Blog

-

Geiger Readings for Feb 21, 2016

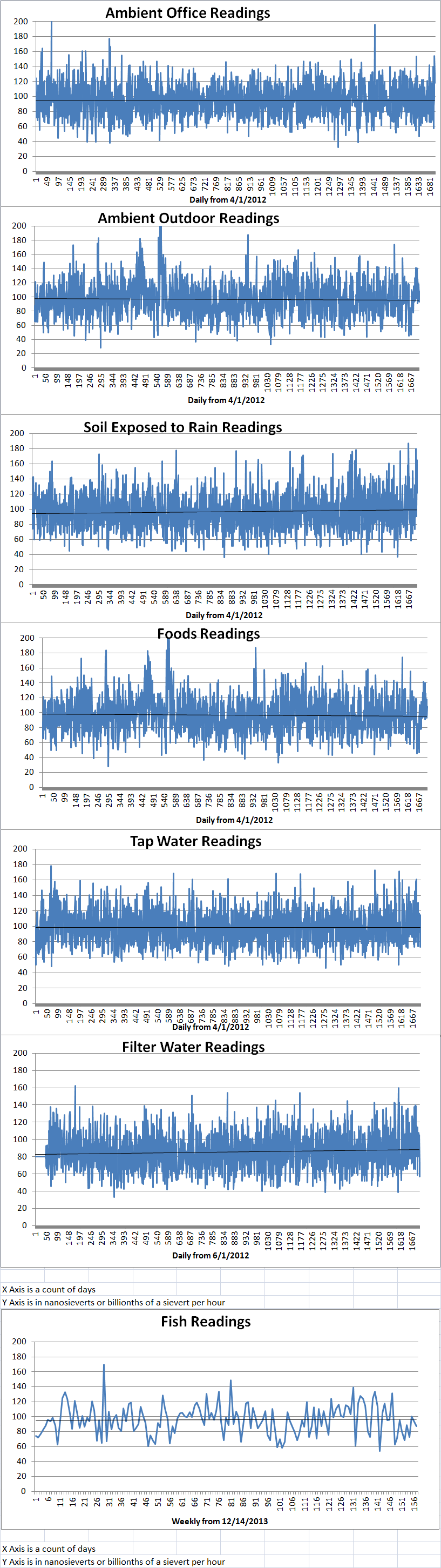

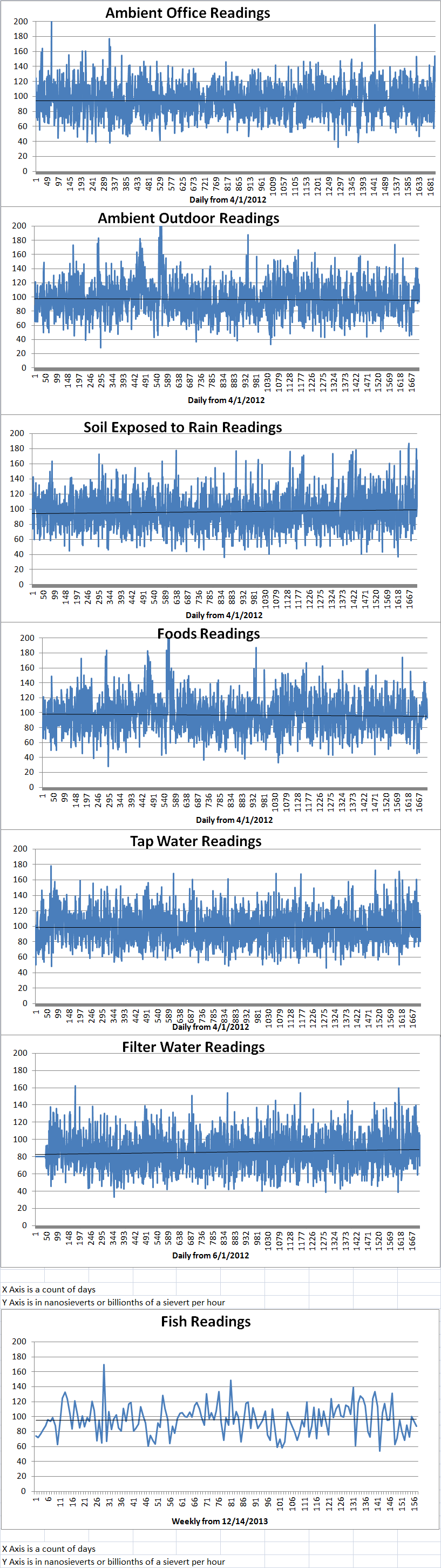

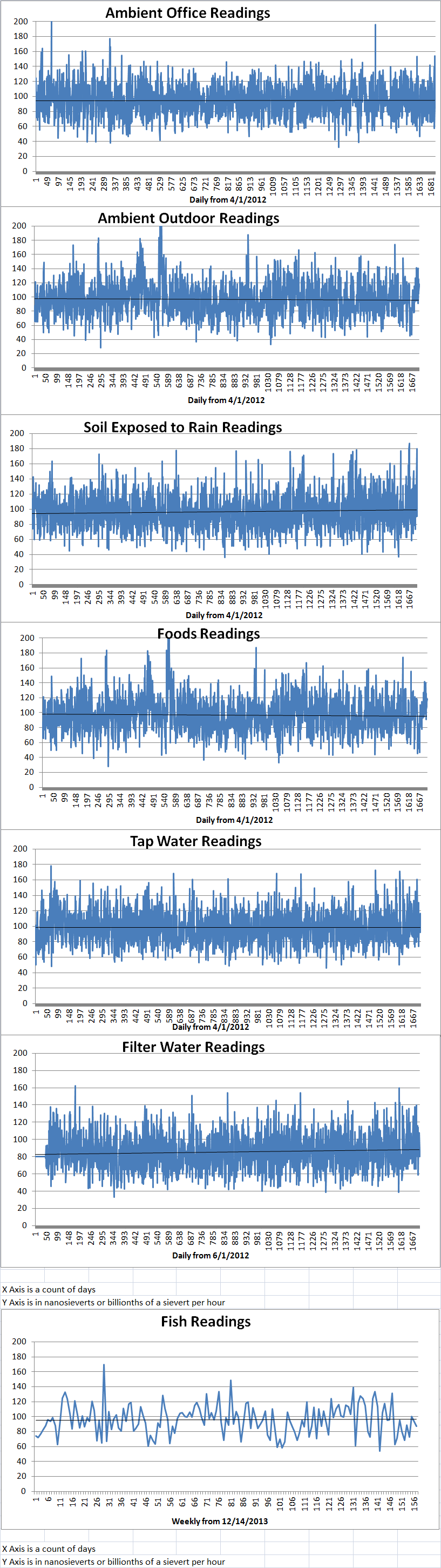

Ambient office = 118 nanosieverts per hourAmbient outside = 118 nanosieverts per hourSoil exposed to rain water = 121 nanosieverts per hourAvocado from Central Market = 108 nanosieverts per hourTap water = 73 nanosieverts per hourFilter water = 57 nanosieverts per hour -

Nuclear Reactors 260 – New Process For Extracting Uranium From Seawater

Although currently uranium is mined from a variety of ore deposits worldwide, it is also possible to extract uranium from seawater. It is estimated that there are over four and a half billion tons of uranium in the water of the world’s oceans. If it could be economically extracted, it could supply fifteen terawatts generated by conventional reactors for over five thousand years. Unfortunately, current extraction methods are impractical due to cost. In addition, as uranium is extracted, the concentration drops in the remaining seawater so the cost would rise steadily. Even with an efficient and cheap extraction method, it has been estimated that after about thirty years of extraction, it would again become too expensive to be practical.

Nuclear power has been promoted as a low-carbon energy source that can provide a bridge from current dependency on fossil fuels to an entirely renewable and sustainable energy economy. Although uranium binds with many other elements in a variety of compounds and uranium ore is found in many places, there are still many countries which have no uranium sources that can be mined and extracted economically.

A Japanese team working on uranium extraction estimated in 2012 that the available technology should be able to produce uranium for about one hundred and thirty dollars a pound. That is about six times of the current price of uranium. If a cheaper way to extract uranium could be developed, even countries without any native uranium sources could be assured that they would be able to obtain their own uranium to fuel nuclear power reactors without being dependent on any other country.

An article about improved uranium production from sea water has just been published in the journal Natural Energy by a group of researchers at Stanford University which includes the previous Energy Secretary of the Unites States, Steven Chu.

Uranium dissolved in seawater combines with oxygen to form uranyl ions which have a positive charge. Current extraction methods employ plastic fibers impregnated with a chemical called amidoxime. Uranyl ions attach themselves to the amidoxime in the fibers when they are dipped into seawater. When the fibers become saturated with uranyl ions, they are chemically treated to release the uranyl.

The efficiency and utility of this process depend on three variables. The first variable involves how rapidly the ions can be captured by the fibers. The second variable involves how much of the dissolved uranyl sticks to the fibers. And the third variable involves how many times a particular fiber can be reused.

The Stanford team were able to create a combination carbon and amidoxime fiber which is activated with an electrical pulse. The new fibers can capture nine times more uranyl ions before becoming saturated than previous fibers. During a recent test, the new fibers were able to capture three times as many uranyl ions in solution when compared to current fibers. And, finally, they were able to be reused three times as much as existing fibers.

