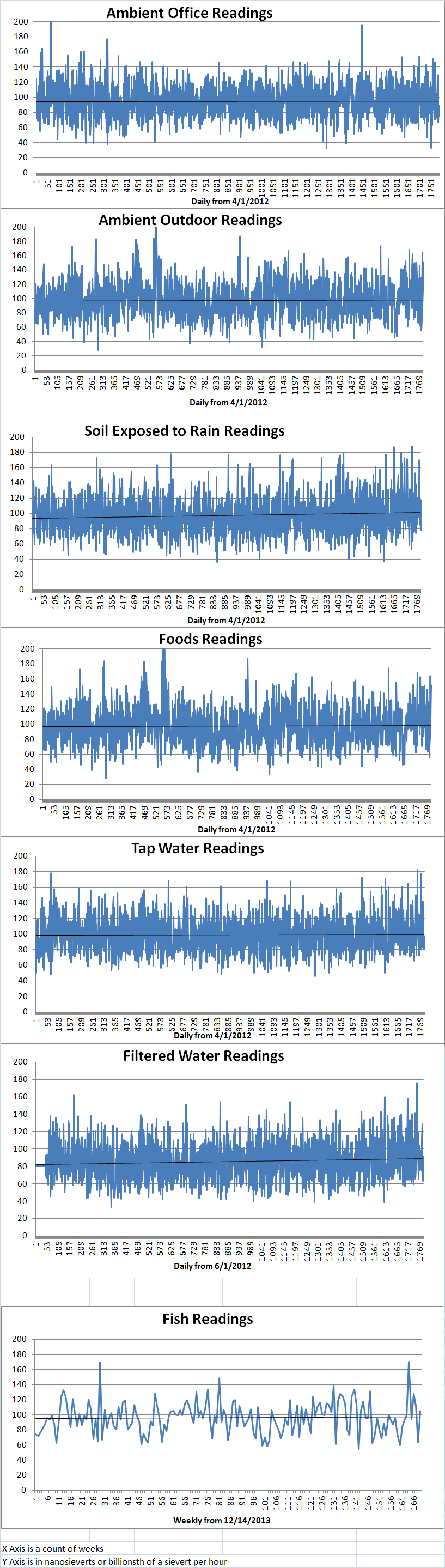

Geiger Readings for May 20, 2017

Ambient office = 84 nanosieverts per hourAmbient outside = 105 nanosieverts per hourSoil exposed to rain water = 106 nanosieverts per hourYellow bell pepper from Central Market = 119 nanosieverts per hourTap water = 105 nanosieverts per hourFilter water = 94 nanosieverts per hourPetrale sole – Caught in USA = 73 nanosieverts per hour -

Radioactive Waste 231 – Cave In At Excavation At The Idaho National Laboratory

I have been blogging lately about the railroad tunnel cave in at the Hanford Nuclear Reservation. The ceiling of an old railroad tunnel containing highly radioactive railway cars and contaminated waste spontaneously collapsed. The U.S. Department of Energy had been warned for decades that the intense radiation was weakening the structure of the tunnel and that a cave in was inevitable.

It turns out that Hanford is not the only national nuclear waste site that is having problems with underground nuclear waste storage. It has just been reported that there has been a cave in at the Idaho National Laboratory (INL) during excavation of nuclear waste.

The accident occurred in the nuclear landfill called the Subsurface Disposal Area (SDA) at the INL. The site contains radioactive waste from nuclear research at the INL during the 1950s. During the 1950s and 1960s, the site received nuclear waste from nuclear weapons research and development at the Rocky Flats nuclear weapons plant near Denver, Colorado. Spent nuclear fuel was also sent to the SDA from commercial power reactors for decades.

Eventually the State of Idaho sued the Federal government to stop the shipments of spent nuclear fuel and to clean up the SDA. The Federal government is bound by a legal agreement signed in 1995 to remove all transuranic waste from the INL. Transuranic wastes include plutonium, americium and other highly radioactive elements that lie above uranium in the periodic table and are man-made.

An excavator was digging inside a large building at the ninety seven acre SDA when the side of the pit collapsed. The entire two acre excavation site is enclosed in a soft-sided building designed to prevent any escape of any radioactive materials. At the time of the collapse, the depth of the excavated pit was about twenty one feet.

