France’s Framatome and Germany’s Technical University of Munich (TUM) have agreed to create an industrialization process for the manufacture of monolithic molybdenum-uranium (U-Mo) fuel for the TUM’s FRM II research reactor. Framatome said that this low-enriched fuel will benefit from the highest uranium fuel density ever loaded into a European research reactor.

The twenty thermal megawatt FRM II research reactor has been operating since 2005. It is one of the most effective sources of high-flux neutrons in the world. The reactor is not used to generate electricity. It is used to provide a neutron source for industrial and scientific use. The neutrons it generates are also used to produce medical radioisotopes and for the doping of high-purity silicon for the semiconductor industry. The reactor has a facility for teletherapy of malignant tumors using fast neutrons.

The FRM II currently uses fuel enriched to over ninety five precent uranium-235 to generate its dense neutron flux. Such high-enriched uranium (HEU) is considered to be a nuclear proliferation risk. TUM has agreed with the German government and the Bavarian State, who finance the reactor, to work towards converting it to fuel with lower enrichment when a suitable fuel is becomes available. This is also a condition of the reactor’s operating license, which was issued in 2003.

Monolithic U-Mo is the only fuel which can allow the reactor to perform as intended while using a low enrichment of less than twenty percent uranium-235, according to TUM. This is possible because of the high uranium density in the fuel, Framatome said.

In 2019, TUM contracted Framatome to develop the U-Mo foils manufacturing technique to utilize the existing technology of embedded foils in a cladding of aluminum. The first U-Mo foils were successfully manufactured in 2022 at Framatome’s Compagnie pour l’Étude et la Réalisation de Combustibles Atomiques (CERCA) Research and Innovation Laboratory (CRIL) at Romans-sur-Isère in France. Inaugurated in 2019, CRIL is dedicated to developing uranium-based fuel for international research in physics and nuclear medicine.

CRIL, in cooperation with TUM, developed the key steps of the manufacturing process for a high-quality U-Mo fuel. This has included the manufacture of small-scale prototypes, the establishment of a qualification procedure, and the installation of a pilot line in its research facility in Romans. Irradiation of the first monolithic U-Mo fuel plate prototype is scheduled for late 2024.

François Gauché is Vice-President of CERCA. He said, “We have been working on this project since 2019 and we are proud to celebrate this important milestone with our client. Our teams rose to the challenge of developing a high-tech fuel to meet the needs of research reactors and ensure their sustainability. We are now ready to take this to the next level and manufacture this innovative fuel.”

Christian Pfleiderer is the scientific director of the FRM II. He said, “FRM II and Framatome have been working since 2019 to set up a European production line for monolithic U-Mo fuel The hard work of our teams has paid off. This new fuel is the guarantee for a reliable and sustainable supply of neutrons for research and innovation.”

Blog

-

Nuclear Reactors 1379 – Framatone Working On New Fuel For University of Munich Research Reactor.

-

Nuclear News Roundup April 27, 2024

Facility To Advance New-era Nuclear Research miragenews.com

Federal Environment Minister: Nuclear power too expensive, too protracted and too risky marketscreener.com

Russia says it’s deploying tactical nukes in drills as Ukraine cries ‘blackmail’ usatoday.com

Belarus launches nuclear drills a day after Russia announces them, with Ukraine in mind washingtontimes.com

