Radioactive Waste 388 - Holtec Checking Scratches On Spent Fuel Canister At San Onofre Nuclear Power Plant

holtec-hi-storm-100.png

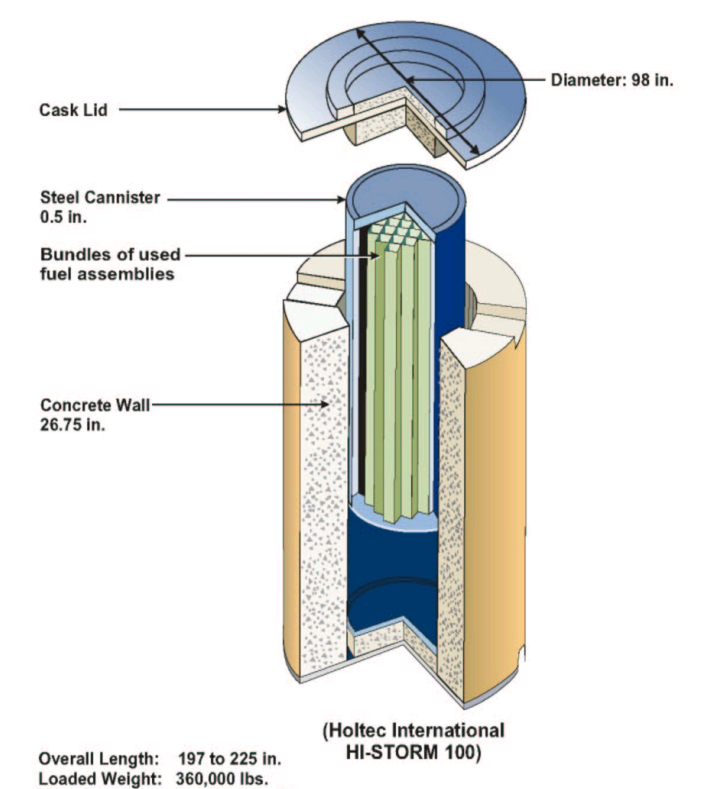

A couple of days ago, I blogged about the San Onofre nuclear power plant where transfer of spent nuclear fuel into dry canisters for underground storage has been halted because there have been multiple violations of NRC regulations. One of the issues raised has been that the surface of some of the stainless-steel canisters have been scratched as they were being lowered into the Holtec International storage bunker. Critics fear that these scratches could result in corrosion and cracks which may release radioactive materials. The NRC has refused to allow the transfer of any more spent fuel into the storage bunker until the possible danger of the scratches can be properly assessed.

The final safety analysis for the Holtec UMAX dry canisters said that when the transfer was carried out, “There will not be scratches on the canisters.” However, the NRC license issued to Southern California Edison, the owner of the San Onofre nuclear power plant, authorizing the use of the Holtec UMAX canisters only says that the system and process must comply with the American Society of Mechanical Engineers specifications. These specifications do permit some scratching on the canisters.

Scott Morris is the Region IV administer for the NRC. He said that, “Clearly, there’s an inconsistency between these two documents that has to be rectified. Edison has to resolve this. But you can’t just say, ‘It’s OK to have scratches.’ There has to be a technical basis for it. You have to have an analysis that says why it is OK. Give me the calculations. Give me the data.”

SCE and Holtec first tried to allay the NRC concerns by providing calculations that showed that the scratches were not a problem. After the NRC rejected that work, SCE and Holtec stress tested the metal of the shells of the canisters but this called into question the original calculations. Linda Howell is the deputy director of the NRC’s Division of Nuclear Materials Safety. She said, “How do you know what you have scratched? You have to actually look. Actually look at an actual canister, instead of at these surrogates.”

Holtec speeded up the development of a robotic inspection system in order to comply with the NRC demands for seeing the actual scratches on the canisters. Last week, a flat square robot equipped with 3D cameras began crawling around on a few of the dry canister and inspecting the scratches to determine how deep and wide they are. So far, the robot has been able to inspect ninety five percent of the chosen canister exteriors. It checked the surface of three of the canisters that have already been loaded into the storage bunker. Two of the inspected canisters were involved in the problems covered in my previous post. The robot also inspected the surface of a random canister.

The 3D camera on the robot can see scratches that are only one one thousandth of an inch deep. The robot has documented scratches that are twenty-six one thousandths of an inch deep. Morris says that if these are the deepest scratches, then they are well within acceptable tolerances. Tom Palmisano works for SCE. He said at a public panel that the deepest scratches are about the width of a credit card. He added that the oxide layer on the exterior of the canisters should reform quickly so there is no danger that there will be any corrosion.

The NRC is waiting for SCE to provide the data on the robotic inspection. They will then decide if the work and analysis of the canister scratches are sufficient to satisfy the requirements of the NRC. There are twenty-nine canisters in the Holtec storage bunker with forty-three more canisters waiting for NRC permission.