If an efficiency factor is created from the three variables, then you could say that the efficiency of the new process is nine X three X three or about eighty-one times as efficient as the previous process. If the cost of the production, electrification and extraction method for the new process is not more than eighty-one times the cost of the old process, then the new process should be able to produce uranium at around the current market price.

-

Geiger Readings for Feb 20, 2016

Ambient office = 120 nanosieverts per hourAmbient outside = 146 nanosieverts per hourSoil exposed to rain water = 165 nanosieverts per hourBartlett Pear from Central Market = 93 nanosieverts per hourTap water = 80 nanosieverts per hourFilter water = 70 nanosieverts per hour -

Geiger Readings for Feb 19, 2016

Ambient office = 129 nanosieverts per hourAmbient outside = 95 nanosieverts per hourSoil exposed to rain water = 105 nanosieverts per hourMango from Central Market = 118 nanosieverts per hourTap water = 114 nanosieverts per hourFilter water = 105 nanosieverts per hour -

Nuclear News Roundup Feb 18, 2016

On August 1, 2016, the New York Public Service Commission (“PSC”) adopted a sweeping energy bill, the Clean Energy Standard Order, with the goals of combating climate change and ensuring a diverse and reliable low-carbon energy supply. One provision implements a nuclear-specific zero-emissions credits (“ZEC”) program that is intended to prevent the premature retirement of three of New York’s nuclear power plants. Nuclear power plants generate zero carbon emissions. mondaq.com

Australia will boycott global negotiations on a treaty to ban nuclear weapons at the United Nations next month. theguardian.com

-

Geiger Readings for Feb 18, 2016

Ambient office = 154 nanosieverts per hourAmbient outside = 83 nanosieverts per hourSoil exposed to rain water = 91 nanosieverts per hourIceberg lettuce from Central Market = 119 nanosieverts per hourTap water = 92 nanosieverts per hourFilter water = 80 nanosieverts per hourPacific Cod – Caught in USA = 87 nanosieverts per hour -

Nuclear Reactors 259 – New System For Automatically Finding Cracks In Nuclear Reactor Components

As nuclear power plants age, they are subjected to “cracking, fatigue, embrittlement of metal components, wear, erosion, corrosion and oxidation.” Embrittlement is a is the formation of cracks in the steel components over time as they are bombarded by neutrons. This creates tiny holes inside the crystal matrix of the steel. These tiny holes combine to form bigger and bigger holes that eventually become visible cracks. It is a major problem at nuclear power plants. As more and more cracks develop from damage to the crystal matrix, the steel becomes increasingly brittle and the danger of leak developing or a component actually breaking increases. Cracks in the steel containment vessel that encloses the core could lead to a breach of containment and a serious release of radioactive materials.

Regular inspections of steel components are necessary but such inspections are subjective, boring, and time consuming. In addition, many of the components are submerged in water and are too dangerous for human inspection because they are radioactive. Robots with video cameras can be sent to do the inspections but the underwater conditions make visual inspection of the video images by human operators difficult. Recent analysis of the accuracy of direct human inspection and human inspection of videos recorded by robots are not sufficient to satisfy modern safety requirements.

Automated systems are being developed to carry out these inspections but they have had problems because cracks are often small, have low visual contrast, and are similar in appearance to welds, scratches and grind marks. The Lyles School of Civil Engineering at Purdue University has recently created an advanced automated inspection system for cracks in nuclear components. Their new system is superior to previous systems in the identification of such cracks. The new system is called CRAQ which stands for “crack recognition and quantification”. They used machine learning to develop an advanced algorithm that uses the changing visual texture around cracks to identify them.

Previous automatic inspection systems were only able to process single images. The new CRAQ system can process multiple video frames for better results. They are using Bayesian data fusion that combines data from multiple video frames to enhance crack detection. The Bayesian approach allows the system to excel at determining whether a particular visual feature is actually a crack or some other type of marking such as a weld or scratch. The system outlines detected visual features with a box on the screen so a human operator can easily find them. The color of the box is a measure of the confidence of the algorithm with a red box indicating the highest confidence for the presence of a crack.

Future work will involve developing a completely automated system that utilizes computational software and advanced simulations. The second version of the software will utilize Constitutional Neural Networks and “deep learning” to improve performance. This type of artificial intelligence has been found to be particularly good at developing sophisticated visual recognition systems.

-

Nuclear News Roundup Feb 17, 2016

Energy Fuels Inc., said Friday that the U.S. Environmental Protection Agency (EPA) had issued the company an aquifer exemption for the Jane Dough wellfield in the Nichols Ranch ISR Project , a necessary regulatory step for the company to sustain long term production at the in situ recovery facility in northeast central Wyoming. nuclearstreet.com

Toshiba’s dramatic exit from the business of building nuclear power plants lands another blow to a beleaguered sector, undermining new development and research on advanced reactor designs. technologyreview.com