X-energy and Cavendish Nuclear have been awarded four and a quarter million dollars by the U.K. government to assess how domestic manufacturing could support the construction of an advanced small pebble-bed nuclear reactor. The pair want to build twelve reactors in Hartlepool by the early 2030s to help decarbonize local industry.

The government funding comes through the Future Nuclear Enabling Fund (FNEF) which will assist companies to develop their technologies ahead of the government selecting which projects will help meet national targets for more nuclear generation.

X-energy and Cavendish Nuclear will match the government funding and use the money to review domestic manufacturing and supply chain opportunities. Kier Group, Sheffield Forgemasters, and the Nuclear Advanced Manufacturing Centre will help X-energy and Cavendish Nuclear carry out the assessment. The collaborators want U.K. firms to receive eighty percent of the value of their Xe-100 reactor projects.

Mick Gornall is the managing director of Cavendish Nuclear. He said, “A fleet of Xe-100s can complement renewables by providing constant or flexible power and produce steam to decarbonize industry and manufacture hydrogen and synthetic transport fuels.”

The Xe-100 is an eighty-megawatt high-temperature gas-cooled reactor design that is optimized to operate as a four-unit plant. This four-unit system will deliver three hundred and twenty megawatts of electricity or two hundred megawatts of heat. The reactor works like a gumball machine with new fuel pebbles the size of billiard balls being fed into the top of the reactor to refresh the older ones being ejected from the bottom of the reactor. Each pebble remains in the core for around three years. They are circulated through the reactor up to six times to achieve full burnup. Helium is cycled through the reactor to extract the heat and feed it to a steam generator.

The reactor design is currently being examined by regulators in the U.S. and Canada. The partners say they plan to engage with U.K. nuclear regulators to evaluate licensing approaches. In 2022, X-energy signed a letter of intent with Dow to install reactors at one of its U.S. Gulf Coast chemical complexes. Last year Dow selected its Seadrift manufacturing site in Texas. The installed reactors will provide power and steam to the chemicals manufacturing site. CO2 emissions should be reduced by an estimated 440,000 tons per year.

Carol Tansley is the X-energy vice-president. Speaking in December about a report exploring how novel nuclear reactors could help decarbonize heavy industry, she said, “This is a huge opportunity for Teesside and the country as a whole. There is a skilled nuclear workforce, with decades of experience of high temperature gas reactor technology, already in place at Hartlepool power station and the plant will be reaching the end of its life just as our project entered development and construction. We can provide high quality local jobs and the broadest range of decarbonization options for the area’s industrial base, and then use that experience to benefit similar regions across the U.K.”

Building on their plans for constructing reactors for Hartlepool, X-energy and Cavendish Nuclear say they want to build as many as 40 Xe-100 reactors in the U.K.

In February of this year, Westinghouse Electric said it was developing plans for four small modular nuclear reactors near Stockton-on-Tees, which is close to Hartlepool. The reactors would also provide low carbon power for the region’s chemicals industry.

Blog

-

Nuclear Reactors 1367 – X-energy and Cavendish Energy Get U.K. Funding For Hydrogen Cooled Reactors