-

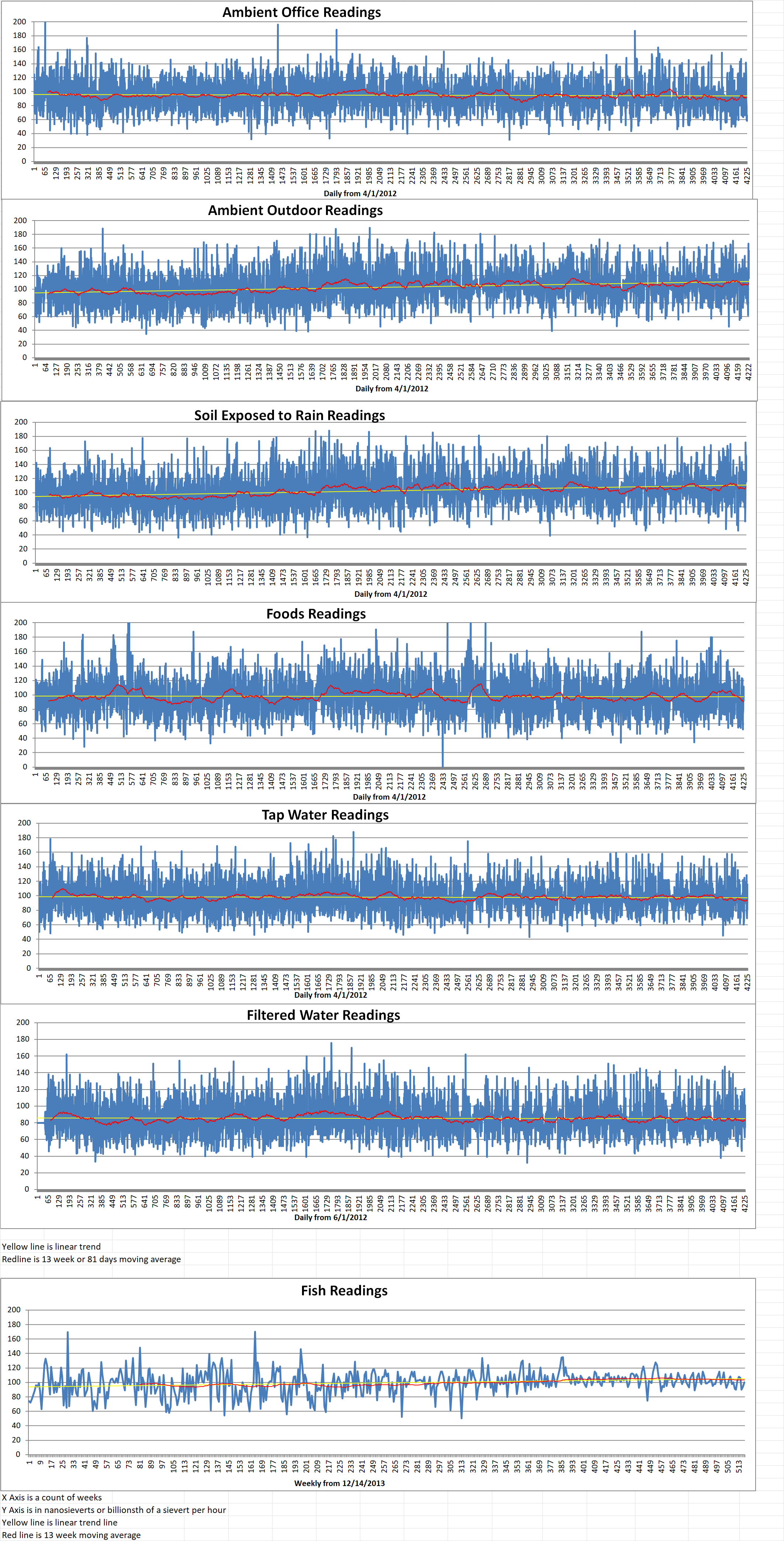

Geiger Readings for April 27, 2024

Ambient office = 61 nanosieverts per hour

Ambient outside = 126 nanosieverts per hour

Soil exposed to rain water = 126 nanosieverts per hour

Roma tomato from Central Market = 102 nanosieverts per hour

Tap water = 81 nanosieverts per hour

Filter water = 75 nanosieverts per hour

Dover Sole from Central = 100 nanosieverts per hour

-

Nuclear Reactors 1378 – Holtec and Energoatom Collaborating on Small Modular Reactors Manufacturing In Ukraine.

Energoatom and Holtec just signed an agreement to collaborate on SMR manufacturing facilities.

The collaboration agreement provides for the creation in Ukraine of manufacturing capabilities for components for small modular reactors (SMRs), plus storage and transportation systems for spent nuclear fuel.

The collaboration agreement is intended to speed up the deployment of Holtec’s SMRs in Ukraine “and to support unimpeded reactor operations through a successfully deployed used fuel storage facility”.

Herman Halushchenko is the Energy Minister of Ukraine. He said, “It is very important that we sign this document at such a turbulent time, demonstrating to the enemy our stability and determination to deepen the Ukrainian-American partnership and develop the future of Ukrainian energy using leading technologies.”

Petro Kotin is the Acting Chairman for Energoatom. He said, “This agreement is important not only for Energoatom, but also for the entire energy industry of Ukraine and the national economy. The creation of nuclear energy production facilities in the country will contribute not only to the strengthening of the country’s energy security … this Master Agreement will lead to a modern manufacturing and training facility which will spur economic development, create well-paying jobs, and pave the way for Ukraine’s emergence as the regional hub for Holtec’s SMR-300 and used fuel technology.”