The operator of the excavator stayed inside his sealed cabin for an hour and a half while his crew made sure that it would be safe for him to climb out of the pit. The excavator cab has its own air supply and the rest of the crew working at the site have respirators to protect them from airborne radioactive particles.

Ed Simpson is with Fluor Idaho, the contractor hired to clean up the Subsurface Disposal Area. He reported that there was no radiation released into the environment and that no one was injured in the accident. He said “Our crews had been exhuming waste for about 30 minutes when a portion of the pit wall where the excavator was operating sloughed off and the excavator slid into the pit. We’re working on a path to remove the excavator from the edge of the pit and basically make some additional enhancements to protect the operators and the excavators from this point forward.”

Flour Idaho procedures call for excavators to never be closer to the side of the pit they are working on than two feet. The excavator that slid into the excavation was more than four feet from the edge of the pit before it collapsed so correct procedures were being followed. Fluor Idaho is studying the cause of the accident and may revise their procedures to stay further from the edge of a pit being excavated.

-

Geiger Readings for May 19, 2017

Ambient office = 80 nanosieverts per hourAmbient outside = 95 nanosieverts per hourSoil exposed to rain water = 103 nanosieverts per hourCrimini mushroom from Central Market = 119 nanosieverts per hourTap water = 96 nanosieverts per hourFilter water = 79 nanosieverts per hour -

Radioactive Waste 230 – Holtec International Building Dry Cask Storage Facility For Ukaine

One of the biggest problems with nuclear power is how to dispose of the spent nuclear fuel produced by nuclear power reactors. One solution is to reprocess the fuel to recover uranium and plutonium which can be used to make more nuclear fuel but can also be used to make nuclear weapons. Nuclear fuel reprocessing is complex and dangerous. Another solution is to store it in a deep geological repository which is a good solution except that there are only a few national repositories and this solution is not available for most of spent nuclear fuel.

A temporary solution is to store the spent nuclear fuel in dry cask currently made of steel and concrete. This is a solution that has been adopted by some nuclear plant operators. The canisters can either be stored on the same site as the reactors or they can be transported to an interim storage facility. It is hoped that such canisters can last at least a hundred years by which time it is hoped that a better alternative for disposal will have been found and implemented.

Holtec International is an equipment supplier for the nuclear power industry. They manufacture dry casks. They have plants in Pittsburgh, Pennsylvania, Orrville, Ohio and Camden New Jersey. In January of this year, Holtec announced a new fuel basket for fast track decommissioning. Fuel baskets hold the spent fuel assemblies in the dry casks.

The new baskets are made of Metamic HT which is an aluminium boron carbide metal matrix composite. The baskets are welded with a technique called friction-stir welding. This type of welding is superior to conventional welding and does not have the distortion typical of a regular weld. The new baskets have over ten times the thermal conductivity of conventional stainless steel fuel baskets. This means that instead of waiting seven years for spent fuel to cool enough to be transported, the fuel will typically be cool enough in two and one half years. Holtec estimates that a closed nuclear power plant site could be restored to its original condition in about five and a half years.

Ukraine currently has fifteen nuclear power reactors which provide about half of its electricity. They pay Russia about two hundred million dollars a year to remove, transport and reprocess their spent nuclear fuel.

In 2004, Energoatom, the Ukrainian nuclear power agency, contracted with Holtec to build a Central Spent Fuel Storage Facility (CSFSF). The project was repeatedly stalled due to the political instability in Ukraine but work resumed in 2014 after things calmed down. In 2015, it was announced that the technology necessary to construct the dry casks would eventually be transferred to Ukraine’s Turboatom under a memorandum of understanding between the two companies and Energoatom. The contract was amended in 2016 to have the CSFSF built at the site of the Chernobyl nuclear power plant. Initial plans call for the CSFSF to store spent nuclear fuel from three Ukrainian nuclear power plants: Khmelnitsky, Rovno and South Ukraine. Ultimately, Holtec will deliver ninety four dry cask storage systems to Ukraine by 2020.

In early May of this year, Energoatom officials took a tour of Holtec’s Orrville plant. The President of Energoatom said “We’re very pleased with what we saw. The quality of the individual items of equipment that have already been manufactured by the American specialists for our order convincingly demonstrates that Ukraine will receive one of the most modern and safest storage facilities for used nuclear fuel in the world.”

-

Geiger Readings for May 18, 2017

Ambient office = 102 nanosieverts per hourAmbient outside = 111 nanosieverts per hourSoil exposed to rain water = 106 nanosieverts per hourBartlett pear from Central Market = 135 nanosieverts per hourTap water = 126 nanosieverts per hourFilter water = 103 nanosieverts per hour -

Nuclear Reactors 281 – Financial Problems At Toshiba And Westinghouse Cast Doubt On U.K Moorside Nuclear Power Plant Plant

The Moorside Nuclear Power Station is a proposed power station to be build near Sellafield on the northwest coast of the Cumbrian state of the United Kingdom. Three AP1000 nuclear power reactors are planned to be built by NuGeneration (NuGen), the British subsidiary of Westinghouse Electric Company which is, in turn, a subsidiary of Toshiba, the Japanese company. The plan was to acquire the necessary permits and licenses by 2018 followed by site preparation by 2020. The plant was supposed to come online in 2024.

NuGen is a joint venture between Japan’s Toshiba and France’s Engie with Toshiba holding sixty percent and Engie holding forty percent. These two companies have a great deal of experience in the construction of nuclear power plants and they chose the AP1000 reactor design from Westinghouse Electric Company.

Last October, the U.K. National Grid announced plans to spend three billion four hundred million dollars to connect the planned plant in Cumbria to the nation’s electrical network. The announcement was followed by ten weeks of consultation with stakeholders.

On February 14th of this year, Toshiba said that it was withdrawing from nuclear power reactor projects outside of Japan due to serious financial problems but NuGen said on the same day Toshiba remained dedicated to the Moorside project. NuGen said that it had always planned to use an independent contractor to build the Moorside reactors.

On March 30th of this year, the AP1000 reactor design successfully completed the Generic Design Assessment process in the U.K. Unfortunately for the project, Westinghouse filed for Chapter 11 bankruptcy protection on March 29th. Toshiba has announced that it may report an operating loss of eight billion four hundred million dollars for 2016-1017 financial year which ends on March 31st.

On April 4th of this year, Engie said that it was going to exercise it right under contract to require that Toshiba purchase all of the forty percent of the shares that Engie held in NuGen.

Today NuGeneration (NuGen) has stated that it will conduct a strategic review of the project. In response, representatives for the National Grid said “NuGen has announced it is conducting a strategic review to look at its ownership and technology vendor. NuGen is confident this review will lead to an outcome that provides a more robust, stable and sustainable platform to meet its commitment to deliver the next generation of nuclear power. As a result of focusing their efforts on this review, NuGen are pausing work on their development consent order for Moorside. In light of this, we have decided to pause our work to consent NuGen’s connection and take the time to understand NuGen’s program to make sure our projects are aligned. It is important that we make sure the consents run broadly in parallel, so the Planning Inspectorate can examine the consent application for our connection knowing there is a strong need for it.”

“Despite this pause, we are confident the connection will still be ready when NuGen requires it and are continuing to work closely with them. We would like to thank people and stakeholders once again for all their efforts in responding to our previous consultation. We will let you know more about how we are developing our connection as soon as we are able.”

The National Grid proposal for connecting the Moorside plant to the nation’s electrical grid took into account the Lake District National Park. The plan called for putting lines underground and taking down pylons in the Park. The plan also included putting lines in a tunnel under Morecambe Bay. They also proposed taking down existing pylons and replacing them with fewer, taller pylons. The suspended plan called for submitting an application to the appropriate federal agency with construction starting in 2019 if the application was approved. The connection to the National Grid was supposed to take place in 2024.

Now that Toshiba and Westinghouse financial problems have called the whole power plant project into question, NuGen is going to review various options for moving forward with the project. They admit that it is critical that any new plans also be acceptable to all the stakeholders involved in the project.

-

Geiger Readings for May 17, 2017

Ambient office = 76 nanosieverts per hourAmbient outside = 130 nanosieverts per hourSoil exposed to rain water = 118 nanosieverts per hourAvocado from Central Market = 152 nanosieverts per hourTap water = 81 nanosieverts per hourFilter water = 65 nanosieverts per hour