-

Nuclear News Roundup April 09, 2024

Two days of strikes planned at nuclear power ca.news.yahoo.com

Manufacturing business plans for private nuclear reactor in Butte mtpr.org

Norwegian town initiates nuclear plant zoning work world-nuclear-news.org

Eletronuclear responds to report on Angra 3 costs world-nuclear-news.org

-

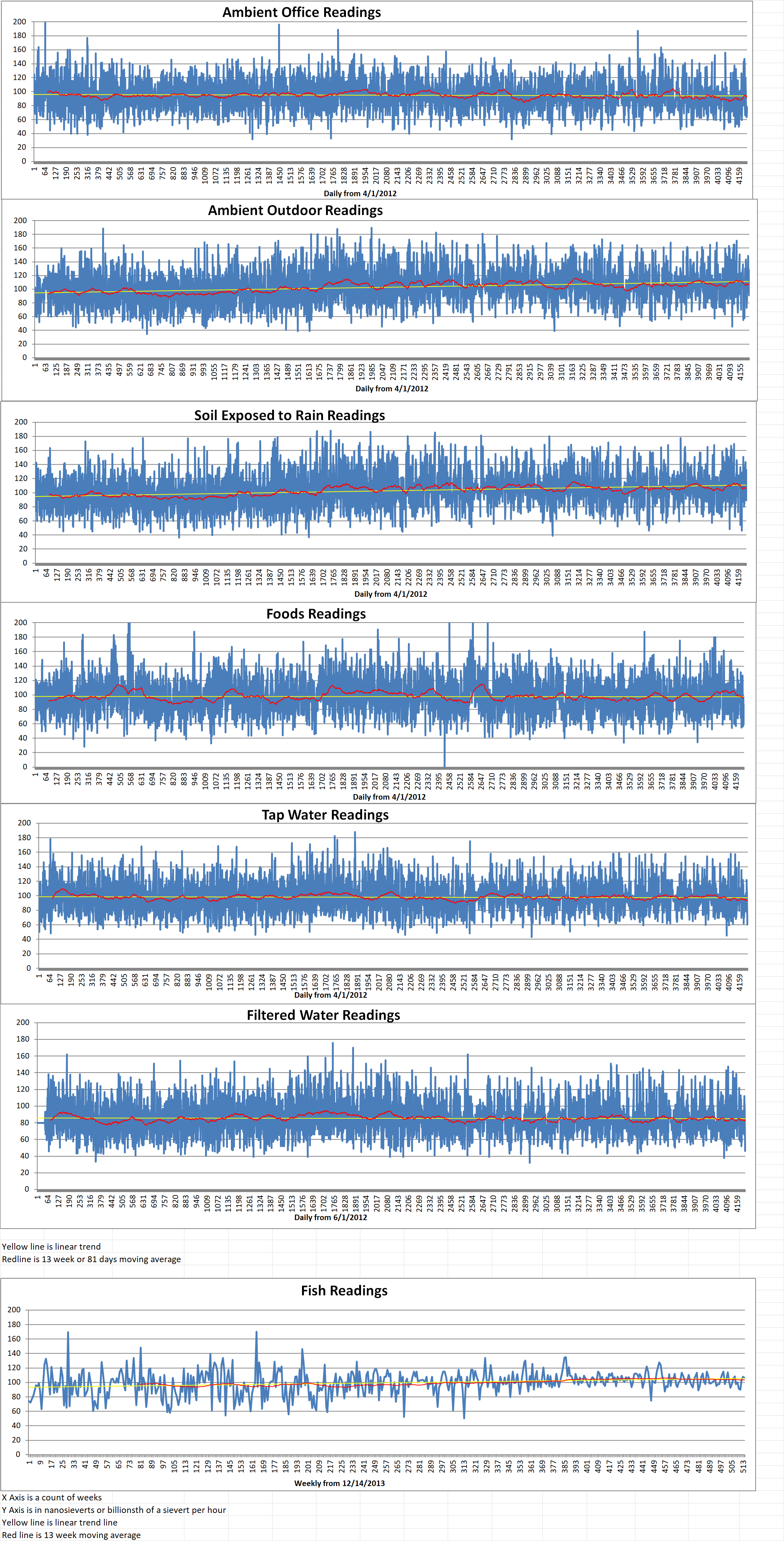

Geiger Readings for April 09, 2024

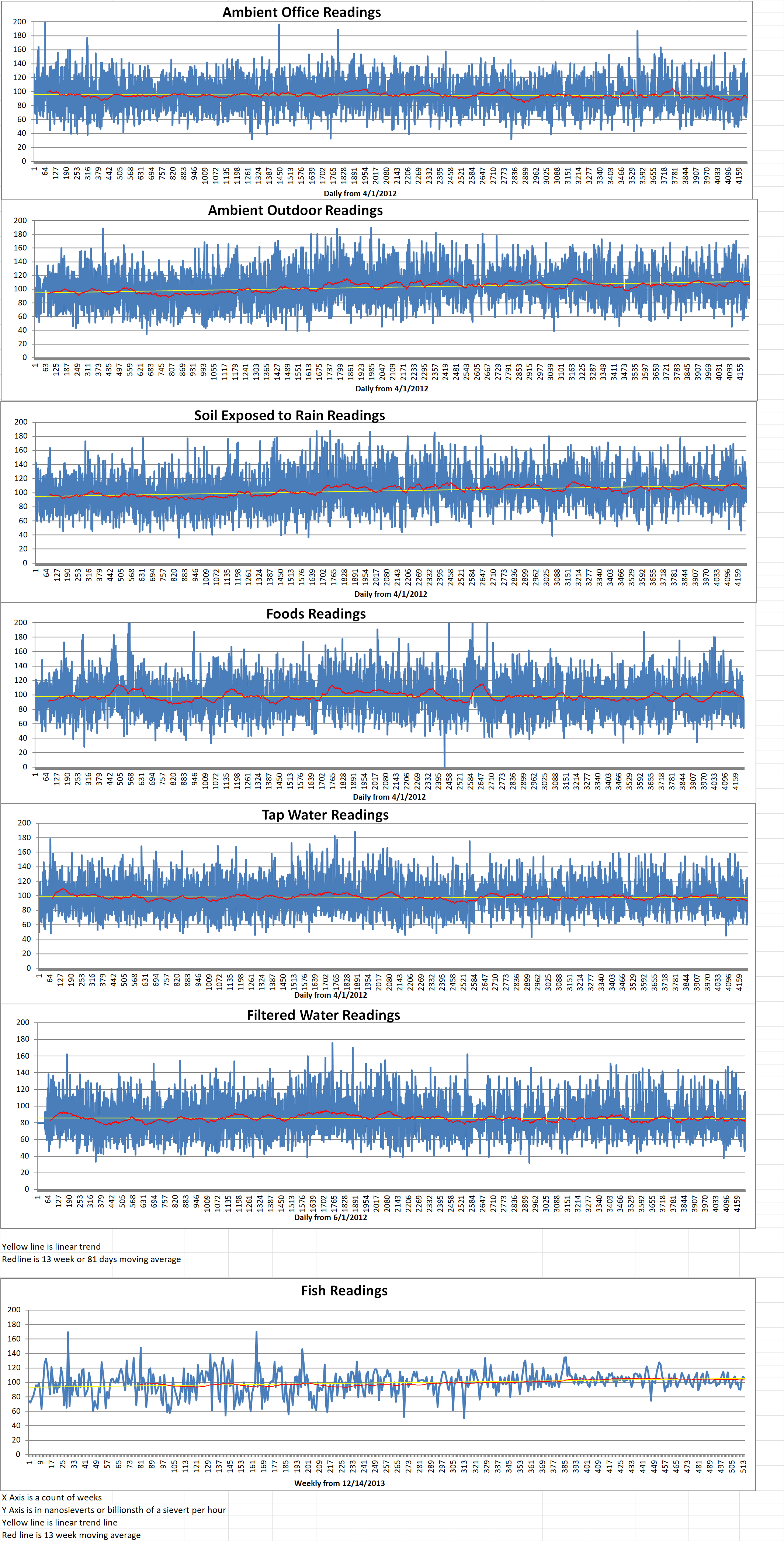

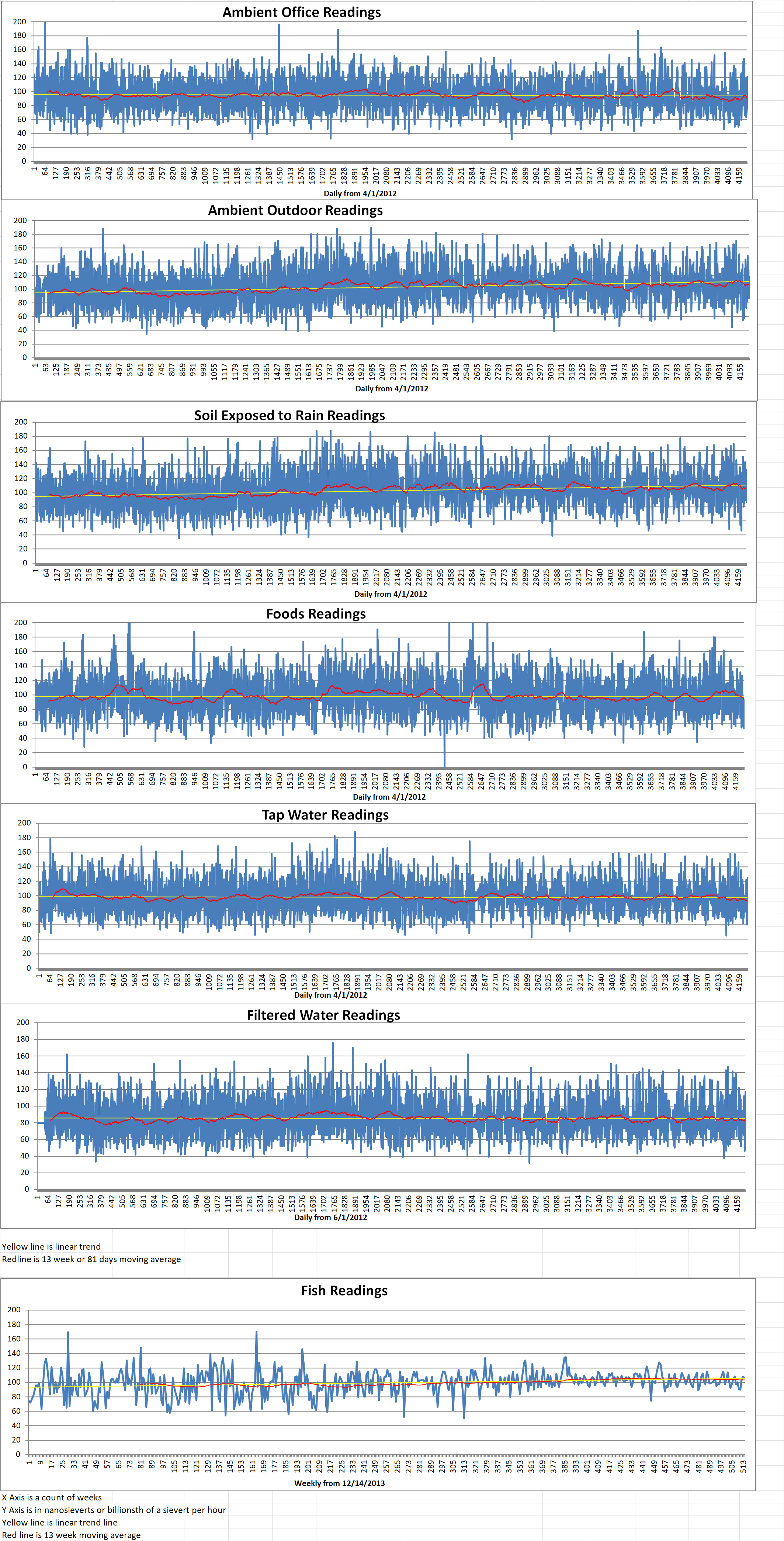

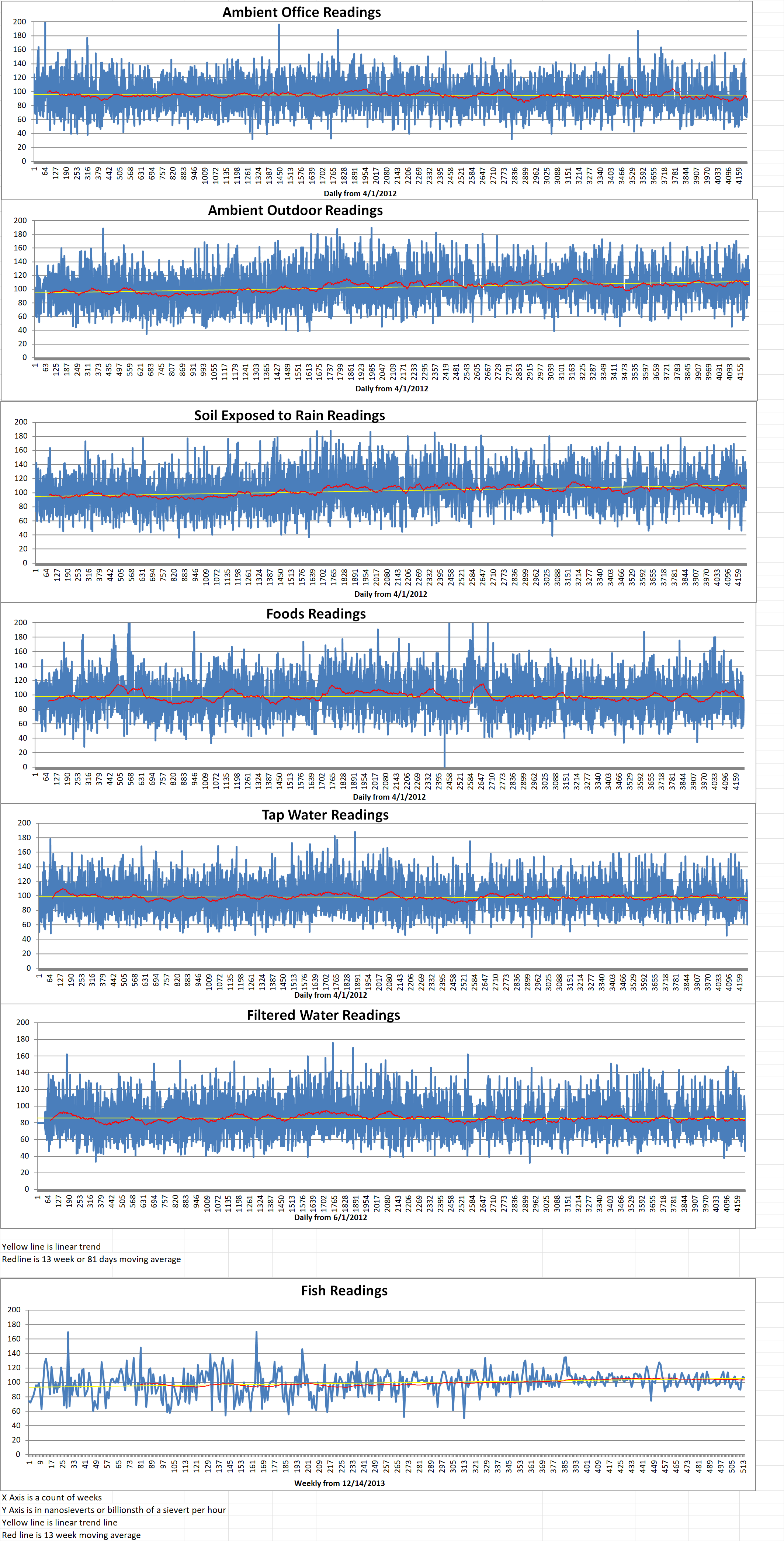

Ambient office = 126 nanosieverts per hour

Ambient outside = 97 nanosieverts per hour

Soil exposed to rain water = 99 nanosieverts per hour

Russett potato from Central Market = 83 nanosieverts per hour

Tap water = 103 nanosieverts per hour

Filter water = 93 nanosieverts per hour

-

Nuclear Fusion 69 – First Light Fusions Experiments With An Electric Gun For Inertial Confinement Fusion

Korean-based energy technology startup First Light Fusion (First Light) has announced a breakthrough for its novel nuclear fusion technology. First Light is a spin-off from the University of Oxford. It has successfully tested its “electric gun” to ignite fuel in its test reactor’s core.