Shawn Anderson is the U.S. Embassy’s Department of Energy Office Director and Energy Attaché for Ukraine. He said, “The signing of the Master Agreement marks a significant milestone as it paves the way for the establishment of a cutting-edge manufacturing facility aimed at localizing the production of equipment for Holtec SMRs, spent nuclear fuel storage and transport systems, and other nuclear energy-related necessities in Ukraine. This collaborative effort between Energoatom and Holtec International is not only a critical step but also an inspiring one that promises to enhance Ukraine’s national and energy security, thus bolstering its economy.”

Holtec has been working on the development of its SMR line since 2011 and the company has long established links with Ukraine. In April 2023, an agreement between Energoatom and Holtec sought to pave the way for up to twenty of its SMR-160 units to be deployed in the country. Holtec says its SMR has undergone several design evolutions. The most recent change is the incorporation of forced flow capability overlayed on gravity-driven flow in the plant’s primary system for the SMR-300, which is a pressurized water reactor producing around three hundred megawatts of electrical power or one thousand and fifty megawatts of thermal power for process applications, and which Holtec says, remains “walk-away safe”.

Holtec and Energoatom announced in November that they were planning to construct a plant in Ukraine for the production of containers for radioactive materials. These containers are currently made in the USA for storage of spent nuclear fuel. This followed on from the commissioning in 2022 of the Holtec International-built Centralized Spent Fuel Storage Facility (CSFCS) in the Chernobyl Exclusion Zone, contracts for which were signed for its construction in 2005. The CSFCS is a dry storage site for spent nuclear fuel assemblies. -

Nuclear News Roundup April 26, 2024

Trawsfynydd ruled out of new nuclear power plan yahoo.com

US remains committed to diplomacy despite North Korea’s nuclear escalation voanews.com

Tackling microplastics in Antarctica using nuclear tech – Chile and IAEA sign MoU world-nuclear-news.org

Former Canadian uranium mine site returned to province world-nuclear-news.org

-

Geiger Readings for April 26, 2024

Ambient office = 66 nanosieverts per hour

Ambient outside = 156 nanosieverts per hour

Soil exposed to rain water = 152 nanosieverts per hour

Pineapple from Central Market = 112 nanosieverts per hour

Tap water = 116 nanosieverts per hour

Filter water = 101 nanosieverts per hour

-

Nuclear Reactors 1377 – Roll-Royce Seeking Faster Licensing For Small Modular Reactors – Part 2 of 2 Parts

Part 2 of 2 Parts (Please read Part 1 first)

Rafael Grossi is director-general of the IAEA. “For this business model to succeed, we need regulatory approaches to adapt to a new circumstance. We cannot afford the luxury of these regulatory marathons lasting five, six, seven years.”

Many nuclear experts point to aviation as an example for the nuclear industry to follow. William Magwood is the CEO of the Nuclear Energy Association (NEA), an intergovernmental agency. “[Airlines] don’t build a different design for each market, making the quality higher and bringing costs down. If every country needs a slightly different design because of different regulatory requirements, this makes getting that efficiency very, very difficult.”

The IAEA talks, which involve regulators from 29 countries as well as developers, have included discussion on issues such as information sharing and how to implement greater collaboration. One possibility is that reactor designs would go through an initial review under a global framework, reducing the time spent in national processes.

However, consensus is elusive. “It’s been a really useful discussion which has pushed the thinking,” said Rolls-Royce’s Perry. “Unfortunately, there are a few strong voices pushing for ‘we’re doing it like the aero industry or we’re not doing it at all’. That’s not going to be quick enough for the energy transition.”

Member countries would still need time to adopt any changes that were agreed to at the IAEA level.

David Durham, president for energy systems at Westinghouse Electric, a US nuclear power company. He said, “People understand the benefits and there are a lot of people with open minds. But I don’t think anyone thinks this is going to be resolved tomorrow.”

Efforts at international reform are underway as the Nuclear Regulatory Commission (NRC) in the U.S. has taken steps to accelerate domestic SMR approvals.

TerraPower is a next-generation nuclear reactor company founded by billionaire philanthropist Bill Gates, that could become a test case. It applied for a construction permit to the regulatory commission this month for the first commercial nuclear plant that uses liquid sodium as a coolant. TerraPower says that this would provide a lower-cost alternative to water-cooled reactors.

Chris Levesque is the TerraPower CEO. “The NRC is seen as a gold standard for safety. So if we want to bring a fairly new reactor design to Asia, Europe, Africa and Indonesia, we have to prove [them] in rich countries first and we will do that with the NRC.”

