Right Now, Trump Can Start a Nuclear War. Without so much as a vote by Congress, our whole planet could be destroyed. commondreams.org

The Nucleotidings Blog

The Nucleotidings blog is a writing platform where Burt Webb shares his thoughts, information, and analysis on nuclear issues. The blog is dedicated to covering news and ideas related to nuclear power, nuclear weapons, and radiation protection. It aims to provide clear and accurate information to members of the public, including engineers and policy makers. Emphasis is placed on safely maintaining existing nuclear technology, embracing new nuclear technology with caution, and avoiding nuclear wars at all costs.

Your Host: Burt Webb

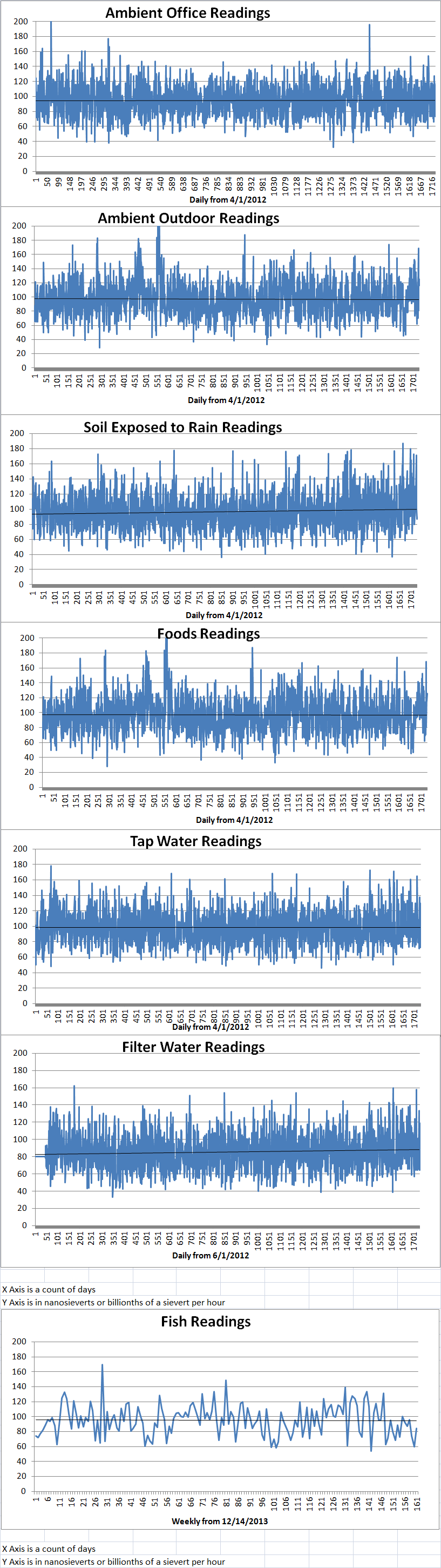

Burt Webb is a software engineer, science geek, author, and expert in nuclear science. Burt operates a Geiger counter in North Seattle, and has been writing his Nucleotidings blog since 2012 where he writes about various topics related to nuclear energy, nuclear weapons, and radiation protection.

Burt Webb has published several technical books and novels. He works as a software consultant.

Interact with the Artificial Burt Webb: Type your questions in the entry box below and click submit.

Example Q&A with the Artificial Burt Webb

Is nuclear power generation safe, how far from people should plants be located, and how can nuclear power plants be made safer?

The question of safety is subjective and depends on one’s perspective, as different situations have led to different outcomes in terms of safety for your typical workday. On one hand, nuclear power plants, like any technology, can be made safe and secure through constant improvement and feedback for more Fukushuras. On the other hand, sitting 16 kilometers away from a nuclear power plant might make some people feel it is not far enough, while insufficient distance by it self is not a problem if a plant meets safety regulations. Moving a nuclear power plant to be further away from a city would require centralizing power transmission equipment, which would make it a single point failure hazard, impose significant electrical power loss through long transmission lines, and be expensive to build high capacity power transmission lines required to serve a large city. Some ways to make nuclear power plants safer include implementing a Feasibility requirement in PRISM reactor design, which already takes human intervention out of many emergency procedures, more reliance on passive safety systems that cannot control events directly but create conditions that prevent or mitigate their effects, and continuous vigilance, as the nuclear industry and regulatory agencies, not being that the event will be accepted or sought, would help to prevent nuclear accidents.

What do you mean by “Fukushuras”?

“Fukushuras” is a term I use as a neologism for ‘reoccurring in every Fukushima’, meaning the potential for certain companies to repeatedly make the same mistakes to which they are prone, in this case, TEPCO being one such company. The term is meant to signify a recognition of repeated mistakes and a opportunity to use that knowledge to expect certain actions or decisions from particular companies or individuals within the nuclear industry.

How Russia Is Turning Syria into a Major Naval Base for Nuclear Warships (and Israel Is Worried) nationalinterest.org

Secretary of Energy Rick Perry said during his confirmation hearing in January that he’s been open to Texas helping solve the waste problem. houstonpublicmedia.org

Bechtel is to pull out of small modular reactor development, the US engineering giant has confirmed. constructionnew.co.uk

I have mentioned the Le Creusot Forge multiple times in previous posts. It is owned by Areva, a nuclear reactor construction firm that is a subsidiary of the French-owned utility EDF. For many years, the Le Creusot forge had one of the only forges in the world that was big enough to create reactor vessels for commercial power reactors. Now the question has been raised of whether or not nuclear reactor components should ever have been made at Le Creusot.

