One of the big problems with nuclear power reactor construction has to do with the materials selected to withstand the impact of temperatures, pressures and bombardment of neutrons that occur inside a nuclear reactor. The stainless steel alloy used in containment vessels must be manufactured correctly to withstand the stresses it will encounter. A French manufacturer of containment vessels recently used the wrong amount of carbon to make steel which resulted in a containment vessel being about half as strong as it was supposed to be. Even when the alloy is made correctly, the steel of containment vessels becomes brittle over the decades of operation of a nuclear reactor. Newer reactors are running at higher pressures and generate more fast moving neutrons which puts even more stress on the steel.

Now researchers in Finland and the U.S. have discovered a new type of alloys that may be able to withstand the stress of nuclear power reactors better than stainless steel. These new metals are called "high-entropy" alloys (HEAs). These alloys are created by combining equivalent quantities of five or more metals. Traditionally, alloys were made by taking one or two "base" metals and adding other substances to the mix to create an alloy with specific desirable properties. One technical definition of HEAs says that they were alloys of five or more metals that could form a solid solution with no intermetallic phases where two metals in the alloy formed special relationships. HEAs are considerably lighter, with a higher degree of fracture resistance, tensile strength, as well corrosion and oxidation resistance than conventional alloys. HEAs have been researched for more than two decade but only since 2014 has there be sufficient quantities manufactured to allow for serious research into applications.

Neutron bombardment damages steel by dislodging atoms from the crystalline structure of the steel. These damages to the crystal lattice can result in the formation of tiny cracks that weaken the structural integrity of the steel. Because these steel alloys consist mainly of iron atoms, most of the dislodged atoms will be iron atoms. On the other hand, a HEA has similar proportions of five different metals atoms so the probability of any one type of atom being dislodged is distributed over the different elements which reduces the impact of the damage.

The researchers tested sheets of two different HEAs against a steel plate made of an iron and chromium alloy. Each plate was bombarded with atoms of gold and nickel to simulate the bombardment inside a nuclear reactor. The result was that the two HEAs had one half to one third of the defects found in the steel. The next series of tests that the researchers need to carry out will involve testing the HEAs against the actual steel alloy that is used in nuclear reactors.

Unfortunately, the new HEAs are very expensive to manufacture. Even with the huge amount of money needed to construct a nuclear reactor, the HEAs are just too expensive to replace steel. It is hoped that eventually with the evolution of manufacturing methods, HEAs may drop in price to the point where they could be used in future nuclear power reactors.

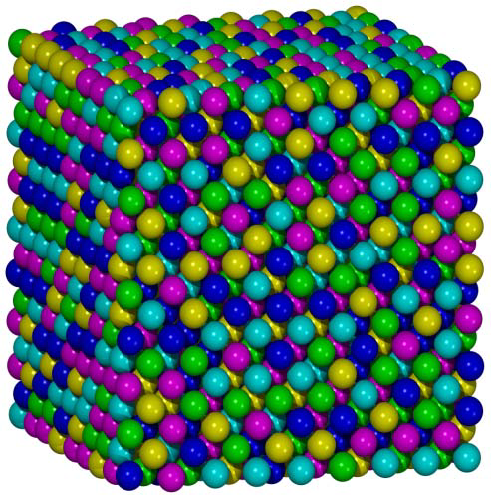

Artist's concept of a high entropy alloy:

Iron atoms are magenta, cobalt atoms are green, chromium atoms are blue, nickel atoms are cyan and manganese atoms are yellow.