This milestone was announced just weeks after another breakthrough at its American test facility. It brings sustainable nuclear fusion closer to reality. By using the electric gun, the company has increased the distance its reaction-starting projectile travels by a factor of ten.

In its previous design, the company used a pulsed power machine to electromagnetically launch projectiles. This permitted them to achieve a maximum standoff distance of 1cm.

First Light explained in a press release, “The major milestone will help solve one of the key engineering challenges in designing a projectile fusion power plant. It forms part of the Oxford-based firm’s ongoing work to design a pilot power plant capable of producing commercial energy from fusion,”

First Light is investigating nuclear fusion by using a unique method called inertial confinement fusion. This method involves firing a high-speed projectile to create high temperatures and pressures. These, in turn, trigger a fusion reaction.

This new method generates the high temperatures and pressures required for fusion reactions by using a projectile to compress a target containing fusion fuel at a very high speed. This process resembles the firing of a spark plug in an internal combustion engine.

First Light explained that “This creates the extreme temperatures and pressures required to achieve fusion by compressing a target containing fusion fuel using a projectile traveling at a tremendous speed. The ‘Standoff’ distance is the distance between where the ‘projectile’ is launched and the ‘target’— where the fusion implosion happens,”

First Light faced a major challenge to increase the distance between the projectile and the target in its fusion reactor. Employing the electric gun method, the start-up managed to increase the projectile distance to ten cm, ten times more than its previous record.

First Light explained that “The challenge is to be able to launch a projectile accurately, at velocities of several kilometers per second, while keeping it in a solid state when it hits the fusion fuel. This is a major challenge in First Light’s approach with its pilot power plant design requiring the projectile to be fired at very high speeds and accuracy.”

This is only part of the challenge for First Light with its novel reactors. They also need to reach a distance of about ten feet to create a viable power plant. However, the technique promises to bring this “Holy Grail” of energy production to life.

First Light explains that “First Light’s aim is to design the lowest risk and simplest, most scalable plant design possible. By increasing the energy per shot, and reducing the frequency, First Light aims to achieve a smaller overall plant size with a much lower risk,”

Mila Fitzgerald is a Scientist at First Light Fusion. She said that “This is a milestone moment for First Light and the result of a huge amount of effort, time, and perseverance from the whole team. As we scale up our approach and look to design a pilot power plant based on First Light’s projectile approach – one of the key challenges is being able to fire a projectile at high speeds and from a further distance. That is the basis of our current pilot plant design. This experiment demonstrates a way for us to do that and is an exciting step in the right direction.” -

Geiger Readings for April 08, 2024

Ambient office = 121 nanosieverts per hour

Ambient outside = 87 nanosieverts per hour

Soil exposed to rain water = 87 nanosieverts per hour

Red bell pepper from Central Market = 54 nanosieverts per hour

Tap water = 125 nanosieverts per hour

Filter water = 117 nanosieverts per hour

-

Geiger Readings for April 07, 2024

Ambient office = 89 nanosieverts per hour

Ambient outside = 106 nanosieverts per hour

Soil exposed to rain water = 106 nanosieverts per hour

Mini cucumber from Central Market = 93 nanosieverts per hour

Tap water = 100 nanosieverts per hour

Filter water = 87 nanosieverts per hour

-

Nuclear News Roundup April 06, 2024

Protesters oppose nuclear power plant extension en.rti.org.tw

Carper, Capito Secure Key Nuclear Energy Extension in Funding Bill epw.senate.gov

Putin’s Nuclear Arsenal ‘Spooks’ U.S. Air Force; ‘Russia’s Modern Strategic Weapons…’ hinustantimes.com

Newcleo signs agreement with CEA to develop nuclear technology in France power-technology.com

-

Geiger Readings for April 06, 2024

Ambient office = 78 nanosieverts per hour

Ambient outside = 118 nanosieverts per hour

Soil exposed to rain water = 122 nanosieverts per hour

Green onion from Central Market = 87 nanosieverts per hour

Tap water = 66 nanosieverts per hour

Filter water = 51 nanosieverts per hour

Dover Sole from Central = 106 nanosieverts per hour