Some international collaborative efforts are already under way. Last month, the U.K. joined Canadian and U.S. regulators in agreeing to work more closely together to assess SMR designs. European regulators are collaborating on a joint early review of EDF’s Nuward design.

Jane Bowie is the director of regulation at the new nuclear reactors division of the U.K.’s ONR. He said, “We consider the greatest potential for streamlining and accelerating processes to be via much greater collaboration.

European regulators are also observing the ONR’s assessment of Rolls-Royce’s design. This marks an important change in approach and the industry hopes there is more to come.

Ronan Tanguy is the program lead for safety and licensing at the WNA, which is also working on the issue. He said, “I see genuine effort across the board. There’s a recognition nuclear has to be part of the energy mix going forward. However, regulatory harmonization was absolutely essential. Without it [SMRs will] struggle to be competitive outside of very large markets.” -

Nuclear News Roundup April 25, 2024

Argentina Budget Cuts Hitting Nuclear Energy Ambitions, Atomic Body Says money.usnews.com

South Bruce signs hosting agreement with NWMO world-nuclear-news.org

France Increases State Funding for Advanced Nuclear R&D Project rigzone.com

Government plans for new nuclear: EAC welcomes ambition but seeks detail committee.parliament.uk

-

Geiger Readings for April 25, 2024

Ambient office = 58 nanosieverts per hour

Ambient outside = 116 nanosieverts per hour

Soil exposed to rain water = 116 nanosieverts per hour

Red bell pepper from Central Market = 93 nanosieverts per hour

Tap water = 97 nanosieverts per hour

Filter water = 89 nanosieverts per hour

-

Nuclear Reactors 1376 – Roll-Royce Seeking Faster Licensing For Small Modular Reactors – Part 1 of 2 Parts

Part 1 of 2 Parts

Executives at Rolls-Royce estimate that U.K. regulators will take four and a half years to assess the safety of its design for a small modular reactor (SMR). The U.K. company must endure more lengthy approval processes in other countries where it wants to build its SMRs.

Helena Perry is the Rolls-Royce’s regulatory director. She criticized the typical international approval process. She said, “It’s incredibly time-consuming.” She noted that, the company submitted its plans to the U.K. Office for Nuclear (ONR) Regulation two years ago.

Rolls-Royce is one of many developers and officials supporting a global drive to overhaul nuclear regulation amid concern the set-up is ill-suited to the nascent industry for small modular reactors (SMRs). SMRs have attracted huge interest as countries look to find new sources of low-carbon energy.

Since 2022 the International Atomic Energy Agency (IAEA) has led efforts to synchronize regulatory standards and processes. The first phase of their efforts is due to be completed this year. However, there are doubts over how much can be achieved, in view of the sensitive nature of the industry and embedded working practices.Allison Macfarlane is former chair of the US Nuclear Regulatory Commission (NRC). She said, “Countries approach regulation differently, from a different starting philosophy. You can share information and try to align, but you are never going to have the same regulatory scheme everywhere.”

The push to overhaul regulation comes as the positive publicity around nuclear technology has been tempered by concerns over long development timeframes and some early setbacks. Nu-Scale cancelled what would have been the first SMR in the US last year because they could not find enough buyers signed up for its power. In addition, construction costs had risen sharply the previous year.

Macfarlane added, “From my analysis, the thing that’s holding them up is the economics, the supply chains. There’s lots of roadblocks.”

The International Energy Agency (IEA) estimates that nuclear power capacity will have to more than double by 2050 to meet global goals of net zero carbon emissions. Over twenty countries, including the U.S. and the U.A.E., agreed at the COP28 climate conference in November to work towards tripling global nuclear capacity.

SMRs are designed to be prefabricated. This means that large parts of SMRs are designed to be built in factories rather than onsite. This makes them easier to deploy, driving costs down as several smaller models are completed. That prospect has attracted politicians and investors looking to avoid the cost overruns and lengthy development times of large-scale nuclear power plants.

About sixty to seventy SMR designs are being developed, according to nuclear energy bodies. These range from those drawing on standard nuclear technology used by large-scale plants today, to more “advanced” reactors using lead or sodium as coolants.

Yet only three SMR developers have been awarded an operating license. The licenses have been issued in China, Russia and Japan. Supporters fear that current regulation could hinder the rollout of SMRs. Design approval for nuclear reactors usually takes several years because of the complexity of reactor designs and dangers of radioactive materials.

Please read Part 2 next