Nuclear Reactors 351 - Lightbridge Developes New Kind Of Nuclear Fuel

After decades of stagnation, nuclear power is enjoying a renaissance. There are sixty five new reactors being build across the globe including the first new power reactors in the U.S. in twenty years. There are plans for one hundred and seventy three more. France, China, Russia, South Korea, Japan and the U.S. are all interested in export nuclear technology. Developing countries are being courted by nuclear companies with the assistance of their respective national governments offering attractive loans.

Since the March 2011 nuclear disaster at Fukushima, Japan, safety has been of paramount concern at nuclear power plants. In addition, competition from cheap fossil fuels and sustainable renewable energy sources has put pressure on nuclear firms to lower costs of construction and operation. A nuclear industry trade group recently announced a project aimed at cutting costs by as much as one third.

All nuclear power plants require nuclear fuel. The common type of fuel in most nuclear power reactors consists of small, short cylindrical ceramic pellets of uranium oxide enriched to boost the proportion of U-235 to at least three percent. The pellets are loaded into long thin tubes made from a zirconium alloy called Zircaloy -4. A set of these tubes is bundled together in what is called a fuel assembly.

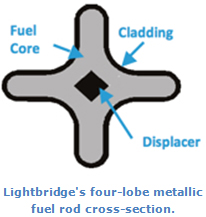

A company in Reston, Virginia called Lightbridge has been working on improving nuclear fuel technology for the past twenty five years. They just announced a new type of metallic fuel for nuclear power reactors. Instead of putting pellets of uranium oxide in a long thin tube of zirconium, Lightbridge has invented a uranium-zirconium alloy. The fuel rod is made with ridges and twisted into a helix shape. The shape has more surface area than the traditional fuel rod and that allows the flow of coolant water to transfer more heat. This makes the reactor more efficient. The greater surface area also allows the fuel rods to sustain nuclear reactions at lower temperatures. They can operate at a temperature of three hundred and sixty degrees centigrade as opposed to traditional fuel rods which operate at over twelve hundred degrees centigrade. Aside from greater efficiency and less stress on the metals of the reactor core, this also makes the new fuel rods safer to utilize.

The Lightbridge CEO said that "renewables alone will not get us there from here in terms of meeting our climate goals in time. New types of reactors will not get us there in time. The increased use of today’s reactors and new [conventional] reactors is a necessary component of any successful path to meeting climate goals."

Lightbridge is working with the French owner company Areva, a major player in the international nuclear industry, to turn the new fuel design into a commercial product. The firms hope to be able to offer the new fuel rods by 2020. It is claimed that the new fuel rods can increase the power output of existing reactors by ten percent. Refueling with the new rods should only be necessary about every twenty four months instead of the current eighteen months refueling cycle.

Critics of the new Lightbridge fuel rods point out that they have a much lower melting point than traditional uranium oxide fuel. This means that if there is a loss of coolant, they could spontaneously combust and melt down at a much lower temperature than traditional fuel rods. Currently research is being done to create new fuel rods that could withstand higher temperatures in case of an accident, the opposite of the properties of the Lightbridge fuel rods.