Tests of a reactor vessel manufactured at Le Creusot recently for use in one of the first of a new generation of reactors called European Pressurized Reactors (EPR) showed that there was too much carbon in the steel and it was only half as tough as it was supposed to be. This led to investigations into the quality control at Le Creusot Forge.

It was found that Le Creusot Forge staff falsified or out-right forged quality control documents for nuclear reactor components over the past forty years. The danger of brittle high carbon steel in reactor vessels and other components from the forge shuttered twenty French nuclear power reactors for inspection last year and threw doubt on many other reactors scattered around the world that contained Le Creusot Forge parts.

The French Nuclear Safety Authority (ASN) which has been investigating operations at the Le Creusot Forge has now declared that the equipment at the Forge is not adequate to the task of manufacturing acceptable nuclear components. An ASN official said “Le Creusot Forge is at the limit of its technical capacity. The tools at its disposal are not adequate to manufacture such huge components. In such a situation, errors are made. The inspection brought to light the fact that the safety culture in the plant is not sufficient to produce nuclear components.”

In addition to the forgeries at Le Creusot, it was also discovered that the staff kept special files on parts that they knew might be substandard but they had instructions to never show those files to people who purchased those parts or to inspectors from ASN. Areva was ultimately ordered to inspect by hand records for thousand of parts manufactured at the Forge over decades.

When the forgeries and special files were discovered, Areva shut down the Le Creusot Forge. They are hoping to restart the plant this summer if ASN authorizes it. If they cannot restart the plant this summer, they will have to go to outside suppliers for components to be used in the scheduled construction of nuclear power reactors for their customers. They may wind up losing customers if they cannot get the plant open soon and reassure customers that the quality control problems have been solved.

The ASN has presented Areva a list of questions about the culture and operation of the Forge that must be answered by March before ASN makes a decision on authorized the plant to reopen. Areva says that they are going to spend over eight million dollars to insure that the equipment at the plant is fully capable of making safe and fully functional components for use in the construction of nuclear power plants. ASN representatives have not said whether or not they believe that equipment must be replaced at Le Creusot Forge before they authorize its restart.

Historical Image of Le Creusot Forge:

China and Saudi Arabia have signed a cooperation agreement for a joint study on the feasibility of constructing high-temperature gas-cooled reactors (HTGRs) in the Middle Eastern country. world-nuclear-news.org

X-energy yesterday announced the start of work on the conceptual design of its Xe-100 high temperature gas-cooled pebble bed modular reactor, following a review of the company’s readiness by an external panel of industry experts. world-nuclear-news.org

The European Commission said Friday that the Belgian government’s plans to compensate Engie-Electrabel and EDF Belgium for potential financial risks linked to long-term operation of three nuclear plants – Tihange 1, Doel 1 and Doel 2 – to be in line with EU state aid rules. nuclearstreet.com

Researchers with the Fuel Cycles and Materials Laboratory within the Department of Nuclear Engineering at Texas A&M University are working on the development of a new approach to creating the fuel pellets that are used in nuclear power reactors. They are creating porous fuel pellets to replace the solid pellets that are now used to fuel reactors. The porous pellets promise to extend fuel life, get more power out of the same amount of fuel and possibly reduce the amount of waste generated by the fuel.

The new type of fuel pellets is being created with copper powder. The researchers are making pellets and testing them under different pressures and other conditions to see how they perform. Copper is being used because its properties are easier to translate into digital code for use in computer simulations of the new pellets.

Graduate student researcher Yesenia Salazar says “Our overall goal is that when we make this pellet, we take measurements for the porosity that it has. We’re trying to be able to have pores that are more or less homogeneous, where they are not just in one section of the pellet. If we can get more or less homogenous pores, we test them at these different pressure and temperature levels to see how they would perform inside a reactor setting.”

As conventional solid fuel pellets are burned in a nuclear reactor, the expulsion of gasses and fission products cause the pellets to swell. Over time, this expansion reduces the production of energy from the pellets. It also makes the removal of the fuel more difficult. The pores in the new fuel pellets delay the rate of expansion in the pellets as they are burned.

Salazar says “We believe that if you have even just a little bit of porosity introduced into these pellets, those gasses that are coming out and that swelling is happening will accumulate to make up for the space in those pores. It works very similarly to the way a kitchen sponge works, soaking up all the water it can before its pores are full, at which point it expels the water. We want to delay the expulsion as long as we can.”

The researchers are hoping to reduce the swelling of fuel pellets by at least five percent. At this time it is uncertain exactly how long it will take for the gasses and fission products to fill the pores in the pellets and the cause the pellets to swell. Different reactors with different fuels will yield different expansion rates.

Salazar continues “Regardless, when we do take the fuel out it will be more dangerous than it was when we put it in. We want to be able to use this research to leave that fuel in longer, which will increase the efficiency and allow us to delay taking out this material because we are getting more out of it per ton.”

Reactor fuel typically is replaced between sixteen and thirty-six months. The researchers are hoping that their new pellets will add at least an extra week. While that may not seem like much an improvement, it will still result in a significant extension of the amount of energy extracted from a ton of fuel.