I have often mentioned the lack of storage for spent nuclear fuel rods in the United States. It is estimated that all the spent fuel pools in U.S. reactors will be full of spent fuel within five years. If new storage is not created for spent fuel, the reactors will have to be shut down. I have also blogged about the steam generator fiasco at the California San Onofre nuclear power plant that has resulted in the permanent shut down of the reactors at that plant. Although that plant is no longer generating electricity, they still have to decide exactly what to do about the spent fuel.

The Chief Nuclear Officer at the San Onofre plant says that Southern California Edison (SCE) has allocated over four hundred million and is going to decide either this month or next month on which vendor to purchase spent nuclear fuel canisters and dry casks from. A public citizen group called Residents Organized for a Safe Environment (ROSE) is pressuring the California Public Utility Commission (CPUC) to delay funding the construction of spent fuel storage at the San Onofre power plant until critical issues are resolved.

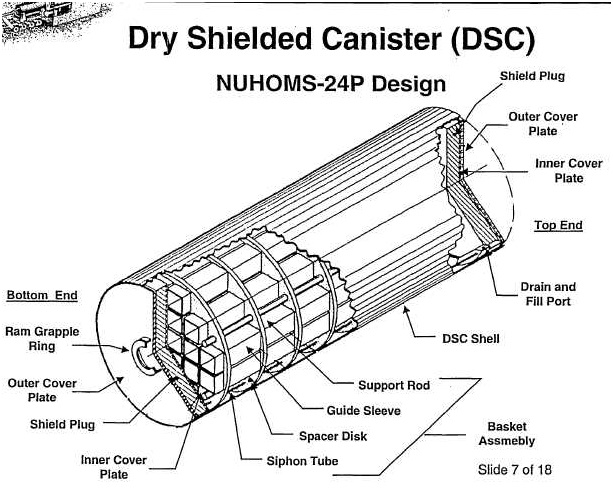

ROSE pointed out that the design of the spent nuclear fuel canisters and dry casks that SCE is considering may fail within thirty years according to the U.S. Nuclear Regulatory Commission. The stainless steel in the walls of the proposed canisters is from one half to five eights of an inch thick and is especially vulnerable to corrosion in costal environments. These canisters are not inspected once they are inserted into the concrete housing. The stainless steel canisters do not block gamma radiation. It is extremely difficult to remove one of them to check for aging and cracking. The NRC is going to give the nuclear industry five years to develop such technology but only one canister will have to be monitored at each nuclear power plant every five years. The concrete structures called dry casks housing the canisters also have aging issues that are exacerbated by the coastal climate.

ROSE has suggested that SCE should use ductile cast iron canisters in place of stainless steel canisters because of the effects of the coastal environment . There is a nickel coating inside of cast iron canisters and an epoxy resin coating on the outside. They are not prone to corrosion and cracking and do not require the concrete dry cask that is required to house the stainless steel canisters. Instead of the fraction of an inch thickness of the stainless steel, cast iron canisters can be up to twenty inches thick.

This cast iron type of canister is in wide use in the rest of the world for storage and transportation of spent nuclear fuel. However, the U.S. nuclear industry rejected it in favor of stainless steel because of the greater cost of cast iron. With the current lower costs for ductile cast iron, the difference in price between stainless steel and cast iron is much smaller. These cast iron canisters have pressurized lid monitoring which can detect gas build up and increases in temperature.

(See Part Two)

NUHOMS stainless steel spent nuclear fuel canister design being considered by SCE: